Description

Flanged butterfly valve

Double flanged butterfly valve features a bonded liner extending over the flanges. The double flange design is suitable for high pressure loading and for use in heavy industry, shipbuilding, severe vacuum applications and water treatment industry like potable water, water treatment and wastewater applications.

Double flanged butterfly valve – a versatile and high-performance solution for fluid control applications. Engineered with precision and crafted from top-quality materials, this innovative valve offers unparalleled performance, durability, and ease of use.

Material & Specifications

Flange Butterfly Valve is made from robust materials to ensure longevity and resistance to corrosion. The valve body is available in WCB, CF8M, DI, and CI. The disc is manufactured from CF8M, CF8, 2507, and 1.4529 materials, providing you with a wide range of options tailored to your requirements. Moreover, the valve seats come in EPDM, NBR, VITON, and PTFE materials, catering to the diverse needs of fluid control systems.

Product Function

This advanced valve system serves multiple functions, such as:

- Fluid Control: Precise regulation of fluid flow within pipes and channels

- Switch Control: Seamless switching between fluid flow lines and process streams

- Modulating Control: Accurate adjustment of fluid flow rates for optimal process control

Key Features & Benefits

Our Flanged Butterfly Valves boasts several cutting-edge features that set it apart from other valve systems:

ISO5211 Top Flange

The ISO5211 top flange, coupled with a stem heat design, makes it perfect for direct mounting of actuators. This feature allows for easy integration with your existing fluid control infrastructure and eliminates the need for additional adaptors or couplings.

No Exposed Pins or Bolts

The stem-to-disc connection is equipped with a secure and streamlined design. By eliminating exposed pins and bolts, the chances of leakage or corrosion are significantly reduced, ensuring optimum performance and an extended service life.

For added versatility, our butterfly valve flange type is compatible with both pneumatic and electric actuators. This compatibility allows you to choose the most suitable actuation method for your specific needs and ensures flawless operation.

To sum up, the Flanged Butterfly Valve offers a superior solution for a vast array of fluid control applications. Backed by robust materials, advanced features, and unmatched versatility, our valve system ensures seamless integration, optimal performance, and lasting durability. Upgrade your fluid control system with our Flanged Butterfly Valve – a game-changer for precise and efficient fluid management.

FEATURES

1,ISO5211 top flange together with stem heat suitable for direct mounting of actuators

2,Stem anti-blowout design keep safety in field use

3,Bonded seat protects the body and shaft out of contact with medium

4,No exposed pins or bolts for stem-to-disc connection

5,Single flange mounting is possible

6,Can be installed in any desired position

7,Bubble-tight shut off at full pressure rating

8,Large flow capacity and enough strength

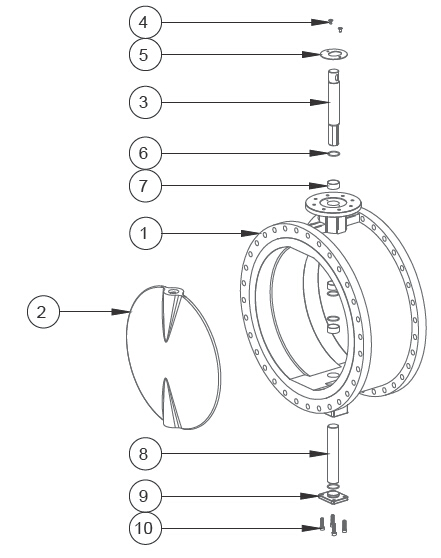

PARTS LIST AND MATERIAL SPECIFICATION

| NO. | Part name | Material |

| 1 | Body | ASTM A536 65-45-12, WCB, CF8M Bonded with NBR or EPDM |

| 2 | Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 |

| 3 | Stem | SS420,SS431 |

| 4 | Screw | SS304 |

| 5 | Retainer | SS201 |

| 6 | Weather seal | NBR |

| 7 | Bearing | RPTFE with Graphite on I.D. |

| 8 | Lower Stem | SS420, SS431 |

| 9 | Bottom cover | Same as body |

| 10 | Bolt | SS304 |

| 11 | Screw | SS304 |

TECHNICAL DATA

| Body style | Flange |

| Nominal diameter | 2″ – 88″ (DN50mm – DN2000mm) |

| Top flange | ISO5211 |

| Operating pressure | 16bar for DN50-DN300, 10bar for DN350-DN2200 |

| Temperature range | -20 °C to + 140 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150AS 4087 PN10/ PN16JIS 5K/10K |

