A metal seated butterfly valve is a type of valve used to control the flow of various liquids and gases. These valves consist of two halves, each with a disc-shaped opening in the center surrounded by a circular rim. As the valve is opened and closed, the two discs move past each other to regulate the amount of flow passing through them. The metal seating provides an extra layer of protection against wear and tear, resulting in better performance over time. Understanding how these valves work can help you make smarter decisions on which type best suits your industrial or domestic needs.

Introduction to the Metal Seated Butterfly Valve

The metal seated butterfly valve is a type of valve designed for regulating the flow of liquids and gases. Its design consists of two halves: an upper and a lower, both with a disc-shaped opening in the center surrounded by a circular rim. Opening and closing the valve causes the discs to move past each other, regulating the amount and rate of flow through it. This type of valve is usually made from stainless steel or other corrosion-resistant materials which provide extra protection against wear and tear, increasing its durability over time. Due to its unique design and reliable performance, this type of butterfly valve is used in many industrial applications such as water supply systems, oil pipelines, food processing plants, chemical plants, and more. Furthermore, it can be easily installed on almost any size pipes thanks to its low weight and ability to fit into tight spaces.

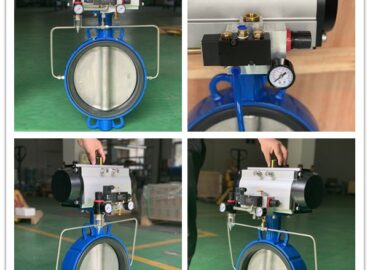

Overview of its Design and Working Principles

The metal seated butterfly valves are designed with two half-discs, which open and close as the valve handle is turned. Inside the assembly, the two discs have a central hub on one of the discs which is attached to a shaft. As the switch is turned, this shaft rotates and causes the discs to move together or apart depending upon their position.

This movement causes an alteration in the size of an opening which regulates the flow-rate of liquids or gases passing through it. The design also features a seat that gets clamped onto each butterfly disc when they’re moved away from each other, preventing any chance of backflow and ensuring reliable sealing. Additionally, each disc has a lip seal which provides further protection against leakage and contamination within your system. Compared to many other valves available today, metal seated butterfly valves offer superior performance and flexibility due to their unique design, making them ideal for both domestic and industrial uses.

Benefits of Utilizing a Metal Seated Butterfly Valve

Using a metal seated butterfly valve can provide several advantages to your applications. Firstly, the valve is highly resistant to corrosive liquids and gases, allowing for long-term use in harsh environment. Additionally, their design affords great flexibility, allowing them to be installed onto any size pipe and providing accurate control of flow rate and pressure.

Furthermore, their unique structure allows them to provide superior sealing capabilities due to the lip seals on each disc and the seat clamped between them which provides extra protection against backflow. Lastly, they are easy to maintain since most components are accessible with either hand screws or bolts and require only minimal maintenance over time. All these features make metal seated butterfly valves an ideal choice for any fluid control application where reliability and durability are important factors.

Different Types of Metal Seated Butterfly Valves

There are several different types of metal seated butterfly valves available on the market, each suited to a specific application. Ball-seated butterfly valves feature spherical surfaces which act as both sealing and bearing elements, providing excellent leak-tightness without compromising on ease of operation. Another type is the unidirectional or bidirectional double eccentric butterfly valve which utilizes a cam system to ensure robust performance when used with high pressure applications. Additionally, seat-bonded or pin-bonded metal seated butterfly valves are also available, both offering superior resistance to abrasion and ensuring long service life. With such a wide range of options available, it’s easy to find the right valve for your needs.

Installation Considerations for Metal Seated Butterfly Valves

When installing a wafer butterfly valve, numerous considerations must be taken into account, such as the environmental conditions and the desired flow rate. Specifically, the user should ensure that the valve is suitable for the operating temperature and pressure range of their application in order to prevent failure or damage. Resilient Seated Butterfly Valve

Additionally, adequate clearance must be provided between the disc seat face and any other components within close proximity. Careful alignment of the valve should also be observed during installation to prevent leakage and ensure that there are no obstructions in the flow path of the valve. Lastly, great attention should be taken on any accessories used with metal seated butterfly valves in order to achieve maximum performance from your application.

Advantages and Disadvantages of Metal Seated Butterfly Valves

Metal seated butterfly valves have a number of advantages over other types of valves, such as their ability to handle extreme temperatures and pressures, durability and high flow rates. In addition, they also offer excellent leak-tight sealing and can be easily serviced with minimal downtime. On the other hand, metal-seated butterfly valves can be quite heavy and expensive, so users should carefully consider their individual needs before investing in one.

They may also require frequent maintenance due to the wear of their seat from frequent operation, depending on the type of material used for the seat. Nevertheless, when appropriately chosen and maintained, metal seated butterfly valves offer unparalleled performance and reliability in most applications.

Conclusion

In conclusion, a metal seated butterfly valve is an essential component in many industrial piping applications. It functions by having a circular disc with a hinge at its center. When the valve is opened, the disc pivots to allow fluid to pass through. This type of valve is durable, reliable, and capable of handling extreme temperatures and pressures, making it suitable for a wide variety of uses. It is important to note that careful selection and maintenance should be done for metal seated butterfly valves in order to ensure maximum performance from your application.