Description

Lug Butterfly Valve

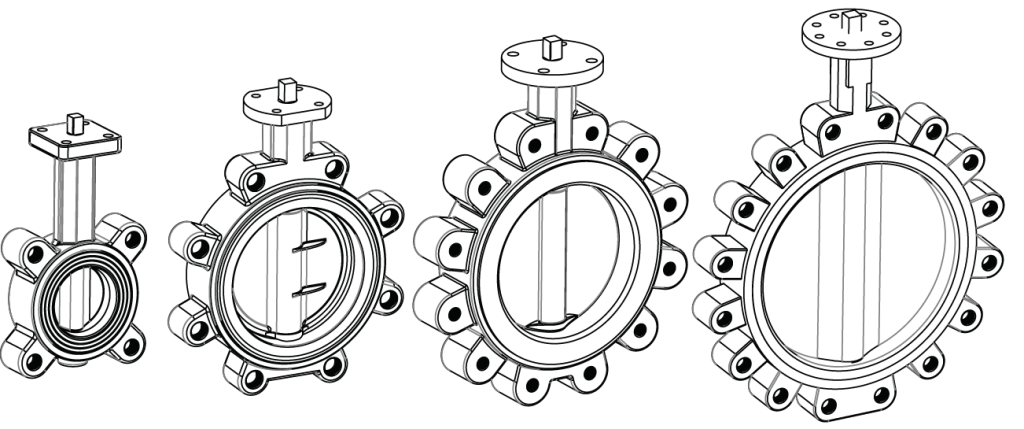

Lug butterfly valve is a type of quarter-turn valve that is ideal for regulating the flow of liquids or gases in industrial applications. It consists of a circular disc that rotates around a central axis within a pipe, controlling the flow of the medium. We offer a wide range of lug style butterfly valve designed for various industrial applications. Our valves are constructed using high-quality materials and meet industry standards such as ISO and API. Our lug type butterfly valve come in various sizes, materials, and configurations, including manual, electric, or pneumatic actuation. The valve’s lug design ensures easy installation and removal, making the valves ideal for piping systems that need regular maintenance.

The benefits of our lugged butterfly valve are numerous, such as precise flow control, low operating torque, and low-cost installation. The valves’ design makes them ideal for applications requiring bidirectional flow control or in applications with limited space. Our expert team of professionals works closely with trusted suppliers to source high-quality materials to build our butterfly valve lug type. Pov’s commitment to quality means our valves are simple to operate and long-lasting, providing maximum performance and productivity.

Contact us today to learn more about our range of lug type valve and how we can help you optimize the efficiency and productivity of your industrial processes.

FEATURES

1,ISO5211 top flange together with stem square suitable for direct mounting of actuators

2,Stem anti-blowout design keep safety in field use

3,Dirtscraper prevents moisture penetrating into the shaft area

4,Suitable for high pressure and full vacuum service due to the use of a cartridge seat design

5,Full rated unidirectional dead-end service is achieved by a lip designed in the lug body

