Description

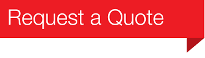

Pneumatic ptfe lined butterfly valve

Pneumatic pfa lined butterfly valves are ideal for applications involving increased temperatures and/or aggressive chemicals. The PTFE lining on the body and stem offers superior corrosion resistance by allowing for possible contact with media such as acids, alkalis and extreme temperatures without risking damage or wear. Moreover, its self-lubricating properties also ensure smoother functional operations compared to standard metal valves. Furthermore, pneumatic ptfe lined butterfly valves require less energy consumption while providing a higher level of controllability than manual operated valves. They can be used in a wide range of industrial process control applications such as shutoff, throttling or regulating service in oil refineries, chemical plants and water treatment units. Contact us to find the perfect lined ptfe butterfly valve for your system today!

FEATURES

- ISO5211 direct mounting pad for easy automation

- Isolation height according to plant prescription

- Dirtscraper prevents moisture penetrating into the shaft area

- Three PTFE impregnated SS316L bearings are provided for precision alignment of the disc-shaft

- 3 layers sealing system ensures environment protection

- PTFE seat and rubber seat version interchangeable each other• PTFE-liner for chemically toxic and highly corrosive media, rubber liner for various of industry applications

- Silicon rubber energized back behind PTFE seat makes the sealing between liner and disc stable and offer a wide range of temperature

- One-piece disc-shaft design reduces the valve torque and increases Kv

- PTFE or rubber lined disc design option avoids high cost by expensive metal in corrosive applications

- Bubble-tight shut of at full pressure rating

- Can be disassembled, material-specific recycling possible

- Wave shape flange face design ensures the flange sealing of seat face not damaged by flange pressing, also avoids shrink of seat inside diameter because of flange pressing

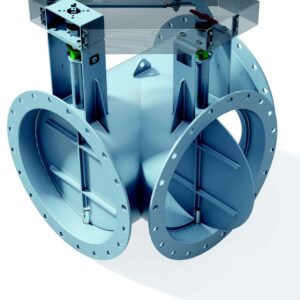

PARTS LIST AND MATERIAL SPECIFICATION

| No. | Part name | Material | |||

| 1 | Body | GGG40 | |||

| 2 | Disc/shaft one piece | CF8M | 1.4462 | CF8M FEP lined | CF8 EPDM lined |

| 3 | Seat | PTFE,FPM,EPDM,PU,NBR | PTFE | EPDM | |

| 4 | Seat Energizer | SR | |||

| 5 | Weather seal | NBR | |||

| 6 | Bearing | PTFE impregnated SS316L | |||

| 7 | Gland | PTFE | |||

| 8 | Screw | SS304 | |||

| 9 | Belleville washer | SS304 | |||

| 10 | Stuffing collar | SS316 | |||

| 11 | O ring | FPM | |||

| 12 | V ring | PTFE | |||

TECHNICAL DATA

| Body style | wafer |

| Nominal diameter | 2″ – 24″ (DN50mm – DN600mm) |

| Top flange | ISO5211 |

| Operating pressure | 16bar for DN50-DN200, 10bar for DN250-DN600 |

| Temperature range | -20 °C to + 180 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

| Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

Pneumatic actuator

| action | |

| Double acting | Failure to maintain |

| Single acting normally closed | Failure to close |

| Single acting normally open | Failure to open |

| Optional accessory | Solenoid valve limit switch box air filter relief pressure valve, E/P positioned manual device. |

