Description

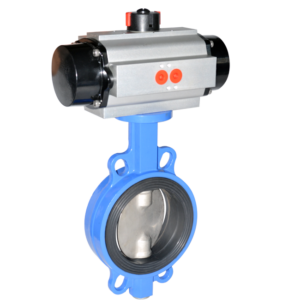

Pneumatic Triple Offset Butterfly Valves

Introducing the Triple Offset Pneumatic Butterfly Valve, the perfect solution for reliable and efficient flow control in various industrial applications. This high-performance valve is designed with a triple offset disc that ensures bubble-tight shut-off and eliminates any rubbing between the disc and seal, minimizing wear and tear and extending the valve’s lifespan. Additionally, the pneumatic actuator provides precise and responsive control, allowing for fast and accurate adjustments in high-pressure and high-temperature systems. The valve body is constructed with robust materials, providing excellent durability and corrosion resistance even in harsh environments. With its low-maintenance design and easy installation, the Offset Pneumatic Butterfly Valve is an ideal choice for oil and gas, chemical processing, power generation, and other demanding industries where reliability and efficiency are paramount.

GENERAL INFORMATION

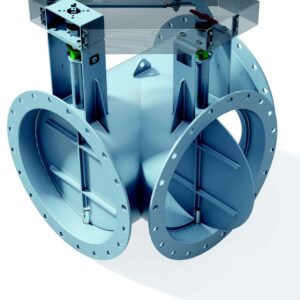

Flanged triple offset butterfly valves provides zero leakage through no-rubbing 90-degree rotation across a wide range of pressure and temperature conditions.

Widely used in many industries such as Oil & Gas, Chemical & coal, petrochemical, desalination plants, waterworks, fossils, district heating, nuclear, Iron & Steel, Mining, automotive, shipyards, aerospace.

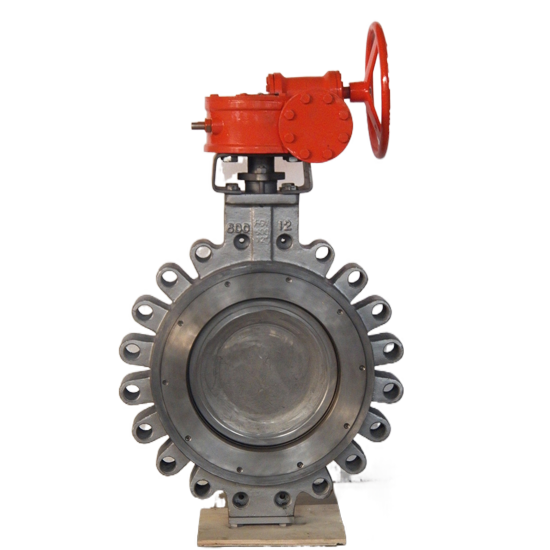

FEATURES Triple Offset Butterfly Valves

- ISO 5211 bracket for easy mounting of actuators

- Triple offset and ellipsoidal sealing geometry

- Bubble tight shut-off

- Inherently firesafe by design

- A metal seal ring in Duplex and a highly wear-resistant Stellite grade 21 seat ensure prolonged superior tightness

- Single piece cast body with face to face dimensions to ISO5752, ASME B16.10 and API 609 double flanged short pattern, guarantees interchangeability with other valve types

- Extensively hardened bearings, incorporating a standard reinforce, braided, flexible graphite bearing protector, ensure increased reliability

