Valve positioner is the main accessory of pneumatic actuator control valve. It takes stem displacement signal as input feedback measurement signal and controller output signal as setting signal for comparison. When there is a deviation between the two, the output signal to the actuator is changed to make the actuator act, and the one-to-one correspondence between the valve stem displacement times and the controller output signal is established.

Functions of valve positioner:

1. It is used for the important regulating system with high requirements on regulating quality to improve the positioning accuracy and reliability of regulating valve.

2. Used in situations where the pressure difference between two ends of the valve is large. By increasing the pressure of air source and increasing the output force of actuator, the unbalanced force generated by liquid on spool can be overcome and the travel error can be reduced.

3, When the medium to adjust for high temperature, high pressure, low temperature, toxic, flammable, explosive, in order to prevent external leakage, packing is often press very tight, so the friction between the valve stem and packing is large, at this time using the locator can overcome the time delay.

4, The medium to adjust for viscous fluid or containing solid suspended matter, the locator can overcome the medium of the valve stem movement resistance.

5, Used for large diameter regulating valve to increase the thrust output of the actuator.

6. When the distance between the regulator and the actuator is more than 60m, the locator can overcome the delay in transmission of control signals and improve the action response speed of the valve.

7, Used to improve the flow characteristics of the control valve.

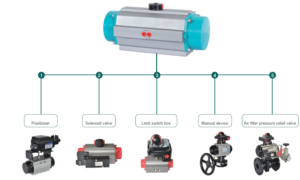

Classification of valve positioner:

1. According to the structure and working principle, valve positioner is divided into:

1) Pneumatic valve positioner: The input signal is standard gas signal.

For example, 20~100kPa gas signal, its output signal is also the standard gas signal.

2) Electric valve positioner: The input signal is standard current or voltage signal.

For example, a 4 to 20mA current signal whose output signal is a standard gas signal.

3) Intelligent valve positioner

2, According to whether the valve positioner with CPU can be divided into: general electric valve positioner and intelligent electric valve positioner.

The situation of pneumatic actuator control the positioner:

(1) When the medium pressure is high and the pressure difference is large;

(2) Large diameter of regulating valve;

(3) When it is necessary to improve the operation speed of the regulating valve;

(4) High or low temperature regulating valve;

(5) When using standard signals and operating non-standard spring actuators;

(6) When the valve achieves reverse action;

(7) When used for interval control;

(8) When it is necessary to change the flow characteristics of the valve;

(9) There is no spring actuator or piston actuator to achieve proportional action;

(10) When using electrical signals to operate pneumatic actuators, the valve positioner must be distributed.