Butterfly valves are an important component for many applications due to their reliable operation and cost effectiveness. One of the most popular types of butterfly valves is the double eccentric butterfly valve, which is known for its superior performance and reliability. This article will explore the different types of double eccentric butterfly valves, their individual advantages, and their drawbacks.

Introduction double eccentric butterfly valve

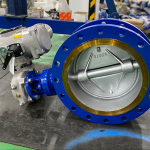

Double eccentric butterfly valves are becoming an increasingly popular choice for applications with high-pressure, temperature and flow requirements. These valves consist of two concentric discs, with the inner disc rotating to control the flow.

This design provides maximum sealing reliability, making them a great option for applications where tight shutoff is needed and minimal leakage is expected. However, there are several different types of this valve which vary in features and performance capabilities. In this blog post, we’ll explore the benefits and drawbacks of each variety of double eccentric butterfly valves.

Overview of Double Eccentric Butterfly Valve

Double eccentric butterfly valves are a type of shutoff valve that are designed to provide tight shutoff and minimal leakage. Hey consist of two concentric discs, with the inner disc rotating to control the flow. This allows for maximum sealing reliability with minimal effort on the part of the user.

The double-eccentric design also provides extra long service life due to its low friction coefficient, which reduces wear and tear over time. Additionally, double eccentric butterfly valves can operate up to 10 times faster than traditional gate valves, providing a more efficient means of controlling the flow.

Double eccentric butterfly valves have been used in many applications ranging from petrochemical processing plants to food and beverage production lines. As such, they offer a wide range of features and performance capabilities depending on the specific requirements of each application.

Benefits of Double Eccentric Butterfly Valve

Double eccentric butterfly valves offer several notable benefits when compared to traditional gate valves. Firstly, they are relatively easy to install, maintain and operate. Additionally, their double-eccentric design provides tight shutoff and minimal leakage, making them suitable for applications where tight shutoff is required but minimal leakage is expected.

Secondly, the low friction coefficient of the double eccentric design increases the life span of the valve by reducing wear and tear over time. Finally, double eccentric butterfly valves are able to operate up to 10 times faster than traditional gate valves, leading to more efficient management of flow control. As such, these valves provide a great balance between cost-effectiveness and performance capabilities across many different industries.

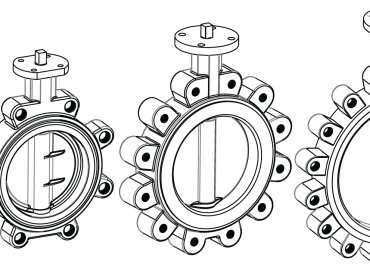

Different Types of Double Eccentric Butterfly Valve

Double eccentric butterfly valves come in many different types, depending on the application requirements. Wafer type double eccentric butterfly valves are designed for use in tight spaces and require minimal installation Space. Hey can be used for isolated shutoffs or pressure isolation applications, as well as to provide an absolute zero leakage solution. Lugged double eccentric butterfly valves are designed for use in larger pipe systems.

They have a similar design to wafer type valves but with longer stems and stronger body parts that allow them to withstand higher pressures and temperatures. Flanged double eccentric butterfly valves are suitable for large-scale systems like industrial processing plants.

Finally, Gear operated double eccentric butterfly valves are typically used when accurate control is required with minimal effort on the part of the user. All of these types offer reliable performance capabilities while providing optimal cost savings compared to traditional gate valve solutions.

Full Cone Disc Model

The full cone disc model is a type of double eccentric butterfly valve that is designed to provide tight shutoff over a wide range of applications. It features a unique full cone design which allows the valve to open and close with minimal effort.

This model is ideal for those who require precise control and requires minimal leakage, making it suitable for any application where accurate control and efficient operation are paramount.

Additionally, its capability to handle high pressure and temperature conditions makes it an ideal choice for applications requiring secure connection points and strong resistance to extreme climates. Furthermore, the full cone disc model offers cost savings compared to traditional gate valves due to its easy installation and maintenance requirements.