- Blowout proof devices on shaft keep sure safety of shaft operating

- Pin-less shaft to disc connection makes the valve convenient for parts replacement and reliable even under corrosion

| action | |

| Double acting | Failure to maintain |

| Single acting normally closed | Failure to close |

| Single acting normally open | Failure to open |

| Optional accessory | Solenoid valve limit switch box air filter relief pressure valve, E/P positioned manual device. |

| Connection | Double flange |

| Size | 3″-80″ for PN10,PN16,Class150; 3″-48″ for PN25,PN40,Class300; 3″-24″ for Class600 |

| Pressure | PN10,PN16,PN25,PN40,Class150,Class300,Class600 |

| Flange standard | ASME B16.5 Class150,Class300,Class600; EN1092 PN16,PN25,PN40 |

| Face to face | ISO 5752, ASME B16.10, API609 Double flanged short pattern |

| Pressure test | API 598, ISO 5208 Rate A, ANSI B16.104(ANSI/FCI 70-2)Class Ⅵ |

| Temperature | -29°C to +538°C |

| Operator | Lever,Gear box,Pneumatic actuator,Electric actuator |

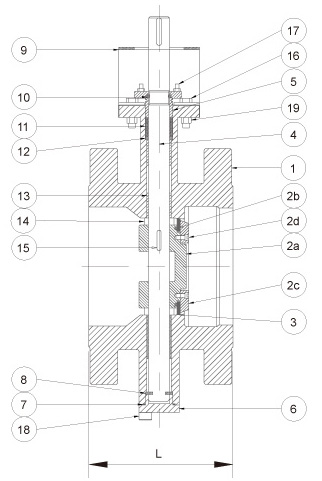

| No. | Part name | Material | |

| 1 | Body | WCB | CF8M |

| 2a | Disc | WCB,CF8 | CF8M |

| 2b | Disc sealing | UNS31803(duplex)+graphite | |

| 2c | Disc sealing retainer | SS304 | SS316 |

| 2d | Disc sealing retainer screw | SS304 | SS316 |

| 3 | Seat welded surface | Stellite Gr.21 | |

| 4 | Shaft | 17-4 PHSS,1.4462 | |

| 5 | Packing gland | CF8 | |

| 6 | Bottom cover | Same as body | |

| 7 | Cover seal | Graphite | |

| 8 | Thrust washer | SS316 | |

| 9 | Bracket | WCB | CF8M |

| 10 | Retaining ring | SS304 | |

| 11 | Packing | RPTFE, Graphite | |

| 12 | Packing ring | SS316 | |

| 13 | Bearing | SS316+PTFE | |

| 14 | Thrust bearing | SS316 | |

| 15 | Key | SS316 | |

| 16 | Bolt | SS304 | |

| 17 | Bolt | SS304 | |

| 18 | Bolt | SS304 | |

| 19 | Nut | SS304 | |

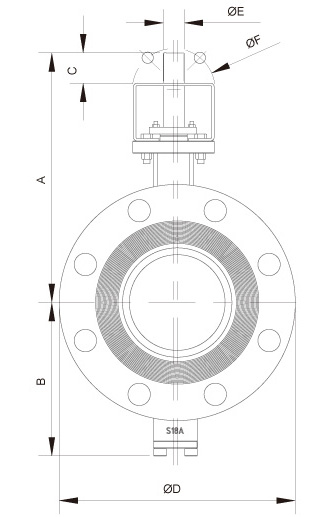

| SIZE | A | B | C | D | E | Top Flange | L | WT(kg) | ||||

| Class150 | PN10 | PN16 | PN25 | |||||||||

| DN | INCH | Class150,PN10,PN16,PN25 | ||||||||||

| 80 | 3″ | 260 | 125 | 17.5 | 190 | 200 | 200 | 200 | 14 | F07 | 114 | 30 |

| 100 | 4″ | 290 | 141 | 17.5 | 230 | 220 | 220 | 235 | 14 | F07 | 127 | 40 |

| 125 | 5″ | 310 | 150 | 17.5 | 255 | 250 | 250 | 270 | 14 | F07 | 140 | 45 |

| 150 | 6″ | 330 | 165 | 18.5 | 280 | 285 | 285 | 300 | 17 | F10 | 140 | 50 |

| 200 | 8″ | 385 | 214 | 24.5 | 345 | 340 | 340 | 360 | 22 | F10 | 152 | 85 |

| 250 | 10″ | 425 | 243 | 24.5 | 405 | 395 | 405 | 425 | 22 | F10 | 165 | 120 |

| 300 | 12″ | 490 | 286 | 30 | 485 | 445 | 460 | 485 | 27 | F12 | 178 | 160 |

| 350 | 14″ | 525 | 312 | 30 | 535 | 505 | 520 | 555 | 27 | F12 | 190 | 195 |

