Description

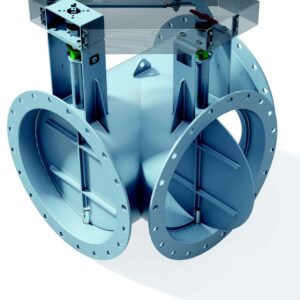

Wafer concentric butterfly valve features a cartridge type seat, streamlined disc and strong stem-to-disc connection for easy use in many industrial applications such as food and beverage, pulp and paper, chemical, mining, water treatment, power plants, etc.

Introducing the Wafer Butterfly Valve, the next-generation solution for efficient flow regulation and corrosion resistance in your projects!

With its innovative design, our Wafer Butterfly Valve outperforms other valves in the market, offering both exceptional performance and remarkable durability. Designed with precision engineering, this valve redefines industry standards and is ideal for various applications, including water, oil, and gas systems.

Key Features of Wafer Butterfly Valve:

- Compact and Lightweight Design: With its slim and solid structure, the Wafer Butterfly Valve offers easy installation and minimal maintenance, reducing overall costs and disruptions.

- Size Flexibility: Catering to various requirements, our Wafer Butterfly Valve is available in a wide range of sizes 1″-80″ DN25-DN2000

- Quality Material: Constructed with top-grade materials, our valves are resistant to rust, corrosion, and chemical damages, prolonging their service life and enhancing overall performance. Stainless Steel 304, Stainless Steel 316, Stainless Steel 316L, Duplex 2507, Duplex 1.4529, Aluminum Bronze C95800, Nickel Bronze, Titanium

- Superior Sealing Mechanism: Engineered for optimal performance, this valve features a bi-directional bubble-tight seal, ensuring zero leakage and maintaining the integrity of the valve and the system it serves. NBR, PTFE, EPDM sealing seat

- Easy Operability: Designed to provide maximum efficiency, the Wafer Butterfly Valve can be easily controlled, both manually and actuator operated, allowing effortless management and high adaptability to various systems. Pneumatic Actuator, Electric Actuator, Hydraulic Actuator

In a world of ever-evolving valve technology, the Wafer Butterfly Valve sets new benchmarks with its unique combination of state-of-the-art design and uncompromising performance. This valve is designed to meet even the most stringent industry requirements, making it the reliable and cost-effective choice for professionals seeking a modern and advanced solution to their flow control challenges.

Experience the unparalleled flow control and durability offered by the Wafer Butterfly Valve in your systems. Whether you are a technical expert or new to the world of valves, our Wafer Butterfly Valve provides a user-friendly, high-performing solution that guarantees excellent flow control and extends operational life.

Don’t compromise on quality, performance, or reliability – choose the Wafer Butterfly Valve and unlock the full potential of your projects!

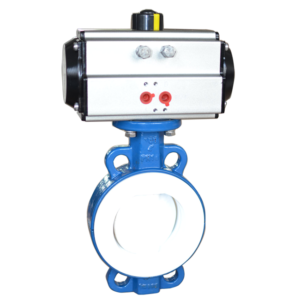

1: ISO5211 top flange together with stem square suitable for direct mounting of actuators

2: Stem anti-blowout design keep safety in field use

3: Dirtscraper prevents moisture penetrating into the shaft area

4:Multi-standard alignment holes suitable for various standard of flanges of EN1092 PN10, PN16, ASME B16.5 CLASS150, JIS B2239 10K, 16K, BS 10 Table D, Table E

5: Suitable for high pressure and full vacuum service due to the use of a cartridge seat design

