Description

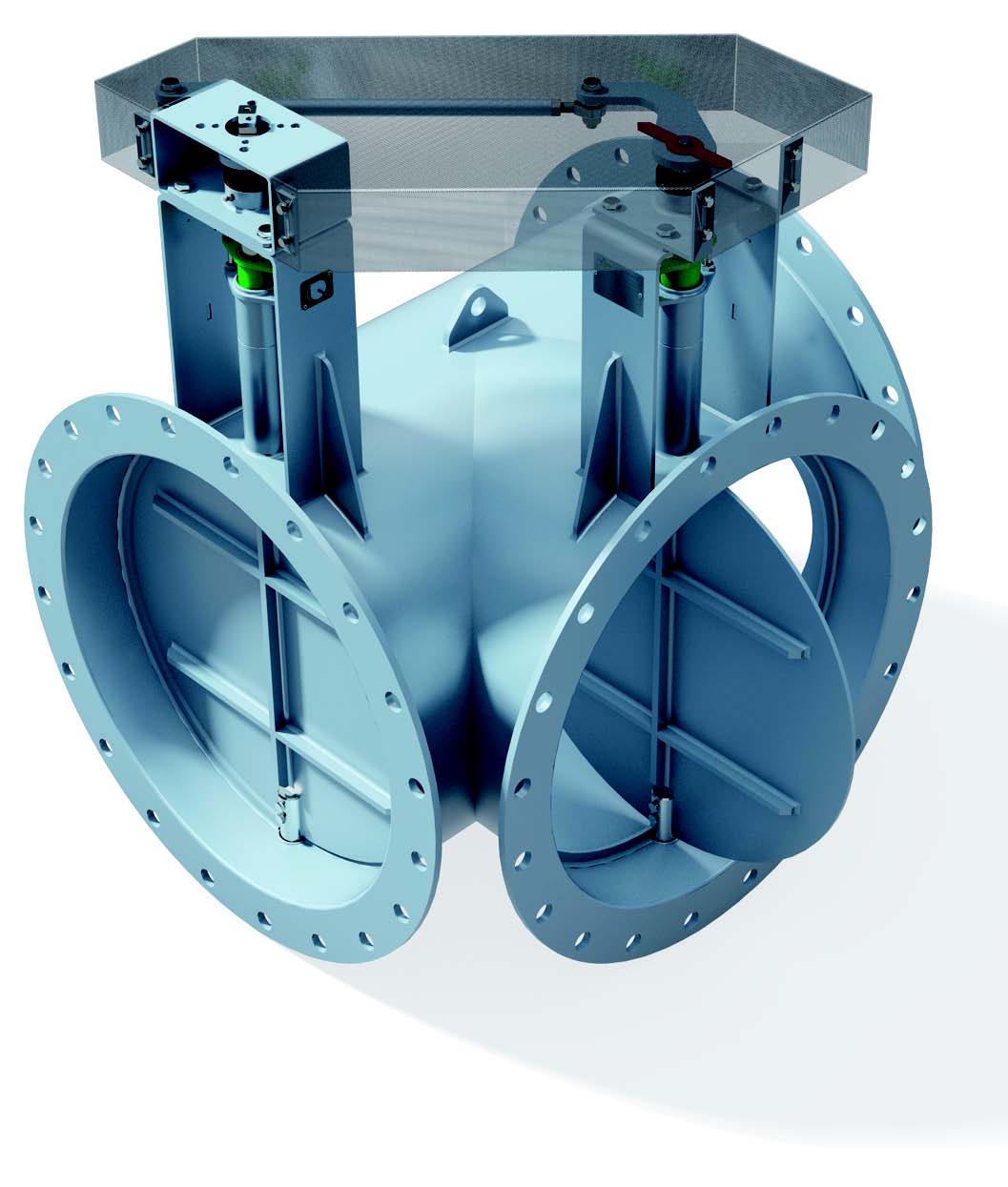

Three Way Butterfly Valve: Design, Operation, and Applications

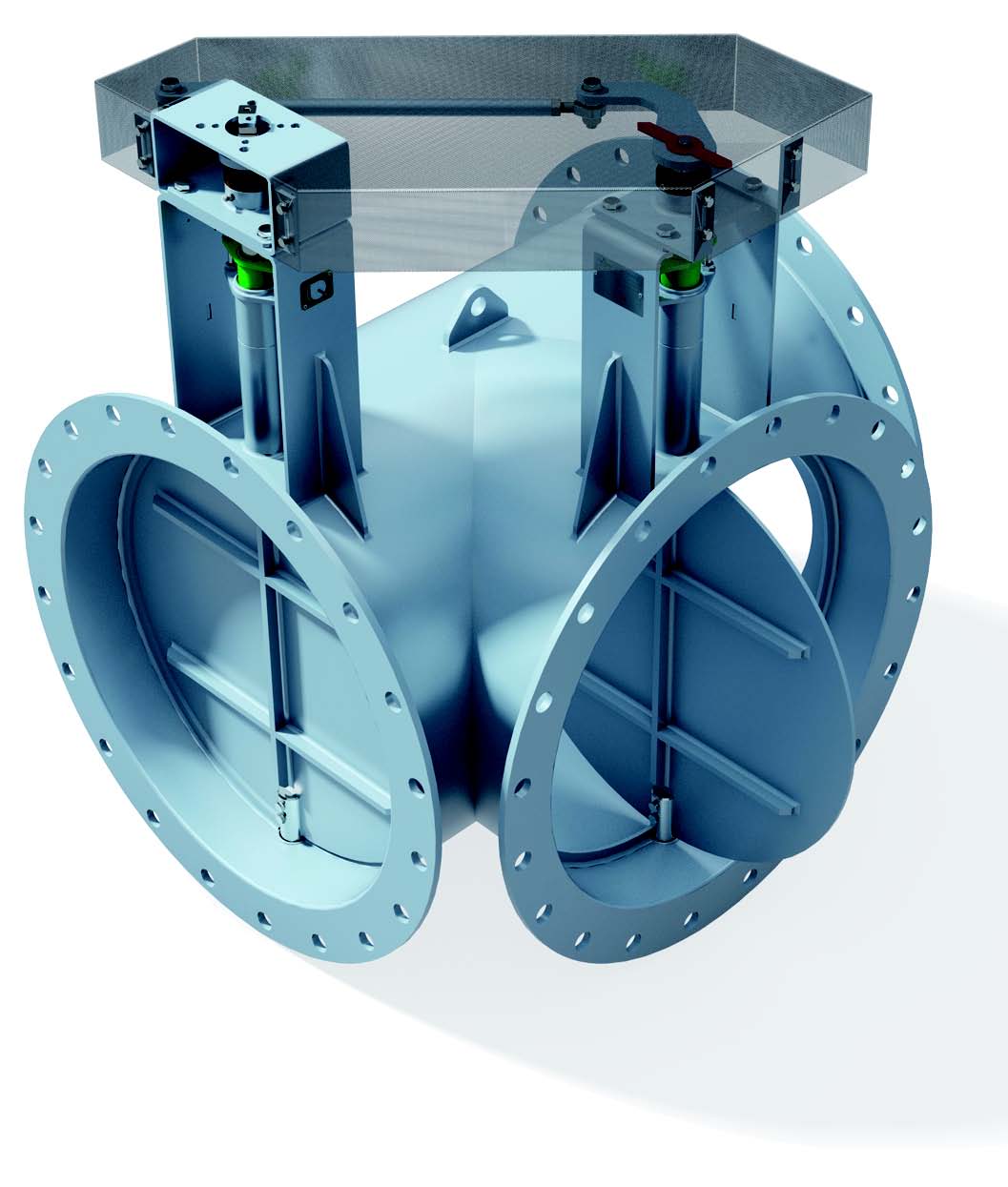

3 way butterfly valve is a versatile and robust valve designed for controlling the flow of fluids in various industrial applications. This detailed analysis will cover the valve’s design, operation, and applications within industries such as chemical, food and beverage, pharmaceutical, and water treatment.

Valve Structure and Materials

The 3-way butterfly valve features three key components: the body, disc, and stem. The body houses the stem and disc, while the disc rotates within the body to regulate the flow. The stem connects the disc to the actuator, transmitting the actuator’s movement to the valve.

Key materials used in the construction of 3-way butterfly valves include:

- Body: ASTM A536 65-45-12, WCB, CF8M, UPVC

- Disc: ASTM A536 65-45-12 Nylon coated, CF8, CF8M, UPVC

- Seat: EPDM, NBR, FRM, PTFE

- Stem: SS420, SS431

These materials offer excellent corrosion resistance, durability, and compatibility with various media, making them ideal for a wide range of applications.

