Description

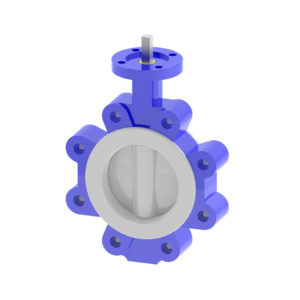

Pneumatic flange butterfly valve

Invest in a air actuated butterfly valve today for maximum efficiency and convenience! This pneubutterfly valve provides precise control over the flow rate, offering continuous fluid flow with minimal pressure drop and outstanding performance. The lightweight, compact design is easy to install between flanges and requires minimum upkeep. Thanks to its two-piece construction and rotatable disc, the pneumatic butterfly valve allows for precise regulation of the flow rate. Achieve ultimate reliability with no need for external power sources – choose a air operated butterfly valve now for superior performance at an affordable price! Upgrade your system today – invest in quality, invest in a butterfly valve actuator

Technical parameters

| Body | ASTM A536 65-45-12, WCB, CF8M |

| Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 |

| Seat | EPDM,NBR,FRM.PTFE |

| Stem | SS420,SS431 |

| Body style | wafer |

| Nominal diameter | 2″ – 80″ (DN50mm – DN2000mm) |

| Top flange | ISO5211 |

| Operating pressure: | 16bar for DN50-DN300, 10bar for DN350-DN2000 |

| Temperature range: | -20 °C to + 140 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

Pneumatic actuator

| action | |

| Double acting | Failure to maintain |

| Single acting normally closed | Failure to close |

| Single acting normally open | Failure to open |

| Optional accessory | Solenoid valve limit switch box air filter relief pressure valve, E/P positioned manual device. |