| Applications | Potable Water, Wastewater, Seawater, HVAC |

| Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

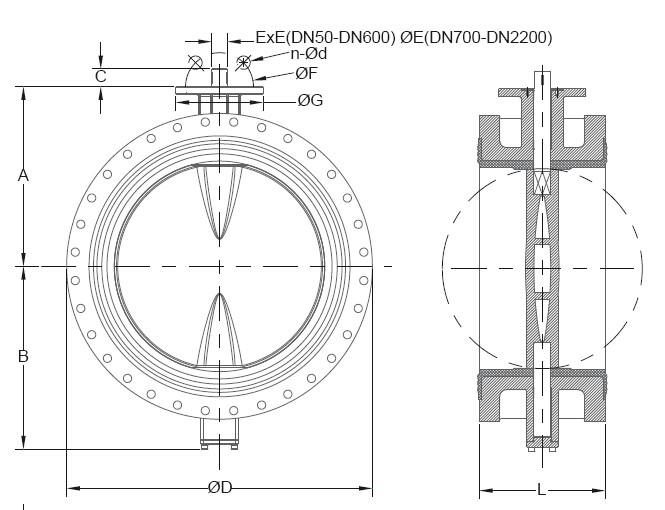

DIMENSIONS (mm)

| SIZE | A | B | C | D | E | F | n | d | G | J | L | WT(kg) | |

| DN | INCH | ||||||||||||

| 50 | 2″ | 142 | 80 | 13.5 | 165 | 9 | 50 | 4 | 8 | 70 | 15 | 108 | 9 |

| 65 | 2 1/2″ | 155 | 89 | 13.5 | 185 | 9 | 50 | 4 | 8 | 70 | 15 | 112 | 10 |

| 80 | 3″ | 161 | 95 | 13.5 | 200 | 9 | 50 | 4 | 8 | 70 | 17 | 114 | 12 |

| 100 | 4″ | 180 | 114 | 13.5 | 229 | 11 | 70 | 4 | 10 | 90 | 17 | 127 | 16 |

| 125 | 5″ | 193 | 127 | 17.5 | 254 | 14 | 70 | 4 | 10 | 90 | 19 | 140 | 24 |

| 150 | 6″ | 205 | 139 | 17.5 | 285 | 14 | 70 | 4 | 10 | 90 | 19 | 140 | 29 |

| 200 | 8″ | 250 | 175 | 24.5 | 343 | 17 | 102 | 4 | 12 | 125 | 21 | 152 | 39 |

| 250 | 10″ | 282 | 203 | 25 | 406 | 22 | 102 | 4 | 12 | 125 | 23 | 165 | 60 |

| 300 | 12″ | 326 | 242 | 25 | 483 | 22 | 102 | 4 | 12 | 125 | 24 | 178 | 82 |

| 350 | 14″ | 358 | 267 | 30 | 533 | 27 | 125 | 4 | 14 | 150 | 24 | 190 | 108 |

| 400 | 16″ | 380 | 301 | 30 | 597 | 27 | 125 | 4 | 14 | 150 | 28 | 216 | 145 |

| 450 | 18″ | 422 | 381 | 39 | 640 | 36 | 140 | 4 | 18 | 175 | 33 | 222 | 183 |

| 500 | 20″ | 479 | 387 | 39 | 710 | 36 | 140 | 4 | 18 | 175 | 40 | 229 | 230 |

| 600 | 24″ | 562 | 457 | 49 | 840 | 46 | 165 | 4 | 22 | 210 | 40 | 267 | 303 |

| 700 | 28″ | 560 | 465 | 95 | 910 | 63.35 | 254 | 8 | 18 | 300 | 40 | 292 | 410 |

| 750 | 30″ | 610 | 508 | 95 | 984 | 63.35 | 254 | 8 | 18 | 300 | 43 | 308 | 552 |

| 800 | 32″ | 620 | 519 | 95 | 1025 | 63.35 | 254 | 8 | 18 | 300 | 43 | 318 | 610 |

| 900 | 36″ | 692 | 576 | 130 | 1125 | 75 | 254 | 8 | 18 | 300 | 46 | 330 | 750 |

| 1000 | 40″ | 735 | 640 | 130 | 1255 | 85 | 254 | 8 | 22 | 300 | 50 | 410 | 945 |

| 1100 | 44″ | 813 | 735 | 150 | 1355 | 85 | 254 | 8 | 22 | 300 | 53 | 450 | 1120 |

| 1200 | 48″ | 917 | 783 | 150 | 1485 | 105 | 298 | 8 | 22 | 350 | 57 | 470 | 1350 |

| 1400 | 56″ | 1000 | 925 | 200 | 1685 | 120 | 356 | 8 | 32 | 415 | 60 | 530 | 1700 |

| 1500 | 60″ | 1050 | 950 | 200 | 1820 | 140 | 356 | 8 | 32 | 415 | 78 | 570 | 2000 |

| 1600 | 64″ | 1150 | 1045 | 200 | 1930 | 140 | 356 | 8 | 32 | 415 | 65 | 600 | 2500 |

| 1800 | 72″ | 1260 | 1156 | 280 | 2130 | 160 | 406 | 8 | 40 | 475 | 70 | 670 | 3500 |

| 2000 | 80″ | 1363 | 1350 | 280 | 2345 | 160 | 406 | 8 | 40 | 475 | 75 | 760 | 4000 |

| 2200 | 88″ | 1500 | 1430 | 300 | 2555 | 180 | 483 | 12 | 40 | 560 | 85 | 636 | 4500 |

FAQs

What is a flanged butterfly valve?

