In general, the correct choice of electric actuator is based on the following:

1. Operating torque.

Operating torque is the most important parameter for selecting valve electric device. And the output torque of electric actuator should be 1.2 ~ 1.5 times of the maximum operating torque of valve.

2. Output speed.

If the opening and closing speed of the valve is too fast, water hammer will easily occur. Therefore, the appropriate opening and closing speed should select according to different operating conditions.

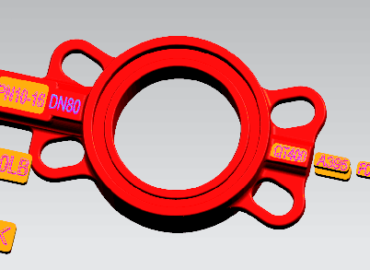

3. There are two main structures for operating thrust valve electric device. One is the direct output torque without the configuration of thrust disc. The other is equipped with a thrust disc, and the output torque is convert to output thrust through the stem nut in the thrust disc.

4. Stem diameter for multi-turn type open stem valves. If the maximum permitted stem diameter of the electric device cannot pass through the stem of the valve. It cannot assemble into an electric valve.

Therefore, the inner diameter of the hollow output shaft of the electric device must be larger than the outer diameter of the stem of the rising stem valve.

5. The output shaft rotational laps: valve electric actuator output shaft rotation circle the number of how many and nominal diameter of the valve. The valve stem thread pitch, thread, according to M = H/ZS calculation (M for electric devices should satisfy the total number of rotating ring, H is height of valve opens, S for stem drive screw pitch, Z for the stem thread).

6. Valve actuators have special requirements that must be able to limit torque or axial force. The valve is usually electrically operate with a torque limiting coupling. When the specification of the electric device is determine, the control torque is also determine. Generally run in a predetermined time, the motor will not overload.