When it comes to industrial processes, valve selection is a critical step. One valve type that has gained popularity in a range of industries is the wafer butterfly valve. This valve is a cost-effective, versatile, and energy-efficient option that is easy to install and requires low maintenance. It’s excellent for flow control, and due to its resilient nature, it can withstand pressure and temperature variations. In this blog post, we will take an in-depth look at the benefits of using a wafer butterfly valve, its applications across different industries, any potential drawbacks, and why it’s a popular selection for the industrial sector.

Introduction

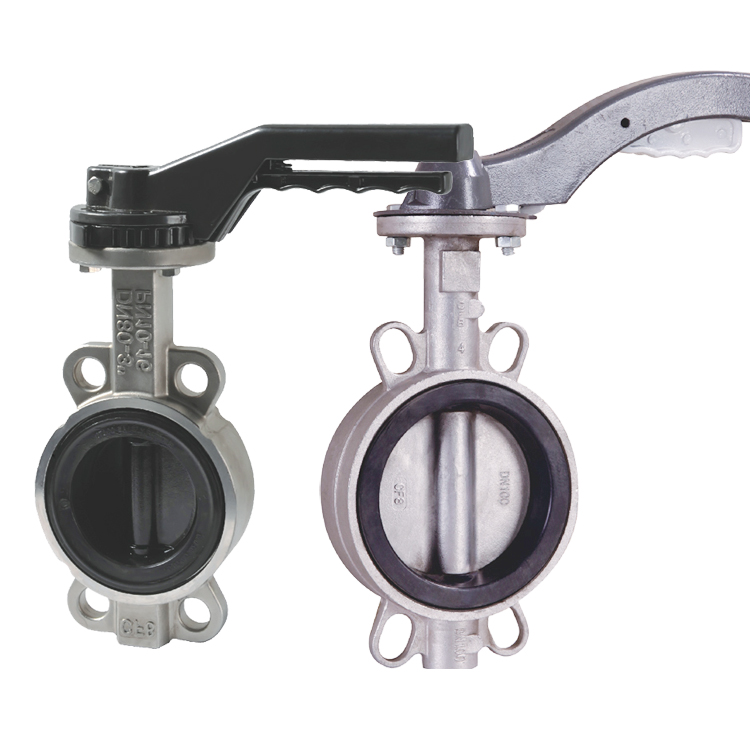

Wafer type butterfly valve is a type of control valve that is designed to regulate the flow of fluid by rotating a disc-shaped element within the valve’s body. The butterfly valve is a cost-effective valve type that is highly regarded in the industrial sector due to its effectiveness, practicality, and affordability. It is commonly used in the manufacturing, chemical processing, food and beverage, and water treatment industries. The valve is also easy to install, low maintenance, and highly versatile, making it an ideal choice for a wide range of applications. In this blog post, we will provide an in-depth overview of wafer butterfly valves, the benefits of using them in industrial processes, their applications, potential drawbacks, and why they are a popular choice.

Definition of a wafer butterfly valve

A wafer style butterfly valve is a control valve that regulates the flow of fluid by rotating a disc-shaped element within the valve’s body. The valve’s design consists of a lightweight disc that rotates around a central axis, allowing for smooth and accurate control of fluid flow. The thin profile of the wafer butterfly valve makes it a light and cost-effective option, and the absence of raised faces provides a compact installation. The valve is designed to operate with minimal torque, making it useful for automation purposes. It is commonly used to regulate the flow of water, air, and non-corrosive liquids in a broad range of industries.

Purpose of the blog post

The purpose of this blog post is to provide readers with an overview of the benefits of using wafer valves in industrial processes. The blog post will give an in-depth analysis of the applications, benefits, and potential drawbacks of using wafer butterfly valves, and how they compare to other valve types. The article will also provide examples of industries that use wafer butterfly valves, and why they are a popular choice for fluid control. By the end of this blog post, readers should have a comprehensive understanding of wafer butterfly valves and why they are a cost-effective, versatile, and reliable choice for the industrial sector.

Benefits of Using Wafer Butterfly Valve

Using wafer type butterfly valve in industrial processes provides several benefits. These valves are a cost-effective option compared to other types of control valves, making them ideal for industries that require large quantities of valves. Another significant advantage of wafer butterfly valves is their energy efficiency; they require lower energy consumption for operation than other valves, ultimately reducing operational costs. Wafer butterfly valves are easy to install, and their installation does not require any specialized tools or techniques. Additionally, maintenance costs of these valves are low due to their simple design and the few parts that make them up.

