A resilient seated butterfly valve is a specialized type of butterfly valve that uses a rubber-like material to form a tighter seal when in the closed position. This provides better control over pressure and flow rates, making it an ideal choice for applications where precise regulation is necessary. When in the open position, the resilient seat moves back and away from the valve body, allowing fluids or materials to pass through. The operation of this type of valve can be manual or automated depending on the requirements of the system. Resilient seated butterfly valves offer many advantages for industrial and commercial use, including superior shutoff capability, high performance, and reliable operation.

Introduction

A resilient seated butterfly valve is a type of device used in industrial and commercial settings to regulate the flow of liquids or gases. The valve consists of a disc-shaped element that is mounted on a rod, which can be turned to open or close the valve. When in the closed position, the resilient seat material – typically made from rubber – forms a tight seal around the perimeter of the disc, providing superior shutoff performance and pressure control. When in the open position, the resilient seat moves back away from the centerline of the disk, allowing for efficient flow through the valve body.

Resilient seated butterfly valves offer many benefits for use in industrial applications, including their relatively low cost, easy installation and maintenance requirements, precision control and excellent performance characteristics. Depending on the needs of a particular system and environment, these valves can be either manually operated or automated by an actuator to achieve desired results. They are commonly used in water treatment facilities, chemical processing plants, oil refineries and other similar industries due to their reliable operation and durability.

Overview and History of Resilient Seated Valves

Butterfly valve are a special type of valve that have been in use for many years. First developed in the early 20th century, these valves feature a rubber-like material that forms a tighter seal when in the closed position. This provides better pressure and flow control, allowing users to achieve precise regulation of their systems. Since then, resilient seated valves have evolved with improvements to their design and technology, allowing them to be used in a variety of different industrial applications.

Today, they are commonly found in water treatment plants, chemical processing facilities, oil refineries, and more – due to their excellent shutoff capabilities, precision control and reliable operation. Over time, resilient seated valves have become an essential component of ensuring effective flow regulation within commercial and industrial settings.

Advantages of Using Resilient Seated Valves

Resilient seated valves offer many advantages over traditional valve solutions. For one, they provide superior shutoff capabilities and pressure control due to the rubber-like seal that forms around the perimeter of the disk when in the closed position. This prevents any leakage between the disk and its seat, ensuring tight shut off that can be relied upon for years of use.

They are also highly durable and require little maintenance due to their simple yet effective construction. Moreover, resilient seated valves are relatively low cost compared to other valve types, making them a cost-effective solution for many applications. Finally, these valves can be easily automated by an actuator, allowing users to quickly and conveniently adjust settings according to their specific needs. All together, these features make resilient seated valves an ideal choice for industrial and commercial systems that require reliable flow regulation.

Anatomy of a Resilient Seated Valve

Resilient seated valves are composed of several components that work together to form an effective shutoff and flow regulation solution. At their core, resilient seated valves feature a disk-like shape with an aperture in the center that allows for fluid flow as well as a rubber-like material around its edges. This material tightly seals against the seat, allowing for a reliable shutoff when the valve is closed.

When open, fluid flows through the aperture in the disk and can be adjusted by turning the wheel along its bottom edge. Additionally, resilient seated valves feature pressure plates within its body as well as flanges on either side used to secure it into place. All these components work together to provide precise control over pressure and flow, making them an ideal choice for many industrial and commercial systems.

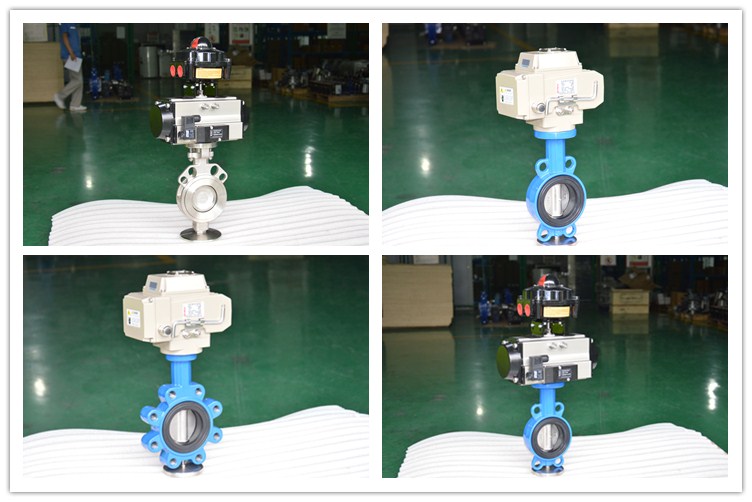

Types of Butterfly Valves with Resilient Seats

Butterfly valves with resilient seats are one of the most common types of valves used in industrial and commercial applications. These kinds of valves feature a disk-like structure that rotates to control the flow of fluid. This disk is connected to an actuator which is used to open, close, and adjust the flow rate when necessary. Resilient seated butterfly valves are designed to provide perfect shutoff even at low pressure differentials. In particular, rubber rings around the perimeter of the disk help form a safe seal against their seat preventing any leakage when engaged. Depending on need, these valves can be manual or automated for convenience. Furthermore, they come in various sizes and materials making them ideal for many types of applications.

Operation and Maintenance Considerations

In order to keep resilient seated valves functioning correctly, it is important to consider their operation and maintenance. For starters, the disk of a valve should always be properly aligned with its seat to ensure full closure when needed. This means that any physical damage or misalignment needs to be fixed immediately. Additionally, users should inspect the disc and its rubber rings periodically for any signs of wear and tear as well as checking if they have remained tight against the seat during operation.

All other components used in the valve should also be regularly inspected for proper working condition. Finally, it is essential to make sure that all parts are securely fastened and seals remain leak-proof before each use. Properly caring for resilient seated valves will ensure they work optimally and last through many uses.

Applications for Resilient Seated Butterfly Valves

Resilient seated butterfly valves have a variety of uses due to their versatile design. These kinds of valves are perfect when low-pressure differentials and perfect shutoff is needed, making them ideal for controlling flow in pipelines carrying water, air, oil, gas, and other liquids. They are used in industries ranging from plumbing to food and beverage processing to even manufacturing. They can also be used in domestic applications such as swimming pools where accurate control over the flow through pipes is essential. Ultimately, resilient seated butterfly valves provide a secure seal in many applications where precise control or isolation is needed.

Conclusion

In conclusion, wafer butterfly valves offer a range of benefits in various industrial and domestic applications. They provide a secure seal, accuracy in controlling pressure differentials, and the ability to be used in multiple pipelines without compromising the quality of their performance. Additionally, they are easy to maintain with regular inspection and servicing required to ensure their efficacy and longevity. With these advantages combined, resilient seated butterfly valves can prove to be an invaluable asset in any workplace or home project.