Description

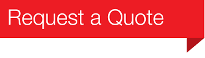

High performance butterfly valve

Introducing the High-Performance Butterfly Valve: Revolutionizing Reliability, Efficiency, and Durability

The High performance Butterfly Valve is specifically designed to address the needs of various industries by providing top-quality sealing, longevity, and effortless operability. Unlike conventional butterfly valves, our High-performance Butterfly Valve stands out through its innovative design, advanced features, and proven reliability for a wide range of applications.

Key Benefits and Features

- Seat Retainer Support: This one-of-a-kind design enables easy changeout of the seat, significantly reducing downtime during maintenance and parts replacement.

- Double Offset Disc: The valve’s double offset disc design drastically minimizes torque, which translates to improved efficiency and durability.

- Alloy Harden Disc Surface: By incorporating an alloy harden disc surface for metal seats, our valve ensures increased sealing life, leading to longer-lasting performance.

- Integral Disc Stop: This additional feature prevents disc over-travel, further contributing to the valve’s durability and reliable performance.

- Replaceable Seat Options: Our soft seat, fire-safe seat, and metallic seat options are fully interchangeable, allowing for tailored performance and industry-specific solutions.

- PTFE Lined SS316 Bearing: To support the stem and increase service life, our High-performance Butterfly Valve utilizes PTFE lined SS316 bearings, thus offering superior corrosion resistance.

- Thrust Ring for Anti-Blowout and Anti-Static: This advanced feature safeguards against potential hazards and ensures consistent, safe performance.

Improved Efficiency, Profitability, and Sustainability

The high performance butterfly valve manufacturers advanced design and capabilities translate to tangible benefits for a wide array of industries. With features like easy changeout, replaceable seat options, and improved durability under corrosion, this valve is a valuable asset that contributes to both the efficiency and effectiveness of any operation.

Straightforward maintenance and increased service life lead to reduced long-term costs and improved profitability for businesses. Moreover, our valve’s design encourages sustainability by promoting fewer replacements and waste generation.

High performance butterfly valves provides a cost-effective solution for a wide range of applications where bubble-tight shut-off is required. Utilizing an eccentric disc and offset shaft, the design incorporates the flexible-lip sealing system into a lightweight, compact body. The result is that in many cases the valve can replace globe valve and gate valve yet easier operating, longer lasting and lower cost.

Significant performance makes the valve widely used in many applications such as Airport refueling, Hydrocarbon processing, HVAC, Air treatment, Chemical processing, Purified gas, Steam and vacuum services, Potable water, Powder and pulp processing, etc. Wafer design makes the valve convenient for connection between flanges and save length in pipe line.

FEATURES

- One-piece stem design with ISO 5211 square drive

- ISO 5211 direct mounting flange on the valve body

- Easy-adjust gland packing accessible with actuator mounted in place

- Belleville washers on the gland nut offer reliable primary sealing between shaft and packing

- Retaining ring for both equably pressing on packing and stem blowout proof

- Multiply rows of RPTFE chevron for soft seat valve and Graphite chevron for fire safe and metallic seat

- Extended neck for pipe insulation

- Self-energized seat resulting in longer life and reduced maintenance·Pin-less shaft to disc connection makes the valve convenient for parts replacement and reliable even under corrosion

- Seat retainer supports the seat and allows for easy changeout

- Double offset disc reducing the valve torque

- Alloy harden disc surface for metal seat increases the sealing life time

- Integral disc stop prevent disc from over travel

- Soft seat, fire safe seat and metallic seat are replaceable each other

- PTFE lined SS316 bearing support stem and increase service life

- Thrust ring for anti-blowout and anti-static

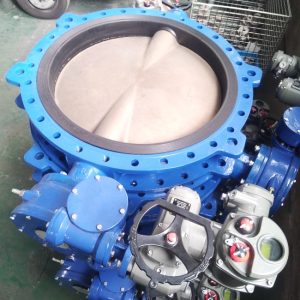

PARTS LIST AND MATERIAL SPECIFICATION

| No. | Part name | Material | |

| 1 | Body | WCB | CF8M |

| 2 | Disc | CF8* | CF8M* |

| 3 | Seat | RPTFE,SS316+RPTFE,SS316 | |

| 4 | Shaft | 17-4 PHSS,1.4462 | |

| 5 | Packing gland | CF8 | |

| 6 | Bottom cover | Same as body | |

| 7 | Cover seal | Graphite | |

| 8 | Thrust washer | SS316 | |

| 9 | Seat retainer | WCB | CF8M |

| 10 | Gasket | RPTFE, Graphite | |

| 11 | Retaining ring | SS304 | |

| 12 | Packing | RPTFE, Graphite | |

| 13 | Packing ring | SS316 | |

| 14 | Bearing | SS316+PTFE | |

| 15 | Thrust bearing | SS316 | |

| 16 | Key | SS316 | |

| 17 | Bolt | SS316 | |

| 18 | Bolt | SS304 | |

| 19 | Bolt | SS304 | |

| 20 | Nut | SS304 | |

| 21 | Belleville washer | SS304 | |

| *Supersonic spray welding of different materials on sealing surface of metal seating valve according to requirements | |||

