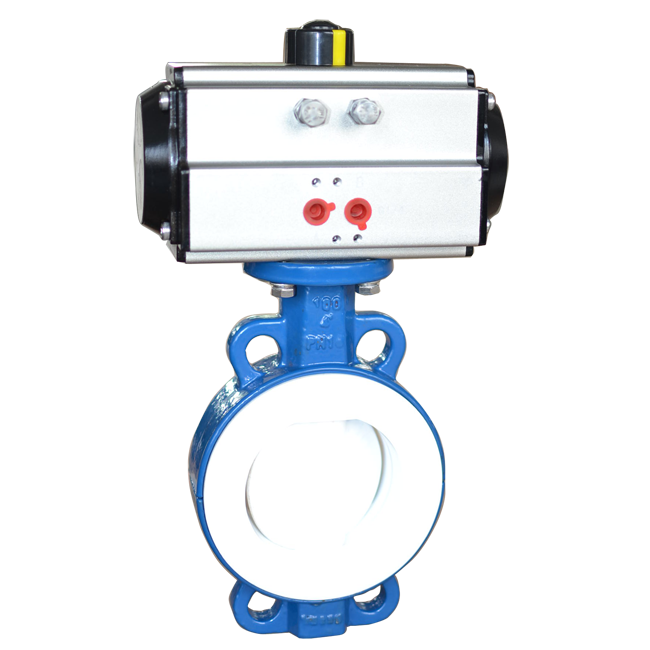

Pneumatic actuator butterfly valves

Pneumatic butterfly valves are an efficient, reliable valve option often used in industrial applications. Butterfly valve with pneumatic actuator use compressed air to power the actuator which allows for precise opening and closing of the valve, enabling optimal control over the flow configuration of materials. The butterfly-shaped disc inside the air operated butterfly valve seals tightly while allowing minimal friction and wear, ensuring an efficient operation. Installation is quick and simple due to their compact size, also making them suitable for limited space environments. Air actuated butterfly valve are cost-effective solutions for many industries and are especially advantageous in situations where accurate control over fluid flow rates is required. Butterfly valve actuator is especially suitable for the control of water, gas, oil, powder and other media

FAQs

In what kind of applications is a pneumatic butterfly valves suitable for?

A pneumatic actuator butterfly valve is a versatile and economical choice for a multitude of applications, from controlling industrial processes to operating systems in the nuclear and aerospace industries.

In industrial settings, such as power plants, petrochemical plants, paper mills and steel mills, these valves can be used for flow rate control in pipelines carrying steam or gases. They are often found in low-flow diverting services between two or more lines at the same pressure. They are also ideal for use as isolation valves on higher pressure systems.

Due to their simple design with no moving parts exposed to the line fluid, they come with several benefits such as long service life due to minimal wear during operation and easy maintenance because of their smooth interior surfaces that reduce friction drag losses. Pneumatic butterfly valves offer fast response times and require less energy than any other type of valve due to their air/gas actuator mechanism which enables effortless opening or closing regardless of process conditions changes over time. In addition, they feature excellent strength ratings that make them suitable for high-pressure applications where other types fail under normal operations loadings; this makes them an ideal choice for higher pressure piping systems in chemical processing facilities.

Air actuated butterfly valve are increasingly being adopted by those working in hazardous environments such as oil refineries since it allows personnel a safe distance from potentially contaminated fluids thanks to its remote controlled actuation system using compressed air cylinders instead of manual operators like handles located near the valve body itself. Furthermore, because pneumatic butterfly valves don’t require direct contact with hazardous chemicals it eliminates many safety risks associated with manual handling so they have become very popular among plant engineers involved in safety compliance audits.

So if you ever find yourself looking into quick response time solutions which need precise closure performance then most likely you'll end up finding out that a pneumatic butterfly valve will fit your needs perfectly!

Pneumatic actuator butterfly valves quality assurance

Pneumatic butterfly valves are subject to rigorous quality control and assurance processes. Each valve is tested for performance and safety before it is delivered to the customer. The validation process covers design, mechanical operation, flow rate characteristics, pressure drop, air leakage and noise levels, ensuring that all valves meet the most demanding international standards of quality. Additionally, the pneumatic actuator is fitted with features such as end-of-travel limit switches to prevent overtravel and related problems, ensuring safe operation in any application.

How many days is the delivery time of pneumatic butterfly valves

Delivery time for pneumatic butterfly valves typically takes between 5-20 business days after the order has been placed and accepted. During this period, the valves will be inspected and tested to ensure that they meet all quality requirements before being shipped out. Orders can be expedited to ensure faster delivery if needed, but additional costs may be associated with this service. At any rate, customers are guaranteed prompt delivery of their orders no matter what their needs may be.

What is a pneumatic butterfly valves?

A pneumatic butterfly valve is a type of quarter-turn rotary flow control valve used to shut off or regulate the flow of air, liquids, and other materials. It is composed of two halves—the disc-shaped body, which contains the actuator and the internal components, and a butterfly disk that can be rotated within the body. The butterfly disk has a hole in its center for controlling the amount of fluid passing through it.

A pneumatic butterfly valve operates when compressed air is supplied to an actuator mounted on top of or beneath its body and causes it to rotate against springs (normally closed) or magnets (normally open). This rotation slides a stem attached to an eccentric hub on the backside of the plug into position at varying degrees from completely closed position down near 0% opening up near 100%, depending on how much travel is required by design. This process opens or closes their valves according to pre-programmed data set by engineers