Actuated butterfly valves are a popular choice for many industrial applications due to their reliability, efficiency and long-term durability. From controlling the flow rates and directions of liquids in pipelines to regulating temperature and pressure, as well as effectively blocking sudden surges or other dangerous situations, actuated butterfly valves offer many advantages that make them ideal for use in many industries. In this article we will explore the types of industrial settings where actuated butterfly valves are most commonly recommended, as well as the advantages they offer when used in these settings.

Introduction

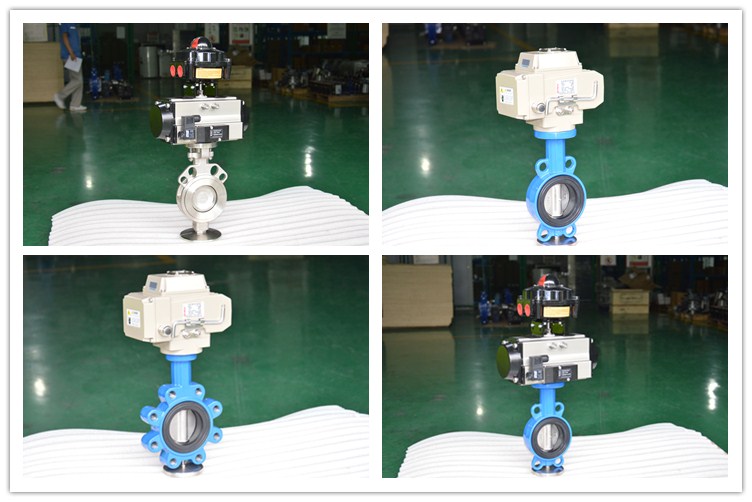

Pneumatic butterfly valve are highly efficient, compact and reliable flow control devices which can be used to regulate the flow of fluids or gases in industrial settings. They work by using a pivoting circular disc (or “butterfly”) that is sealed inside a pipe or fitting. In order to change the valve position, an actuator (either pneumatic, hydraulic or electric) pushes or pulls on the rotary stem of the valve. Since they require less space than traditional gate valves, they are better suited for systems with limited room and can be installed in any direction due to their symmetric design. In addition to requiring less space, actuated butterfly valves also offer other key benefits such as cost-effectiveness, easy maintenance and longer wear life. They also provide excellent flow control capabilities by allowing for precise adjustment of their opening and closing positions depending on pressure and temperature changes within the system. Finally, actuated butterfly valves are suitable for both manual operation and automation so that it can be integrated into a variety of control systems easily. Overall, actuated butterfly valves offer many advantages in industrial settings that make them a great solution for many applications.

Types of Industries that benefit most from Actuated Butterfly Valves

Electric butterfly valve can be found in many industries, from water and wastewater systems to chemical process plants, as they offer a variety of advantages over traditional gate valves. They are particularly effective for controlling the flow rates and direction of liquids within pipelines, where their compact design is ideal for tight spaces and high-pressure lines. Additionally, actuated butterfly valves are becoming more popular in the petroleum industry due to their effectiveness at regulating temperature and pressure in refining and transportation operations. The pharmaceutical sector also relies on actuated butterfly valves due to their ability to provide fast and accurate control of flow that is essential for maintaining product quality. Other industries such as food processing and manufacturing also benefit from the use of these valves as they are highly efficient at controlling flow with minimal pressure drop. In short, actuated butterfly valves can be found in a wide range of industrial settings due to their reliability, cost-effectiveness, accuracy and long-term durability.

Water Treatment Plants

Water treatment plants are facilities which utilize physical, chemical and biological processes to treat water so that it is safe to use. These plants typically involve several steps such as filtration, sedimentation, aeration, clarification and disinfection in order to remove impurities from the source water. In addition to treating potable water for consumption, these plants are also used for wastewater treatment and industrial purposes. They are usually operated by a team of technicians who monitor the quality of the system on a regular basis and adjust the treatment processes accordingly. Water treatment plants play an important role in the protection of public health and the environment by ensuring that all drinking water meets strict health standards before it is sent out into homes and businesses.

