Butterfly valves are one of the most versatile and useful types of valves available today. They are used in a variety of industries, from the food and beverage industry to wastewater management and plumbing. A butterfly valve is an efficient shut-off device that controls water flow between two pipes or tubes, with a rotating disc inside the body of the valve that opens to allow flow through and closes when it is not required. Understanding how this type of valve works is essential for any application where reliable flow control is needed.

What Is An Electric Butterfly Valve?

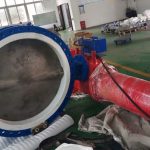

Experience the power of electric actuated butterfly valves in action. Discover how these innovative valves effortlessly control and regulate media with precision. Dive into our informative video to uncover the working principle behind these game-changing valves. Don’t miss out on this opportunity to deepen your understanding and enhance your knowledge of actuated butterfly valve.

Introduction

Butterfly valves are typically used to regulate, direct or stop the flow of liquids and gases in a system. They are relatively simple devices consisting of a cylindrical body with a disc-like component inside that rotates on an axis. When the valve is opened, the disc is rotated so that it is at an angle to the flow, allowing it to pass through unrestricted; when closed, the disc creates a barrier that prevents flow. Butterfly valves come in various sizes and materials and can be used for both high and low pressure conditions, making them ideal for a variety of industries.

Definition of butterfly valves adalah

butterfly valve seat ptfe Adalah are a type of shut-off valve that uses a disc-shaped closing element that is rotated in the body of the valve to regulate the flow of media. The ability to open or close a butterfly valve is controlled by an actuator in most applications. The disc can be positioned at various angles, allowing for precise control over the amount and direction of flow. This type of valve is often used in applications where space is limited, as it takes up less space than other types of valves. They also require minimal maintenance and are highly reliable.

Benefits of butterfly valves adalah

triple offset butterfly valve Adalah offer a number of benefits for various applications. The compact design of butterfly valves means they take up less space than other types of valves, making them ideal for applications in which space is limited. Additionally, their lightweight build makes them easier to transport and install. With minimal maintenance required, these valves provide reliable service over long periods of time, while their precise control over flow direction and amount make them suitable for precise regulation of pressure and temperature.

Types of butterfly valves adalah

Butterfly valves come in a variety of types to suit different needs. Wafer-type butterfly valves are designed as a two-part construction, with the body and disc connected by two bolts rather than a single stem. These valves have a compact design that allows them to occupy less space than other valve types, and they can also be used in applications where tight shutoff is not required. Lug-style butterfly valves are single-piece designs that feature either handwheels or levers for manual operation, while flanged butterfly valves have a connecting flange around the edges of the disc that makes them ideal for high pressure operations. High performance butterfly valves provide superior flow control capabilities by using an o-ring seal between the body and disc. Finally, resilient seat butterfly valves are constructed out of flexible rubber seats which provide improved sealing capabilities compared to other types of butterfly valves.

Wafer Style

Wafer-style fungsi butterfly valve are designed as a two-part construction, with the body and disc connected by two bolts rather than a single stem. These valves have a compact design that allows them to occupy less space than other valve types, and they also provide precise control over flow direction and amount. Additionally, wafer style butterfly valves can be used in applications that require frequent opening and closing as they possess significant resistance to wear and tear. Furthermore, these valves are cost effective due to their simple design and the moderate pressure requirements for proper operation.

Lugged Body

Lugged body butterfly valves have a single-piece design that features either handwheels or levers for manual operation. These valves are typically used in higher pressure applications and can be easily cleaned and serviced, making them ideal for system maintenance. Furthermore, lugged body butterfly valves provide excellent performance in terms of sealing against leakage due to their contact ring mechanism, making them efficient and reliable even under extreme conditions. Additionally, these valves are cost effective due to their simple construction and low manufacturing requirements.

High Performance V-notch Design

High performance V-notch butterfly valves are designed with a “V” shaped metal disc that can precisely control the flow rate. These valves feature an integrated seal design, providing excellent sealing against leakage and no requirement for additional gaskets. Additionally, they provide superior service life due to their corrosion-resistant construction and superior wear resistance. Furthermore, high performance V-notch butterfly valves are suitable for use in both high pressure and low pressure applications due to their robust design. They also provide low maintenance requirements, making them cost effective and reliable over the long-term.