Valve Operation and Flow Direction

A 3-way butterfly valve’s primary function is to control fluid flow in three different directions. These directions are as follows:

- Full open: The disc is parallel to the flow, allowing unrestricted fluid passage.

- Full closed: The disc is perpendicular to the flow, blocking the fluid entirely.

- Throttling: The disc is partially turned, regulating the fluid flow rate.

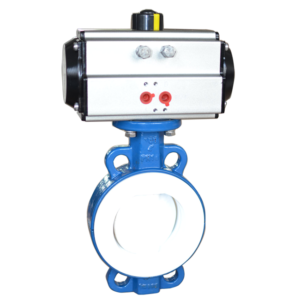

The flow direction is controlled by the actuator, which can be either a pneumatic or electric type. Pneumatic actuators utilize air pressure to drive the valve, while electric actuators use an electric motor. There are two main actuator modes: double-acting (air-to-open, air-to-close) and single-acting (spring-return).

Key Features

Some essential features of 3-way butterfly valves include:

- Actuation Method: Pneumatic (double-acting, single-acting) or electric (ON-OFF type, adjustable type).

- Sealing: The seat provides a tight, leak-proof seal between the disc and body, preventing fluid from escaping. Materials such as EPDM, NBR, FRM, and PTFE deliver high sealing performance and resistance to various media.

- Pressure Rating: These valves accommodate various pressure ratings, including DIN PN10 PN16, JIS 5K 10K, and ANSI CLASSS 150LB, allowing for application versatility.

Installation, Maintenance, and Repair

Installation

- Ensure the valve is compatible with the process media, temperature, and pressure requirements.

- Always use the appropriate gasket material for flange connections.

- Install the valve with the disc in a slightly open position to prevent damage during tightening.

- Align the actuator and ensure that it operates smoothly without excessive force.

- Make sure to follow the manufacturer’s guidelines for installation.

Maintenance

- Routinely inspect the valve for leaks, corrosion, and wear.

- Regularly test actuator functionality

Body:ASTM A536 65-45-12, WCB, CF8M,UPVC

Disc:ASTM A536 65-45-12 Nylon coated, CF8, CF8M,UPVC

Seat:EPDM,NBR,FRM.PTFE

Stem:SS420,SS431

Body style:wafer、lug、flange

Nominal diameter:2″ – 80″ (DN50mm – DN2000mm)

Flange accommodation: DIN PN10 PN16,JIS 5K 10K,ANSI CLASSS 150LB

Pneumatic actuator: Double acting, Single acting, Electric actuator: ON-OFF type, adjustable type

FAQs

Advantages of 3-way butterfly valve

Our 3-Way Butterfly Valves offer distinct advantages, making them a preferred choice for various industrial applications:

- Directional Flexibility: The defining feature of a 3-Way Butterfly Valve is its ability to manage the flow of media in three different directions. This multi-directional functionality allows for more complex fluid handling systems, providing enhanced flexibility in system design and operation.

- Efficient Flow Control: These valves are designed with an advanced disc mechanism that can be precisely positioned to regulate flow. This ensures efficient throttling and precise control of media flow, resulting in optimal performance and reduced energy consumption.

- Space-Efficient Design: Given their ability to handle multiple flow paths, 3-Way Butterfly Valves can replace multiple 2-way valves in a system, saving considerable space. This makes them ideal for installations where space is at a premium.

- Durability and Longevity: Built with high-quality materials resistant to wear, corrosion, and extreme temperatures, our 3-Way Butterfly Valves are designed to withstand harsh industrial environments, ensuring durability and long service life.

In which industries are three-way butterfly valves used?

Chemical and Pharmaceutical Industries: IN these sectors, three-way butterfly valves are frequently used due to their resistance to corrosive materials and extreme temperatures. They ensure safe and efficient handling of various chemical substances, contributing to operational safety and efficiency

Oil and Gas Production: The oil and gas industry uses three-way butterfly valves for their durability and the ability to withstand high pressures, making them suitable for controlling the flow of gases and crude oil

Building and Process Control Industries: These sectors appreciate the three-way butterfly valves for their versatility and compatibility with a variety of actuators. They are commonly used in HVAC systems for efficient temperature regulation

What is the driving method of three-way butterfly valve?

The driving method of a three-way butterfly valve is an integral aspect of its design that dictates how the valve operates within various industrial systems.

Predominantly, these valves are driven by manual, electric, or pneumatic actuators.