I. Introduction 3 way ball valve in UAE

Ball valves one of the most commonly use valves in various industries such as oil and gas, chemical, water treatment, and many others. They are highly versatile, reliable, and easy to operate. Among the different types of ball valves available in the market. 3 way ball valves stand out for their unique design and functionality.

In this document, we will dive deep into the world of 3 way ball valves. Exploring their features, applications, and importance in the UAE market. We will also discuss the various types of 3 way ball valves available and their differences.

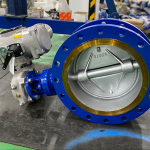

A 3 way ball valve consists of a T or L-shaped body with three openings or ports. The flow of fluid can be controlled by rotating the ball inside the valve, Which has a hole through its center. By aligning the hole with different ports, the flow can direct in various directions.

- Versatility: 3 way butterfly valves offer multiple flow options. Making them suitable for a wide range of applications. They can use to merge two flows, divert a flow, or isolate different lines.

- Compact design: Unlike other valves that require multiple fittings and connections. 3 way ball valves have a compact design with only one valve required for multiple functions.

- Easy operation: The quarter-turn operation of the ball inside the valve makes it easy to operate and control the flow of fluids. This also helps in reducing the chances of valve failure and maintenance.

- Durability: 3 way ball valves made from high-quality materials such as stainless steel, brass, and PVC. Making them highly durable and resistant to corrosion and wear.

III. Unpacking the Role of 3-Way Ball Valves in Industrial Applications

3 way ball valve in UAE widely use in various industries for their unique features and functionality. Some of the common applications include:

- Mixing and blending: In industries such as chemical processing. 3 way ball valves are used to mix different types of fluids or chemicals by controlling the flow through different ports.

- Diverting flow: In oil and gas pipelines, 3 way ball valves use to divert the flow of oil or gas from one line to another in case of maintenance or repairs.

- Temperature control: In HVAC systems, 3 way ball valves use to control the temperature by mixing hot and cold water streams.

- Sampling: In laboratories and research facilities. 3 way ball valves use to collect samples of liquids or gases for testing and analysis.

- Water treatment: 3 way ball valves use in water treatment plants to control the flow of different streams for processes such as filtration, chlorination, and pH balancing.

These are just a few examples of how 3 way ball valves are crucial components in various industrial applications. Their versatility and reliability make them an essential part of any system that requires precise flow control.

IV. Types of 3 Way Ball Valves

There are primarily three types of 3 way ball valve in UAE available in the market: T-port, L-port, and a combination of both. Let’s take a closer look at each type:

- T-Port: As the name suggests, this type of valve has a T-shaped opening with one inlet and two outlets at 90-degree angles. T-port valves commonly use for mixing and blending applications. Where the flow is divided into two streams.

- L-Port: This type of valve has an L-shaped opening with one inlet and two outlets at 180-degree angles. L-port valves often use for diverting or isolating flow in different directions.

- Combination port: As the name suggests, this type combines both T and L-shaped openings. Providing maximum flexibility for flow control. It can be used for both mixing/diverting and isolating applications.

In conclusion, 3 way ball valves play a crucial role in the industrial sector, offering versatility, compact design, easy operation, and durability. In the UAE market, these valves widely use in various industries for their unique features and functionality. As technology advances, we can expect to see further developments in 3 way ball valves. Making them even more efficient and reliable in the future. So, it is essential to keep up with the latest advancements and choose the right type of valve for your specific application needs. Now that you have a deeper understanding of 3 way ball valves. You can make an informed decision for your next industrial project.

IV. Emphasizing Quality Assurance in Valve Manufacturing

As with any industrial equipment, quality assurance is crucial in the manufacturing process of 3 way ball valves. In the UAE, there are strict regulations and standards that must follow to ensure the safety and reliability of these valves.

Some important factors to consider for quality assurance in valve manufacturing include:

- Material selection: The materials used in the construction of 3 way ball valves must be of high quality and compatible with the fluid transport.

- Design and testing: Proper design and thorough testing are essential to ensure the functionality and reliability of 3 way ball valves.

- Compliance with standards: Manufacturers must comply with industry standards such as API, ASME, and ISO to ensure the quality and safety of their products.

- Regular maintenance and inspection: It is important to regularly maintain and inspect 3 way ball valves to identify any potential issues and ensure proper functioning.

By emphasizing quality assurance in valve manufacturing. We can ensure that 3 way ball valves continue to be reliable and efficient components in various industrial applications. As customers, it is important to choose valves from reputable manufacturers who prioritize quality assurance in their production process. So, always do your research and choose a trusted brand for your industrial valve needs. With proper installation, maintenance, and quality assurance. 3 way ball valves can offer long-term efficiency and reliability in any industrial setting.

V. Case Study: Real-world Application of 3-Way Ball Valves in UAE

To further understand the importance of 3 way ball valves in industrial applications. Let’s look at a real-world case study from the UAE.

In an oil refinery plant in Dubai, 3 way ball valves use to control and divert flow in different pipelines for maintenance and safety reasons. With regular maintenance and inspection, these valves have been functioning efficiently for over 10 years. Ensuring the smooth operation of the refinery. This is a testament to the durability and reliability of 3 way ball valves in harsh industrial environments.

In another application, a chemical processing plant in Abu Dhabi uses 3 way ball valves for mixing different types of corrosive chemicals. The stainless steel material and corrosion-resistant properties of these valves have made them an ideal choice for this application. The precise flow control offered by the valves has also improved the accuracy and consistency of their chemical mixing process. Resulting in cost savings and increased productivity.

These case studies highlight just a few examples of how 3 way ball valves are essential components in various industries in the UAE, contributing to efficient and reliable operations. It further emphasizes the importance of selecting high-quality valves from trusted manufacturers for maximum performance and safety.

VI. The Influence of International Collaborations on Valve Manufacturing

As the demand for 3 way ball valves continues to rise globally. International collaborations and partnerships have played a significant role in the development of these valves. With advancements in technology and increased market competition. Manufacturers have been able to improve the quality and efficiency of 3 way ball valves through cross-border collaborations.

For instance, many valve manufacturers in the UAE have partnered with companies from countries such as Germany. Japan, and the US to improve their production processes and incorporate advanced technologies in valve manufacturing. This has not only enhanced the quality of valves produced but also helped these companies expand their market reach.

Additionally, international collaborations also allow for the exchange of knowledge and expertise between manufacturers from different countries. Leading to continuous improvements in 3 way ball valves. As a result, customers in the UAE and around the world can benefit from high-quality valves that meet international standards and offer reliable performance.

VII. Conclusion 3 way ball valve in UAE

3 way ball valves are versatile and essential components in various industrial applications. With their unique design, compact size, and efficient flow control. They become widely use in the UAE market. Quality assurance and advancements through international collaborations have further enhanced the performance and reliability of these valves. Making them crucial components for smooth operations in industries such as oil and gas, chemical processing, and more. As industries continue to evolve and demand for efficient and reliable valves increases. We can expect to see further developments in 3 way ball valves. Making them even more essential in the future.

So, it is essential to keep up with the latest advancements and choose the right type of valve for your specific application needs. Now that you have a deeper understanding of 3 way ball valves. You can make informed decisions when it comes to selecting and using them in your industrial processes. Remember, prioritize quality assurance and maintenance for long-term efficiency and reliability of 3 way ball valves in any application.