Butterfly valves are used in a variety of applications, ranging from industrial and commercial to residential. Selecting the right type of actuator for a butterfly valve is essential for achieving optimal performance as well as keeping costs at an acceptable level. This guide will provide an overview of common actuator types, discuss their pros and cons, and outline the key factors to consider when choosing the right actuator for a butterfly valve.

Introduction

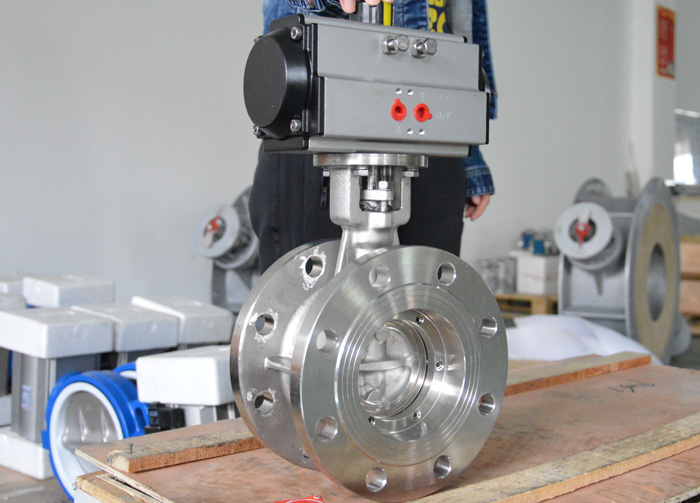

The butterfly valve is a quarter-turn rotary control valve that employs a disc to control the flow of liquid or gas. Used in various industrial, commercial, and residential applications, the butterfly valve has several advantages over other types of valves including reduced installation cost, fast opening and closing, and minimal maintenance. A key component of a butterfly valve system is the actuator, which operates to open and close the valve by using mechanical energy sources such as manual operation, electric power, pneumatic pressure, or hydraulic fluid.

Each type of actuator has its own individual characteristics that should be taken into account when selecting one for a particular application. Manual actuators allow for simple operation but may not be suitable for all applications due to limited power output, while electric actuator butterfly valve are considered more reliable but require higher initial investment costs. Pneumatic actuator butterfly valve provide remote operation capabilities while hydraulic systems provide smooth and quiet operation. In addition to these considerations, other factors such as operating pressure range, application requirements, and cost efficiency should also be kept in mind when selecting an appropriate actuation system for a butterfly valve.

Types of Actuators – Manual, Electric, Pneumatic, and Hydraulic

Actuators are an essential component in the operation of butterfly valves, as they are responsible for the opening and closing of the valve through mechanical energy sources. Manual actuators involve manual operation and have limited power output; they are relatively easy to install but may not be suitable for all applications. Electric actuators provide high power output with reliable operation, but require connecting cables between the main control panel and the valve.

Pneumatic actuators work by using compressed air to move the valve, thereby providing remote capabilities, while hydraulic actuation systems make use of pressurized oil-filled cylinders for actuation; both offer highly efficient and reliable operation but tend to take longer to install due to their complex nature. Additionally, when selecting a type of actuator for a particular application, one must consider factors such as pressure ratings, size, materials used, and operating temperature in order to ensure optimal performance from the butterfly valve system.

Advantages and Disadvantages of each type

Each type of actuator for a Butterfly valve has its own advantages and disadvantages. Manual actuators require manual operation, but are relatively inexpensive and easy to install. Electric actuators provide reliable operation with high power output, but require connecting cables between the main control panel and the valve. Pneumatic systems offer remote capabilities due to their compressed air actuation, but tend to take longer to install due to the complexity of the system.

Hydraulic actuation systems are highly efficient and reliable, but involve more installation time and cost due to their reliance on oil-filled cylinders for actuation. Additionally, it is important to factor in pressure ratings, size, materials used, and operating temperature before choosing a particular type of actuator in order to ensure optimal performance from the butterfly valve system.

Factors to Consider when Choosing an Actuator for a Butterfly Valve

When selecting an actuator for a butterfly valve, there are several key factors to consider. Firstly, the pressure rating of the valve needs to be appropriate for the application’s pressures and temperatures. Secondly, size should also be taken into account when choosing an actuator; larger valves may require more power and therefore a larger actuator. Thirdly, materials used must withstand the conditions of operation; some actuators can deteriorate over time due to stress from extreme temperatures or pressure.

Finally, operating temperature is important too; higher temperatures will reduce the life span of an actuator and thus it should be chosen with this in mind for optimal performance. Additionally, one must decide between manual or automated operation and whether electric, pneumatic, or hydraulic actuation is best suited for the job at hand. Ultimately, careful consideration of all these factors will ensure that you choose a suitable actuator for your butterfly valve system.

Operating Pressure

Operating pressure is a key factor to consider when selecting an actuator for a butterfly valve. The operating pressure of the valve must be able to withstand the pressure and temperatures of the application, or else its performance may be compromised. Typically, it is best practice to select an actuator with a higher maximum operating pressure than what is needed in order to ensure optimal performance. Additionally, some types of materials used can become brittle under high pressures, so choosing one which will not deteriorate over time due to extreme temperatures or pressures should also be taken into consideration.

Application Requirements

When selecting an actuator for a butterfly valve, one should carefully consider the application requirements. For example, if the valve is to be used in a system with high temperatures and pressures then an actuator with a higher maximum operating pressure must be chosen. Additionally, one should also consider whether electric, pneumatic or hydraulic actuation is best suited for the job at hand. Furthermore, it is important to consider the size of the actuator; larger valves may require more power and therefore a larger actuator. Finally, materials used must be able withstand the conditions of operation or else they may become brittle over time and reduce performance. Taking all of these factors into account will ensure that you choose an appropriately sized and suitable actuator for your specific application needs.

Cost Efficiency

Cost efficiency should be taken into consideration when selecting an actuator for a electric butterfly valve. Choosing the most expensive option is not always optimal; it is important to take into account all factors such as operating pressure, material used, and type of actuation in order to ensure you are getting the best deal. Oftentimes opting for a cheaper option can provide the same performance at a lower cost while still being able to meet the requirements of the application. Additionally, choosing an actuator that requires less maintenance or has extended lifespans can also help reduce costs overall. Evaluating cost efficiency carefully will ultimately help secure a better deal when selecting an actuator for your butterfly valve.

Conclusion

When it comes to selecting the right actuator for a pneumatic butterfly valve, there are many factors to consider. Taking into account the application requirements and cost efficiency are essential when making an informed decision. Knowing the different types of actuation available and their respective pros and cons can be incredibly useful in helping you make the best choice for your Butterfly Valve needs. Furthermore, being aware of materials used, size, and other technical specifications is important for ensuring you get a valve that meets your exact specifications. With this comprehensive guide to choosing the right actuator for a butterfly valve, you should now have all of the necessary information at your fingertips for selecting the ideal option for your application!

-370x270.jpg)