Description

Lined butterfly valve

Introducing the innovative and versatile PTFE Lined Butterfly Valve – a high-quality solution for fluid, switch, and modulating controls, even in the most corrosive environments. Designed for resilience and outstanding performance, our lined pfa butterfly valve is manufactured with top-grade materials and offers a robust, leak-free sealing mechanism.

Material & Specifications

The PTFE Lined Butterfly Valves is available in different configurations to suit your application needs:

- Body: WCB+PTFE, CF8M+PFA, DI+PTFE, CI+PFA

- Disc: CF8M+PTFE, CF8+PTFE

- Seat: PTFE

With its wide-ranging compatibility with various liners such as PTFE, EPDM, NBR, FPM, and PU, the lined wafer butterfly valve meets the requirements of diverse industries. Additionally, the valve can be equipped with your choice of pneumatic or electric actuator for actuation flexibility.

*Dimensions, weight, pressure ratings, and temperature ranges will vary based on specific valve models.

Advantages

The Body PTFE Lined Butterfly Valve offers numerous benefits over competing products:

- Corrosion-Resistant: The advanced PTFE lining provides excellent resistance against harsh chemicals, including acids, alkalis, and other corrosive media.

- Leak-Free Sealing: A reliable and secure sealing mechanism prevents leakage and ensures top functionality.

- Low Maintenance: High-quality materials and expert engineering reduce the need for frequent maintenance, saving you time and money.

- Customization: We offer different material and configuration options to meet your unique requirements.

Applications

The Pfa Lined Butterfly Valves expertly handles a variety of chemical and process industries, including:

- Chemical processing

- Petrochemicals

- Water treatment

- Food and beverage

- Pharmaceuticals

Due to its corrosion-resistant properties, the valve is well-suited for managing various fluids, including acids, alkalis, and other corrosive media.

Lined wafer butterfly valve is split body designed for a wide variety of liners such as PTFE, EPDM, NBR, FPM, PU to fit a wide range of applications.

PTFE is the preferred material for corrosive applications in chemical industry.

PU is the preferred material for abrasive applications.

EPDM is the preferred rubber for water industries.

NBR is the preferred rubber for oil transportation.

FPM is the preferred rubber for wide range of medium composition and temperature.

Wafer design makes the valve convenient for connection between flanges and save length in pipe line.

FEATURES

- ISO5211 direct mounting pad for easy automation

- Isolation height according to plant prescription

- Dirtscraper prevents moisture penetrating into the shaft area

- Three PTFE impregnated SS316L bearings are provided for precision alignment of the disc-shaft

- 3 layers sealing system ensures environment protection

- PTFE seat and rubber seat version interchangeable each other• PTFE-liner for chemically toxic and highly corrosive media, rubber liner for various of industry applications

- Silicon rubber energized back behind PTFE seat makes the sealing between liner and disc stable and offer a wide range of temperature

- One-piece disc-shaft design reduces the valve torque and increases Kv

- PTFE or rubber lined disc design option avoids high cost by expensive metal in corrosive applications

- Bubble-tight shut of at full pressure rating

- Can be disassembled, material-specific recycling possible

- Wave shape flange face design ensures the flange sealing of seat face not damaged by flange pressing, also avoids shrink of seat inside diameter because of flange pressing

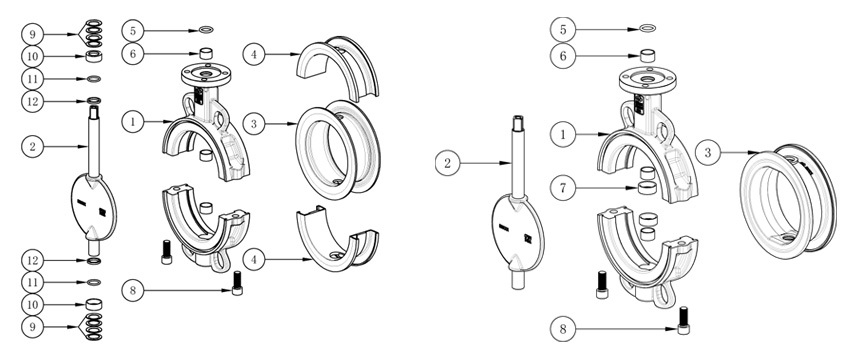

PARTS LIST AND MATERIAL SPECIFICATION

| No. | Part name | Material | |||

| 1 | Body | GGG40 | |||

| 2 | Disc/shaft one piece | CF8M | 1.4462 | CF8M FEP lined | CF8 EPDM lined |

| 3 | Seat | PTFE,FPM,EPDM,PU,NBR | PTFE | EPDM | |

| 4 | Seat Energizer | SR | |||

| 5 | Weather seal | NBR | |||

| 6 | Bearing | PTFE impregnated SS316L | |||

| 7 | Gland | PTFE | |||

| 8 | Screw | SS304 | |||

| 9 | Belleville washer | SS304 | |||

| 10 | Stuffing collar | SS316 | |||

| 11 | O ring | FPM | |||

| 12 | V ring | PTFE | |||

TECHNICAL DATA

| Body style | wafer |

| Nominal diameter | 2″ – 24″ (DN50mm – DN600mm) |

| Top flange | ISO5211 |

| Operating pressure | 16bar for DN50-DN200, 10bar for DN250-DN600 |

| Temperature range | -20 °C to + 180 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

| Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

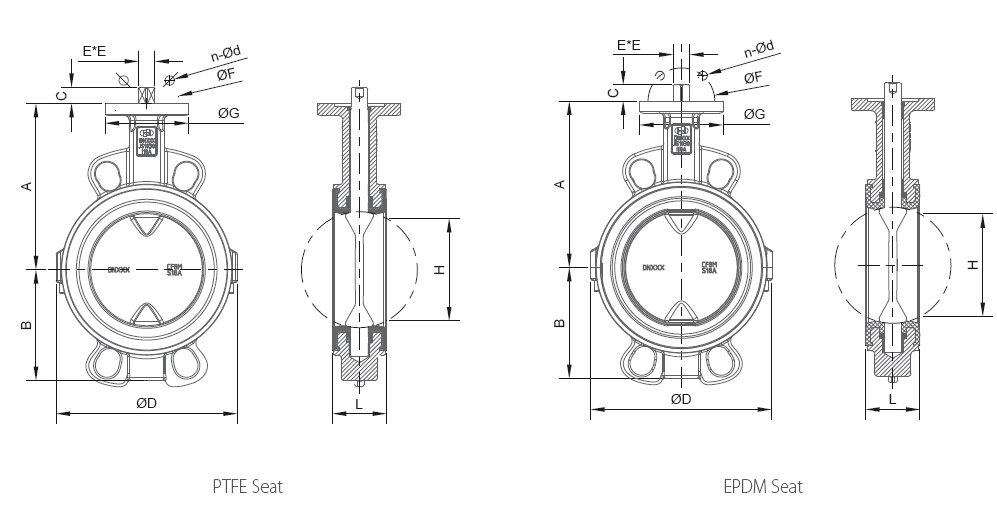

DIMENSIONS (mm)

| SIZE | A | B | C | D | E | F | d | G | H | L | WT(kg) | |

| DN | INCH | |||||||||||

| 50 | 2″ | 126 | 65 | 13.5 | 116 | 11 | 50 | 8 | 65 | 25 | 43 | 2 |

| 65 | 2 1/2″ | 138 | 79 | 13.5 | 136 | 11 | 50 | 8 | 65 | 59 | 46 | 3 |

| 80 | 3″ | 138 | 79 | 13.5 | 136 | 11 | 50 | 8 | 65 | 59 | 46 | 3 |

| 100 | 4″ | 167 | 97 | 17.5 | 170 | 14 | 70 | 10 | 90 | 86 | 52 | 5 |

| 125 | 5″ | 180 | 129 | 17.5 | 196 | 14 | 70 | 10 | 90 | 112 | 56 | 7 |

| 150 | 6″ | 203 | 142 | 18.5 | 227 | 17 | 70 | 10 | 90 | 140 | 56 | 8 |

| 200 | 8″ | 228 | 172 | 18.5 | 279 | 17 | 102 | 12 | 125 | 191 | 60 | 13 |

| 250 | 10″ | 266 | 213 | 24.5 | 336 | 22 | 102 | 12 | 125 | 241 | 58 | 22 |

| 300 | 12″ | 291 | 242 | 24.5 | 392 | 22 | 102 | 12 | 125 | 290 | 78 | 31 |

| 350 | 14″ | 332 | 262 | 30 | 445 | 27 | 125 | 14 | 150 | 331 | 78 | 44 |

| 400 | 16″ | 363 | 303.5 | 30 | 503 | 27 | 125 | 14 | 150 | 377 | 102 | 64 |

| 450 | 18″ | 397 | 324.5 | 39 | 553 | 36 | 140 | 18 | 175 | 425 | 114 | 86 |

| 500 | 20″ | 425 | 357 | 39 | 608 | 36 | 140 | 18 | 175 | 474 | 127 | 116 |

| 600 | 24″ | 498 | 419 | 49 | 717 | 46 | 165 | 22 | 210 | 570 | 154 | 179 |

FAQs

What is lined butterfly valve?