The versatile design of the wafer butterfly valve makes them an ideal option for most flow control applications in industries such as water treatment, food and beverage, and manufacturing sectors. These valves allow for precise flow control due to their rotational disc, which can be positioned anywhere in between fully opened to fully closed.

Wafer butterfly valves are also resilient against pressure and temperature variations. Their design allows for tight shutoff capabilities, even in high-pressure environments. Therefore, they can accommodate a broad range of fluids, from liquids to gases.

Overall, using wafer butterfly valves in industrial processes has several benefits, including cost-effectiveness, energy efficiency, easy installation, low maintenance, and versatility. Due to these advantages, wafer butterfly valves are an ideal choice for a range of applications in various industries.

Cost-effective option

One of the primary benefits of using wafer style butterfly valve in industrial processes is their cost-effectiveness. Compared to other types of control valves, wafer butterfly valves are lightweight, compact, and require less material to manufacture, ultimately reducing the cost. The low cost of these valves makes them an attractive option for industries that require a large number of valves in their production processes. Additionally, wafer butterfly valves provide significant energy efficiency advantages, leading to reduced operational expenses. Their ease of installation and low maintenance requirements further reduce costs, making them a highly cost-effective option for controlling fluid flows in industrial processes.

Energy efficient

Wafer butterfly valves are highly energy-efficient valves that require less energy consumption for operation compared to other valve types. This is due to their simple design and lightweight materials, allowing for lower torque requirements to actuate the valve. As a result, less energy is required to move the valve disc in place, leading to reduced operational costs. Wafer butterfly valves can operate at low flow rates and retain good throttling control, saving energy and reducing costs in the long run. Energy efficiency is an essential factor in any industrial process, and wafer butterfly valves are a great option for industries looking to reduce energy consumption and save costs in their operations.

Easy to install

Another significant benefit of lug vs wafer butterfly valves is their ease of installation. Their design allows for compact installation, and they do not require any special flanges or bolting, making them lightweight compared to other valves. The wafer butterfly valve design does not feature raised faces, and they only require two sets of fasteners to install, reducing installation time and complexity. Furthermore, the lightweight design of these valves means that they can be moved and adjusted easily by hand, making them easy to install in tight spaces or confined areas. With their easy installation process, industries can save time and money during the installation and commissioning phases of their production processes.

Low maintenance

In addition to being easy to install, wafer butterfly valves are also low-maintenance valves. Their simple design and low number of components make the valves easy to inspect, clean and repair. They are less prone to wear and tear compared to other types of valves, which reduces the chances of breakdown and downtime, ultimately saving costs in the long run. Additionally, the resilient nature of the wafer butterfly valve allows it to operate effectively under different temperature and pressure conditions, minimizing the likelihood of malfunction or damage to the valve. With low maintenance requirements, industries can significantly reduce operational costs and maintenance costs and focus more on their production.

Versatile

Wafer butterfly valves are highly versatile valves, which makes them an ideal option for various applications across different industries. Their design and range of sizes allow them to handle different fluid flows, ranging from liquid to gas. They also have exceptional throttling control capabilities, allowing for precise flow control in different applications. The wafer butterfly valve’s versatility extends to its compatibility with different piping systems, and it can fit into even the most compact spaces due to its low profile design. Industries such as water treatment, manufacturing, food and beverage, among others, all benefit from the versatility of the wafer butterfly valve, enabling them to control different fluid flows with one device. The versatility of these valves makes them a preferred option for many industrial processes.

Good for flow control

The wafer butterfly valve is an excellent valve type for flow control. The valve’s design allows for precise flow control due to the positioning of the disc-shaped element anywhere in between fully opened to fully closed. With the rotational disc design, the valve can operate at low flow rates while retaining good throttling control, making it an ideal option for applications that require consistent flow rates. Additionally, the valve can handle bidirectional flow, making it an ideal choice for reversing flow applications. The wafer butterfly valve is a reliable option for controlling fluid flow rates in various industries, including chemical processing plants, oil and gas, water treatment plants, and food and beverage processing industries. The valve’s ability to control fluid flow through precise throttling and modulation ensures that processes run smoothly, and production remains consistent.

Resilient against pressure and temperature variations

Another primary benefit of the wafer butterfly valve is its resilience against pressure and temperature variations. Due to their design, these valves can handle a wide range of fluid temperatures and pressures, making them the best fit for industrial applications that require precise fluid control under extreme conditions. The valve’s design allows it to withstand high-pressure conditions, minimizing the chances of breakage and malfunctioning of the valve. Additionally, wafer butterfly valves can handle different temperature conditions, making them an ideal choice for processes that involve a wide range of temperatures. The resilient features of the wafer butterfly valve make it a reliable option for controlling different fluid flows in challenging industrial settings, providing a sense of assurance and peace of mind to industries that rely on these types of valves.

