Description

A Comprehensive Guide to Triple Offset Butterfly Valves

Triple Offset Butterfly Valve are industrially significant, offering a reliable and zero-leakage mechanism. In this guide, we will cover:

- The technical specifications of the valve

- The advantages of using this type of valve

- The applications in which they are best suited

- Comparisons to other valve types

- Important maintenance and repair procedures

- Common issues that may arise with Triple Offset Butterfly Valves

Technical Specifications

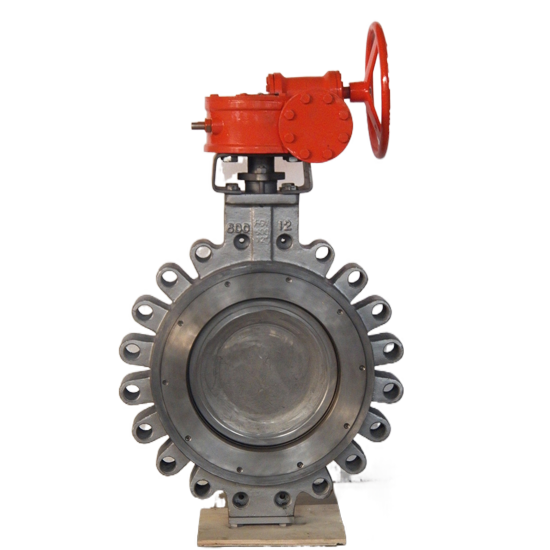

Double offset butterfly valve are engineered to provide zero leakage through a no-rubbing 90-degree rotation mechanism across a wide range of pressure and temperature conditions. Some key technical specifications include:

- Connection: Double flange

- Size Range: 3″-80″ for PN10,PN16,Class150; 3″-48″ for PN25,PN40,Class300; 3″-24″ for Class600

- Pressure Range: PN10,PN16,PN25,PN40,Class150,Class300,Class600

- Flange Standard: ASME B16.5 Class150,Class300,Class600; EN1092 PN16,PN25,PN40

- Face to Face: ISO 5752, ASME B16.10, API609 Double flanged short pattern

- Pressure Test: API 598, ISO 5208 Rate A, ANSI B16.104(ANSI/FCI 70-2)Class Ⅵ

- Temperature Range: -29°C to +538°C

- Operator Options: Lever, Gearbox, Pneumatic actuator, Electric actuator

Advantages of Triple Offset Butterfly Valves

The primary advantages of triple offset butterfly include:

- Zero Leakage: The valve is designed to achieve zero leakage, making it highly suitable for applications demanding tight shutoff.

- Versatility: These valves can handle high-temperature and high-pressure applications, making them useful across a wide range of industries.

- Lower Torque Requirements: The triple offset design reduces the torque requirement for opening and closing the valve, making it more energy-efficient.

- Longevity: Due to the no-rubbing action during rotation, the valve components experience less wear, increasing the overall lifespan of the valve.

Applications of Triple Offset Butterfly Valves

Triple Offset Butterfly Valves are used in various industries such as:

- Oil & Gas

- Chemical & Coal

- Petrochemical

- Desalination Plants

- Waterworks

- Fossil Fuel Applications

- District Heating

Comparisons to Other Valve Types

Triple offset valve excel compared to other valve types in several ways:

- Superior to Globe Valves: Due to their compact design and lower cost, Triple Offset Butterfly Valves are a more economical choice when compared to Globe Valves.

