Description

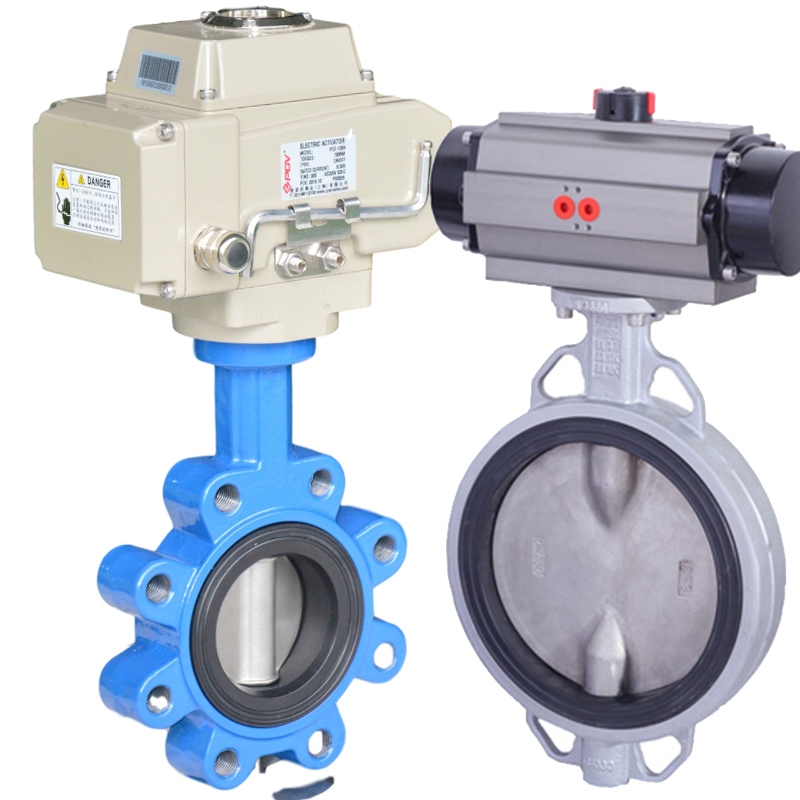

Electric Butterfly Valve

Electric Butterfly Valve: Overview, Benefits, and Applications

An electric actuated butterfly valve is a type of flow control device that is widely used in various industries for controlling and regulating the flow of fluids through pipelines. The actuated butterfly valve stands apart from manual valves and other industrial valves because of its unique design, efficient operation, and electric actuator.

How Electric Butterfly Valves Work

Motorized butterfly valve work by utilizing an electric actuator to open, close or modulate the position of a disc-shaped element within the valve. This disc, known as the butterfly, is positioned in the center of the pipe, and it rotates to either restrict or permit flow through the valve. The orientation of the butterfly can be adjusted precisely with the help of an electric actuator.

Electric Actuator

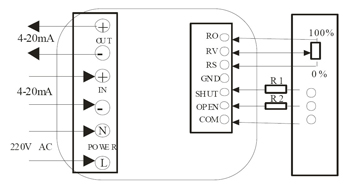

The electric actuator is the heart of the electric butterfly valve, responsible for driving the movement of the butterfly disc. It uses an electric motor to convert electrical energy into mechanical motion, which then rotates the valve stem, adjusting the position of the butterfly disc. When the actuator receives an input signal such as 4-20mA, 0-10V or 1-5V, it interprets this signal to determine the target position of the butterfly and adjusts the disc accordingly.

Design and Components

The main components of an electric butterfly valves include the body, disc, seat, stem, and electric actuator. The body of the valve is typically constructed from materials like ASTM A536 65-45-12, WCB, or CF8M, while the disc can be made from materials such as ASTM A536 65-45-12 with a Nylon coating, CF8, CF8M, 2507, or 1.4462. The seat can be comprised of EPDM, NBR, FRM, or PTFE and the valve stem is typically made from SS420 or SS431.

The body style of the electric butterfly valve is generally wafer-type, which allows for easy installation and replacement. The top flange of the valve is designed according to ISO5211 standards, and it can accommodate various flange types such as EN 1092 PN 6/PN10/PN16, ASME Class 150, AS 4087 PN10/PN16, and JIS 5K/10K.