Applications of Wafer Butterfly Valve

Wafer butterfly valves have a wide range of applications due to their versatility, low-cost design, and ease of installation. The valve’s design allows for precise flow control, and their rotational disc enables their use in various flow control applications. They are commonly used in the water treatment industry to regulate the flow of water and wastewater treatment chemicals. In manufacturing, they are commonly used to control the flow of fluids during production, such as chemical processing, oil and gas, and pharmaceutical industries. The food and beverage industry also widely use wafer butterfly valves for controlling the flow of liquids and gases in sanitation and cleaning systems due to their hygiene features.

Due to their low-pressure rating, flanged butterfly valves are best suited for low to medium-pressure applications within the industries that require such operating pressure ranges. Some of these industries include the cooling, heating, and air conditioning industry, where the wafer butterfly valves are used to regulate the flow of water, steam, or air in HVAC systems.

Overall, wafer butterfly valves are versatile, cost-effective, and efficient valves that can handle different types of fluid flows. They are suitable for different processes and industries that require precise flow control, making them a popular choice in the industrial sector. However, while wafer butterfly valves are an ideal option for many applications, they are not suitable for all types of fluids, and their low-pressure rating may limit their use in certain industrial processes.

HVAC systems

Wafer butterfly valves are a popular choice for controlling water or steam flow in HVAC (heating, ventilation, and air conditioning) systems. The valve’s compact design and lightweight body make them a space-efficient option for HVAC systems, where valves are usually installed in areas with limited space. These valves are ideal for regulating the flow of water or air in chiller systems, boilers, and heat exchangers. Wafer butterfly valves are energy-efficient, and their ability to operate smoothly even in low-flow rates makes them an ideal choice for HVAC systems. The versatility of the wafer butterfly valve also allows it to regulate the flow of various fluids in both residential and commercial HVAC systems. The valve’s efficient performance and hygienic features make it an excellent option for HVAC systems used in hospitals, hotels, and nursing homes, where cleanliness is essential to maintain indoor air quality.

Water treatment plants

Wafer butterfly valves are widely used in water treatment plants for controlling the flow of water and wastewater treatment chemicals. The valves can be installed in various water treatment processes, such as sedimentation tanks, potable water treatment plants, desalination, and sewage treatment among others. The valve’s compact design makes them an ideal option for water treatment plants, where space is often a constraint. They are also cost-effective, which makes them the preferred valve type in water treatment facilities which require a high number of valves. Wafer butterfly valves are efficient for regulating the flow of water; they can accurately control the flow of treated water and chemicals, ensuring the appropriate chemical dose is added to water in the treatment process. They also have excellent throttling capabilities, making them useful in controlling the flow rate of wastewater or chemicals in water treatment processes. Overall, the versatility, low maintenance, and energy efficiency features make wafer butterfly valves, a reliable and efficient valve type for water treatment processes.

Chemical processing plants

Wafer butterfly valves are extensively used in chemical processing plants, where flow control is essential in the production process. The valve’s versatile design makes it an ideal choice for regulating the flow of chemicals in chemical processing plants, including oil refineries, fertilizer production, and petrochemical plants. Unlike other valve types, the wafer butterfly valve’s simple design makes the valves easier to clean and maintain, which reduces the chances of contamination in the chemical processing plant. Additionally, the valve’s low pressure rating makes it a suitable option for handling low-pressure fluids in chemical processing plants. Wafer butterfly valves have excellent precision and provide accurate flow control, making them reliable for dosing chemicals and controlling fluid flow in chemical reactions. The valve’s durability and resilience against high pressure and temperature variations make it a dependable valve type for the harsh operating conditions present in chemical processing plants.

Food and beverage industry

Wafer butterfly valves are often used in the food and beverage industry for controlling the flow of fluids and gases. The valves are typically found in applications such as bottling plants, canning processes, and breweries, as well as other industries that process food and beverages. Wafer butterfly valves offer excellent flow control capabilities; they can accurately regulate the flow rate of liquids, gases, and mixtures. Furthermore, their compact design makes them a great option for limited space installations; this is especially beneficial in food processing plants where space is often a constraint. The valve’s low-pressure rating makes it suitable for handling low-pressure fluids commonly found in the food and beverage industry. Additionally, their durability against corrosion helps protect them from harsh operating conditions, which is essential in protecting the quality of food being processed in these facilities.