Triple Offset Valves

Triple offset valves are designed with two concentric discs, separated by a third disc which is offset from the center of the other two. This design provides superior tight shut off and performance, making them ideal for use in high pressure applications. Furthermore, these valves feature low operating torque and excellent control capabilities, allowing for precise flow regulation. Additionally, triple offset valves are corrosion resistant and require minimal maintenance for long lasting reliability. They also provide superior sealing against leakage even in extreme conditions, making them an efficient and reliable choice for many systems.

Resilient Seated Valves

Resilient seated valves are designed with a flexible rubber seal which allows them to handle high pressure systems and provide superior sealing against leakage. Additionally, their plastic or metal body construction makes them resistant to corrosion and extreme temperatures. Furthermore, they feature low torque operation, allowing for easy and precise flow control. They also require minimal maintenance due to the self-lubricating properties of the seats, making them cost-effective over the long-term. Resilient seated valves are an efficient choice for many industrial applications due to their reliable performance and excellent sealing capabilities.

Flanged End Butterfly Valve

Flanged end butterfly valves are an excellent choice for many applications due to their efficient and reliable performance. They feature a disc-shaped valve body which is hinged on one side, allowing it to open and close quickly while maintaining a tight seal. Additionally, they come with flanges at each end which make them easier to install in existing pipelines, as well as making them suitable for use in high pressure systems. Furthermore, flanged end butterfly valves are corrosion resistant and require little maintenance over the long term. Their versatile design makes them an ideal choice for many industrial systems that require dependable flow control and sealing capabilities.

Three Piece Body Construction

Three-piece body construction is an efficient and reliable design for many industrial valves. This type of construction utilizes three separate parts joined by bolts or threads, which makes assembly and maintenance easy. Additionally, the three-piece design provides superior sealing capabilities due to its increased sealing surface area. Furthermore, this type of construction can handle high pressure systems without sacrificing performance or precision. Three piece body construction is an ideal choice for applications requiring dependable flow control and excellent sealing properties.

Working Principle and Maintenance Tips

Butterfly valves work by using a disc-shaped valve body that is hinged on one side and opens and closes quickly to maintain a tight seal. The butterfly valve relies on a circular disc attached to the stem, which rotates within the interior of the valve body to control the flow. When the opening in the disc is aligned with the flow path, it permits full flow; when it is perpendicular, it blocks off all flow. To ensure optimal performance and longterm reliability, proper maintenance of butterfly valves is essential. This includes cleaning away dirt and debris from around the valve body, maintaining seals in good condition, lubricating shafts regularly, checking for any wear or damage, and replacing worn-out parts as needed. Additionally, regular tests should be conducted to ensure that valves are working effectively within their specifications.

Overview of the Operating Principle Behind Butterfly Valves

Butterfly valves are highly efficient shut-off and flow control valves used in many industrial applications. The operating principle behind this type of valve is based on a disc-shaped rotary body that opens and closes quickly to create a tight seal when needed. When the opening in the disc is aligned with the flow path, it permits full flow; when it is perpendicular, it blocks off all flow. This allows precise control over the rate or direction of liquid or gas flow while maintaining high performance and reliability. Butterfly valves are known for their simplicity, affordability, and resistance to clogging as well as having a wide range of available sizes, materials of construction, pressure ratings and configurations.

Essential Maintenance Tips for Keeping Your Butterfly Valve in Optimal Condition

Essential maintenance tips for keeping your butterfly valve in optimal condition include cleaning away dirt and debris from around the valve body, maintaining seals in good condition, lubricating shafts regularly, checking for any wear or damage, and replacing worn-out parts as needed. Additionally, regular tests should be conducted to ensure that valves are working effectively within their specifications. Depending on the application, it may also be a good idea to check the seal pressure of the disc periodically and adjust it if necessary. Proper maintenance of these valves is essential to not only maintain peak performance but also ensure reliable operation over an extended period of time.

Conclusion

From what we have explored in this blog post, butterfly valves are a highly efficient type of shut-off and flow control valve which can be used in many industrial applications. They allow precise control over the rate or direction of liquid or gas flow while maintaining high performance and reliability. As with any piece of equipment, proper maintenance is key to ensure that these valves are working effectively within their specifications and remain reliable over time. With the right knowledge and care, butterfly valves can be invaluable tools that help keep your operations running smoothly and efficiently.