- Low Maintenance vs. Ball Valves: Triple Offset Butterfly Valves have fewer moving parts, making them easier to maintain and repair compared to Ball Valves.

| Connection | Double flange |

| Size | 3″-80″ for PN10,PN16,Class150; 3″-48″ for PN25,PN40,Class300; 3″-24″ for Class600 |

| Pressure | PN10,PN16,PN25,PN40,Class150,Class300,Class600 |

| Flange standard | ASME B16.5 Class150,Class300,Class600; EN1092 PN16,PN25,PN40 |

| Face to face | ISO 5752, ASME B16.10, API609 Double flanged short pattern |

| Pressure test | API 598, ISO 5208 Rate A, ANSI B16.104(ANSI/FCI 70-2)Class Ⅵ |

| Temperature | -29°C to +538°C |

| Operator | Lever,Gear box,Pneumatic actuator,Electric actuator |

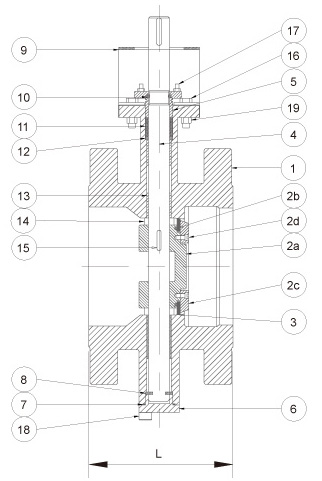

| No. | Part name | Material | |

| 1 | Body | WCB | CF8M |

| 2a | Disc | WCB,CF8 | CF8M |

| 2b | Disc sealing | UNS31803(duplex)+graphite | |

| 2c | Disc sealing retainer | SS304 | SS316 |

| 2d | Disc sealing retainer screw | SS304 | SS316 |

| 3 | Seat welded surface | Stellite Gr.21 | |

| 4 | Shaft | 17-4 PHSS,1.4462 | |

| 5 | Packing gland | CF8 | |

| 6 | Bottom cover | Same as body | |

| 7 | Cover seal | Graphite | |

| 8 | Thrust washer | SS316 | |

| 9 | Bracket | WCB | CF8M |

| 10 | Retaining ring | SS304 | |

| 11 | Packing | RPTFE, Graphite | |

| 12 | Packing ring | SS316 | |

| 13 | Bearing | SS316+PTFE | |

| 14 | Thrust bearing | SS316 | |

| 15 | Key | SS316 | |

| 16 | Bolt | SS304 | |

| 17 | Bolt | SS304 | |

| 18 | Bolt | SS304 | |

| 19 | Nut | SS304 | |

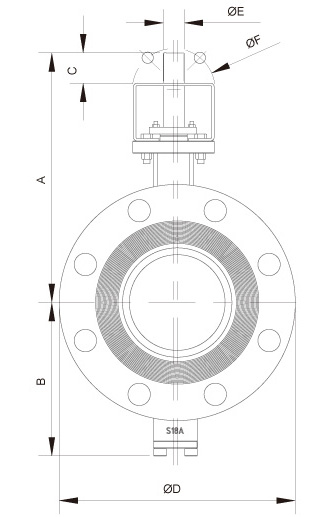

| SIZE | A | B | C | D | E | Top Flange | L | WT(kg) | ||||

| Class150 | PN10 | PN16 | PN25 | |||||||||

| DN | INCH | Class150,PN10,PN16,PN25 | ||||||||||

| 80 | 3″ | 260 | 125 | 17.5 | 190 | 200 | 200 | 200 | 14 | F07 | 114 | 30 |

| 100 | 4″ | 290 | 141 | 17.5 | 230 | 220 | 220 | 235 | 14 | F07 | 127 | 40 |

| 125 | 5″ | 310 | 150 | 17.5 | 255 | 250 | 250 | 270 | 14 | F07 | 140 | 45 |

| 150 | 6″ | 330 | 165 | 18.5 | 280 | 285 | 285 | 300 | 17 | F10 | 140 | 50 |

| 200 | 8″ | 385 | 214 | 24.5 | 345 | 340 | 340 | 360 | 22 | F10 | 152 | 85 |

| 250 | 10″ | 425 | 243 | 24.5 | 405 | 395 | 405 | 425 | 22 | F10 | 165 | 120 |

| 300 | 12″ | 490 | 286 | 30 | 485 | 445 | 460 | 485 | 27 | F12 | 178 | 160 |

| 350 | 14″ | 525 | 312 | 30 | 535 | 505 | 520 | 555 | 27 | F12 | 190 | 195 |

| 400 | 16″ | 545 | 350 | 39 | 595 | 565 | 580 | 620 | 36 | F14 | 216 | 255 |

| 450 | 18″ | 580 | 383 | 49 | 635 | 615 | 640 | 670 | 46 | F16 | 222 | 310 |

| 500 | 20″ | 640 | 407 | 49 | 700 | 670 | 715 | 730 | 46 | F16 | 229 | 390 |

| 600 | 24″ | 690 | 484 | 60 | 815 | 780 | 840 | 845 | 55 | F25 | 267 | 565 |

| 700 | 28″ | 720 | 525 | 130 | 925 | 895 | 910 | 960 | 80 | F30 | 292 | |

| 750 | 30″ | 750 | 550 | 130 | 985 | 80 | F30 | 318 | ||||

