When it comes to selecting a triple offset butterfly valve manufacturer for your industrial process, several criteria should be considered to ensure the proper functioning and longevity of the valve. Given the valve’s critical role in fluid flow control, it is essential to select a manufacturer that produces high-quality, reliable products. The right manufacturer should also have expertise and experience in producing triple offset butterfly valves, use high-quality materials and production processes, and offer competitive pricing, delivery time and excellent customer service, and support. In this blog post, we will discuss in detail the criteria that an engineer should consider when choosing a triple offset butterfly valve manufacturer.

Introduction

When choosing a triple offset butterfly valve manufacturer, several criteria should be considered. First, the manufacturer’s performance and quality should be verified, and their products should meet industry standards. Second, the expertise and experience of the manufacturer’s team should be considered. Manufacturers that can offer customized solutions and have years of experience should be preferred. Third, the material selection and manufacturing process should be verified to ensure the production of high-quality valves. Fourth, the manufacturer’s pricing and delivery time should be considered to ensure that they are affordable and reliable, respectively. Finally, customer service, technical support, installation, and maintenance services, as well as warranty, should be verified to ensure excellent post-sales support. By considering these criteria, engineers and manufacturers can ensure that the right triple offset butterfly valve manufacturer is selected to meet their industrial process requirements.

Explanation of triple offset butterfly valve

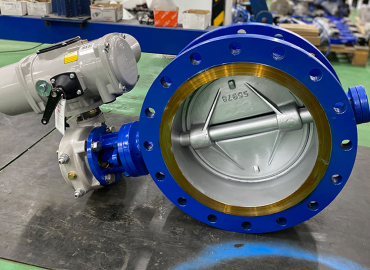

A triple offset butterfly valve is a valve that is designed to control fluid flow through a system. The “triple offset” refers to the offset disc positioned against the seat ring that provides a tight seal, resulting in zero leakage even in high-pressure conditions. Unlike traditional butterfly valves, triple offset butterfly valves are constructed with machined metal discs that create precise, smooth, and steady throttling, making them ideal for precise fluid flow control. They are commonly used in industries such as oil and gas, chemical processing, water treatment, and power generation, where industrial processes require accurate and reliable fluid flow control in challenging conditions.

Importance of valve manufacturer in industrial applications

The valve manufacturer plays a crucial role in industrial applications. It is essential to ensure that the manufacturer provides high-quality, reliable valves that meet industry standards and can withstand harsh operating conditions. The right valve manufacturer can provide customized solutions to meet the specific needs of an industrial process, ensuring efficient and reliable operation. Moreover, an experienced and skilled manufacturer will use high-quality materials and production processes to produce durable and robust valves that require minimal maintenance. Finally, a valve manufacturer that provides excellent customer service and support will ensure that any issues are quickly resolved, leading to minimal disruption to operations. Overall, choosing the right valve manufacturer is essential for optimizing industrial processes’ efficiency, minimizing downtime, and reducing maintenance costs.

Brief overview of valve manufacturer criteria

When selecting a valve manufacturer, several criteria must be considered to ensure the proper functioning and longevity of the valve. These include performance and quality, expertise and experience, material selection and manufacturing process, pricing and delivery time, and customer service and support. The manufacturer’s products must meet industry standards, be reliable, and offer customized solutions to meet specific industrial process needs. The team should be experienced and skilled, using high-quality materials and production processes that result in durable and robust valves requiring minimal maintenance. The delivery time should be reliable, pricing affordable, and customer service and technical support, excellent. Such criteria must be verified to ensure that the right valve manufacturer is selected.

Criteria for Choosing a Triple Offset Butterfly Valve Manufacturers

Choosing the right triple offset butterfly valve manufacturer requires careful consideration of several essential criteria to ensure efficient fluid flow control, minimal downtime, and reduced maintenance costs.

Firstly, the performance and quality of the manufacturer’s valves must be verified. The manufacturer should have a proven track record of producing high-quality valves that meet industry standards, have undergone testing, and are reliable in operation. Such valves would feature a tight seal and precise, smooth throttling, ideal for precise fluid flow control.