A lined butterfly valve is a type of valve used in various industrial sectors for controlling the flow of fluid through pipes. It consists of a disc or plate that rotates and is mounted inside the body. This disc/plate, when rotated, can open or close the valve and regulate the flow rate through it accordingly. The advantage of this type of valve lies in its simplicity and low cost compared to other types of valves.

The most common lining material used on butterfly valves is PTFE (polytetrafluoroethylene). PTFE lined butterfly valves are usually more durable than non-lined ones as they offer greater resistance to corrosion, abrasion, erosion, wear and tear due to their chemical inert nature.

Moreover, these types of butterfly valves are very easy to maintain and clean due to their smooth surface texture which allows them to keep dirt particles away from clogging or sticking onto the surfaces. Additionally, with proper pre-treatment before installation these types provide enhanced sealing along with reliable pressure tight operation even at high temperatures thanks to their temperature resistant properties.

What material is butterfly valve lining?

A butterfly valve lining is typically composed of a variety of materials, depending on its intended application. The most common types of materials used for butterfly valve linings are polytetrafluoroethylene (PTFE), ethylene propylene rubber (EPDM), and nitrile rubber (NBR).

PTFE, also known as Teflon, is an incredibly strong material that has excellent chemical and temperature resistance. This makes it ideal for use in highly corrosive environments or locations where temperatures exceed 200°F or 93°C. It is often used for applications ranging from food processing to aerospace.

Ethylene propylene rubber (EPDM) offers superior abrasion and wear resistance. EPDM also offers great weathering resistance, making it perfect for outdoor applications such as water treatment plants or those exposed to direct sunlight. It can be modified with additives to improve flex fatigue life or offer better performance against high temperatures up to 300°F/150°C in some cases.

Nitrile Rubber (NBR), sometimes referred to as Buna-N, provides good oil resistance which makes it suitable for petrochemical processing industries as well as automotive engineering and marine operations involving fuel lines connections and hydraulic systems using petroleum-based fluids like diesel fuel. This kind of liner should not be used above 212°F/100°C, however since the material may begin to break down beyond this temperature range due its polymer structure being altered by heat loss over time thus reducing functionality within the valve itself causing hardening & cracking in the NBR liner along with other adverse effects over long term exposure times at higher temperatures than mentioned before here so always best practice when selecting a Butterfly Valve Lining accordingly based upon service requirements thoroughly prior any installation work commences.

What is PTFE lined butterfly valve?

A PTFE lined butterfly valve is a specialized type of control valve used in a variety of industries, such as oil and gas, petrochemical, pharmaceutical, and food processing. It is constructed with an inner core that has been lined with polytetrafluoroethylene (PTFE). This lining provides the benefits of non-contamination abilities while also having excellent resistance to most chemicals. The liner also minimizes power consumption and torque requirements for operation, allowing tight shutoff while providing superior sealing capabilities.

The primary benefit of using PTFE lined valves are that they provide superior performance in highly corrosive environments due to their strong chemical compatibility. There are three main layers found within the design; the outer shell which contains all mechanical elements like body, disc, stem etc., the middle layer which acts as a support between inner and outer shells to transmit forces generated by actuation mechanism along with some degree of insulation from heat transfer from outside shell into interior components such as seat and disc/shaft packing seals etc., and finally the inner surface contact layer – this is where PTFE comes into play – it is applied either manually or via spraying on pre-machined surfaces inside body flanges/bores for optimal protection against corrosion attacks from inside out i.e external environment does not have direct access to internal parts thanks to presence of this protective lining material! Depending upon specific application need parameters like size range availability (from 2” up till 48”), pressure & temperature ranges specified by customers etc… different types may be selected e.g lugged or wafer style designs featuring soft seated constructions vs metal-seated styles etec..

What is PFA lined butterfly valve?

A PFA lined butterfly valve is a type of shut-off valve with an opening through which fluid and gas can pass. It consists of a disc or circular plate, which is rotated by an actuator to control flow. The valves are usually located in the middle of the pipe where it connects two other components and allows one-way or two-way flow depending on whether it opens fully or partially.

The key feature that sets this particular kind of valve apart from others is its Polytetrafluoroethylene (PTFE) lining, often referred to as PFA (perfluoro alkoxy). This thermoplastic liner provides excellent chemical resistance against highly corrosive substances like acids, bases and salts while also providing superior heat resistance up to 500 degrees Fahrenheit. In addition, PFA offers excellent lubricity and low coefficient of friction so it won’t stick when opened/closed repeatedly.

This makes them ideal for use in harsh environments containing aggressive liquids or vapors such as petrochemicals and caustic chemicals, steam services in food processing plants; acids in paper mills; fuels in power generation facilities; water pipes etc., where regular rubber linings would not be suitable due to their short lifespan under extreme temperatures and aggressive fluids.