6,No exposed pins or bolts for stem-to-disc connection

7,No need for flange gaskets

8,No risk of damage to the valve during installation in closed position

9,Bubble-tight shut of at full pressure rating

10,Large flow capacity and enough strength because of streamline disc design

11,Plug with O-ring sealing eliminates any leakage from the stem

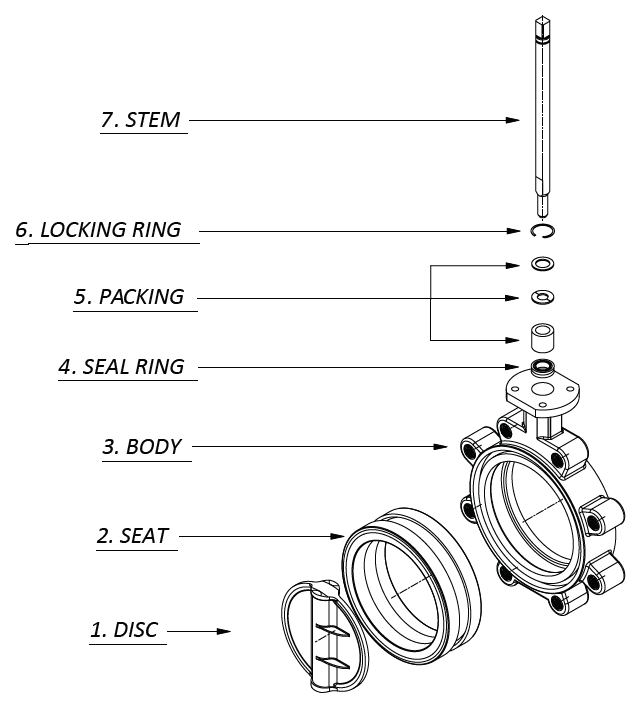

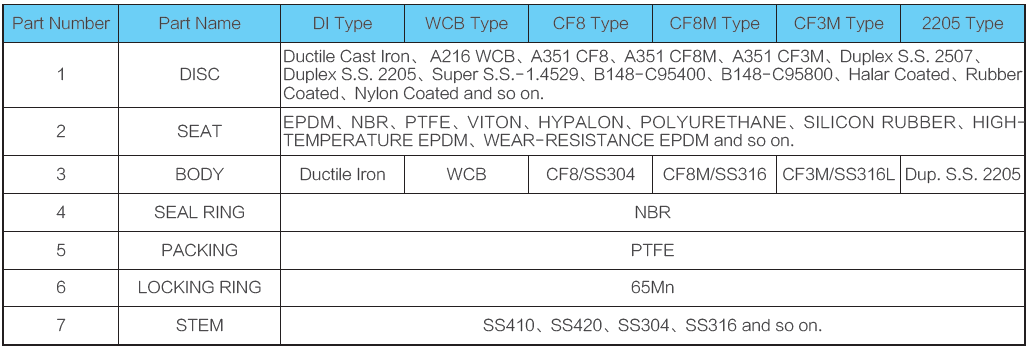

PARTS LIST AND MATERIAL SPECIFICATION

TECHNICAL DATA

| Body style | FLug |

| Nominal diameter | 2″ – 80″ (DN50mm – DN2000mm) |

| Top flange | ISO5211 |

| Operating pressure | 16bar for DN50-DN300, 10bar for DN350-DN2200 |

| Temperature range | -20 °C to + 140 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

| Applications | Potable Water, Wastewater, Seawater, HVAC |

| Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

DIMENSIONS (mm)

| SIZE | A | B | C | D | E | F | d | G | H | J | L | WT(kg) | |

| DN | INCH | ||||||||||||

| 50 | 2″ | 126 | 78 | 13.5 | 117 | 9 | 50 | 8 | 70 | 31 | 34 | 43 | 2.8 |

| 65 | 2 1/2″ | 134 | 84 | 13.5 | 131 | 9 | 50 | 8 | 70 | 45 | 36 | 46 | 3.7 |

| 80 | 3″ | 138 | 92 | 13.5 | 176 | 9 | 50 | 8 | 70 | 64 | 36 | 46 | 5.1 |

| 100 | 4″ | 167 | 114 | 13.5 | 206 | 11 | 70 | 10 | 90 | 91 | 40 | 52 | 6.9 |

| 125 | 5″ | 180 | 129 | 17.5 | 236 | 14 | 70 | 10 | 90 | 110 | 44 | 56 | 9.3 |

| 150 | 6″ | 203 | 144 | 17.5 | 258 | 14 | 70 | 10 | 90 | 146 | 44 | 56 | 10.5 |

| 200 | 8″ | 228 | 179 | 24.5 | 321 | 17 | 102 | 12 | 125 | 193 | 50 | 60 | 17.4 |

| 250 | 10″ | 266 | 216 | 25 | 395 | 22 | 102 | 12 | 125 | 241 | 57 | 68 | 28.1 |

| 300 | 12″ | 291 | 247 | 25 | 461 | 22 | 102 | 12 | 125 | 292 | 66 | 78 | 40 |

| 350 | 14″ | 332 | 273 | 30 | 511 | 27 | 125 | 14 | 150 | 329 | 62 | 78 | 55 |

| 400 | 16″ | 363 | 317 | 30 | 580 | 27 | 125 | 14 | 150 | 376 | 84 | 102 | 85 |

| 450 | 18″ | 397 | 348 | 39 | 630 | 36 | 140 | 18 | 175 | 425 | 94 | 114 | 114 |

| 500 | 20″ | 425 | 393 | 39 | 700 | 36 | 140 | 18 | 175 | 475 | 110 | 127 | 144 |

| 600 | 24″ | 498 | 453 | 49 | 823 | 46 | 165 | 22 | 210 | 573 | 120 | 154 | 227 |

| 700 | 28″ | 626 | 531 | 90 | 928 | 63.1 | 254 | 18 | 300 | 674 | 54 | 165 | 342 |

| 750 | 30″ | 660 | 564 | 90 | 984 | 63.1 | 254 | 18 | 300 | 727 | 54 | 165 | 400 |

| 800 | 32″ | 666 | 601 | 90 | 1061 | 63.1 | 254 | 18 | 300 | 771 | 60 | 190 | 485 |

| 900 | 36″ | 722 | 660 | 110 | 1170 | 74.7 | 254 | 18 | 300 | 839 | 60 | 203 | 605 |

| 1000 | 40″ | 806 | 728 | 120 | 1290 | 83.7 | 298 | 22 | 350 | 939 | 60 | 216 | 776 |

| 1100 | 44″ | 826 | 771 | 140 | 1404 | 94.7 | 298 | 22 | 350 | 1036 | 50 | 255 | 985 |

| 1200 | 48″ | 941 | 874 | 150 | 1511 | 104.7 | 298 | 22 | 350 | 1137 | 62 | 276 | 1190 |

| 1400 | 56″ | 1000 | 940 | 175 | 1685 | 139.9 | 356 | 32 | 415 | 1351 | 62 | 279 | 1380 |

| 1600 | 64″ | 1155 | 1085 | 195 | 1930 | 160 | 356 | 32 | 415 | 1548 | 65 | 318 | 2054 |

| 1800 | 72″ | 1200 | 1170 | 195 | 2170 | 174.5 | 406 | 39 | 475 | 1703 | 70 | 356 | 3075 |

| 2000 | 80″ | 1363 | 1360 | 245 | 2345 | 199 | 406 | 39 | 475 | 1938 | 75 | 406 | 4500 |

FAQs

What is a lug style butterfly valve?