Secondly, the expertise and experience of the manufacturer are critical in choosing the right manufacturer. The manufacturer should have an experienced and skilled team capable of producing triple offset butterfly valves made to meet specific industrial process requirements. They should also be experienced in producing triple offset butterfly valves and have a proven track record to show for it. Such experience ensures the manufacturer has a deeper understanding of the valves’ practical use, thus ensuring quality production.

Thirdly, material selection and manufacturing process are other essential criteria. The right valve manufacturer should use high-quality materials and industry-standard manufacturing processes resulting in durable and robust valves that require minimal maintenance. These materials should have proven reliability in specific applications and be suited to particular environments such as high-pressure, caustic or corrosive environments.

Fourthly, pricing and delivery time must be considered to ensure affordability and reliability respectively. The manufacturer should have competitive pricing without compromising on the quality of the valves. Additionally, the delivery time should meet specific needs, ensuring minimal downtime and delays in system operations.

Lastly, the manufacturer’s customer service and support must be verified, particularly in areas such as technical support and installation and maintenance services. It is essential to choose a manufacturer who provides excellent post-sales customer support, ensures efficient handling of issues, and provides warranty and maintenance services when necessary.

In conclusion, when choosing a wafer butterfly valve manufacturer, several criteria must be considered to ensure efficient fluid flow control, minimal downtime and reduced maintenance costs. The performance and quality, expertise and experience, material selection and manufacturing process, pricing, and delivery time, and the manufacturer’s customer service and support, must all be verified before selecting the right manufacturer.

Reliability and Reputation

Reliability and reputation are critical factors to consider when choosing a triple offset butterfly valve manufacturer. It is crucial to select a manufacturer with a reputation for producing reliable and durable valves that require minimal maintenance. The right manufacturer should have a proven track record of supplying valves that meet industry standards and have a history of excellent customer satisfaction. Such a manufacturer will also take pride in the quality of their valves, provide warranties and maintenance services, ensuring any issues that arise are quickly resolved. In addition, a manufacturer with a solid reputation will have a reliable support team, who can handle any problems that occur, minimizing the risk of valve failure and system downtime. Overall, a reliable and reputable valve manufacturer will ensure maximum efficiency in fluid flow control, reduced maintenance costs, and minimal system downtime.

Product Quality

The quality of the product is a crucial factor to consider when choosing a triple offset butterfly valve manufacturer. The right manufacturer should produce high-quality valves that meet industry standards and have undergone testing, ensuring their reliability during operation. The manufacturer should also use high-quality materials, such as alloy steel, to construct the valves, which can handle the stresses and demands of harsh environments. Furthermore, valves must have precise, smooth motion with tight shutoffs to provide accurate control in demanding applications. A manufacturer with a comprehensive quality assurance program, including both in-house and third-party testing, will verify the product quality of their valves at every stage of production. This will result in reliable, durable, and efficient valves that can function efficiently, reducing maintenance costs, downtime and increasing overall system efficiency.

Customization triple offset butterfly valve manufacturers

Customization is an essential criterion when selecting a lug butterfly valve manufacturer for industrial applications. The right manufacturer should have experience and expertise in designing and producing customized valves that cater to specific industrial process requirements. These customized solutions can include variations in valve size, material, disc materials, control accessories, and other features that meet specific requirements. The manufacturer should work closely with the customer to understand their unique process requirements and design valves that meet those needs. Additionally, the manufacturer should offer support throughout the process, from design and testing to installation and maintenance. Customized solutions provide optimal performance and efficiency, reducing operating costs and minimizing downtime, making it critical to choose a manufacturer that can provide customized solutions.

Support and Service

Support and service are critical factors to consider when choosing a triple offset butterfly valve manufacturer. The right manufacturer should provide excellent customer service and technical support, as well as installation and maintenance services, to ensure maximum efficiency and minimal downtime. The manufacturer should have a strong support team that can handle any issues that arise promptly. Additionally, the manufacturer should provide technical support to ensure the valves are installed, maintained, and operated correctly. The manufacturer should also offer warranties, maintenance and repair services, and replacement parts, ensuring any issues that arise are quickly resolved, minimizing system downtime. Overall, a manufacturer that provides exceptional support and service ensures that their valves operate reliably, reducing maintenance costs and increasing overall system efficiency.