| 400 | 16″ | 545 | 350 | 39 | 595 | 565 | 580 | 620 | 36 | F14 | 216 | 255 |

| 450 | 18″ | 580 | 383 | 49 | 635 | 615 | 640 | 670 | 46 | F16 | 222 | 310 |

| 500 | 20″ | 640 | 407 | 49 | 700 | 670 | 715 | 730 | 46 | F16 | 229 | 390 |

| 600 | 24″ | 690 | 484 | 60 | 815 | 780 | 840 | 845 | 55 | F25 | 267 | 565 |

| 700 | 28″ | 720 | 525 | 130 | 925 | 895 | 910 | 960 | 80 | F30 | 292 | |

| 750 | 30″ | 750 | 550 | 130 | 985 | 80 | F30 | 318 | ||||

| 800 | 32″ | 760 | 600 | 130 | 1060 | 1015 | 1025 | 1085 | 98 | F30 | 318 | |

| 900 | 36″ | 795 | 660 | 150 | 1170 | 1115 | 1125 | 1185 | 120 | F35 | 330 | |

| 1000 | 40″ | 815 | 720 | 180 | 1290 | 1230 | 1255 | 1320 | 130 | F35 | 410 | |

| 1050 | 42″ | 850 | 750 | 180 | 1345 | 150 | F35 | 410 | ||||

| 1200 | 48″ | 995 | 825 | 200 | 1510 | 1455 | 1485 | 180 | F40 | 470 | ||

| SIZE | A | B | C | D | E | Top Flange | L | WT(kg) | ||

| Class300 | PN40 | |||||||||

| DN | INCH | Class300,PN40 | ||||||||

| 80 | 3″ | 260 | 100 | 17.5 | 210 | 200 | 14 | F07 | 180 | 30 |

| 100 | 4″ | 290 | 124 | 17.5 | 255 | 235 | 14 | F07 | 190 | 40 |

| 125 | 5″ | 330 | 144 | 18.5 | 280 | 270 | 17 | F10 | 200 | 60 |

| 150 | 6″ | 350 | 150 | 24.5 | 320 | 300 | 22 | F10 | 210 | 75 |

| 200 | 8″ | 415 | 204 | 30 | 380 | 375 | 27 | F12 | 230 | 115 |

| 250 | 10″ | 455 | 238 | 39 | 445 | 450 | 36 | F14 | 250 | 170 |

| 300 | 12″ | 490 | 268 | 39 | 520 | 515 | 36 | F14 | 270 | 170 |

| 350 | 14″ | 545 | 294 | 49 | 585 | 580 | 46 | F16 | 290 | 315 |

| 400 | 16″ | 575 | 320 | 60 | 650 | 660 | 55 | F25 | 310 | 415 |

| 450 | 18″ | 660 | 341 | 60 | 710 | 685 | 55 | F25 | 330 | 490 |

| 500 | 20″ | 700 | 383 | 80 | 775 | 755 | 75 | F30 | 350 | 600 |

| 600 | 24″ | 785 | 442 | 80 | 915 | 890 | 75 | F30 | 390 | 900 |

| 700 | 28″ | 800 | 590 | 150 | 1035 | 120 | F35 | 430 | ||

| 750 | 30″ | 830 | 600 | 180 | 1090 | 130 | F35 | 450 | ||

| 800 | 32″ | 860 | 720 | 200 | 1150 | 170 | F40 | 470 | ||

| 900 | 36″ | 940 | 780 | 200 | 1270 | 180 | F40 | 510 | ||

| 1000 | 40″ | 910 | 750 | 250 | 1240 | 200 | F48 | 550 | ||

| 1050 | 42″ | 950 | 800 | 250 | 1290 | 210 | F48 | 570 | ||

| 1200 | 48″ | 1000 | 850 | 250 | 1465 | 220 | F48 | 630 | ||

| SIZE | A | B | C | D | E | Top Flange | L | WT(kg) | |||

| Class600 | PN63 | PN100 | |||||||||

| DN | INCH | Class600,PN63,PN100 | |||||||||

| 80 | 3″ | 260 | 145 | 17.5 | 210 | 215 | 230 | 14 | F07 | 180 | 50 |

| 100 | 4″ | 298 | 185 | 24.5 | 275 | 250 | 265 | 22 | F10 | 190 | 70 |

| 125 | 5″ | 400 | 200 | 30 | 330 | 295 | 315 | 27 | F12 | 200 | 90 |

| 150 | 6″ | 420 | 216 | 39 | 355 | 345 | 355 | 36 | F14 | 210 | 125 |

| 200 | 8″ | 445 | 265 | 39 | 420 | 415 | 430 | 36 | F14 | 230 | 200 |

