Description

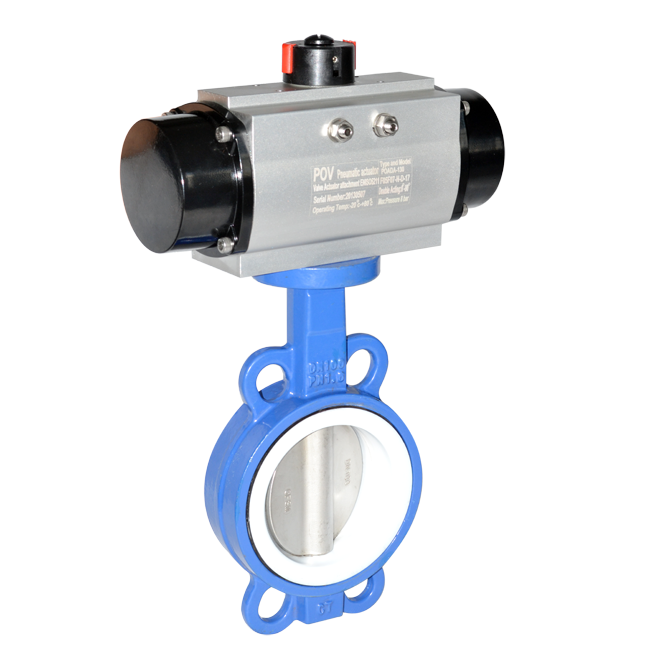

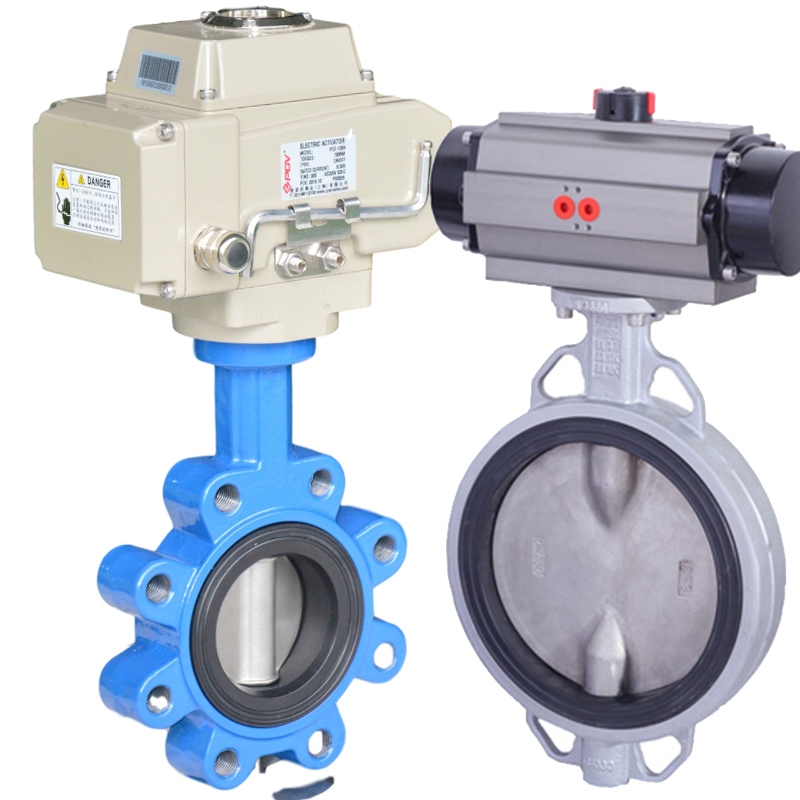

Pneumatic Butterfly Valve

Introducing our top-of-the-line air actuated butterfly valve, an innovative and reliable choice for flow control in various industrial applications. This high-performance valve combines advanced pneumatic actuators with a robust and durable central line of butterfly valves. Built with industry-leading materials and state-of-the-art technology, it ensures efficient operation, flawless performance, and long-lasting durability. Don’t settle for anything less than the best when it comes to flow control in your systems.

Features and Benefits

- The butterfly valve actuator boasts quick and precise 90-degree rotation, ensuring full open or full close action for effective regulation of fluid flow.