6: No exposed pins or bolts for stem-to-disc connection

7: No need for flange gaskets

8: No risk of damage to the valve during installation in closed position

9: Bubble-tight shut of at full pressure rating

10: Large flow capacity and enough strength because of streamline disc design

11: Plug with O-ring sealing eliminates any leakage from the stem

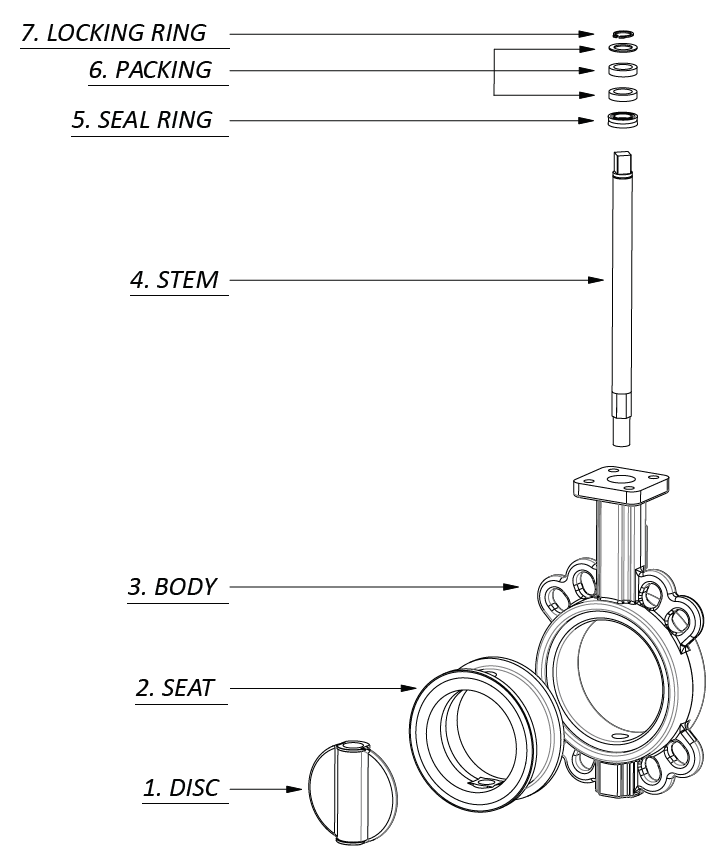

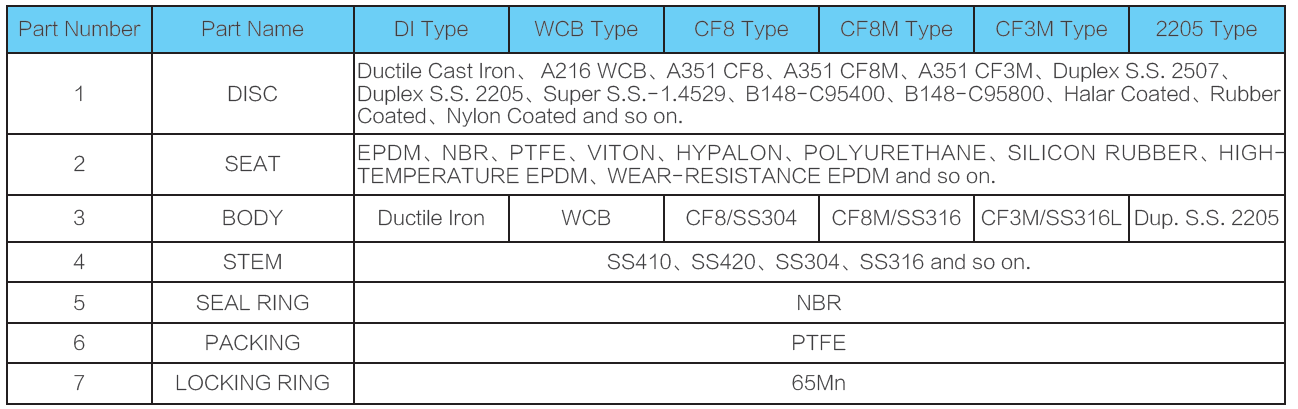

PARTS LIST AND MATERIAL SPECIFICATION

TECHNICAL DATA

| Body style | wafer |

| Nominal diameter | 1″ – 80″ (DN25mm – DN2000mm) |

| Top flange | ISO5211 |

| Operating pressure | 16bar for DN50-DN300, 10bar for DN350-DN2000 |

| Temperature range | -20 °C to + 140 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