| SIZE | A | B | C | D | E | F | d | G | H | L | WT(kg) | |

| DN | INCH | |||||||||||

| 50 | 2″ | 126 | 65 | 13.5 | 116 | 11 | 50 | 8 | 65 | 25 | 43 | 2 |

| 65 | 2 1/2″ | 138 | 79 | 13.5 | 136 | 11 | 50 | 8 | 65 | 59 | 46 | 3 |

| 80 | 3″ | 138 | 79 | 13.5 | 136 | 11 | 50 | 8 | 65 | 59 | 46 | 3 |

| 100 | 4″ | 167 | 97 | 17.5 | 170 | 14 | 70 | 10 | 90 | 86 | 52 | 5 |

| 125 | 5″ | 180 | 129 | 17.5 | 196 | 14 | 70 | 10 | 90 | 112 | 56 | 7 |

| 150 | 6″ | 203 | 142 | 18.5 | 227 | 17 | 70 | 10 | 90 | 140 | 56 | 8 |

| 200 | 8″ | 228 | 172 | 18.5 | 279 | 17 | 102 | 12 | 125 | 191 | 60 | 13 |

| 250 | 10″ | 266 | 213 | 24.5 | 336 | 22 | 102 | 12 | 125 | 241 | 58 | 22 |

| 300 | 12″ | 291 | 242 | 24.5 | 392 | 22 | 102 | 12 | 125 | 290 | 78 | 31 |

| 350 | 14″ | 332 | 262 | 30 | 445 | 27 | 125 | 14 | 150 | 331 | 78 | 44 |

| 400 | 16″ | 363 | 303.5 | 30 | 503 | 27 | 125 | 14 | 150 | 377 | 102 | 64 |

| 450 | 18″ | 397 | 324.5 | 39 | 553 | 36 | 140 | 18 | 175 | 425 | 114 | 86 |

| 500 | 20″ | 425 | 357 | 39 | 608 | 36 | 140 | 18 | 175 | 474 | 127 | 116 |

| 600 | 24″ | 498 | 419 | 49 | 717 | 46 | 165 | 22 | 210 | 570 | 154 | 179 |

FAQs

What is a Lined pfa ptfe butterfly valve?

A lined PFA butterfly valve is a type of specialized industrial valve designed to control the flow of various fluids or gases. The main components of this kind of valve include a butterfly plate, a seat, and four lined sleeves made out of an ultra-clean polymer such as polytetrafluoroethylene (PTFE) or Perfluoroalkoxyalkane (PFA).

The butterfly plate is located in the center and has a rounded disc on one side with an opening for the fluid/gas to pass through. This disc rotates around its axis when control lever is moved up and down, allowing for adjustment in pressure regulation. The two sealed ends are usually composed of fusion welded stainless steel rings connected by gaskets held together with bolts.

The seat area between the two ends contain gasket seals that allow for complete tightness across the entire circumference while commanding absolute leak proof protection against any media passing through it. It also helps to ensure that no air enters into cylinder from outside atmosphere when changing direction during operation and helps prevent leakage along shafts owing to flanges at both end points pressed tightly against each other using external pressure bolts.

Finally, lining PFA material used on interior walls provides superior corrosion resistance benefits compared to other metals typically found inside conventional valves; this makes it highly suitable for handling aggressive environments especially those involving acids, alkalis or salts which would otherwise corrode standard metal surface if left untreated over time. Lined PFA butterfly valves provide reliable performance under these tough conditions while still maintaining its efficiency throughout its lifespan without ever compromising safety standards associated with them

What are the industry applications of lined ptfe butterfly valves?

Lined PTFE butterfly valves are renowned for their low friction and non-stick characteristics, which make them ideal for controlling fluids in a wide range of industries. These valves offer excellent compatibility with many corrosive fluids, and can be effectively used to control the flow of materials between two different parts in a variety of applications.

In industrial medium applications, lined PTFE butterfly valves have been increasingly adopted as they provide superior performance compared to other valve types due to their tight shut-off capabilities. Specifically, these valves are well suited for mediums such as acids, alkalis, salts, solvents, oils and hydrocarbons that require reliable flow control. Additionally, these valves possess an average minimum pressure rating of 20 psi (1.4 bar) up to 150 psi (10 bar), depending on size and type which makes them suitable for a wide range of operating pressures even in harsh conditions. Furthermore they also prevent leakages due to its double O-ring sealers residing close together at the top position within the same retainer – allowing total or partial drawings during operation .

Lined PTFE butterfly valves are also easily accessible when it comes time for maintenance or repair since there is no need to disconnect piping; only one side needs to be accessed in order open/shut down the valve flap enabling fast operations with minimal downtime losses. As such they provide highly efficient flow control solutions without having extra access points placed through pipelines or additional moving parts exposed outside resulting in less product contamination thereby reducing work hours required from maintenance personnel as well as energy consumption associated with it making this type of valve extremely cost effective over long term operations span across various industries including but not limited Pharmaceuticals & cosmetics , Petrochemicals & refining , Biotech , Food Processing & Beverage applications etc..

How do I choose a Lined ptfe butterfly valve?

