When shopping for butterfly valves, it’s important to understand the unique qualities of each manufacturer. By comparing different manufacturers and their products side-by-side, you can make an informed decision based on quality control standards, reputation/history in the industry, cost, durability and reliability of product.

This is especially true when you are looking for specific features or capabilities from a butterfly valve that may be only available from certain manufacturers. Comparing multiple manufacturers ensures that you get the best value for your money, as well as a product designed for safe and reliable operation.

Introduction

Butterfly valves are a type of control valve primarily used in the regulation and on/off control of fluid flow. These valves feature a unique disc-like shape, which is the main distinguishing factor from other types of valves.

Depending on the design and configuration, butterfly valves can be used for controlling either low or high pressure systems, suspended solids such as slurries or corrosive fluids. When selecting a butterfly valve manufacturer, it is important to understand the unique qualities offered by each one.

It should not be assumed that all manufacturers have equal quality or capabilities. For example, some manufacturers may specialize in high pressure applications while others may specialize in low pressure applications.

Additionally, materials compatibility is critical when selecting the right type of butterfly valve for your application; some manufacturers offer specific product lines that are constructed out of certain types of metals or plastics which can provide improved performance and longevity in certain environments.

Other factors to consider when selecting a manufacturer include product durability ratings and overall performance testing standards; this will help ensure you get a quality product that will perform as expected over its lifetime.

Reputation and history in the industry should also be taken into account; established manufacturers with years of experience in butterly valve technology are often considered more reliable choices than newcomer companies who have yet to prove themselves in the market. Finally, cost should always be factored into your decision – you should never sacrifice quality over budget constraints but make sure to compare overall value versus cost with each possible supplier before making your choice.

What is a butterfly valve?

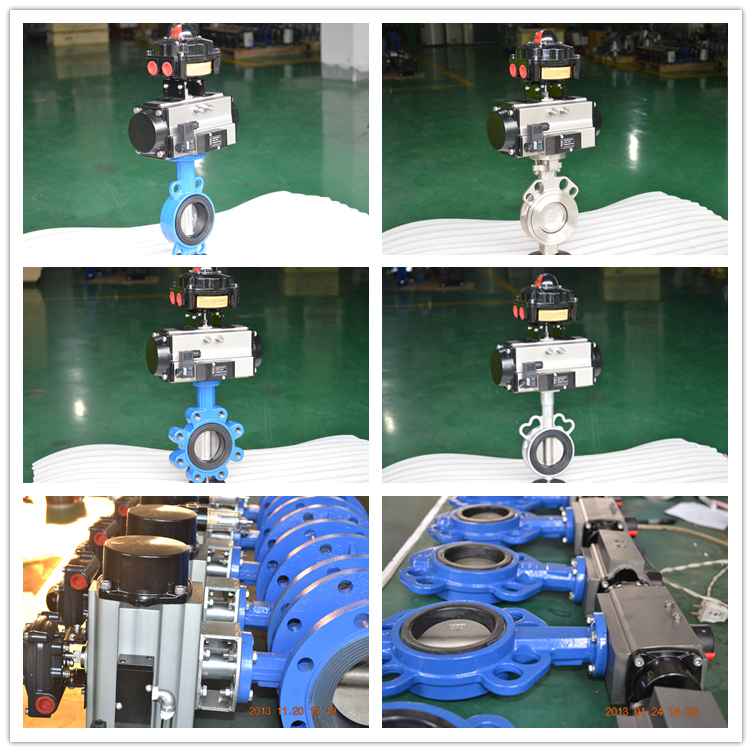

A lug butterfly valve is a type of quarter-turn valve used to control the flow of liquid or gas in a piping system. It operates on the principle of circular movement – when the disc inside is turned, it opens or closes an opening, thereby controlling the flow rate. Butterfly valves are often preferred for their compact size, easy maintenance and smooth operation.

They can be used in a wide range of industrial applications such as pumps, compressors and manifolds. Butterfly valves are available in two main types: lug-style and wafer-style, each offering different advantages based on their design and installation requirements.

Lug-style butterfly valves are better suited for higher pressure applications while wafer-style valves work best in lower pressure systems due to their thinner profile. Additionally, certain materials may be required for specific applications; stainless steel is often used for corrosive environments while resilient seats made from plastic or rubber provide better sealing capabilities without excessive wear on the components.

What do they accomplish?

Pneumatic Butterfly valves are used to control and regulate the flow of liquids and gases in piping systems. By turning the disc inside the valve, it can open or close an opening so as to adjust the rate of flow. Through this mechanism, butterfly valves are able to maintain a constant pressure in the system by controlling the velocity of fluid flows.

They are also capable of completely shutting off a supply line when necessary. Additionally, butterfly valves are used in applications which require low pressure drop and quick shutoff capabilities, making them ideal for use in areas where cost efficiency is a priority. Furthermore, they can provide tight shutoffs with minimal leakage and can be easily automated with pneumatic or electric actuators for remote operation.

