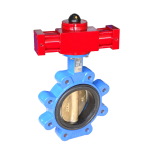

Aluminum bronze butterfly valves are a popular choice for many applications requiring low reactivity, high pressure and extreme temperatures. These valves are known for their superior quality, strength and resistance to wear and corrosion, making them perfect for aquatic and marine settings. On top of that, their cost efficiency allows you to save money in the long run. Additionally, aluminum bronze butterfly valves offer excellent thermal conductivity that helps reduce power consumption and accelerate heat transfer processes. With such capabilities in mind, it’s no wonder these valves have found their way into many industries.

Introduce

Pneumatic butterfly valve are an essential component in many residential and industrial applications due to their corrosion resistance, durability and high pressure capabilities. These valves have countless uses and can be found in industries such as water treatment, fire safety, HVAC systems, food processing, oil and gas production, as well as many more. butterfly valve price

By understanding the appropriate materials used, pressure rating, temperature rating and sealing requirements for each application one can select the perfect aluminum bronze butterfly valve for the job.

Introduction to Aluminum Bronze Butterfly Valves

Aluminum bronze butterfly valves are an ideal choice for many industrial applications due to their superior corrosion resistance, low reactivity and high pressure environment. Made of aluminum nickel-bronze alloy, these valves come in a variety of sizes and configurations to fit different types of systems. They are often used in aggressive media environments, such as water and wastewater treatment, sewage, oil and gas refineries, pulp and paper mills and power plants. pneumatic ball valve

Additionally, they can withstand extreme temperatures from -80°F to +1000° F (−62°C to +538°C), which makes them a great choice for various applications including closed loop cooling systems for air conditioning; marine/offshore drilling operations; chlorination systems; de-chlorination systems; fire protection systems; irrigation systems; hydroelectric power plants; aerospace fuel shut off valves; cryogenic rocket nozzle valves; reefer tanks and many more.

Advantages of Using an Aluminum Bronze Butterfly Valve

Aluminum bronze butterfly valves offer a wide range of advantages. Firstly, they are designed for superior performance even in the most demanding environments. They can handle high pressures and extreme temperatures better than other types of valves and also benefit from their low reactivity in aggressive media applications, such as water and wastewater treatment systems. Secondly, they have superior corrosion resistance due to the nickel content in the alloy material which makes them an ideal choice for harsh conditions. Thirdly, they are extremely cost effective because they require very little maintenance and allow you to save money over time. Finally, these valves also come with excellent thermal conductivity that helps reduce power consumption and accelerate heat transfer processes.

Different Uses and Applications for an Aluminum Bronze Butterfly Valve

Aluminum bronze butterfly valves have a wide range of uses and applications. In industrial settings, they are often used to regulate the flow of fluids such as water, oil, gas and other corrosive or aggressive media. Additionally, they can be found in residential applications such as fire protection systems, irrigation systems and air conditioning. They are also commonly used on airliners for fuel shut off valves. The high pressure capabilities of these valves make them an ideal choice for aerospace fuel control systems, cryogenic rocket nozzle valves and reefer tanks. Furthermore, aluminum bronze butterfly valves can be used for process control in chlorination systems, de-chlorination systems, power plants, oil and gas refineries, pulp and paper mills and marine/offshore drilling operations.

Technical Considerations for Specifying an Aluminum Bronze Butterfly Valve

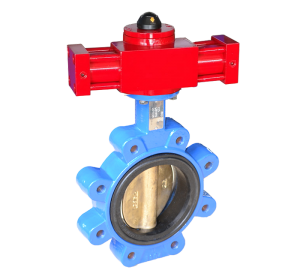

When specifying an wafer butterfly valve, there are several key technical considerations that must be taken into account. Firstly, the choice of valve material should be carefully considered in order to ensure it is suitable for the application and environment. Also, the pressure rating must meet or exceed the operating conditions, while the temperature rating should also be matched to the application and environment. Secondly, sealing requirements must also be taken into consideration; usually a double seat design is best for tight shut-off capabilities. Thirdly, operators should ensure that any accessories – such as actuators – are compatible with the particular valve model being used and that they perform appropriately in relation to its specifications. Finally, actuators can help improve safety by providing increased control over process operations.

Concluding Statement

Aluminum bronze butterfly valves are an ideal choice for a wide range of industrial and residential applications, thanks to their high pressure capabilities and corrosion resistance. However, when specifying an butterfly valve, there are several technical considerations that must be taken into account to ensure safety and optimal performance. With careful consideration on the materials used, pressure rating, temperature rating and sealing requirements, as well as considering any additional accessories such as actuators, the valve can be selected for any particular application with confidence.

Conclusion

Aluminum bronze butterfly valves are an essential component in numerous industrial and residential applications due to their ability to offer corrosion resistance and high pressure capabilities. From water treatment, fire safety, and HVAC systems to food processing, oil and gas industries, the uses of aluminum bronze butterfly valves are virtually endless. By selecting the right valve based on its materials used, pressure rating, temperature rating and sealing requirements, as well as considering any additional accessories such as actuators, one can trust that they will be able to rely on it for years to come. With so many potential applications out there it is worth taking the time to research each one properly before making your final selection.