Lugged Butterfly Valves are incredibly versatile valves that come in various mounting configurations. These mechanical shut off components are being used in a wide range of industries such as mining, petroleum, chemical production and water treatment. Understanding the different configurations available can help to ensure proper installation and maintenance in order to maximize their efficiency and lifespan. In this blog post, we’ll explore the features and benefits of lugged butterfly valves as well as discuss some important tips for maintenance and troubleshooting.

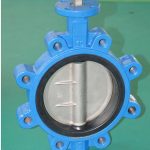

Introduction to Lugged Butterfly Valve

Lugged butterfly valves are widely used for controlling the flow of fluids, gases and slurries in industries such as mining, petroleum and chemical production. The lugs on the valve allow it to be mounted using either flange or lug connectors. Depending on the configuration chosen, these valves can have a single or double flange design.

These components are generally made from stainless steel and other corrosion-resistant materials, making them ideal for use in hostile environments. Additionally, they offer the advantage of being able to control the flow by pressing down on a disc connected to a stem in order to open or close the valve completely. Wafer butterfly valve

This provides great flexibility when it comes to controlling pressure, which is extremely important in industrial applications. Furthermore, lugged butterfly valves are relatively easy to install due to their simple design and because of their lighter weight compared to traditional gate or ball valves.

Finally, thanks to their robust construction, they offer excellent durability and reliability over an extended period of time with minimal maintenance requirements.

Overview of features and characteristics

Lugged butterfly valves offer a number of features and characteristics that make them ideal for industrial applications. Firstly, the shape of the disc ensures a self-centering action which creates a secure seal when in the open or closed position.

Additionally, these valves provide low torque operation compared to other types of valves which helps to reduce maintenance costs over time. Moreover, they are constructed from corrosion-resistant materials allowing them to handle harsh environments while still providing peak performance.

Additionally, they have solid body construction making them incredibly durable as well as tamper-resistant so that they remain secure from unauthorized access or tampering. Furthermore, lugged butterfly valves provide bi-directional flow capability for greater flexibility in various settings. Finally, their lightweight design makes them easier to install and replace without requiring heavy equipment.

Types of Configurations Available

Lugged butterfly valves come in a range of different configurations to meet the needs of various industrial applications. The basic configuration consists of a body, disc, stem, seat and lug attachments. The body is typically made from metal or plastic and can be either single-piece or segmented depending on the application.

The disc is usually shaped like a winged wheel, allowing for easy self-centering action when placed in the valve opening. The stem connects the disc to the handwheel on top of the body and is generally produced from stainless steel for strength and corrosion resistance. The seat is usually made from rubber or synthetic materials to provide a secure seal when the disc covers it entirely. Finally, lugs are added to both sides of the body which allows it to be attached to pipes using bolts, making installation easier and faster compared to other types of valves. In conclusion, lugged butterfly valves offer numerous configuration options that make them ideal for many different industrial applications.

Flange vs lug mounting Lugged Butterfly Valve

When choosing a lugged butterfly valve, it’s important to consider the type of mounting that will be used. The two most popular types are flange and lug mounting. Flange mounting is the simplest option, involving bolting the valve to a pre-drilled flange on pipes connected to either side. This method is often preferred when space limitations prevent other forms of installation. On the other hand, lug mounted valves use lugs attached to both sides of the body which allow for direct connection with pipes using bolts and gaskets.

In addition, this installation method allows for easy replacement and assembly in tight spaces where flanged connections would not fit. Each type has its own advantages and disadvantages, so it’s best to evaluate your needs before deciding which is right for you.

Double flange configurations Lugged Butterfly Valve

Double flange configurations are a popular choice for lugged butterfly valve systems. This type of configuration includes two sets of lugs on the valve body, one set at the top and one set at the bottom. By using two flanges instead of one, double flange configurations provide additional support and strength to the valves, making it ideal for high-pressure and highly corrosive applications.

Double flange configurations also allow for quick connection with mating surfaces without a gasket, creating an even better seal than single-flanged designs. In addition, double-flanged designs require less space for installation, making them perfect for tight areas such as pipelines and water tanks. Pneumatic ball valve

Benefits of Using Lugged Butterfly Valve

Lugged butterfly valves offer a variety of benefits for all types of applications. The most obvious benefit is their installation flexibility – they can easily be mounted in any situation, regardless of the layout or access difficulties. The lugs also provide superior sealing capabilities when compared to flanged valves, eliminating leakages and ensuring greater safety. Their lightweight construction makes them easier to transport and install, while their small size saves space in crowded areas.

Furthermore, lug butterfly valves can be used to control highly corrosive liquids or gases due to their enhanced strength, making them an ideal choice for hazardous materials handling systems.

They are also easier to maintain as they do not require as much disassembly or special tools compared with other valve types. In addition, lugged butterfly valves provide excellent flow control which allows precise application-specific regulation of pressure and temperature. Overall, lugged butterfly valves offer reliable performance for a wide range of industrial requirements that other valves cannot match.

Installation advantages

Pneumatic butterfly valve offer numerous advantages when it comes to installation. The lugs provide superior sealing capabilities, eliminating leakages and ensuring a more secure fit than flanged designs.

Additionally, the valves’ lightweight construction makes them much easier to transport and install, while their small size conserves space in confined locations such as pipelines or water tanks. Furthermore, they don’t require as much disassembly or special tools compared to other valves, making it easier to maintain them over time. This makes lugged butterfly valves an ideal choice for industrial applications due to their reliable performance and easy-to-install nature.

Durability and reliability

Wafer butterfly valves are renowned for their durability and reliability. Their lugs provide an improved sealing system that is more effective at stopping leaks than flanged models, as well as providing greater strength for handling hazardous materials.

This makes them ideal for applications involving corrosive liquids or gases. Additionally, lugged butterfly valves are designed to facilitate precise flow control, allowing users to regulate pressure and temperature with outstanding accuracy.

This feature is invaluable in industrial applications such as chemical plants and power stations. Thanks to its robust construction, a lugged butterfly valve can handle high temperatures and pressures while maintaining the highest levels of performance throughout its lifespan.

Maintenance and Troubleshooting Tips

Maintenance and troubleshooting on lugged butterfly valves should be fairly straightforward, as they are easy to disassemble and inspect. Start off by ensuring the valve is clean and free of sediment or foreign matter; this should be done regularly for optimal performance.

You can then check all the parts for damage or wear and tear, replacing them if necessary. If you find any leaks, it is usually a sign that the butterfly seal needs to be refitted. Additionally, make sure O-rings and other components are properly in place and have not been damaged from incorrect handling or installation.

Troubleshooting on lugged butterfly valves requires some knowledge of their operating principles; however, there are many online guides designed specifically to help users understand how the valve works. With these maintenance tips in mind, you can ensure your lugged butterfly valve continues to deliver reliable performance for years to come.

Conclusion

Understanding the many different configurations involved in electric butterfly valves is essential to ensuring they perform as expected. Whether you need a lugged butterfly valve for a chemical plant, power station or other industrial application, it’s important to identify the desired pressure and temperature requirements of that particular environment.

You will also want to ensure the valve can handle any hazardous materials or corrosive liquids or gases that may be present. In addition to these parameters, you should also consider how easy maintenance and troubleshooting will be for your particular setup, as well as how reliable and durable the product is. By taking all these considerations into account before buying, you can ensure your lugged butterfly valve is correctly configured for safe and efficient operation.