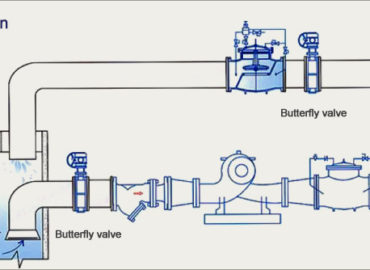

How to maintain pneumatic butterfly valves?(I)

Installation precautions:

1, Before installation should keep dry, not stored in the open air.

2, Before the installation of butterfly valve to check the pipeline, to ensure that there is no welding slag and other foreign bodies in the pipeline.

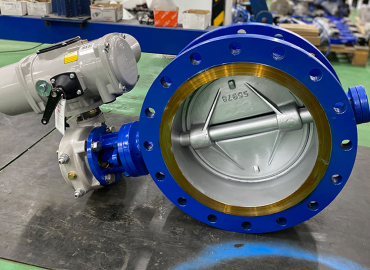

3, Butterfly valve body manual opening and closing resistance is moderate, butterfly valve torque and the selected actuator torque matching.

4, Butterfly valve connection flange specification is correct, pipe clamp flange and butterfly valve flange standard. It is recommend to use butterfly valve special flange, do not use flat welding flange.

5. Confirm the flange welding is correct. Do not weld the flange after the butterfly valve is installed to avoid scald the rubber parts.

6. The installed pipe flange shall align and aligned with the butterfly valve.

7. Install all flange bolts and tighten them by hand to confirm that the butterfly valve and the flange have been aligned, and then carefully open and close the butterfly valve to ensure flexible opening and closing.

8, Fully open the valve, with a wrench in diagonal order to tighten the bolt, no washer, do not screw the bolt too tight, in case of serious deformation of the valve ring, opening and closing torque is too large.