| 800 | 32″ | 760 | 600 | 130 | 1060 | 1015 | 1025 | 1085 | 98 | F30 | 318 | |

| 900 | 36″ | 795 | 660 | 150 | 1170 | 1115 | 1125 | 1185 | 120 | F35 | 330 | |

| 1000 | 40″ | 815 | 720 | 180 | 1290 | 1230 | 1255 | 1320 | 130 | F35 | 410 | |

| 1050 | 42″ | 850 | 750 | 180 | 1345 | 150 | F35 | 410 | ||||

| 1200 | 48″ | 995 | 825 | 200 | 1510 | 1455 | 1485 | 180 | F40 | 470 | ||

| SIZE | A | B | C | D | E | Top Flange | L | WT(kg) | ||

| Class300 | PN40 | |||||||||

| DN | INCH | Class300,PN40 | ||||||||

| 80 | 3″ | 260 | 100 | 17.5 | 210 | 200 | 14 | F07 | 180 | 30 |

| 100 | 4″ | 290 | 124 | 17.5 | 255 | 235 | 14 | F07 | 190 | 40 |

| 125 | 5″ | 330 | 144 | 18.5 | 280 | 270 | 17 | F10 | 200 | 60 |

| 150 | 6″ | 350 | 150 | 24.5 | 320 | 300 | 22 | F10 | 210 | 75 |

| 200 | 8″ | 415 | 204 | 30 | 380 | 375 | 27 | F12 | 230 | 115 |

| 250 | 10″ | 455 | 238 | 39 | 445 | 450 | 36 | F14 | 250 | 170 |

| 300 | 12″ | 490 | 268 | 39 | 520 | 515 | 36 | F14 | 270 | 170 |

| 350 | 14″ | 545 | 294 | 49 | 585 | 580 | 46 | F16 | 290 | 315 |

| 400 | 16″ | 575 | 320 | 60 | 650 | 660 | 55 | F25 | 310 | 415 |

| 450 | 18″ | 660 | 341 | 60 | 710 | 685 | 55 | F25 | 330 | 490 |

| 500 | 20″ | 700 | 383 | 80 | 775 | 755 | 75 | F30 | 350 | 600 |

| 600 | 24″ | 785 | 442 | 80 | 915 | 890 | 75 | F30 | 390 | 900 |

| 700 | 28″ | 800 | 590 | 150 | 1035 | 120 | F35 | 430 | ||

| 750 | 30″ | 830 | 600 | 180 | 1090 | 130 | F35 | 450 | ||

| 800 | 32″ | 860 | 720 | 200 | 1150 | 170 | F40 | 470 | ||

| 900 | 36″ | 940 | 780 | 200 | 1270 | 180 | F40 | 510 | ||

| 1000 | 40″ | 910 | 750 | 250 | 1240 | 200 | F48 | 550 | ||

| 1050 | 42″ | 950 | 800 | 250 | 1290 | 210 | F48 | 570 | ||

| 1200 | 48″ | 1000 | 850 | 250 | 1465 | 220 | F48 | 630 | ||

| SIZE | A | B | C | D | E | Top Flange | L | WT(kg) | |||

| Class600 | PN63 | PN100 | |||||||||

| DN | INCH | Class600,PN63,PN100 | |||||||||

| 80 | 3″ | 260 | 145 | 17.5 | 210 | 215 | 230 | 14 | F07 | 180 | 50 |

| 100 | 4″ | 298 | 185 | 24.5 | 275 | 250 | 265 | 22 | F10 | 190 | 70 |

| 125 | 5″ | 400 | 200 | 30 | 330 | 295 | 315 | 27 | F12 | 200 | 90 |

| 150 | 6″ | 420 | 216 | 39 | 355 | 345 | 355 | 36 | F14 | 210 | 125 |

| 200 | 8″ | 445 | 265 | 39 | 420 | 415 | 430 | 36 | F14 | 230 | 200 |

| 250 | 10″ | 505 | 315 | 49 | 510 | 470 | 505 | 46 | F16 | 250 | 315 |

| 300 | 12″ | 600 | 362 | 49 | 560 | 530 | 585 | 46 | F16 | 270 | 435 |

| 350 | 14″ | 610 | 390 | 60 | 605 | 600 | 655 | 55 | F25 | 290 | 485 |

| 400 | 16″ | 680 | 440 | 60 | 685 | 670 | 55 | F25 | 310 | 685 | |

| 450 | 18″ | 683 | 460 | 80 | 745 | 75 | F30 | 330 | 815 | ||

| 500 | 20″ | 795 | 526 | 80 | 815 | 75 | F30 | 350 | 1050 | ||

| 600 | 24″ | 885 | 623 | 940 | F35 | 390 | 1600 | ||||

| 700 | 28″ | ||||||||||