| Applications | Potable Water, Wastewater, Seawater, HVAC |

| Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

| SIZE | A | B | C | D | E | F | d | G | H | L | WT(kg) | |

| DN | INCH | |||||||||||

| 50 | 2″ | 126 | 78 | 13.5 | 94.3 | 9 | 50 | 8 | 70 | 31 | 43 | 2 |

| 65 | 2 1/2″ | 134 | 84 | 13.5 | 107.6 | 9 | 50 | 8 | 70 | 45 | 46 | 2.5 |

| 80 | 3″ | 138 | 92 | 13.5 | 123.9 | 9 | 50 | 8 | 70 | 64 | 46 | 3 |

| 100 | 4″ | 167 | 114 | 13.5 | 157 | 11 | 70 | 10 | 90 | 91 | 52 | 4.5 |

| 125 | 5″ | 180 | 129 | 17.5 | 181.5 | 14 | 70 | 10 | 90 | 110 | 56 | 6 |

| 150 | 6″ | 203 | 144 | 17.5 | 212 | 14 | 70 | 10 | 90 | 146 | 56 | 7 |

| 200 | 8″ | 228 | 179 | 24.5 | 267.4 | 17 | 102 | 12 | 125 | 193 | 60 | 12 |

| 250 | 10″ | 266 | 216 | 25 | 323.6 | 22 | 102 | 12 | 125 | 241 | 68 | 17 |

| 300 | 12″ | 291 | 247 | 25 | 377.4 | 22 | 102 | 12 | 125 | 292 | 78 | 25 |

| 350 | 14″ | 332 | 273 | 30 | 425 | 27 | 125 | 14 | 150 | 329 | 78 | 41 |

| 400 | 16″ | 363 | 317 | 30 | 484 | 27 | 125 | 14 | 150 | 376 | 102 | 58 |

| 450 | 18″ | 397 | 348 | 39 | 537 | 36 | 140 | 18 | 175 | 425 | 114 | 80 |

| 500 | 20″ | 425 | 393 | 39 | 589.5 | 36 | 140 | 18 | 175 | 475 | 127 | 97 |

| 600 | 24″ | 498 | 453 | 49 | 693.1 | 46 | 165 | 22 | 210 | 573 | 154 | 169 |

| 700 | 28″ | 626 | 531 | 90 | 928 | 63.1 | 254 | 18 | 300 | 674 | 165 | 252 |

| 750 | 30″ | 660 | 564 | 90 | 984 | 63.1 | 254 | 18 | 300 | 727 | 165 | 290 |

| 800 | 32″ | 666 | 601 | 90 | 1061 | 63.1 | 254 | 18 | 300 | 771 | 190 | 367 |

| 900 | 36″ | 722 | 660 | 110 | 1170 | 74.7 | 254 | 18 | 300 | 839 | 203 | 465 |

| 1000 | 40″ | 806 | 728 | 120 | 1290 | 83.7 | 298 | 22 | 350 | 939 | 216 | 606 |

| 1100 | 44″ | 826 | 771 | 140 | 1404 | 94.7 | 298 | 22 | 350 | 1036 | 255 | 805 |

| 1200 | 48″ | 941 | 874 | 150 | 1511 | 104.7 | 298 | 22 | 350 | 1137 | 276 | 900 |

| 1400 | 56″ | 1000 | 940 | 175 | 1685 | 139.9 | 356 | 32 | 415 | 1351 | 279 | 1158 |

| 1600 | 64″ | 1155 | 1085 | 195 | 1930 | 160 | 356 | 32 | 415 | 1548 | 318 | 1684 |

| 1800 | 72″ | 1200 | 1170 | 195 | 2170 | 174.5 | 406 | 39 | 475 | 1703 | 356 | 2645 |

| 2000 | 80″ | 1363 | 1360 | 245 | 2345 | 199 | 406 | 39 | 475 | 1938 | 406 | 4000 |

FAQs

What is a wafer butterfly valve?

A wafer butterfly valve is a type of shut-off valve that uses a disc with a centrally located stem to enable flow through it. It is sometimes referred to as the “butterfly” because the disc resembles one, and its rotation provides an effective opening/closing mechanism for regulating systems containing liquids or gases.

The wafer butterfly valves are installed between two flanges and are designed for easy installation without need for extra parts or tools. The discs in such valves generally have holes which allow for easy adjustment, adding flexibility on when they can be used effectively in certain systems. This also makes them suitable where space is an issue, since they require minimal space compared to other types of valve design.