Pharmaceutical industry

The wafer butterfly valve is a popular option for controlling the flow of liquids and gases in the pharmaceutical industry. Pharmaceutical production lines operate in sterile conditions, making it important to have valves that can withstand potential contamination and maintain product purity. The wafer butterfly valve’s low-pressure rating makes it suitable for handling low-pressure fluids commonly found in pharmaceutical production, while the valve’s simple design makes it easier to clean and maintain. Additionally, its lightweight construction enables easy installation and maintenance; this is particularly useful when there are space constraints present. Furthermore, thanks to their precision and accuracy when regulating flow rate, wafer butterfly valves help ensure products produced meet safety requirements set out by relevant authorities. ball valve

Drawbacks of Wafer Butterfly Valve

Wafer butterfly valves are generally considered an inexpensive and reliable option for controlling the flow of fluids, gases and mixtures. However, they do have some drawbacks. For example, their compact size can make them difficult to install in tight spaces; if there is insufficient space present the valve will be unable to fit properly resulting in it not functioning as intended. Furthermore, depending on the application certain additives may need to be added to the valve in order for it to operate correctly; this can cause issues as these additives can sometimes damage other components due to chemical incompatibility. Additionally, wafer butterfly valves may not be suitable for applications requiring high-pressure handling; they are designed primarily for low-pressure applications due to their design and construction making them unsuitable for higher pressures. In addition, since wafer butterfly valves rely on mechanical seals which create friction when operated this can reduce their lifespan considerably when used frequently.

Not suitable for all types of fluids

wafer style butterfly valve may not be suitable for all types of fluids. For example, they are not commonly used to handle viscous liquids due to their design which means they cannot regulate the flow of these materials accurately. Furthermore, the use of a mechanical seal also means that the valve will struggle to handle more abrasive materials such as sand and gravel; this can lead to premature wear and tear on the valve’s components. In addition, wafer butterfly valves are typically designed for low-pressure applications meaning that if used with higher pressures it could cause damage or malfunctioning of important components. Due to these drawbacks it is therefore important that the user considers what type of fluid they are using in order to ensure the best results from their wafer butterfly valve.

Limited pressure rating

Wafer type butterfly valve are typically designed for low-pressure applications and have limited pressure ratings. As such, it is essential to select the correct valve in order to ensure safe operation of the system. If an incorrect valve is used then there is a risk of serious damage or malfunctioning; this could potentially lead to higher repair costs due to the need to replace the valve and any additional parts which were affected. For these reasons, it is important that users pay close attention when selecting their wafer butterfly valves, taking into account factors such as pressure rating, material compatibility, flow rate and more. Doing so will help ensure reliable and safe operation of their system.

May not withstand extreme conditions

Wafer butterfly valve are not designed to withstand extreme conditions, including temperatures outside of the normal operating range. If exposed to such conditions then there is a risk of damage and malfunctioning due to the valve becoming brittle or cracking. Furthermore, vibrations or shocks can also cause damage to the valve which could lead to it failing prematurely; this could be costly as it may require extensive repairs or even a complete replacement. Therefore, it is important that users choose their wafer butterfly valve carefully; selecting one with higher pressure ratings, better material compatibility and suitable for their application’s operating conditions in order to ensure reliable performance.

Conclusion

In conclusion, wafer butterfly valve offer a variety of benefits that make them an ideal choice for many applications. They provide reliable and efficient operation, with low pressure drop, high flow rates and great material compatibility. Furthermore, they are also easy to install and maintain. Wafer butterfly valves can be used in a range of applications requiring isolation or regulation of gases and liquids, as well as other types of fluids. As such, they can provide great performance as long as the user takes care to ensure that the valve is suitable for their application’s conditions; taking into account factors such as pressure rating, flow rate and materials compatibility. With all these features in mind, it’s clear why wafer butterfly valves are becoming more popular by the day!

Recap of the benefits, drawbacks, and applications of wafer butterfly valve

Wafer butterfly valve offer several benefits, including low pressure drop, high flow rate, great material compatibility and easy installation and maintenance. On the other hand, they are not designed to withstand extreme temperatures or vibrations/shocks and so should be carefully chosen taking these features into account. In terms of applications, wafer butterfly valves can be used in isolation or regulation of gases and liquids as well as other fluids. In conclusion, with their wide range of benefits and applications, wafer butterfly valves can be a great choice for many users.

Final thoughts on why wafer butterfly valve is a popular choice in the industrial sector

Wafer butterfly valve are a popular choice in the industrial sector due to their range of benefits that make them well suited for various applications. They provide reliable and efficient operation, with low pressure drop, high flow rates and great material compatibility. Furthermore, they are also easy to install and maintain, aiding in their versatility and cost-effectiveness. With the wide range of industries that can benefit from wafer butterfly valves – from food & beverage to chemical processing – it’s clear why they remain a popular choice in today’s world.