- Our valve is available in a wide range of sizes, from 2″ to 80″ (DN50mm – DN2000mm), catering to various industrial requirements.

- The valve is constructed from high-quality materials such as ASTM A536 65-45-12, WCB, CF8M for the body and SS420, SS431 for the stem, guaranteeing long-lasting performance and corrosion resistance.

- The easy-to-install wafer body style offers a compact design to save precious space in your facility.

- It offers broad compatibility with various flange accommodations, including EN 1092 PN 6/PN10/PN16, ASME Class 150, AS 4087 PN10/ PN16, and JIS 5K/10K.

- The valve operates under a pressure of 16bar for DN50-DN300 and 10bar for DN350-DN2000, with a wide temperature range of -20 °C to + 140 °C (depending on pressure, medium, and material).

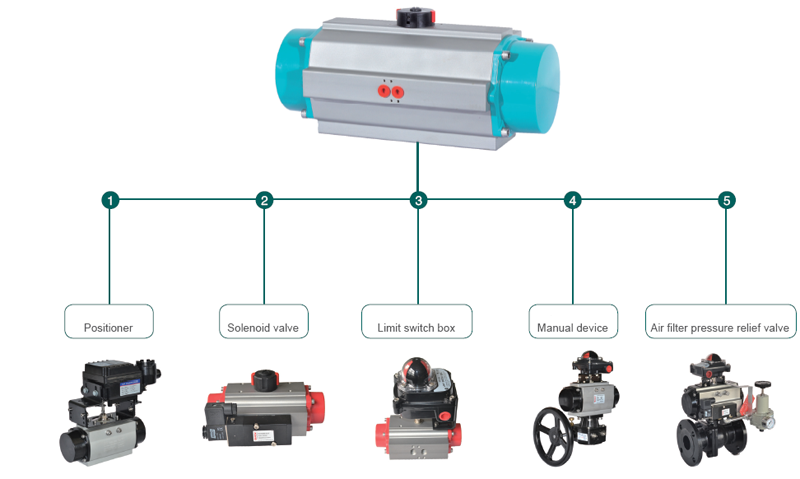

Our butterfly valve with pneumatic actuator comes with a versatile pneumatic actuator that offers:

- Double acting (failure to maintain) action for superior control and efficiency.

- Single acting normally closed (failure to close) or single acting normally open (failure to open) options for added flexibility.

- Optional accessories, such as a solenoid valve, limit switch box, air filter relief pressure valve, E/P positioned, and manual device to customize your valve to perfectly suit your needs.

Why Choose Our Pneumatic Butterfly Valve?

Not only does our butterfly valve air actuator outperform the competition in terms of quality and durability, but it is also designed with the user in mind. Simple installation, wide-ranging compatibility, and customizable options make it the smart choice for any industrial application.

Don’t compromise on performance and efficiency in your flow control systems. Invest in a Pneumatic Butterfly Valve that you can trust. Order now and take advantage of our unbeatable prices and fast shipping!

Upgrade your flow control capabilities with our superior Pneumatic Butterfly Valve today!

Technical parameters

| Body | ASTM A536 65-45-12, WCB, CF8M |

| Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 |

| Seat | EPDM,NBR,FRM.PTFE |

| Stem | SS420,SS431 |

| Body style | wafer |

| Nominal diameter | 2″ – 80″ (DN50mm – DN2000mm) |

| Top flange | ISO5211 |

| Operating pressure: | 16bar for DN50-DN300, 10bar for DN350-DN2000 |

| Temperature range: | -20 °C to + 140 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