Benefits and Limitations

Benefits of Electric Butterfly Valves

- Precise control: The electric actuator allows for precise control of the valve’s operation, ensuring accurate regulation of fluid flow.

- Remote operation: Electric butterfly valves can be controlled remotely, reducing the need for manual intervention and increasing safety in hazardous environments.

- Energy-efficient: Electric actuators consume less energy than pneumatic or hydraulic actuators, making electric butterfly valves an energy-efficient option.

- Simple maintenance: Electric actuation components are compact, making maintenance and troubleshooting more straightforward.

Technical parameters

| Body | ASTM A536 65-45-12, WCB, CF8M |

| Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 |

| Seat | EPDM,NBR,FRM.PTFE |

| Stem | SS420,SS431 |

| Body style | wafer |

| Nominal diameter | 2″ – 80″ (DN50mm – DN2000mm) |

| Top flange | ISO5211 |

| Operating pressure: | 16bar for DN50-DN300, 10bar for DN350-DN2000 |

| Temperature range: | -20 °C to + 140 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

Electric actuator

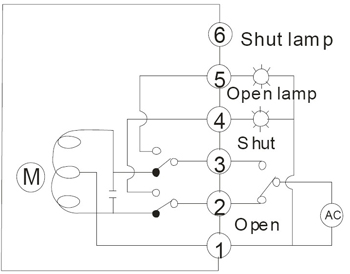

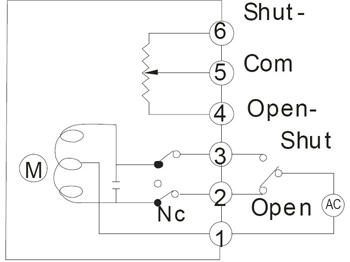

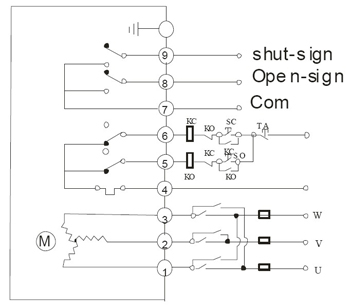

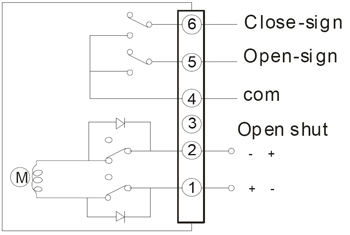

On-off type: feedback signal: Passive contact signal/4-20mA/ resistance signals.

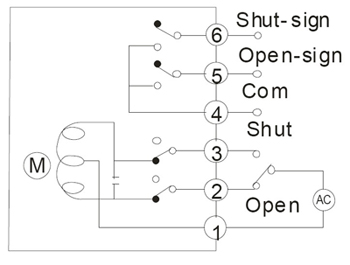

Regulation type: Input signal 4-20mA/0-10V/1-5V;

Feedback signal: 4-20mA/0-10V/1-5V

Voltage: AC220V\380V\110V\24V、DC12V\24V etc;Special voltage can be customized.

Explosion-proof class: Can be choose explosion-proof type EX d IIBT4

| Type | Control type | Function |

| Electric actuator | ON-OFF type | Feedback: the active signal, passive contact signal, resistance, 4-20mA |

| Regulation type | Input and output signal: 4-20mA, 0-10v, 1-5v, switch, MODBUS, PROFIBUS field bus | |

| Filed operation | The field, remote control switch regulation and MODBUS, PROFIBUS field bus |

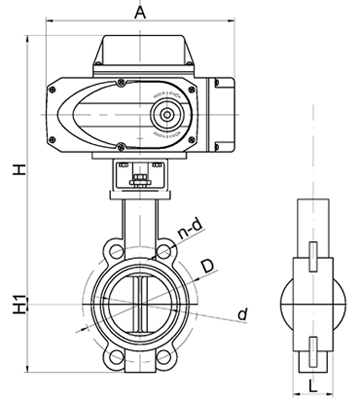

Outline size drawing:

