Installation precautions as below:

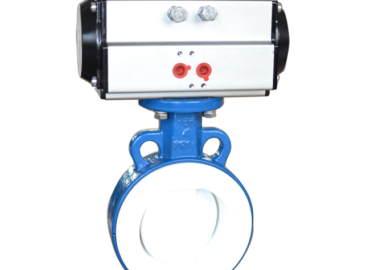

1. Before installation, check that all parts of the pneumatic butterfly valve are free of missing parts, the model is correct, there are no sundries in the valve body, and there is no resistance in the solenoid valve and muffler.

2. Close both the valve and the cylinder.

3. Install the cylinder on the valve (the installation direction can be parallel or vertical to the valve body), and then check whether the screw hole is align without too large deviation. If there is a little deviation, turn the cylinder block a little, and then fasten the screw.

4. After the installation, the pneumatic butterfly valve shall debug (normally the air supply pressure is 0.4 ~ 0.6MPa).

5. The hair shall keep dry before installation and shall not store in the open air.

6. Before installing the butterfly valve, check the pipeline to ensure that there is no welding slag and other foreign matters in the pipeline.

7. The manual opening and closing resistance of butterfly valve body is moderate, and the torque of butterfly valve matches the torque of selected actuator.

8. The specification of flange for butterfly valve connection is correct, and the pipe clamp flange is consistent with the butterfly valve flange standard. It is recommend to use special flange for butterfly valve instead of flat welding flange.

9. Confirm that the flange is welded correctly, and do not weld the flange after the installation of butterfly valve to avoid scalding the rubber parts.

10. The installed pipe flange shall align with the butterfly valve.

11. Install all flange bolts and tighten them by hand. Confirm that the butterfly valve and flange aligned, and then carefully open and close the butterfly valve to ensure flexible opening and closing.

12. Fully open the valve, tighten the bolts with spanner according to the diagonal sequence, without gasket, do not over tighten the bolts, so as to prevent serious deformation of the valve ring and excessive opening and closing torque.