Pneumatic actuator

| action | |

| Double acting | Failure to maintain |

| Single acting normally closed | Failure to close |

| Single acting normally open | Failure to open |

| Optional accessory | Solenoid valve limit switch box air filter relief pressure valve, E/P positioned manual device. |

| DN | Inch | GB standard size(mm) PN10/PN16 | Actuator size | |||||||

| L | D1 | D2 | H1 | H2 | n-Φd | A | B | C | ||

| 50 | 2 | 42 | 52.6 | 125 | 142 | 80 | 4-16 | 163 | 96 | 76 |

| 65 | 2 1/2 | 45 | 64.4 | 145 | 155 | 89 | 4-16 | 195 | 115 | 91 |

| 80 | 3 | 45 | 78.9 | 160 | 161 | 95 | 8-16 | 195 | 115 | 91 |

| 100 | 4 | 52 | 104.1 | 180 | 180 | 114 | 8-16 | 217 | 137 | 11 |

| 125 | 5 | 55 | 123.4 | 210 | 193 | 127 | 8-16 | 258 | 147 | 122 |

| 150 | 6 | 55 | 155.9 | 240 | 205 | 139 | 8-20 | 299 | 165 | 136 |

| 200 | 8 | 60 | 202.8 | 295 | 250 | 175 | 8-20/12-20 | 349 | 182 | 153 |

| 250 | 10 | 66 | 250.8 | 350/355 | 282 | 203 | 12-20/12-24 | 397 | 199 | 173 |

| 300 | 12 | 76 | 301.9 | 400/410 | 326 | 242 | 12-20/12-24 | 473 | 221 | 192 |

| 350 | 14 | 76 | 334 | 460/470 | 358 | 267 | 16-20/16-24 | 560 | 249 | 213 |

| 400 | 16 | 86 | 390 | 515/525 | 380 | 301 | 16-24/16-27 | 601 | 280 | 243 |

| 450 | 18 | 105 | 441 | 565/585 | 422 | 381 | 20-24/20-27 | 738 | 383 | 356 |

| 500 | 20 | 130 | 492 | 620/650 | 479 | 387 | 20-24/20-30 | 738 | 383 | 356 |

| 600 | 24 | 151 | 593 | 725/770 | 562 | 457 | 20-27/20-33 | 940 | 434 | 415 |

Wafer pneumatic butterfly valve china factory

Our professional manufacturing team offers high-quality pneumatic butterfly valves at competitive factory prices. Take a moment to watch our informative video showcasing the meticulous manufacturing process behind these valves.

FAQs

What is a pneumatic butterfly valve?

A pneumatic butterfly valve is a sophisticated flow control device within the valve manufacturing industry, renowned for its precision and reliability in modulating fluid dynamics. This type of valve incorporates a disc mounted on a rotating shaft. When the valve is actuated, the disc, which is aligned at a right angle to the flow when fully open, rotates to allow varying amounts of media through the pipeline. This precise positioning of the disc regulates the flow rate with optimal efficiency.

How does a pneumatic butterfly valve work?

At the heart of its operation lies a robust disc, meticulously crafted to fit within the diameter of the pipe. This disc is mounted on a sturdy shaft which, upon actuation by a pneumatic actuator, rotates the disc over a 90-degree arc. In the fully open position, the disc aligns parallel to the fluid flow, offering minimal resistance and allowing an unimpeded passage. Conversely, when rotated to a closed position, the disc presents itself broadside to the flow direction, effectively halting any fluid movement through the valve.

The pneumatic actuator, which is the muscle behind the valve’s function, is a model of precision. Activated by compressed air, it delivers a swift and responsive adjustment of the valve’s position. This quick action is vital in applications requiring immediate flow cessation or in automated process systems that depend on accurate timing.

What are the advantages of using a pneumatic butterfly valve?

Precision Control: At the forefront of its benefits, a pneumatic actuated butterfly valve offers exceptional control over fluid dynamics. The advanced pneumatic actuation system allows for quick and precise modulation of flow rates, ensuring that the process conditions are maintained with surgical accuracy.

Rapid Actuation: The utilization of compressed air to actuate the valve results in remarkably swift response times. This rapid actuation is essential for processes that require immediate shut-off or flow regulation capabilities, thereby minimizing the risk of downtime or operational discrepancies.

High Durability and Reliability: Constructed with industrial-grade materials, our pneumatic butterfly valves boast superior durability. They are adept at withstanding corrosive, abrasive, and high-temperature environments, ensuring long-term reliability and a reduced need for maintenance.