A flanged butterfly valve is a type of flow control device commonly used in water supply systems, wastewater treatment facilities, and other industrial process applications. It consists of a flat disc mounted to the end of a spindle that is rotated by an actuator. The disc has a circular hole cut into it which can open or close depending on the direction of rotation.

The main benefit of using this kind of valve lies in its capacity for both throttling and shut-off operation. That is to say, while other valves are largely limited to one or the other function (for example, ball valves are typically used for shut-off alone), butterfly valves have proven themselves capable of both throttling and shut-off services depending upon their design parameters. This flexibility makes them particularly useful when dealing with process flows where volume adjustment may be required (such as in chemical plants).

In terms of construction, most flanged butterfly valves feature unpacked glands coupled with soft seal seat rings that permit use over wide temperature ranges without compromising tightness. Furthermore, they can generally be customized for different operating conditions via optional components such as air filters/regulators or anti-static devices – all while maintaining their inherent low pressure drop characteristics and good flow control capabilities.

What are the flange types of butterfly valve?

Butterfly valves come in a variety of flange types, including:

Wafer type butterfly valve: This type of butterfly valve is designed to fit between two pipes or other fittings with the same size and rating. It has two wings that form a disc which seals when they are brought together. The wafer type butterfly valve creates an even seal throughout the system, making it ideal for use in water supply systems and other low-pressure applications.

Lugged type butterfly valves: These have lugs that extend from the body to connect with separate mounting bolts which keep the valve securely closed when tightened down. They are usually used in medium-to–high pressure applications where precise control over flow rate is needed, such as in steam distribution systems or compressed air lines.

Flanged end butterfly valves: This particular type of flanged end is most often seen on industrial pipelines and vessels due to its robust nature and excellent sealing capabilities when compared with conventional wafer designs. It also provides easy access for cleaning purposes by simply removing a few bolts without having to take apart the entire system. A downside to this design may be increased cost since most manufacturers require special hardware for installation as well as additional reinforcements around their flange connectors which can add cost onto your piping infrastructure project budget if you’re not careful!

What is a single flange butterfly valve?

A single flange butterfly valve is a type of control valve that uses a circular disc – or the ‘butterfly’ – to regulate the flow rate of a fluid. This type of valve can be used as an isolation, actuation or throttling device for many industrial applications. The unique construction of the single flange design provides several advantages over other types of valves.

First, because it requires only one flange connection, this reduces total cost and assembly time while allowing for easy installation and maintenance in tight spaces with limited access. Additionally, it features high lift capabilities which allow for better regulation at high flow rates than other designs available on the market today. This feature also makes them more resistant to corrosion and abrasion when compared to standard valves made from traditional materials such as stainless steel or bronze.

Furthermore, this type of valve is one-piece in design, meaning there are no moving parts that can potentially wear out over time. As such, they provide improved reliability when exposed to shock loads associated with unpredictable operations often found in today’s industrial process environments. Because the disc remains completely contained within its housing during operation there are minimal chances for cavitation erosions or external fouling build up around critical areas like seats and seals – making them ideal solutions where safety and sustainability are key factors in your system’s performance requirements.

What is a double flange butterfly valve?

A double flange butterfly valve is a type of rotary disc valve used to regulate the flow of liquids and gases. It consists of two concentric discs with matching grooves encased in an outer body. The inner disc, also known as the “butterfly” rotates around its own axis to open or close off portions of the pipe that is connected to it. When fully opened, the butterfly allows for maximum flow through the pipeline – making it ideal for applications requiring high-flow rates and low pressure drops across valves.

The double flange design adds additional strength compared to single flange models since it offers greater stability when installed between two pipes with different diameters or length differences than what would be possible with a single flange design. This makes it perfect for use in pipelines and heavy duty pressure regulating systems due to its ability to withstand higher pressures without significant leakage or damage. Additionally, this extra layer of protection means that maintenance costs are significantly reduced which can lead to a better return on investment over time when used within commercial facilities, factories, and other industrial settings where cleanliness and regulation may be difficult due to limited access points in tight spaces.

What is the difference between a lug and flanged butterfly valve?

Lug and flanged butterfly valves are two major types of valves used for fluid control systems in many different industries. They serve very similar purposes: both the lug and flanged designs enable a valve to be opened or shut off to regulate flow through a pipe. So, what is the difference between these two valve types?

The most obvious distinction between lug and flanged butterfly valves lies in their installation method – lugs are designed with extended ears or “lugs,” while flanges follow more traditional connection standards such as bolting. Lug connections offer several advantages over other methods: they allow for quicker setup times, require less space when installing multiple valves, provide greater flexibility in piping configurations, all while offering superior structural stability than screwed fittings. Flanges also have their own set of benefits; namely providing higher pressure ratings compared to lugs when using standard bolting. Furthermore, as long as you don’t disassemble the flange bolts too often, they tend to provide excellent service lifetime cycles without any need for maintenance or repair work beyond general cleaning/flushing out of your system components once-in-a-while.