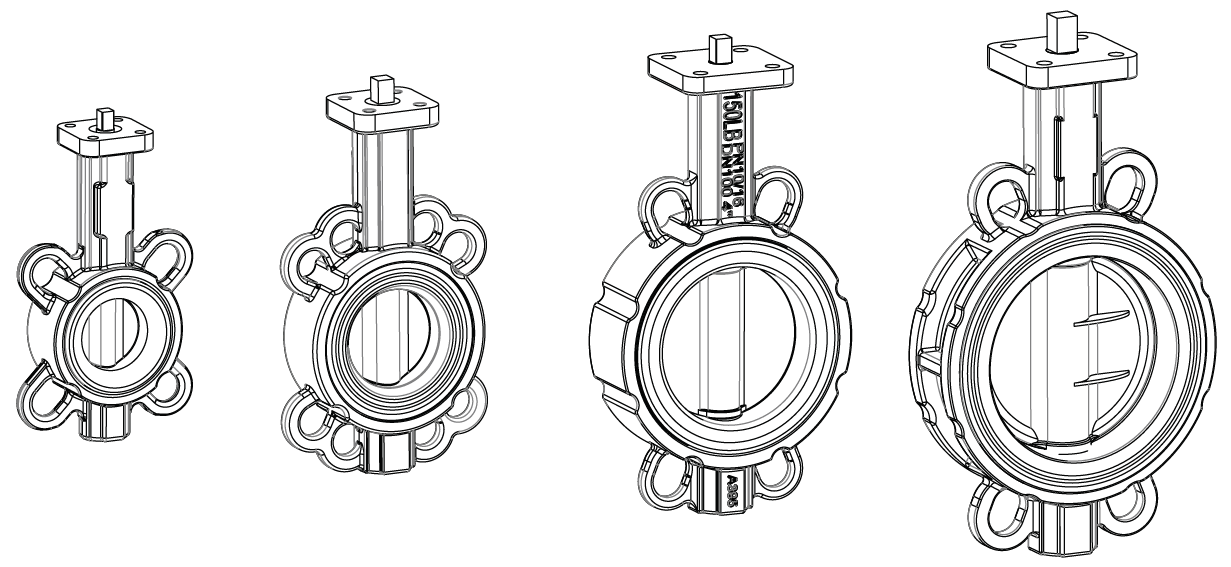

Wafer and lug butterfly valves are two types of Butterfly Valve designs used in HVAC systems. The main difference between the two types is that wafer valves have a compact design with sealants placed at the edges, while lug butterfly valves are more complex, with bolts and nuts keeping the parts together. Other key differences include size, strength, diameter requirements for installation and maintenance processes involved. Both have their own advantages when used in HVAC systems, making it important to understand each type before deciding on which type to install.

Introduction wafer vs lug butterfly valve

Wafer vs lug butterfly valve are two distinct types of valve designs used in HVAC systems for controlling the flow of liquids and gases. The main difference between them is that a wafer valve has an overall more compact design, with sealants placed at the edges. These valves require slightly more pressure to operate, but they can also be installed quickly and easily as they do not require any extra equipment or tools. On the other hand, lug butterfly valves are larger in size and have a more complex design where bolts and nuts keep the parts together. This makes them strong enough to withstand higher pressure but it also means they require more time to install and maintain.

In terms of size considerations when installing either type of butterfly valve, wafer valves come in standard sizes making them easier to fit into existing pipelines, while lug butterfly valves might require custom-made pieces for larger diameter pipes. Additionally, wafer valves provide a greater range of options when it comes to material availability as well as connection types (socket weld or threaded connections). Lug butterfly valves have less options available when it comes to material selection but offer better support for long piping runs. Each type has its own advantages when used in HVAC systems – wafer being ideal for installations that need quick and easy setup; while lug works best where strength is desired over time savings.

Definition of a Wafer type Butterfly Valve

A Wafer Butterfly Valve is a type of valve design used in HVAC systems for controlling the flow of liquids and gases. It has a compact, disc-shaped body with sealants placed at the edges to form a leak-proof joint between pipe flanges. This design requires slightly more pressure to operate, but it can be installed quickly and easily. The valve also comes in standard sizes making it easier to fit into existing pipelines. In addition, wafer type butterfly valves are generally available in any material preference and connection type, such as socket weld or threaded connections.

Definition of a Lug Butterfly Valve

A Lug Butterfly Valve is a type of valve design used in HVAC systems for controlling the flow of liquids and gases. It consists of two parts; a body section with flanges that are joined to the pipeline via bolts and nuts, and a disc-shaped element inside the body. The lug butterfly valve design provides greater strength, allowing it to withstand higher pressure than the wafer type, but it also takes more time to install and maintain. In terms of size considerations when installing, lug valves can handle larger diameter pipes which might require custom-made pieces for fitting. Additionally, there are fewer material options available for lug butterfly valves when compared to wafer styles.

