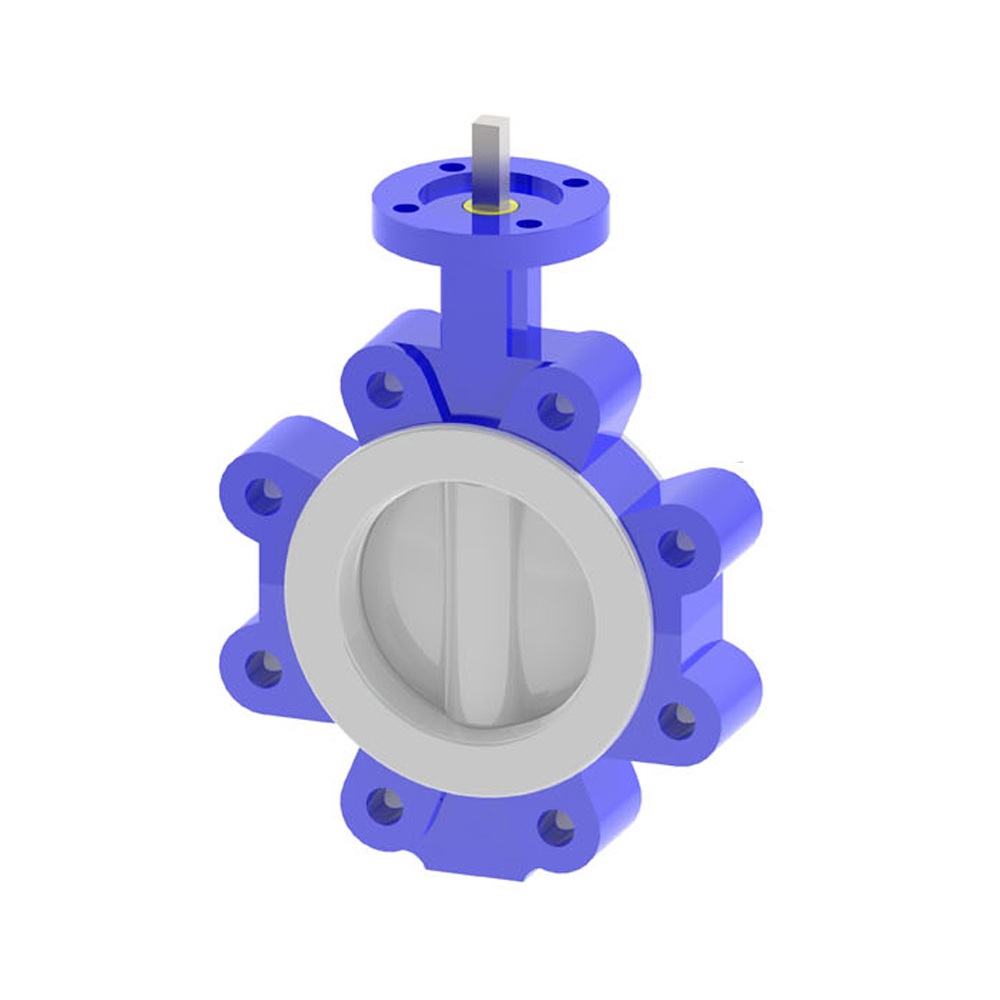

Lug style butterfly valve

Lug butterfly valve are the perfect choice for controlling and regulating fluid flow in any application. Lug style butterfly valve comes with an integral body, making it suitable for use with flat face flanges or spigot ends and allowing easy installation even in tight or cramped spaces. It features a one-piece disc that is coupled to a stem by lugs which can rotate around its axis providing precise control over the flow rate. The body also features two sealing surfaces to create a positive shutoff when closed, so you can depend on it for efficient and reliable operation in a variety of applications. lugged butterfly valve offer economy and quality performance on low pressure systems like water service lines, wastewater treatment plants, chemical processes and more. Investing in this type of lug valve today provides peace of mind that your system will be well-protected from damage caused by high pressure surges or backflow.

What is a lug butterfly valves?

A lug butterfly valves is a specialized type of quarter-turn valve, designed to regulate flow in both directions. It features two semi-circular plates hinged together at the center and actuated with a lever or rotary actuator. This type of valve is used in various industrial applications such as chemical processing, petrochemical processes, water treatment plants, production lines for food and beverage industries, etc.

The main advantage of a lug type butterfly valve lies in its ability to provide an efficient seal with minimal pressure loss when used in high-pressure systems. The lugged valve design facilitates easy installation and replacement without any need for special skills or equipment. Furthermore, the disc can be rotated easily depending on the application requirements or process direction control needs without disrupting pipeline operations.

What are some applications for a lug butterfly valves?

A lug butterfly valve is designed to regulate the flow of gases or liquids in a system, such as water supply systems, cooling systems and air conditioning systems. Here are some of its typical applications:

- Water Supply Systems - Lug butterfly valves provide directional control, pressure throttling and shut-off services for both clean water distribution lines and sewage pipelines. They can also be used for flushing tanks, shower heads and other fixtures that require constant running water.

- Heat Exchangers - Lug butterfly valves are popularly used in heat exchangers due to their flexibility to handle high temperatures which are ideal for transferring steam from boiler feedwater heaters back into the main condenser circuit during start-up operations.

- Cooling Systems - Lug butterfly valves can be used with all types of liquid coolants whether it is closed loop glycol or oil based system such as engine coolant circulation in diesel engines or open loop seawater/brackish water cooling towers.. They offer good controllability even when there is large variation in fluid pressure due to their ability to use low torque motors which reduce maintenance costs significantly.

- Air Conditioning Systems – These reliable medium sized valves have found widespread use in air conditioning systems including rooftop packaged units, chilled water coils, fan coil units and DX coils where they provide reduced cycling wear on fans blowers with stable pressure regulation and temperature control necessary for efficient operation . Additionally ,they serve as isolation points between sections within an HVAC system allowing each section’s performance independently controlled without affecting other areas .

- Pharmaceutical Industries – There has been increased utilization of lug type butterfly valves in pharmaceutical production processes that require long service life intervals . This type of valve is highly suitable for these industries because it provides excellent seal tightness along with considerable corrosion resistance thereby ensuring that no contaminants enter sensitive medications or medical devices throughout its life cycle ..

What is the difference between lug type and double flange?

The difference between lug type and double flange valves lies in their installation, design, and application. The main distinction between the two is that a lug type valve involves two pipelines connecting to each other with threaded lugs from both sides of the valve body, while a double flange valve utilizes two individual flanges on either side of its body.

A lug-type valve uses threads to attach pipes or fittings together by using nuts and bolts that effectively create a leak-proof joint between them. This makes it much easier to assemble than the traditional welded connections used for certain pipe types in prior applications. Lug-type valves are primarily used for low pressure applications because of their lower strength when compared to welded connections. Additionally, these types of valves cost less than double flanged valves due to their simpler design structure and quick installation capabilities.

Lug High Performance Butterfly Valve

Lug High Performance Butterfly Valve Lug butterfly valve 2″-40″

Lug butterfly valve 2″-40″

Pneumatic lug butterfly valve

Pneumatic lug butterfly valve