Overview of Different Butterfly Valve Manufacturers

Butterfly valves are produced by many different manufacturers, each with their own unique designs and materials. Some of the most common valve manufacturers are Bray, Flow seal, Pov valve and Asahi-America. Bray is one of the leading global suppliers of butterfly valves with a wide range of products available in various sizes, body materials and operating pressures. Bray also provides specialized technical support along with full replacement parts availability for their valves.Flowseal has been manufacturing valves since 1950 and offers both lug-style and wafer-style butterfly valves suitable for low to high pressure applications.

Their standard range includes carbon steel models as well as more corrosion resistant stainless steel versions.Pov valve provides an extensive selection of butterfly valves designed for process control in a variety of industries including food & beverage, chemical processing and water & wastewater treatment. Hey offer many features such as controlled closure rates and tight shutoffs which make them suitable for demanding applications. Asahi-America has developed a line of double flanged butterfly valves manufactured from high quality industrial grade plastic specifically designed to meet the needs of steam heating systems.

The company offers optional accessories such as electrical actuators or pneumatic operators that can be used to electronically control the open/closed position of the valve from a remote location.

Overview of various manufacturers and their unique qualities

There are many different manufacturers of butterfly valves, each offering a wide variety of designs and materials. Bray is the global leader in butterfly valve production, providing high-quality products with specialized technical support and full parts availability.Flowseal provides both lug and wafer style models designed for low to high pressure applications. Pov specializes in valves for process control in industries such as food & beverage, chemical processing and water & wastewater treatment, offering features like controlled closure rates and tight shutoffs. Asahi-America manufactures double flanged butterfly valves made from industrial grade plastic, with optional accessories like electric actuators or pneumatic operators that can be used to remotely control their position from a distance.

Each manufacturer has its own unique qualities that make them suitable for different applications and customers’ needs.

Factors to Consider When Choosing a Butterfly Valve Manufacturers

When choosing a manufacturer for butterfly valves, there are several factors to consider. Factors like size and pressure ratings will help determine the specific valve suitable for the application. Knowing what type of body material is required is important as well, with more corrosion resistant versions of stainless steel being available from certain manufacturers. Comparing prices between different suppliers is also an important factor as this can be a significant component of the overall cost.

Additionally, looking into the company that provides technical support or parts availability may make all the difference when trying to maintain operations in the case of an emergency.

Finally, assessing special requirements such as tight shut offs or remote control capabilities can help make sure you get exactly what you need from your supplier.

Quality control standards Butterfly Valve Manufacturers

Quality control is a key factor when evaluating manufacturers of butterfly valves. All quality control standards must be met in order to ensure the safety and reliability of these components. Proper testing should include inspections, visual verification of parts and materials, as well as operation tests.

Some manufacturers perform additional nondestructive testing such as radiography, eddy current testing or ultrasonic flaw detection to further guarantee the safety of their product. High-quality butterfly valve manufacturers use international standard manufacturing protocols such as ASME, API and ISO 9001:2015 for quality assurance.

The combination of these strict regulations and precise inspection processes ensures that each part meets the highest industry performance requirements.

Reputation/history in the industry

One key factor to consider when selecting a manufacturer of butterfly valves is their reputation in the industry. A company’s past performances and experiences should be taken into account when making an informed decision. It is important to take note of any history the manufacturer may have with product recalls or customer complaints.

Make sure to research information, such as awards won, customer feedback, and standards achieved that showcase the level of quality and service provided by the manufacturer. This will help you select a manufacturer with a proven track record for producing reliable products backed by excellent customer support.

Cost, durability and reliability of product

Cost, durability and reliability are all essential attributes to consider when selecting a supplier of butterfly valves. It is important to find a manufacturer that provides the best cost-benefit ratio while still providing a quality product.

The valve’s material should be strong enough to withstand the demands of its application, such as harsh chemicals or extreme temperatures, while also being able to function consistently over time. Furthermore, reliability is key when selecting a butterfly valve; it should be durable enough to handle the rigorous conditions in which it will be used without failure.

Benefits of Working With Established Manufacturers

Working with experienced and established manufacturers of butterfly valves has many benefits. Firstly, they have a wealth of knowledge and technical expertise in their field which can help ensure quality production of the desired product.

Furthermore, they are most likely to offer guarantees for their products, as well as provide complete instruction manuals for installation, usage and repair. Established manufacturers also typically have a wide range of products available, giving customers more options from which to choose the perfect valve for their needs.

Cost savings may also be achieved when buying in bulk or when there are special discounts offered by the company. Lastly, having an established relationship with an experienced supplier can lead to better customer service and extra problem-solving assistance if needed.

Conclusion

Choosing the right butterfly valve manufacturer is essential for obtaining a quality product. It is important to research each individual supplier, as well as understand their unique strengths and features in order to make an informed decision.

Understanding the cost-benefit ratio of the proposed product and comparing different manufacturers’ levels of durability, reliability, customer service and technical expertise are all necessary steps before committing to a purchase.

Overall, understanding the unique qualities that each butterfly valve manufacturer offers will help ensure customers get the best return on investment while still being confident in the quality of their chosen valve.