A lug style butterfly valve is a type of valve that uses a circular disc to control the flow of liquids or gases. It has two halves and is opened and closed by turning the disc around its axis. The main parts are a body, disk, stem, actuator, bonnet, seat ring and mounting lugs.

The most important feature of this type of valve is its lug style design which allows for easy assembly and installation in tight spaces. Lug style butterfly valves can be used in both linear (on/off) applications as well as those requiring throttling (partial closure) such as regulating water pressure or controlling steam temperature/pressure. They also have good bi-directional operation capabilities meaning they can be used in either direction without any flow restrictions due to disk alignment issues. For this reason, they are often found on high-pressure systems where other types of valves may not perform adequately.

In terms of construction material choices for lug butterfly valves there are several options including cast iron, carbon steel bodies with stainless steel trim components; all stainless steel; iron body with bronze trim pieces; aluminum bodies with brass trim components; The choice will ultimately depend on the application requirements such as size requirements, media operating temperature/pressure ratings etc., cost considerations etc.

What are the advantages of a lug butterfly valve?

A lug butterfly valve is a type of shut-off valve that relies on a disk-shaped closure element that rotates inside the body of the valve to open or close it. This type of valve offers numerous advantages over other types, including:

High Flow Rate: Lug butterfly valves are known for their excellent flow rate capacities, allowing them to move large amounts of fluid through pipelines quickly and efficiently without compromising pressure control. They can even be used as throttles when there is an increase in pressure or flow on one side of the line.

Reliability: The design and construction of lug butterfly valves ensures they will last longer than many other types of valves due to their lower number of parts and less complicated assembly processes which reduces chances for leakages or corrosion related problems caused by rusting components within the system.

Low Cost Maintenance: Thanks to its simple design, maintenance costs associated with lug butterfly valves are much lower compared to most other shut-off valves, enabling operators to save money while keeping their systems running reliably and efficiently for years with minimal expenses required for repairs or replacements down the road.

Lug type butterfly valve installation?

The lug type butterfly valve installation is an important component in many pump systems. It allows for the regulation of flow and provides shutoff capabilities when necessary. The installation process can be divided into four main steps: preparing the pipe, mounting the lugs onto the valve, attaching gaskets to both sides of the pipe, and connecting and tightening bolts.

Step 1: Preparing the Pipe – Before beginning this step it’s important to ensure that all pipes are properly aligned and that any debris has been removed. Next, measure out how much space is needed for a successful installation taking into account a safe amount of clearance between each component part. This will help ensure that everything fits correctly without obstructing other parts or fittings during operation.

Step 2: Mounting Lugs – After preparing the pipe for proper fitment, mount two lugs onto either side of your butterfly valve by placing one lug on either end of its body stem tube and then tightly screwing them together using stainless steel washers as cushioning between each point where contact occurs.

Step 3: Attaching Gaskets – To ensure a secure seal around your valves opening attach two gaskets – one facing inside from behind it (drive-side) and another on front outside (flange-side) side so that they match up with their corresponding mounting flanges for your pipes connection points during operation preventing any leakage or erosion throughout their lifespan.

Step 4: Connecting & Tightening Bolts– Lastly connect both sides securely by running bolts through previously placed holes in order to tighten them down firmly according to manufacturer’s instructions before testing functionality with water pressure test kits available at most hardware stores across America after completion – making sure all connections have achieved their desired levels before starting operations again within economical safety guidelines!

Lug vs wafer butterfly valve?

When comparing lug and wafer butterfly valves, there are a few key differences to consider. Lug butterfly valves have flanged ends that allow them to be bolted together in-line with pipe flanges. This allows for less installation time and fewer leak points when compared with traditional gate or globe valves. Wafer butterfly valves, on the other hand, do not require any extra components like bolts or gaskets; instead they just fit between two pieces of pipe and can be tightened down using clamps.

The main difference between the two is that lug butterfly valves are more difficult to install than wafer models because all the necessary components (valve body, disc, bolt kits) must be connected before it’s ready for use. Additionally, because of their size and construction material (usually metal), lug butterlfy valves tend to be much heavier than their wafer counterparts which can make them cumbersome to install in some applications such as low-clearance industrial piping systems where space is limited.