| 250 | 10″ | 505 | 315 | 49 | 510 | 470 | 505 | 46 | F16 | 250 | 315 |

| 300 | 12″ | 600 | 362 | 49 | 560 | 530 | 585 | 46 | F16 | 270 | 435 |

| 350 | 14″ | 610 | 390 | 60 | 605 | 600 | 655 | 55 | F25 | 290 | 485 |

| 400 | 16″ | 680 | 440 | 60 | 685 | 670 | 55 | F25 | 310 | 685 | |

| 450 | 18″ | 683 | 460 | 80 | 745 | 75 | F30 | 330 | 815 | ||

| 500 | 20″ | 795 | 526 | 80 | 815 | 75 | F30 | 350 | 1050 | ||

| 600 | 24″ | 885 | 623 | 940 | F35 | 390 | 1600 | ||||

| 700 | 28″ | ||||||||||

| 750 | 30″ | ||||||||||

| 800 | 32″ | ||||||||||

| 900 | 36″ | ||||||||||

| 1000 | 40″ | ||||||||||

| 1050 | 42″ | ||||||||||

| 1200 | 48″ | ||||||||||

FAQS

What is a Triple Offset Butterfly Valves

A triple-offset butterfly valve manufacturer is a type of valve that is designed to provide precise control over the flow of liquids or gases through a piping system. It is called a triple offset valve because it has three different points of offset in its design, which allows it to seal more effectively and operate more smoothly than other types of butterfly valves.

Triple-offset butterfly valve is between the disc and the valve’s body. The disc is the part of the valve that rotates to open or close the flow of the fluid, and it is offset from the body of the valve to allow for a better seal when the valve is closed.

The second offset is between the disc and the shaft of the valve. The post is the part of the valve that is connected to the handle or actuator, and it is offset from the disc to allow for better control and more precise operation of the valve.

The third Ball Valve offset is between the disc and the seat of the valve. The heart is the part of the valve that the disc seals against when the valve is closed, and it is offset from the disc to allow for a better seal and more efficient operation. Overall, the triple offset design of a butterfly valve allows for more efficient and reliable flow control, making it ideal for use in various applications.

What is a Triple Offset Butterfly Valves used for?

Uses for butterfly valves include regulating the volumes/flows entering into pipe systems during start up operations; isolating areas within larger piping networks; aiding in preventing backflow; serving as check-valves when unexpected flow reversals occur; providing throttling action for modulating fluid flows rates into certain sections of piping systems (similarly applicable to hydraulic pumps); draining fluid out of units where gravity assisted drainage occurs; providing a shutoff option prior to maintenance work being carried out on system components downstream from the unit containing the butterfly valve itself.

