Stainless steel butterfly valve are renowned for their strength and durability. With an efficient, trouble-free operating design, these valves can handle a wide variety of tough industrial applications. The combination of corrosion-resistance and reliable performance make them an ideal choice for many fluid handling systems. In order to ensure that the valve is able to provide superior performance over the course of its lifetime, it is important to consider several factors when looking into stainless steel butterfly valve durability and reliability.

Introduction

Butterfly valve are a popular choice for many industrial applications, due to their ability to quickly and effectively control the flow of liquids in pipes. Their simplistic design allows them to be reliable, cost-effective and easy to install. Stainless steel butterfly valves are even more advantageous, as they offer superior corrosion resistance compared to other materials. Additionally, these valves can be used under extreme conditions such as high temperatures or pressures without sacrificing reliability. When it comes to improving the durability and reliability of stainless steel butterfly valves, there are several considerations that need to be taken into account.

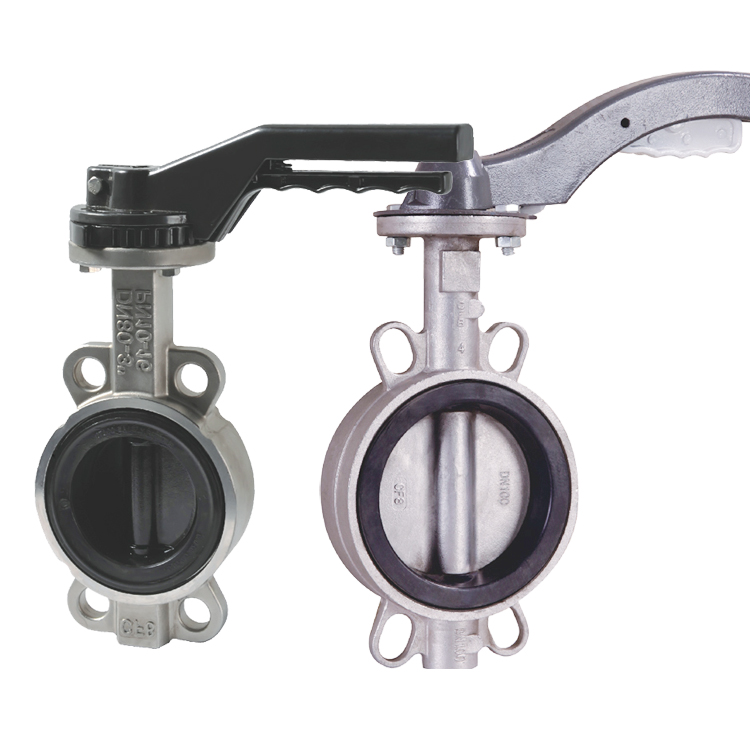

The type of valve is the most important factor when considering durability, with lug-style valves being much more robust than wafer style valves. In addition, the construction and material of the valve all have an effect on its performance, with quality components offering greater flexibility in operating conditions.

Factors such as operational temperature and pressure can also affect the lifespan of a butterfly valve; however, by carefully selecting one for its application results in improved reliability over time. Finally, understanding what kind of applications stainless steel butterfly valves may be used in helps ensure that they will perform optimally when needed most.

Definition of durability and reliability in butterfly valve

The durability and reliability of a wafer butterfly valve comes down to the strength and quality of its components. Butterfly valves are designed to be strong and able to handle extreme temperatures and pressures, as well as corrosive environments. To ensure reliable performance over time, it is important for users to select valves that are made with the highest quality components, as well as properly maintain them according to the manufacturer’s instructions.

Additionally, users may need to consider factors such as the type of valve chosen in order to guarantee long-lasting performance. By understanding what is needed for a durable and reliable butterfly valve, users can ensure they get maximum performance when using this type of industrial valve.

Overview of stainless steel butterfly valve

Pneumatic butterfly valve are a popular choice for many industrial operations, due to their strength and durability. These valves feature a disc that is connected to the stem, which rotates in order to open and close the valve. This design allows for highly efficient and accurate flow regulation, with minimal pressure drop when in operation. Additionally, stainless steel butterfly valves are known for their chemical resistance, meaning they can be used in a variety of corrosive environments. With the combination of strength and corrosion-resistance, stainless steel butterfly valves are an excellent solution for many industrial applications that require reliable performance over time.

Durability of Stainless Steel Butterfly Valve

Stainless steel butterfly valves are renowned for their strength and durability, making them an ideal choice for a variety of industrial applications. These valves are constructed using materials with high corrosion resistance, so they can withstand tough environments without sacrificing performance. In order to ensure that the valve is able to provide superior performance over the course of its lifetime, it is important to consider several factors when looking into stainless steel butterfly valve durability and reliability.