| DN | A | H | H1 | d | D | n-d | L |

| 50 | 157 | 340 | 80 | 52.6 | 125 | 4-16 | 42 |

| 65 | 157 | 354 | 89 | 64.4 | 145 | 4-16 | 45 |

| 80 | 157 | 360 | 95 | 78.9 | 160 | 8-16 | 45 |

| 100 | 208 | 410 | 114 | 104.1 | 180 | 8-16 | 52 |

| 125 | 208 | 423 | 127 | 123.4 | 210 | 8-16 | 55 |

| 150 | 208 | 435 | 139 | 155.9 | 240 | 8-20 | 55 |

| 200 | 256 | 485 | 175 | 202.8 | 295 | 8-20/12-20 | 60 |

| 250 | 256 | 518 | 203 | 250.8 | 350/355 | 12-20/12-24 | 66 |

| 300 | 256 | 562 | 242 | 301.9 | 400/410 | 12-20/12-24 | 76 |

| 350 | 280 | 622 | 267 | 334 | 460/470 | 16-20/16-24 | 76 |

| 400 | 280 | 644 | 301 | 390 | 515/525 | 16-24/16-27 | 86 |

| 450 | 280 | 686 | 381 | 441 | 565/585 | 20-24/20-27 | 105 |

| 500 | 387 | 492 | 620/650 | 20-24/20-30 | 130 | ||

| 600 | 457 | 593 | 725/770 | 20-27/20-33 | 151 |

FAQs

What is electric butterfly valve?

An Electric Actuated Butterfly Valve is a sophisticated piece of equipment utilized in the valve manufacturing industry. This type of valve is characterized by its disc-shaped closure mechanism, which rotates around a central axis to control fluid flow within a pipeline.

What sets the electric butterfly valve apart is its electric actuator – a motor-driven device that automates the valve’s operation. The electric actuator provides precise control over the opening and closing of the butterfly valve, ensuring optimal flow regulation and reducing the need for manual intervention.

What is automatic butterfly valve?

An Automatic Butterfly Valve is a highly specialized component in the valve manufacturing sector. This valve is distinguished by its disc-shaped closure unit, which rotates around a central axis, effectively governing the fluid flow within a pipeline system.

The defining characteristic of an automatic butterfly valve is its actuator, which automates the operation of the valve. This actuator can be powered by various sources such as electricity, air, or hydraulic pressure. The automation offers precise control over the valve’s opening and closing process, ensuring optimal flow regulation and reducing the need for human intervention.

How does a motorized butterfly valve work?

A Motorized Butterfly Valve is a technologically advanced tool in the valve manufacturing industry, designed to regulate fluid flow within a pipeline. The core component of this valve is its disc-shaped mechanism, which rotates around a central axis, effectively controlling the passage of fluid.

The unique feature of a motorized butterfly valve lies in its motor-driven actuator. This electrically powered device automates the operation of the valve, ensuring precise control over the valve’s open and shut process. The motor translates electrical energy into mechanical torque which then rotates the disc either to an open or closed position.

When the motor receives an electric signal, it activates the actuator, causing the disc to rotate. This rotation can be either fully open, fully closed, or somewhere in between, effectively managing the flow of the medium through the pipe. The motorized actuator dramatically reduces the need for manual intervention, enhancing operational efficiency and precision.

The difference between electric butterfly valve and pneumatic butterfly valve?

Electric and Pneumatic Butterfly Valves are both pivotal assets in the valve manufacturing landscape, each designed with precision to control fluid dynamics within a myriad of pipeline systems. However, they are differentiated primarily by their distinct actuation mechanisms.

An Electric Butterfly Valve leverages an electric actuator, a sophisticated motor-driven apparatus that automates the valve’s operation. Upon receiving an electrical impulse, the motor springs into action, instigating the rotation of the disc-shaped closure mechanism around its central axis. This motion effectively regulates the fluid’s passage through the pipeline. The electrically powered operation delivers meticulous control over the valve’s opening and closing process, virtually eliminating the need for manual intervention.

Contrastingly, a Pneumatic Butterfly Valve employs a pneumatic actuator which operates on the principle of compressed air or gas. When a pneumatic signal is dispatched, the actuator responds by inducing the rotation of the disc, consequently governing the fluid flow. The application of pneumatic power facilitates swift response times and robust performance, especially beneficial in larger valves and high-pressure scenarios.