In addition to their various uses listed above, one primary advantage that butterfly valves offer over other types of isolation or control valves is their extremely compact size relative to how much performance they deliver

- Caustic,

- Corrosive,

- Dry Chlorine,

- Oxygen,

- Seawater,

- Sour Gas,

- Steam,

- Toxic

- Ultra Pure Water,

- Vacuum, and

Industries

- Chemical,

- Food and Beverage,

- HVAC,

- Mining,

- Oil and Gas,

- Petrochemical,

- Pharmaceutical,

- Power Generation,

- Pulp and Paper,

- Refining,

- Sugar Processing, and

- Water Filtration.

How do I choose a triple offset butterfly valve?

Choosing a triple offset butterfly valve can seem daunting at first, but with the right knowledge and information, it’s an easy task. To find the right double eccentric butterfly valve for your application, you should consider several factors:

Flow Characteristics – triple offset butterfly valve are designed to control flow rates from low to high levels. Since this type of valve has two seats instead of one, they offer better performance when controlling higher flow rates compared to other types of valves. When selecting a Double Eccentric Butterfly Valve, you’ll need to determine the appropriate size for your intended use and check that it meets any applicable standards (such as ASME or API).

Installation Requirements – Taking into account where and how you plan on installing your Double Eccentric Butterfly Valve is important in making sure that installation is successful and efficient. If your installation site has limited space constraints then choosing a smaller model may be necessary – while also ensuring that its port configuration matches up with existing piping systems connected downstream or upstream from it will make things easier come time for installation

Pressure Rating – The pressure rating provided by your chosen Double Eccentric Butterfly Valve should match up with the requirements needed for operation within its respective application/environment . Pressure ratings typically given in psi (Pounds per Square Inch) or bar(s), so be sure to familiarize yourself beforehand with what data points are included within those units before starting out on this part of selection process!

Materials – Selecting the correct material is critical when selecting any type of valve due its direct impact on system life cycle costs as well as safety considerations; materials used can range from steel alloys such stainless 304L & CF8M depending on chemical compatibility / corrosion resistance requirements associated with particular system fluid being switched through them . Carefully consider these!

Actuation Options– Whether manual operation (lever operated) or automated via actuation , having access to multiple sources available will let users choose whichever option best fits their needs; manual levers provide cost-effectiveness while electric actuators add convenience but can rack up additional costs over time due maintenance etc…

Butterfly valve ASME ANSI CLASS300LB Flange size chart

| NPS | DN | OD | PCB | Bolt | n-bolt |

| 1/2 | DN15 | 95 | 66.5 | 16 | 4 |

| 3/4 | DN20 | 117 | 82.6 | 19 | 4 |

| 1 | DN25 | 124 | 88.9 | 19 | 4 |

| 11/4 | DN32 | 133 | 98.6 | 19 | 4 |

| 11/2 | DN40 | 155 | 114.3 | 22.5 | 4 |

| 2 | DN50 | 165 | 127 | 19 | 8 |

| 21/2 | DN65 | 190 | 149.4 | 22.5 | 8 |

| 3 | DN80 | 210 | 168.1 | 22.5 | 8 |

| 31/2 | (DN90) | 229 | 184.2 | 22.5 | 8 |

| 4 | DN100 | 254 | 200.2 | 22.5 | 8 |

| 5 | DN125 | 279 | 235 | 22.5 | 8 |

| 6 | DN150 | 318 | 269.7 | 22.5 | 12 |

| 8 | DN200 | 381 | 330.2 | 25.5 | 12 |

| 10 | DN250 | 444 | 387.4 | 28.5 | 16 |

| 12 | DN300 | 521 | 450.8 | 32 | 16 |

| 14 | DN350 | 584 | 514.4 | 32 | 20 |

| 16 | DN400 | 648 | 571.5 | 35 | 20 |

| 18 | DN450 | 711 | 628.6 | 35 | 24 |

| 20 | DN500 | 775 | 685.8 | 35 | 24 |

| 22 | (DN550) | 838 | 743 | 41 | 24 |

| 24 | DN600 | 914 | 812.8 | 41 | 24 |

-150x150.jpg)