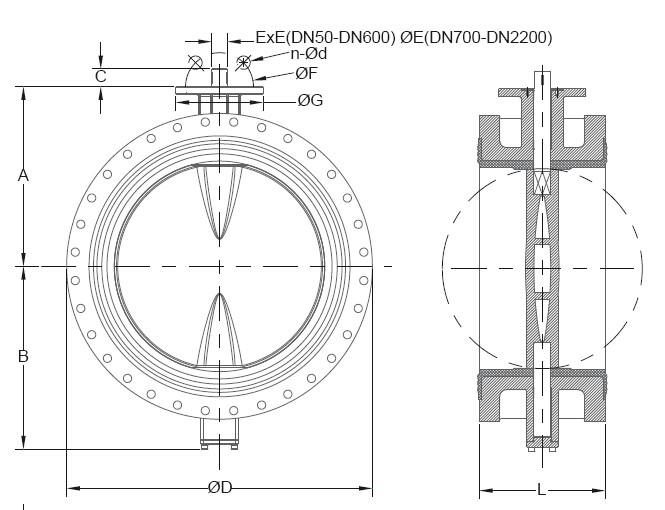

| SIZE | A | B | C | D | E | F | n | d | G | J | L | WT(kg) | |

| DN | INCH | ||||||||||||

| 50 | 2″ | 142 | 80 | 13.5 | 165 | 9 | 50 | 4 | 8 | 70 | 15 | 108 | 9 |

| 65 | 2 1/2″ | 155 | 89 | 13.5 | 185 | 9 | 50 | 4 | 8 | 70 | 15 | 112 | 10 |

| 80 | 3″ | 161 | 95 | 13.5 | 200 | 9 | 50 | 4 | 8 | 70 | 17 | 114 | 12 |

| 100 | 4″ | 180 | 114 | 13.5 | 229 | 11 | 70 | 4 | 10 | 90 | 17 | 127 | 16 |

| 125 | 5″ | 193 | 127 | 17.5 | 254 | 14 | 70 | 4 | 10 | 90 | 19 | 140 | 24 |

| 150 | 6″ | 205 | 139 | 17.5 | 285 | 14 | 70 | 4 | 10 | 90 | 19 | 140 | 29 |

| 200 | 8″ | 250 | 175 | 24.5 | 343 | 17 | 102 | 4 | 12 | 125 | 21 | 152 | 39 |

| 250 | 10″ | 282 | 203 | 25 | 406 | 22 | 102 | 4 | 12 | 125 | 23 | 165 | 60 |

| 300 | 12″ | 326 | 242 | 25 | 483 | 22 | 102 | 4 | 12 | 125 | 24 | 178 | 82 |

| 350 | 14″ | 358 | 267 | 30 | 533 | 27 | 125 | 4 | 14 | 150 | 24 | 190 | 108 |

| 400 | 16″ | 380 | 301 | 30 | 597 | 27 | 125 | 4 | 14 | 150 | 28 | 216 | 145 |

| 450 | 18″ | 422 | 381 | 39 | 640 | 36 | 140 | 4 | 18 | 175 | 33 | 222 | 183 |

| 500 | 20″ | 479 | 387 | 39 | 710 | 36 | 140 | 4 | 18 | 175 | 40 | 229 | 230 |

| 600 | 24″ | 562 | 457 | 49 | 840 | 46 | 165 | 4 | 22 | 210 | 40 | 267 | 303 |

| 700 | 28″ | 560 | 465 | 95 | 910 | 63.35 | 254 | 8 | 18 | 300 | 40 | 292 | 410 |

| 750 | 30″ | 610 | 508 | 95 | 984 | 63.35 | 254 | 8 | 18 | 300 | 43 | 308 | 552 |

| 800 | 32″ | 620 | 519 | 95 | 1025 | 63.35 | 254 | 8 | 18 | 300 | 43 | 318 | 610 |

| 900 | 36″ | 692 | 576 | 130 | 1125 | 75 | 254 | 8 | 18 | 300 | 46 | 330 | 750 |

| 1000 | 40″ | 735 | 640 | 130 | 1255 | 85 | 254 | 8 | 22 | 300 | 50 | 410 | 945 |

| 1100 | 44″ | 813 | 735 | 150 | 1355 | 85 | 254 | 8 | 22 | 300 | 53 | 450 | 1120 |

| 1200 | 48″ | 917 | 783 | 150 | 1485 | 105 | 298 | 8 | 22 | 350 | 57 | 470 | 1350 |

| 1400 | 56″ | 1000 | 925 | 200 | 1685 | 120 | 356 | 8 | 32 | 415 | 60 | 530 | 1700 |

| 1500 | 60″ | 1050 | 950 | 200 | 1820 | 140 | 356 | 8 | 32 | 415 | 78 | 570 | 2000 |

| 1600 | 64″ | 1150 | 1045 | 200 | 1930 | 140 | 356 | 8 | 32 | 415 | 65 | 600 | 2500 |

| 1800 | 72″ | 1260 | 1156 | 280 | 2130 | 160 | 406 | 8 | 40 | 475 | 70 | 670 | 3500 |

| 2000 | 80″ | 1363 | 1350 | 280 | 2345 | 160 | 406 | 8 | 40 | 475 | 75 | 760 | 4000 |

| 2200 | 88″ | 1500 | 1430 | 300 | 2555 | 180 | 483 | 12 | 40 | 560 | 85 | 636 | 4500 |

FAQs

What is a butterfly valve used for?

In the water supply and wastewater management sector, butterfly valves play a pivotal role in managing the flow and pressure of water. In the oil and gas industry, they serve critical throttling services and isolation functions within fuel handling systems. Their utility extends to HVAC systems, chemical industries, and power generation plants, highlighting their broad-based applicability.

What are the different types of butterfly valves?

In the realm of fluid control systems, butterfly valves hold a prominent position due to their effectiveness and adaptability. As a globally recognized leader in the valve manufacturing industry, we offer a variety of butterfly valves, each engineered to cater to distinct operational needs with utmost precision and reliability.

