When it comes to choosing the right lug butterfly valve for your application, it is important to take various factors into account. This guide will help you evaluate different types of lug style butterfly valves, compare their features and benefits, and choose the best option for your particular needs. It will also provide helpful tips on proper installation and maintenance of a quality wafer butterfly valve to ensure its durability and reliability. By understanding the design principles behind this type of butterfly valve, you can make an informed choice that is right for your application.

Introduction

Lug style butterfly valves are a popular choice for many applications due to their high performance and reliability. They are cost-efficient, easy to install and maintain, and feature a compact design that requires less space than other types of valves. Additionally, these valves have unique advantages such as bidirectional flow control, minimal pressure losses and excellent flow control capabilities.

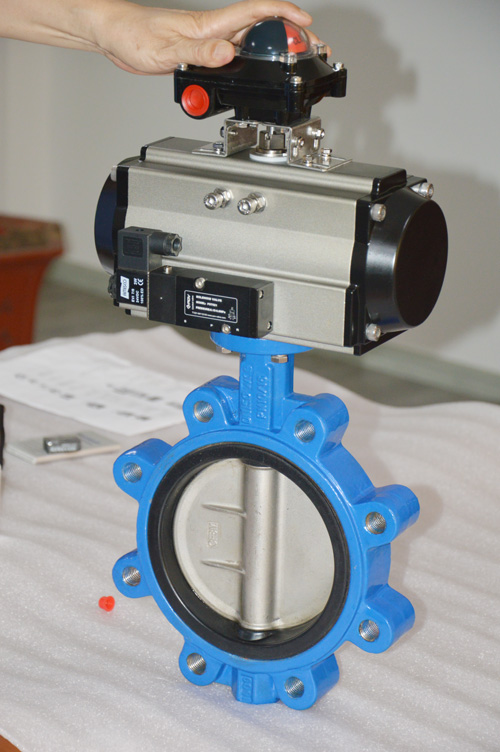

The flanged butterfly valve is the most common type of valve on the market today, with its simple design featuring two discs mounted on a central shaft. The discs can be in either open or closed positions at any given time, allowing for precise flow control. With its solid construction and tight seals, the lug style butterfly valve offers superior performance in demanding environments and is commonly used in industrial facilities, power plants, water treatment plants and other industrial applications. How to choose wafer butterfly valve here

Types of Lug Style Butterfly Valves

Lug style butterfly valves come in a wide range of sizes and materials, making them a versatile option in any industrial setting. They can be made from stainless steel, aluminum, plastic or titanium, depending on the requirements of the application. The most common type is the wafer-style valve, which uses two half-circle discs mounted to an axle that fits into rigid flanges on either side of the pipeline.

Other types include double flanged and single flanged valves for large pipelines, eccentric lug valves for easy access points and sealed lug valves for applications with narrow spaces. Regardless of the style chosen, lug style butterfly valves are typically lightweight and easy to install and maintain.

Features and Benefits of a Lug Style Butterfly Valve

Lug style butterfly valves are an ideal choice for many industrial applications due to their performance and affordability. They feature a simple and compact design, two discs mounted on a central shaft, and bidirectional flow control capabilities that allow for precise flow control. In addition to being lightweight and easy to install, these valves also offer superior performance in demanding environments, with minimal pressure losses and excellent flow characteristics. Other key benefits include low maintenance requirements, cost-efficiency and resistance to corrosion or abrasion. All of these features make lug style butterfly valves an attractive choice for any industrial setting seeking reliable valve performance.

Factors to Consider When Choosing a Lug Style Butterfly Valve

When considering a lug style butterfly valve, several factors should be taken into account to ensure the best fit for the application. The material of the valve is one important factor, as it must be compatible with the medium that will pass through the valve. In addition, there should be a consideration of the size, pressure class and temperature range needed for the specific application.

Flow rate and leakage requirements also need to be determined in order to select the right valve design. Additionally, design verification tests should be performed to verify that all components are working together properly and safely. By taking all of these factors into account, engineers can make an informed decision when selecting a lug style butterfly valve for their application.

Installation and Maintenance Tips

Installing and maintaining a lug style butterfly valve is relatively easy, with just a few tips in mind. Before installation, the valve should be inspected to verify that all components are in good condition, and the environment around it should be suitable for use. During installation, it is important to ensure that the valve is aligned and supported properly, and lubricated according to manufacturer instructions. Maintenance checks should take place at regular intervals to keep the valve functioning for years. This includes cleaning out debris and other contaminants from the discs, shafts and seals; inspecting for signs of distortion or damage; replacing worn parts; and tightening connections as needed. Adhering to these simple installation and maintenance guidelines will help keep your lug style butterfly valves running smoothly for years.

Materials of Construction

When selecting a lug type butterfly valve, the material it is constructed from should be carefully considered. Common materials of construction for these valves include steel, stainless steel and cast iron. Each material has its own benefits and drawbacks that should be taken into account when choosing which one is right for your application. Steel is generally the most economical option and offers good corrosion resistance in some environments. Stainless steel provides greater durability than steel, but is also more expensive. Cast iron can withstand higher temperatures, but has lower strength and poorer corrosion resistance than steel or stainless steel. All materials should be thoroughly tested to ensure they meet the requirements of the application before being installed.

Leakage Requirements for a Lug Style Butterfly Valve

Leakage requirements are a critical factor to consider when selecting a lug style butterfly valve. In general, these valves operate in either the fully open or the fully closed position with very little variation; this ensures that no leakage is allowed through the valve during operation. If an application needs higher levels of protection against leakage, then additional measures may need to be taken. These measures could include special gaskets between the body and disc, as well as selecting a higher quality valve body material. Additionally, diversified actuation should also be used to ensure maximum protection against leakage. Proper testing should be conducted before the valve is installed to guarantee satisfactory performance and meet all leakage requirements.

Temperature and Pressure Ratings

Temperature and pressure ratings are important considerations when selecting a lug style butterfly valve. Generally, the higher the pressure and temperature ratings of the valve, the more expensive it will be. It is important to select a valve that can withstand the application’s specific operating conditions without any problems.

The pressure rating should be checked to make sure it is suitable for the working pressure of the system. Standard valve models usually operate in temperatures up to 300°F but there are also special high-temperature valves available that can withstand temperatures up to 800°F or even higher. Furthermore, different seat materials may also be needed depending on temperature requirements, as some seat materials are more resistant to higher temperatures than others. About butterfly valve price here

Design and Size Requirements

The design and size requirements for a lug style butterfly valve must meet the conditions of the application. Larger valves are often used in high pressure applications, while smaller valves are ideal for low-pressure applications. It is important to choose valve bodies that can accommodate the working pressure differences between inlet and outlet pressures with maximum efficiency. Additionally, all components of the valve should be designed to meet the specific requirements of the intended application, including corrosion resistance and temperature range limitations. The overall size of the valve should also be considered when selecting a model as some sizes may not fit properly or work effectively in restricted spaces. Careful consideration is needed when choosing a lug style butterfly valve to ensure it meets all design and size requirements.

Conclusion

Choosing the right lug style butterfly valve for your application can be a daunting task. There are several factors to consider, such as size and capacity, pressure rating, material of construction, and cost. It is important to make sure that the valve you choose is the best fit for your particular application. You should also ensure that it meets all of your requirements in terms of safety and reliability. Taking all these factors into consideration will help you select the optimal lug style butterfly valve for your needs. Additionally, proper maintenance is necessary to ensure its longevity and performance. With adequate research and guidance from an experienced professional, you can find a quality lug style butterfly valve that meets your specifications and lasts for years.