In terms of performance, wafer butterfly valves usually provide tight shut-off characteristics at low operating torques over a wide range of temperatures, sizes & pressure differences across the system which therefore increases their efficiency when used correctly within systems. They also offer superior corrosion resistance due to their nonmetallic construction allowing them work well with media containing corrosive elements such as seawater & wastewater facilities applications etc . In addition to this most models offer bubble tight sealing even under extreme conditions making them ideal choice especially in industries demanding high safety standards such as oil & gas industries where they are widely used during process control operations

All things considered, it can be said that despite having few drawbacks (such as its vulnerability against external forces), Wafer Butterfly Valves still remain popular amongst industry personnel due its convincing performance qualities along with cost effectiveness advantages – making it stand out from other available options in market!

How does a wafer butterfly valve work?

A wafer butterfly valve is a type of control valve that utilizes a circular rotary disc to regulate the flow of fluids such as air, water, steam and gas. The rotation of the disc allows for an adjustable opening or closing path in order to control the amount and rate of flow passing through the valve.

The mechanism consists mainly of four parts: body, stem, disk (or rotary element) and seat ring. The body is where all other components are held together and connected. The stem connects directly to the disk in order to turn it with its handle, allowing for adjustment of the throttle area size between closed and open positions. The disk also contains two or more holes which act as throttles allowing for precise regulation once open. Finally, seat ring provides sealing when closed by pressing against either sides on its perimeter depending on direction chosen during installation process – inside-out or outside-in mountings being possible according to design requirements from piping system standpoint.

How to install wafer butterfly valve?

Installing a wafer butterfly valve is relatively straightforward, though there are important safety considerations to keep in mind throughout the process. Before beginning, make sure you have all of the components that you need: wrench or socket set for tightening/loosening bolts, flange gasket and contact surface sealant if needed.

Step 1: Begin by installing the two end pieces (also called face seals) onto either side of the body of the valve. Make sure to fasten them securely with bolts using your wrench or socket set.

Step 2: If using a flange gasket, place it on top of both sides before moving on to Step 3. Flanges should also be coated with contact surface sealant at this stage in order to waterproof and reduce corrosion over time; allow any sealant used to dry fully before proceeding with installation.

Step 3: Install the handles onto each side of the valve body, taking care not to cross-thread them as you go along; then attach handles firmly but delicately (avoid overtightening).

Step 4: Attach actuator motor(s), if applicable – follow instructions provided by manufacturer for proper alignment and mounting requirements. Securely fasten any nuts or screws used for attachment purposes following completion of task.

Additionally, both pressure gauges and position indicators may be attached during installation depending on model type; refer specifically to product instructions provided prior to commencing work in these cases as well. Finally, thoroughly test your newly installed valve system for proper functioning prior to use!

What types of wafer butterfly valves are there?

There are generally two types of wafer butterfly valves commonly used in industrial applications: resilient-seated and metal-seated. Resilient seated butterfly valves operate with a flexible rubber seat which enables a tight shut off when the disc is in the closed position. They are designed to reduce operating torque, thus allowing quick shut offs without using excessive actuator power or size. Furthermore, they usually handle lower pressure than their metal-seated counterparts and provide reliable performance over time.

Metal-seated butterfly valves are designed for high pressure and temperature applications where superior sealing is needed due to their hard materials such as stainless steel or chrome alloys among others. The contact between the shoe and body causes a perfect seal under these conditions, however if misaligned they tend to have higher operating torques compared with resilient seating butterfly valves which can lead to leakage problems overtime.

Depending on service requirements, wafer butterfly valve can also have different configurations like single offset (reduced friction), double offset (for minimal flow rebound), concentric (combines both single & double) or triple offset designs providing greater safety against many potential failure modes like backseat blowout caused by an abrupt decrease of media velocity when reaching full closure reducing the risk of leaks during operation through increased security measures when dealing with hazardous media for instance such as vacuum tight sealing capabilities thus making it suitable for variety of operations within oil & gas industry among other sectors requiring particular attention about fluid dynamics under certain circumstances due his precision manufacturing process over traditional wedge gate designs for severe services conditions regarding fluid control .