The type of valve chosen should be based on the application; lug-style valves are generally more robust than wafer style valves, so they are better suited for heavy-duty jobs or those in corrosive environments. In addition, selecting quality components such as chromium-alloy or an ultra-high molecular weight polyethylene ensures greater flexibility in operating conditions.

Operational temperature and pressure also have an effect on the lifespan of a butterfly valve; however, by carefully selecting one for its application results in improved reliability over time. Finally, having knowledge about the applications that stainless steel butterfly valves may be used in will help ensure that they will perform optimally when needed most.

Advantages of lug-style valves over wafer style

Lug butterfly valve have several advantages over wafer style valves. Lug-style valves feature a flange that allows for easy installation and removal when needed, as well as providing additional strength to the valve body.

This design also allows for a gap between the flanges, which provides a reliable seal even in conditions with vibration or misalignment. Additionally, lug-style butterfly valves are more securely fixed than their wafer counterparts and can bear greater temperature and pressure, making them ideal for many industrial applications. Overall, lug-style butterfly valves offer superior performance in terms of durability, reliability, safety and cost effectiveness compared to other types of industrial valves.

Reasons why wafer butterfly valves can be less reliable than lug-style

Wafer butterfly valves can be less reliable than lug-style valves due to their lack of structural reinforcement. The flange of a wafer valve is much thinner and weaker than that of a lug-style valve, leading to an increased chance of failure in high pressure or temperature applications.

Additionally, the gap between two halves of the valve body is small, making it difficult to create an effective seal that will last. This also limits their ability to cope with misalignment or vibration in the pipeline, further increasing the likelihood of leakage or other problems. Overall, wafer butterfly valves are not as reliable as lug-style valves, which offer greater strength and flexibility for industrial applications.

Reliability of Stainless Steel Butterfly Valve

Stainless steel butterfly valves are highly reliable and are suitable for a wide range of industrial applications. The design of the valve ensures that it can regulate flow quickly, accurately and efficiently, resulting in improved system performance. In order to ensure optimal reliability with stainless steel butterfly valves, several factors must be taken into account.

The type of valve should be chosen based on the application; lug-style valves are generally more robust than wafer style valves, so they are better suited for heavy-duty jobs or those in corrosive environments. Additionally, quality components must be used such as chromium-alloy or ultra-high molecular weight polyethylene to ensure greater flexibility in operating conditions. Butterfly valve price

Operational temperature and pressure also have an effect on the lifespan of a butterfly valve; however, by carefully selecting one for its application results in improved reliability over time.

Proper maintenance is also important when achieving optimal reliability and ensuring that the valve is operating correctly at all times. Finally, having knowledge about the applications that stainless steel butterfly valves may be used in will help guarantee that they will perform optimally when needed most.

Factors affecting performance in a stainless steel valve

The performance of a stainless steel valve is affected by several factors. Corrosion resistance is an important factor, as the valve must be able to withstand harsh environmental conditions over long periods of time without becoming damaged. Additionally, wear and tear caused by repeated opening and closing can cause problems such as sticking or slow closure, so the valve must have strong enough material and construction to prevent this from happening.

Temperature resistance should also be taken into consideration, as a valve that can handle higher temperature operating conditions will have more durability in the long run. Finally, the quality of seals used plays an important role in ensuring that fluid does not escape from the valve during operation.

Different applications for stainless steel butterfly valve

Stainless steel butterfly valves are versatile and offer a range of applications. They can be used in wastewater treatment systems, food processing plants, chemical reactors, and industrial heating systems.

Additionally, they are commonly used to regulate the flow of fluids in pipelines and control pressure in tanks. Stainless steel butterfly valves are strong and durable enough to resist corrosion from corrosive chemicals, making them an ideal choice for these types of applications. Furthermore, they are easy to operate due to their simple design and low-pressure actuation requirements.

Conclusion

In conclusion, stainless steel butterfly valves are an ideal choice for many industrial applications due to their strength and durability. When considering reliability, users must factor in the type of valve chosen, as well as quality components used and proper maintenance.

With knowledge about the applications that a stainless steel butterfly valve may be used in, users can ensure optimal performance when needed most. Ultimately, stainless steel butterfly valves offer unmatched reliability while delivering efficient and accurate flow regulation, making them an excellent option for a variety of industrial operations. Butterfly valve price

Summary of the factors that affect durability and reliability in each type

The durability and reliability of stainless steel valves depend on several factors. Corrosion resistance is a must, as the valve must be able to withstand environmental conditions without being damaged. Electric ball valve Additionally, wear and tear caused by frequent use can cause sticking or slow closure if not addressed properly, so high-grade material and construction is key in preventing this issue. Temperature resistance needs to be taken into consideration as higher temperatures have an effect on the valve’s lifetimes. Finally, seal quality plays an important role in ensuring that fluid does not escape from the valve while operating.