Slice Disc Model

The slice disc model is a type of double eccentric butterfly valve that utilizes a unique slicing motion to create the perfect seal.This allows for maximum flow in both directions, making it suitable for applications such as shutoff and pressure isolation.Additionally, its distinctive design makes it highly resistant to vibration and works well in both low and high-pressure systems.

Its compact size and ease of installation make it an ideal choice for those who require precise control with limited space constraints. Furthermore, the slice disc model offers greater cost savings compared to traditional gate valves due to its low maintenance requirements and small size.

Built-in Resilient Seat Ring Model

The built-in resilient seat ring model is a type of double eccentric butterfly valve that utilizes an integrated elastomer sleeve to create the perfect seal. This allows for full shutoff even at low pressures, making it an ideal choice for applications requiring tight shutoff and reliable sealing performance.

Additionally, its built-in elastomer sleeve ensures that the flange connection remains leakproof by eliminating potential voids between the disc and body. Furthermore, this valve model provides excellent corrosion protection due to its stainless steel construction and offers improved safety features such as pressure control and seal integrity monitoring capabilities.

Advantages & Disadvantages of the Different Models

Butterfly valves are a type of divided disc valve that provide precise flow control in a range of applications. Hey come in several different models, each with its own advantages and disadvantages. The resilient seat ring model is a popular choice due to its tight shutoff at low pressures, improved corrosion protection, and safety features.

The slice disc model offers superior flow and vibration resistance while still providing good shutoff capabilities. Its compact size makes it suitable for confined spaces and requires minimal maintenance costs. However, this model’s double eccentric design also creates increased friction which can lead to more difficulty in controlling the pressure or temperature of the system.

Finally, the wafer type butterfly valve is an economical choice for low-pressure systems but demands periodic inspection and cleaning due to its design. All of these designs have their pros and cons when considering their specific application requirements but can offer immense benefits when properly implemented.

Full Cone Disc Model

The full cone disc model is a type of lug butterfly valve that utilizes a conical shaped disc instead of the two flat discs found in other designs. This design provides superior flow characteristics and makes it an ideal choice for industries like oil and gas, chemical, water treatment, and wastewater applications. It also has excellent shutoff capabilities as well as vibration resistance due to its unique shape.

Furthermore, its full cone design creates turbulence at the vena contract which helps reduce cavitation, thus providing superior pressure control when compared with other butterfly valves. All these features make it an ideal solution for a wide range of applications where tight shutoff and precise flow control is required.

Slice Disc Model

The slice disc model of butterfly valve is characterized by its double eccentric design that consists of two flat discs set at an angle. This creates a slicing action when the valve is opened, which allows for superior flow characteristics and vibration resistance due to the reduced contact area between the discs.

Additionally, it also offers excellent shutoff capabilities at low pressures and is highly durable, making it ideal for many applications like on/off or flow control services. Moreover, its compact size allows it to fit into confined spaces and requires minimal maintenance costs, making it a popular choice in many industries like water treatment, wastewater management, and oil & gas.All of these features make it an excellent option when considering precise flow control.

Built-in Resilient Seat Ring Model

The built in resilient seat ring model of wafer butterfly valve is characterized by its integrated sealing mechanism. This design uses an elastomeric material for the seat ring which provides superior shut off capabilities at low pressure and excellent protection against wear and tear. It also helps reduce the risk of leakage due to its resilient nature. Furthermore, this model is ideal for applications requiring a higher degree of control with minimal maintenance costs and can offer long-term reliability due to its robust design.

Additionally, it is relatively lighter than other types of valves, making it easier to transport and install with less effort. All these features make the built-in resilient seat ring model an excellent option for industries requiring tight shutoff services and precise flow control.

Conclusion

In conclusion, double eccentric butterfly valves are a great option for industries looking to control the flow of various media. Depending on their application, they can come in various models such as slice disc, built-in resilient seat ring, and cast iron body. Each of these have distinct features which make them well-suited for specific applications.

The slice disc model offers superior flow characteristics and vibration resistance due to its reduced contact area between discs, while the built in resilient seat ring model is great for applications requiring tight shutoff services and precise flow control with minimal maintenance costs. Cast iron body type is suitable for high temperature and pressure applications. No matter which type you choose, you’re sure to get a reliable valve that will function properly for many years to come.

-150x150.jpg)