Conclusion triple offset butterfly valve manufacturers

In conclusion, choosing the right triple offset butterfly valve manufacturer requires careful consideration of several essential criteria. The valve’s critical role in fluid flow control, particularly in challenging and harsh industrial applications, necessitates selecting a manufacturer that can provide reliable and durable valves that meet specific industrial process requirements.

The performance and quality of the manufacturer’s valves must be verified, ensuring that they meet industry standards and are reliable during operation. The manufacturer should have an experienced and skilled team that can design and produce customized solutions that meet specific requirements.

The material selection and manufacturing process of the valves must meet industry-standard requirements and produce durable and robust valves that require minimal maintenance.

The manufacturer’s pricing and delivery time should also be considered, ensuring affordability and timely delivery to minimize downtime and minimize system disruption.

Lastly, the manufacturer’s customer service and support must be verified, particularly in areas such as technical support, installation, and maintenance services. An excellent post-sales support team is essential to handle any issues that arise, reduce downtime, and ensure efficient system operations.

Considering all these criteria will enable an engineer to choose the best triple offset butterfly valve manufacturer for their industrial process, ensuring maximum efficiency, reduced maintenance costs, and minimal system downtime.

At the end of the day, selecting the right valve manufacturer requires balancing all these criteria, finding a manufacturer that meets both the specifications and the reliability and reputation that an engineer desires. By considering all these critical criteria discussed in this article, selecting the right triple offset butterfly valve manufacturer for a particular industrial application will be easier and efficient.

Recap of valve manufacturer criteria

To recap, when choosing a triple offset butterfly valve manufacturer, it is essential to consider the following criteria: performance and quality, expertise and experience, material selection and manufacturing process, pricing and delivery time, and customer service and support. The manufacturer should produce valves that meet industry standards, provide customized solutions, and ensure precise and smooth throttling. The team should be skilled and experienced in producing triple offset butterfly valves. The manufacturer should use high-quality materials and manufacturing processes, with competitive pricing and reliable delivery times. Additionally, it should offer excellent post-sales support, such as technical support, installation, and maintenance services, as well as warranties and repair services. Considering these criteria will help engineers choose the right triple offset butterfly valve manufacturer for their industrial processes, resulting in efficient fluid flow control, reduced maintenance costs, and minimal system downtime.

Importance of selection for effective industrial processes

The selection of a triple offset butterfly valve manufacturer is crucial to ensuring effective industrial processes. Valves play a key role in regulating fluid flow in industrial applications, and choosing the wrong manufacturer can lead to system inefficiency, increased maintenance costs, and higher downtime. An effective selection will provide high-quality valves with proven reliability, customized solutions to specific industrial process requirements, and excellent technical support, ensuring proper installation and maintenance. Furthermore, a manufacturer that offers lifetime support can provide advice and adjustments as industrial processes evolve over time. Overall, the right manufacturer will optimize industrial processes, decreasing maintenance costs and minimizing the risk of system failures, making the selection of a valve manufacturer crucial to the success of industrial operations.

Recommendations for choosing the right triple offset butterfly valve manufacturers.

When choosing the right triple offset butterfly valve manufacturer, it is essential to consider several critical factors. Firstly, it is crucial to assess the manufacturer’s reliability and reputation, ensuring that they have a track record of producing reliable and durable valves that meet industry standards. It is also important to verify their performance and quality, ensuring that the valves meet specific application requirements. Secondly, consider their expertise and experience in producing triple offset butterfly valves to ensure that they can cater to your specific industrial process needs. Thirdly, check their material selection and manufacturing processes, ensuring that they provide reliable, durable, and robust valves that require minimal maintenance. Fourthly, consider pricing and delivery time, ensuring affordability and reliability. Lastly, examine the manufacturer’s customer service and support, ensuring that they provide excellent post-sales support, technical support, installation and maintenance services, as well as warranties and repair services. By considering all these critical factors, an engineer can select the right triple offset butterfly valve manufacturer, who can offer customized solutions and ensure efficient fluid flow control, reducing maintenance costs and minimizing system downtime.

-150x150.jpg)