Safety and Compliance: Recognizing the critical importance of safety, our pneumatic butterfly valves are designed to operate flawlessly in potentially volatile environments where sparks or electrical malfunction could pose a hazard. They meet stringent international standards such as ISO, ANSI, and API, showcasing our unwavering commitment to compliance and safety protocols.

Energy Efficiency: Pneumatic actuators, by their nature, are efficient consumers of energy. They utilize air—a readily available resource—minimizing operational costs associated with energy consumption. This efficiency translates into an environmentally responsible choice without compromising performance.

What industries commonly use pneumatic butterfly valves?

In the realm of power generation, the valves play a pivotal role in managing steam and water systems, balancing the intricate dynamics of power plants with the assurance of uninterrupted performance.

The water and wastewater treatment domain relies heavily on our pneumatic butterfly valves for the modulation of vast quantities of fluids, ensuring the integrity of treatment protocols and infrastructure.

Irrigation systems, which form the lifeblood of agriculture, harness these valves to regulate water distribution with precision, illustrating our contribution to this critical aspect of food production and land management.

In the food and beverage industry, our valves are integral to maintaining sanitary conditions and managing the flow of not only liquids but also viscous materials, underpinning the safety and quality control measures essential to this sector.

The chemical and petrochemical industries, often dealing with aggressive and corrosive media, require the resilience and adaptability our valves provide. Constructed with corrosion-resistant materials such as stainless steel, they ensure safety and longevity in these challenging environments.

How do I properly maintain and troubleshoot a pneumatic butterfly valve?

Maintaining and troubleshooting a pneumatic butterfly valve involves a regimented approach, underscored by technical acumen and adherence to stringent protocols. This ensures the longevity and optimal performance of the valve as dictated by our rigorous quality control and certification standards.

Routine Maintenance Schedule: Adherence to a scheduled maintenance plan is paramount. Periodic inspection of the actuator and valve body, including the seals, O-rings, and bearings, is essential. The schedule should align with the operational frequency and media type handled by the valve.

Lubrication: Utilizing industry-specified lubricants, pivotal to preserving the integrity of moving components, reduces the friction and wear that could compromise valve performance. The lubrication regimen should match the manufacturer’s specifications and be conducted at regular intervals.

Operational Testing: Regular functional tests should be performed to validate the pneumatic actuator’s response time and to ensure that the valve modulates flow rates with precision. This includes verifying the compressed air supply is within recommended pressure ranges and free from contaminants.

Seal Integrity Checks: The condition of the valve seals is critical to preventing leaks and ensuring efficient operation. Inspect for signs of degradation or damage, replacing the seals when necessary. Use only certified replacement parts to maintain the integrity and warranty of the valve.

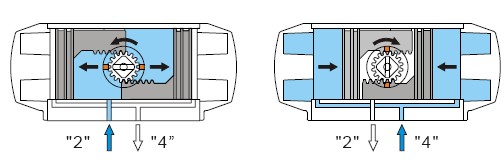

(Counterclockwise)

Compressed air to Port 2 forces the pistons outwards, causing the output shaft to turn counterclockwise, while the air is being exhausted from Port 4.(Clockwise) Air to Port 4 forces the pistons inwards, causing the pinion to turn clockwise while the air is being exhausted from Port 2.

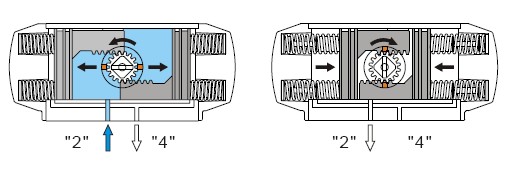

Single acting

(Counterclockwise)

Compressed air to Port 2 forces the pistons outwards, causing the output shaft to turn counterclockwise, while the air is being exhausted from Port 4.(Clockwise) Air to Port 4 forces the pistons inwards, causing the pinion to turn clockwise while the air is being exhausted from Port 2.

Single acting (Clockwise)

Loss of air pressure, the stored energy in the springs forces the pistons inwards,the pinion turns clockwise, while air is being exhausted from Port 4.

(Clockwise)

Loss of air pressure, the stored energy in the springs forces the pistons inwards,the pinion turns clockwise, while air is being exhausted from Port 4.