TECHNICAL DATA

| Connection | Wafer |

| Size | 3″-24″ |

| Pressure | Class150,Class300 |

| Flange standard | ASME B16.5 Class150,Class300; EN1092 PN16, PN25, PN40 |

| Face to face | API 609 Category B valve Wafer |

| Pressure test | API 598 |

| Temperature | PTFE seat -29°C to +200°C,metal seat -29°C to +400°C |

| Operator | Lever,Gear box,Pneumatic actuator,Electric actuator |

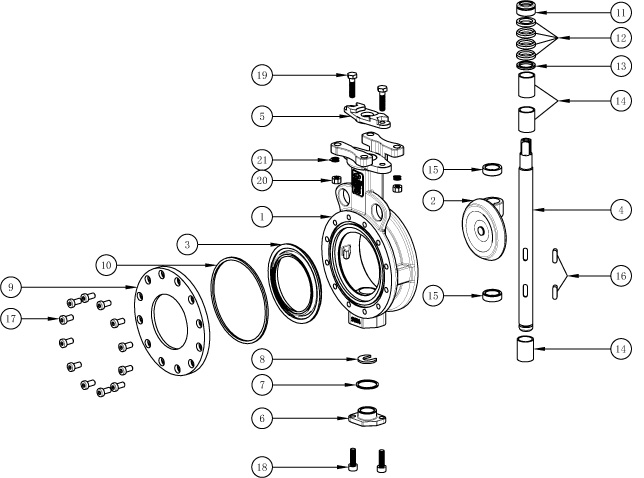

DIMENSIONS (mm)