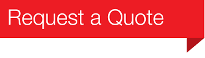

- Wafer Butterfly Valves: Known for their compact, wafer-like bodies, these valves are ideal for systems where space is at a premium. Their design allows for easy installation between pipe flanges, providing an effective shut-off in high-pressure environments.

- Lug Butterfly Valves: Characterized by lugs around the outer edge, these valves can be installed into a system using sets of bolts without the need for nuts. This design permits disconnection on either side of the piping system without causing disruption to the other side, making them suitable for end-of-line applications.

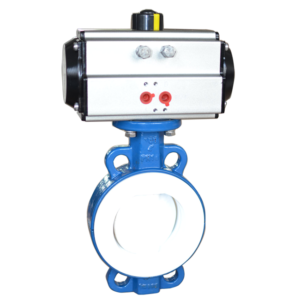

- U-Style Flange Butterfly Valves: These valves feature a U-shaped seal ring that effectively prevents potential leakages, ensuring optimal performance even under extreme operational conditions. They can be installed between two pipeline flanges, offering bi-directional flow control and shut-off functionality.

- Double Offset Butterfly Valves: With two offsets from the centerline, these valves provide a tighter seal, reduced friction, and a longer lifespan. They are designed for higher pressure systems and demanding applications.

- Triple Offset Butterfly Valves: Incorporating three offsets into the design, these valves result in a virtually frictionless seal with minimal wear and tear. They are highly durable and are often used in critical applications involving high temperatures and pressures.

Each type of butterfly valve we manufacture is a testament to our unwavering commitment to quality control, global compliance, and industry-leading standards. With our butterfly valves, you can expect unrivaled performance, reliability, and longevity, further solidifying our position as a trusted authority in the valve manufacturing industry.

How does a pneumatic butterfly valve work?

The operation of a Pneumatic Butterfly Valve is a symphony of mechanical and pneumatic principles working in harmony. The valve comprises a circular disc, mounted on a rotating shaft, housed within a pipe. This disc serves as the pivotal element that controls the fluid flow.

When the valve is activated, compressed air is directed into the pneumatic actuator – a device attached to the valve. This influx of compressed air forces a piston within the actuator to move, which in turn rotates the shaft. As the shaft rotates, so does the disc.

In its fully open position, the disc aligns parallel to the fluid flow, allowing unobstructed passage. Conversely, when the disc rotates to a perpendicular position relative to the flow, the valve is considered ‘closed’, effectively halting the fluid flow.

The pneumatic actuator can be controlled remotely, enabling operators to manage fluid flow with precision, speed, and safety from a distance. Moreover, the actuator returns to its original position when the air supply is cut off – a fail-safe feature that enhances operational safety.

Pneumatic butterfly valve industry applications

In the Oil and Gas Industry, pneumatic butterfly valves are employed in fuel handling systems, providing reliable isolation and throttling services. Their ability to withstand high-pressure environments and corrosive substances ensures optimal performance, even under challenging conditions.

The Water Treatment Sector extensively uses these valves to manage the flow and pressure of water during the treatment process. Their quick response time and precise control capabilities lead to efficient operations and reduced wastage.

In the Chemical Industry, the pneumatic butterfly valve’s resistance to a wide range of chemicals and its ability to operate in high-temperature scenarios make it a preferred choice for controlling the flow of various chemical substances.

The Pharmaceutical Industry also relies on pneumatic butterfly valves due to their sanitary design and easy maintenance. Their ability to ensure a sterile environment is crucial in maintaining the integrity of pharmaceutical processes.

In the Food and Beverage Industry, these valves’ hygienic features and easy-to-clean design make them ideal for managing the flow of edible liquids, ensuring product quality and safety.

At the heart of the Power Generation Plants, pneumatic butterfly valves play a key role in controlling the flow of steam and coolants, contributing to the plant’s overall efficiency and safety.