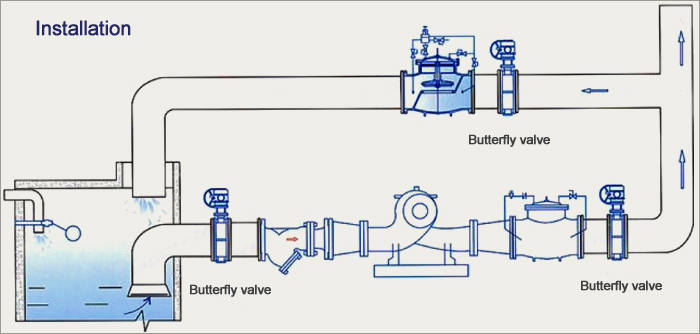

Butterfly valve installation and use

Installation, usage and maintenance The quality of installation butterfly valves may influence usage, please read the following.

(1) Direction and location

In normal cases butterfly valve usually do not have direction requirements. If it is required, installer should identify direction base on the working principle of the butterfly valve.

On horizontal pipeline, direction of the stem can be installed according to the following: vertically facing upwards, horizontally, 45 degree angle upwards; do not install vertically facing downwards.

Direction and location of installing the butterfly valve should be ease to operate, although installation may cause difficulties but operator will benefit in the long run. Manual operator of the valve should be chest height (1.2 meter above ground) for easier operation when opening and closing the valve. For valve installed on the ground, manual operator should face upwards and not lean to one side. Space should be provided for operator to operate the valve. For valve installed against the wall, installer should avoid situation which operator have to operate facing upwards, especially when media passing through the valve are acidic or toxic.

(2) Installation

- Avoid impact to the butterfly valve during or before installation.

- Before installation process, user should check the following; specification of the valve, any damage to the valve, functionality of the valve and to clean any miscellaneous objects inside the valve.

- To avoid damaging the valve when lifting, rope should tie on flange and not tie on the hand wheel or stem.

- Pipeline should be cleaned before installation, avoid miscellaneous objects like iron filings, silt, welding slag etc.

- For butterfly valve needs welding to pipeline should spot welding first then open all closure member and finish welding. Caution: Do not weld flange after butterfly valve is installed to avoid damage to the rubber and anticorrosion coating.

(3) Protection facility

Some valves needs outer protection, for example heat insulation and cold insulation.

Water accumulation should not keep for long term to avoid erosion to the pipeline and valves.

Product operation instruction

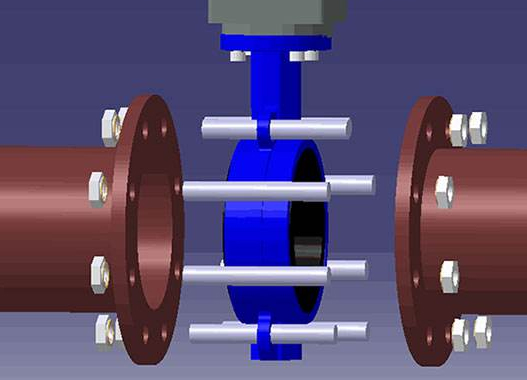

- Pipe flange standards should conform to butterfly valve standards; suggest using welding neck flange, specialized flange for butterfly valves or integral pipe flange; do not use slip-on welding flange, supplier must agreed before user can uses slip-on welding flange.

- The use of pre-installation conditions should be checked whether the use of butterfly valves with the same performance.

- Before the installation user should clean the sealing surface of valve cavity, make sure no dirt attached; simultaneously clean the pipe for welding slag and other debris.

4.When installing, the disc must be in closed position to ensure that the disc do not collide with the pipe flange.

- Both valve seat ends act as flange seal, extra seal is not needed when installing the butterfly valve.

- The butterfly valve can be installed at any position (vertical, horizontal or tilt). Butterfly valve with big size operator may need bracket.

- Collide when transporting or storing the butterfly valve may cause butterfly valve reduce its sealing ability. Avoid butterfly valve disc from bumping to hard objects and it should be open at 4 ° to 5 ° angle position in order to maintain sealing surface from damaging during this period.

- Confirm correctness of flange welding before installation, welding after installation of the butterfly valve may cause damage to the rubber and preservation coating.

- When using butterfly valve operated by pneumatic, the air source should maintain dry and clean to avoid foreign bodies from entering pneumatic operator and affect working performance.

- Without special requirements noted in purchasing order of the butterfly valve can only be mounted vertically and for interior use only.

- Case of disorder, reasons should be identified, troubleshooted, should not knock, hit, prize or lengthen the lever operator by arm of force to forcibly open or close the butterfly valve.

- During the storage and unused period, the butterfly valves should kept dry, sheltered in shade and avoid harmful substances surrounding from erosion.