Manufacturing Processes

Manufacturing processes involve the transformation of raw materials into products. This requires the use of complex machinery, tools, and techniques to ensure that the quality of the final product meets all necessary standards and specifications. Common manufacturing processes include casting, forging, machining, welding, and assembly. These steps can vary depending on the type of product being created, but all will involve using a combination of machines and hand-held tools to cut and shape raw materials into the desired end result. Manufacturing processes are vital for producing high-quality products in mass quantities efficiently and cost-effectively.

Boiler Systems

Boiler systems are used to provide efficient, reliable heat, either for heating large buildings or smaller spaces. Boilers can be fueled by gas, oil, propane, or wood and typically use a hot water system to provide warmth and comfort. The boiler works by heating a large tank of water which is then circulated through pipes and radiators connected throughout the building. Boilers come in a variety of sizes and models depending on the size of the space that needs to be heated. Maintenance of boilers should be done regularly in order to ensure that it is functioning correctly and safely. Proper maintenance will also help prevent any long-term damage to the appliance, making it more energy-efficient over time.

Power Stations

Power stations are plants where energy is generated and supplied to the power grid. They usually generate electricity by burning certain fuels such as coal, oil or natural gas, or using renewable sources like wind, solar or hydropower. The power station works by converting the fuel into electrical energy through a process known as combustion. The electricity from the power station is then distributed to homes and businesses through networks of high-voltage cables. In order to ensure efficient operation, power stations must be carefully maintained with regular checks for any faults that may cause disruption to power supplies.

Advantages of using Actuated Butterfly Valves in Industrial Settings

Actuated butterfly valves are a type of valve commonly used in industrial settings for controlling the flow of liquids and gases. These valves are highly dependable and robust, making them well suited for use in demanding industrial environments. They can be operated manually or with an electric, hydraulic or pneumatic actuator which makes them more efficient to use and easier to control. The design of the valve also allows for low pressure drop, meaning that energy is conserved as the media passes through it. The actuated butterfly valve can easily be retrofitted into existing systems, requiring minimal modifications. Moreover, they provide excellent seal tightness even when operating under varying temperatures and pressures, making them suitable for a wide range of applications. Additionally, their relatively low cost and long service life have further contributed to their popularity in industrial settings.

Reliability

Reliability is the measure of a system, product or service’s ability to work under specified conditions for a specified period of time. Reliability is an important factor in ensuring that products and services are able to deliver on their intended purpose. For instance, reliable power supply systems are necessary to ensure that businesses can continue functioning without interruption. Similarly, reliable transport services are required to facilitate the movement of goods and people. Reliable communication networks are also essential to allow people to stay connected and access information at any time. To ensure reliability in any system, it is important to pay attention to all aspects such as quality control, safety measures, maintenance schedules and data security protocols.

Efficiency

Efficiency is an important measure of how well a process or system is able to produce desired results with minimal waste of resources. In a business context, efficiency means optimizing the use of resources such as time, money, energy and materials in order to maximize output. To ensure efficient operations, organizations need to identify areas of waste and develop strategies to eliminate it. This may involve automating processes and streamlining workflows, adopting modern technology or improving communication procedures. In addition, increasing employee motivation and satisfaction can also help improve overall efficiency by reducing absenteeism and turnover and increasing productivity.

Cost-Effectiveness

Cost-effectiveness is a measure of how well the cost of a product or service balances with its quality, performance and other benefits. As such, cost-effectiveness plays an important role in determining the success of any business venture. In order to achieve cost-effectiveness it is necessary to focus on reducing unnecessary expenses while maximizing returns. This may involve investing in technology and automation solutions that can help improve efficiency, adopting innovative methods of production or focusing on customer satisfaction by providing the best possible service. By making the most out of available resources and making smart decisions, businesses can increase their cost-effectiveness over time.

Conclusion

Actuated butterfly valves are a popular choice for many industrial applications due to their ability to regulate flow capacity, high durability, and low maintenance. They are also a cost-effective solution since they require little energy and have a long lifespan. Moreover, actuated butterfly valves can be controlled remotely with minimal effort and offer excellent efficiency when compared to other valve types. Finally, these valves offer excellent reliability for the most demanding operations making them an ideal choice for various industrial applications.