CLASS 150LB

| SIZE | A | B | C | D | E | Top Flange | G | L | WT(kg) | |

| DN | INCH | Class150 | ||||||||

| 50 | 2″ | 126 | 79 | 13.5 | 92 | 11 | F05 | 45 | 43 | 3 |

| 65 | 2 1/2″ | 126 | 87 | 13.5 | 105 | 11 | F05 | 45 | 46 | 4 |

| 80 | 3″ | 145 | 100 | 17.5 | 130 | 11 | F07 | 72 | 48 | 5 |

| 100 | 4″ | 170 | 124 | 17.5 | 157 | 14 | F07 | 91 | 54 | 6 |

| 125 | 5″ | 185 | 144 | 17.5 | 186 | 14 | F07 | 114 | 57 | 9 |

| 150 | 6″ | 203 | 150 | 18.5 | 216 | 17 | F10 | 145 | 57 | 12 |

| 200 | 8″ | 239 | 186 | 24.5 | 269 | 22 | F10 | 192 | 64 | 19 |

| 250 | 10″ | 275 | 226 | 24.5 | 324 | 22 | F10 | 240 | 71 | 33 |

| 300 | 12″ | 307 | 251 | 30 | 380 | 27 | F12 | 285 | 81 | 42 |

| 350 | 14″ | 337 | 294 | 30 | 416 | 27 | F12 | 328 | 92 | 61 |

| 400 | 16″ | 368 | 320 | 30 | 476 | 27 | F14 | 373 | 102 | 88 |

| 450 | 18″ | 406 | 341 | 39 | 534 | 36 | F16 | 422 | 114 | 135 |

| 500 | 20″ | 442 | 383 | 49 | 588 | 46 | F16 | 470 | 127 | 173 |

| 600 | 24″ | 493 | 442 | 49 | 692 | 46 | F25 | 570 | 154 | 272 |

CLASS 300LB

| SIZE | A | B | C | D | E | Top Flange | G | L | WT(kg) | |

| DN | INCH | Class300 | ||||||||

| 50 | 2″ | 126 | 79 | 13.5 | 92 | 11 | F05 | 45 | 43 | 3 |

| 65 | 2 1/2″ | 126 | 87 | 13.5 | 105 | 11 | F05 | 45 | 46 | 4 |

| 80 | 3″ | 145 | 100 | 17.5 | 130 | 11 | F07 | 72 | 48 | 5 |

| 100 | 4″ | 170 | 124 | 17.5 | 157 | 14 | F07 | 91 | 54 | 6 |

| 125 | 5″ | 185 | 144 | 17.5 | 186 | 14 | F07 | 114 | 57 | 9 |

| 150 | 6″ | 203 | 150 | 18.5 | 216 | 17 | F10 | 145 | 57 | 12 |

| 200 | 8″ | 257 | 204 | 24.5 | 269 | 22 | F10 | 192 | 73 | 23 |

| 250 | 10″ | 288 | 238 | 30 | 324 | 27 | F12 | 240 | 83 | 39 |

| 300 | 12″ | 330 | 268 | 30 | 380 | 27 | F12 | 285 | 92 | 55 |

| 350 | 14″ | 337 | 294 | 39 | 416 | 36 | F14 | 320 | 117 | 79 |

| 400 | 16″ | 368 | 320 | 49 | 476 | 46 | F16 | 363 | 133 | 103 |

| 450 | 18″ | 406 | 341 | 49 | 534 | 46 | F16 | 400 | 149 | 170 |

| 500 | 20″ | 442 | 383 | 49 | 588 | 46 | F25 | 450 | 159 | 225 |

| 600 | 24″ | 500 | 442 | 58 | 692 | 55 | F25 | 550 | 181 | 338 |

FAQs

What is a Wafer high performance butterfly valve?

A High Performance Butterfly Valve is a quintessential device engineered with precision to regulate and isolate process flow in demanding industrial environments. This valve, a specimen of robust construction and meticulous design, is crafted to operate seamlessly under the high pressure and extreme temperature conditions often encountered within the petrochemical, HVAC, and power generation sectors.

Constructed with a double offset shaft, our high performance butterfly valves boast an operational finesse that reduces wear on the resilient sealing components, ensuring longevity and consistent performance. The metal seat design offers a bidirectional shutoff capability, further distinguishing itself as a high integrity solution for critical applications where tight sealing is paramount.

How does a Wafer high performance butterfly valve differ from a regular butterfly valve?

A High Performance Butterfly Valve stands as a testament to technical virtuosity and resilience when juxtaposed with a regular butterfly valve. The design of our high performance butterfly valves embodies a double offset, a pivotal enhancement that precipitates an advanced torque-seated sealing mechanism—this facilitates an exceptional shutoff capability, even under the most straining conditions that surpass the operational spectrum of standard butterfly valves.

Regular butterfly valves function admirably within their prescribed domain—moderate pressure and temperature applications. However, the High Performance Butterfly Valve, with its robust stem and disc architecture, thrives in the face of high-pressure gradients and thermal variances that are the hallmarks of severe industrial environments such as power generation, hydrocarbon processing, and chemical refinement.

Our valves boast a seat design that utilizes specialized materials, chosen for their innate resistance to extreme pressures and temperatures, ensuring bidirectional sealing integrity and longevity. The disc of a high-performance unit is precision-engineered to achieve near-frictionless rotation, minimizing wear and facilitating a tight seal that meets API 607, ISO 5211, and other relevant industry certifications.

What are the advantages of using a Wafer high performance butterfly valve?

In the realm of fluid control and regulation within power generation and heavy industrial applications, High Performance Butterfly Valves stand as the quintessential choice for systems demanding unwavering reliability and exacting precision. These robust valves are engineered to offer unparalleled performance in high-pressure environments, an attribute that is indispensable for energy power plants and other critical industry sectors. Our High Performance Butterfly Valves are constructed to meet and exceed the rigorous standards set forth by the industry, ensuring they deliver nothing short of exceptional functionality.

These valves bring forth additional benefits over their zero offset and double offset counterparts, including superior sealing capabilities and an extended operational lifespan, thus offering a comprehensive solution for applications requiring meticulous flow regulation under varying conditions.

What are some common applications for a Wafer high performance butterfly valve?

In the realm of petrochemical processing, our High Performance Butterfly Valves are instrumental, providing stalwart shutoff and modulating control for high-temperature hydrocarbons and caustic media. The valves exhibit exceptional endurance against abrasive wear and chemical degradation, making them the cornerstone of any refinery or chemical plant’s flow management system.

The energy sector relies heavily upon our valves for their superior performance in power generation facilities, including nuclear and thermal plants. Here, they manage critical processes by controlling the flow of steam, water, and combustible fuels with unerring precision, ensuring the seamless operation of turbines and boilers.

Water treatment and distribution systems enlist our High Performance Butterfly Valves for their formidable capacity to regulate large volumes of flow. Their robust construction and resistance to harsh environmental factors make them indispensable in maintaining the integrity of essential water infrastructure.

HVAC systems benefit from the precise airflow modulation afforded by our valves, optimizing environmental controls within commercial and industrial buildings. Their compact footprint and efficient operation are paramount in these applications, reducing energy consumption without sacrificing control accuracy.

Food and pharmaceutical industries also capitalize on the hygienic design and compliance with stringent health and safety regulations provided by our High Performance Butterfly Valves. These sectors require contamination-free operations, and our valves assure a clean, controlled flow of delicate mediums.