Main Differences Between the Two Valves

The main difference between a Wafer Butterfly Valve and a Lug Butterfly Valve lies in their respective designs. Generally, wafer butterfly valves are more compact, with the disc-shaped body forming a tight seal between the pipe flanges. This type of valve requires slightly more pressure to operate, but it can be quickly and easily installed into existing pipelines thanks to its standard sizing. While they come in any material preference and connection type, their strength is not as great as lug butterfly valves. Lug butterfly valves have two parts; the body section with flanges connected to the pipeline via bolts and nuts, and a disc-shaped element that controls the flow of liquids or gases. This design provides greater strength and resistance to higher pressures than wafer designs which makes them ideal for larger pipes; however, they require longer installation time and fewer material options exist for them compared to wafer valves

Wafer Vs Lug in Terms of Connections and Seals

When comparing wafer and lug butterfly valves, connections and seals are key distinctions between the two. Wafer-style valves have a disc-shaped body that fits tightly between two pipe flanges allowing a secure seal. The size of the valve is usually standard which allows for easy installation into existing pipelines; however, these valves need higher pressure to operate than lug butterfly valves. Lug butterfly valves require more hardware for installation with two parts being bolted together; a body section with flanges connected to the pipeline via bolts and nuts and a disc inside the body controlling the flow. This design provides greater strength, but fewer material options are available as compared to wafer styles. The sealing performance of lug butterfly valves is also superior since they create a tighter seal against higher pressures than wafer styles.

Size, Strength, and Diameter Considerations When Installing the Valves

The size, strength, and diameter of a pipe connection are key considerations when installing pneumatic butterfly valve. Wafer butterfly valves are smaller than lug designs which makes them appropriate for tight spaces since they fit between two flanges instead of being bolted together. However their strength is not as great as lug valves which need higher pressure to operate. Larger pipes generally require lug valves due to their superior strength and resistance to higher pressures. When it comes to the diameter of the pipes the valve must match; wafer-style valves come in standard sizes that match up readily with existing pipes, but for larger diameters, lug styles will usually be necessary.

Installation and Maintenance for Each Type of Valve

Installation of wafer-style butterfly valves is generally quicker and easier than lug varieties since these involve setting the butterfly valve between two pipe flanges without the need for additional hardware. Maintenance on a wafer style valve requires basic tightening which can be done by simply adjusting the nuts and bolts that hold the body together. Lug-style butterfly valves, however, require additional hardware for installation such as bolts and nuts along with tools for tightening them. Maintenance wise there are slightly more moving parts in lug styles compared to wafer designs so it is important to check all components before use such as inspecting seals, lubricating bolts and making sure the disc seating correctly.

Advantages of Using Each Type of Valve in HVAC Systems

Flanged butterfly valves offer advantages in HVAC systems due to their ability to fit in tight spaces and provide just enough pressure for operation. Due to their small size, wafer butterfly valves are an ideal solution for limited space applications as they can easily fit between two flanges with no extra hardware needed. When it comes to ease of installation, wafer butterfly valves require minimal effort since all that is required is sliding the valve between the two flanges and tightening them up with a few bolts. Additionally, these valves are easy to maintain with the only requirement being occasional tightening of the nuts and bolts which hold the body together. Maintenance wise, there are fewer moving parts compared to lug styles making them less prone to wear and tear over time.

Lug-style butterfly valves provide more strength as they need higher pressure to operate effectively. They also tend to have greater flow rate compared to wafer style butterfly valves due to their larger diameter valve opening thus allowing more air or gas through the pipe. Due to this increased flow rate, lug-style butterfly valves are often used in larger scale HVAC systems such as commercial buildings or industrial facilities where higher flows are required. Installation requires some tools along with additional hardware such as bolts and nuts whereas maintenance involves regularly checking seals, lubricating bolts and ensuring disc seating correctly as there are a slightly more number of moving parts when compared with wafer designs.

Conclusion wafer vs lug butterfly valve

In conclusion, there are several differences between wafer-style and lug-style butterfly valves when considering them for use in HVAC systems. Wafer-style valves offer advantages due to their ability to fit in tight spaces, ease of installation with minimal effort and easy maintenance with fewer moving parts. Lug-style butterfly valves provide greater strength, better flow rate and can handle higher pressure than wafer designs. Installation of lug styles requires additional hardware along with tools for fitting and tightening them whereas maintenance involves more complex processes such as checking seals, lubricating bolts and ensuring disc seating correctly since there are a slightly more number of moving parts when compared with wafer designs. It is important to consider the individual needs of each application before selecting which style of valve will be most suitable for use.