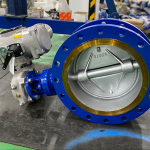

Metal seated butterfly valves.

In order to meet the requirements of various working conditions, butterfly valves have experienced the evolution from concentric to single eccentric, double eccentric and three eccentric.

The development and application of triple eccentric butterfly valve are introduce as follows:

1. Butterfly valve shall be resistant to high temperature, hard seal shall use, but the leakage is large. Zero leakage, soft seal shall use, but not high temperature. In order to overcome the contradiction of double eccentric butterfly valve, the third eccentric of butterfly valve was carried out. The structure is characterized in that the conical axis of the sealing surface of the butterfly plate deviates from the cylinder axis of the body when the shaft axis of the double eccentric valve rod is eccentric. That is to say, after the third eccentric, the sealing section of the butterfly plate is no longer true circle, but ellipse. And the sealing surface shape is also asymmetric because of this. One side is incline to the center line of the body. The other side is parallel to the center line of the body.

2. The three eccentric hard seal butterfly valve is an eccentric metal seal structure. The seal form is metal to metal seal. The replaceable metal seal ring is metal seal. The stainless steel plate and graphite composite plate seal ring are metal seal. The driving form of the hard seal butterfly valve is not only electric, but also manual, worm gear rod drive, pneumatic, etc.

3. The butterfly plate of the three eccentric hard seal butterfly valve is install in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, with the rotation angle between 0 ° and 90 °. When it rotates to 90 °, the valve will be fully open.

4. Three eccentric metal seated butterfly valves is widely use in metallurgy, electric power, petrochemical industry. Water supply, municipal construction and other industrial pipelines with medium temperature ≤ 425 ℃, for regulating flow and cutting off fluid.

-370x270.jpg)