Choosing the right lined PTFE butterfly valve is essential for effective flow control and process reliability. With a wide range of factors to consider when selecting valves, you need an experienced partner who understands the needs of your process system. Here are some important things to take into account when choosing a lined PTFE butterfly valve:

Media type – Consider what kind of media (water, air, gas, etc.) will be flowing through the valve. Depending on the application and temperature conditions, different types of materials will provide better functionality and durability against corrosion or wear in certain environments. Make sure that your choice of material is suitable for use with your media type and application environment.

Operating pressure/temperature conditions – Different valves have different operating characteristics which should be taken into consideration depending on how you want it to perform in given circumstances such as high temperatures or under varying pressures for example flanged end connections can withstand up to 10 bars at 150°C whereas full bore designs are limited to 6 bar at 130°C . It’s important that you select a design suited for your specific requirements; otherwise it may result in unreliable performance or even premature failure due to excessive stress loads placed upon it during normal operation.

Body construction – Your choice of body construction depends largely on how you intend to install/maintain the valve as well as environmental considerations which may vary between indoor applications and outdoor installations where resistance against corrosion is necessary etc.. Popular constructions include wafer-style designs (where both ends slide over two rotating discs)as well as lugged styles (with overlapping halves seated onto fitment flanges). Each design has its own unique advantages so make sure you select one most suited for intended purpose taking all relevant variables into account including anticipated levels of vibration if applicable etc..

Valve size & Cv rating – Size plays an important role since bigger valves usually offer higher Cv ratings than their smaller counterparts due to larger cross sectional areas allowing smoother and more efficient flow rates throughout broad ranges of operating parameters respective other factors such as pressure drop & cavitation remain consistent regardless varying rate capacities associated with any particular model selected whether single seat(unidirectional only) or double seat(bi-directional) traps etc.. As far possible independent tests should also be carried out whenever knowledge about exact requirements especially regarding overall dimensions & clearances between components becomes available prior finalizing purchase decision .

Accessories – Certain accessories such add-on instruments like actuating systems; shutoff devices control elements etc; seals ; backups ; spares ; strainers filters relief vents might also need including according scope any project though this often varies from case case with circumstances possibly playing major role determining eventual outcome certain cases depending severity restrictions among others respectively likewise experiences past precedents should always consulted order ensure most appropriate cost effective solution determined every time ..

In conclusion , picking right Lined ptfe butterfly valve requires careful research detailed study across multiple aspects related application correctly configure same thus providing successful performance operation future usage purposes alike !

Valve PN10 Flange size chart

| NPS | DN | OD | PCB | Bolt | n-bolt |

| 3/8 | DN10 | 90 | 60 | 14 | 4 |

| 1/2 | DN15 | 95 | 65 | 14 | 4 |

| 3/4 | DN20 | 105 | 75 | 14 | 4 |

| 1 | DN25 | 115 | 85 | 14 | 4 |

| 11/4 | DN32 | 140 | 100 | 18 | 4 |

| 11/2 | DN40 | 150 | 110 | 18 | 4 |

| 2 | DN50 | 165 | 125 | 18 | 4 |

| 21/2 | DN65 | 185 | 145 | 18 | 8 |

| 3 | DN80 | 200 | 160 | 18 | 8 |

| 4 | DN100 | 220 | 180 | 18 | 8 |

| 5 | DN125 | 250 | 210 | 18 | 8 |

| 6 | DN150 | 285 | 240 | 22 | 8 |

| 8 | DN200 | 340 | 295 | 22 | 8 |

| 10 | DN250 | 395 | 350 | 22 | 12 |

| 12 | DN300 | 445 | 400 | 22 | 12 |

| 14 | DN350 | 505 | 460 | 22 | 16 |

| 16 | DN400 | 565 | 515 | 26 | 16 |

| 18 | DN450 | 615 | 565 | 26 | 20 |

| 20 | DN500 | 670 | 620 | 26 | 20 |

| 24 | DN600 | 780 | 725 | 30 | 20 |

| 28 | DN700 | 895 | 840 | 30 | 24 |

| 32 | DN800 | 1015 | 950 | 33 | 24 |

| 36 | DN900 | 1115 | 1050 | 33 | 28 |

| 40 | DN1000 | 1230 | 1160 | 36 | 28 |

| 48 | DN1200 | 1455 | 1380 | 39 | 32 |

| 56 | DN1400 | 1675 | 1590 | 42 | 36 |

| 64 | DN1600 | 1915 | 1820 | 48 | 40 |

| 72 | DN1800 | 2115 | 2020 | 48 | 44 |

| 80 | DN2000 | 2325 | 2230 | 48 | 48 |