| 750 | 30″ | ||||||||||

| 800 | 32″ | ||||||||||

| 900 | 36″ | ||||||||||

| 1000 | 40″ | ||||||||||

| 1050 | 42″ | ||||||||||

| 1200 | 48″ | ||||||||||

Triple Offset Butterfly Valves

Gain a comprehensive understanding of the Triple Offset Butterfly Valves by watching our informative video. Discover its intricate inner workings and see how it operates with precision and efficiency.

FAQs

What is a triple offset butterfly valve?

A triple offset butterfly valve, an innovation in valve technology, is a highly engineered product designed with three distinct offsets to overcome the limitations of traditional butterfly valves. These offsets serve to eliminate friction, increase lifespan, and provide a tighter seal, reinforcing our commitment to quality control and exceptional performance.

The first offset involves the placement of the shaft behind the disc, allowing for a complete 360-degree rotation. This design reduces wear and tear on the valve seat and disc, enhancing longevity and reliability.

The second offset pertains to the eccentric mounting of the shaft in relation to the valve centerline. This creates a cam-like action during valve operation, ensuring a frictionless seal-to-seat contact when the valve is closed.

The third offset, a unique feature of this valve type, introduces a conical profile to the seating surface. This geometric modification allows for a tight, bubble-proof seal that can withstand high pressures and temperatures, making these valves especially suited for stringent applications in industries like oil and gas, power generation, and chemical processing.

How does a triple offset butterfly valve work?

To understand how this valve works, it’s crucial to have a basic understanding of its structure. The triple offset butterfly valve consists of three key components: the body, disc, and actuator. The body is responsible for housing the internal workings of the valve while providing a sealed enclosure for fluid flow. The disc acts as the regulating element that controls the opening or closing of the valve based on external commands from an actuator.

Now let’s dive into how this innovative technology operates. Unlike traditional valves with simple circular discs that rotate around a central axis to control flow, a triple offset butterfly valve has three separate offsets or eccentricities – hence its name. This means that when closing or opening the valve, instead of simply rotating on one axis like traditional valves do, it also moves along two other axes simultaneously.

The difference between triple offset and double eccentric butterfly valves

Triple offset butterfly valves, also known as triple eccentric or triple offset disc (TOD), are designed with a metal-to-metal seating configuration instead of the traditional elastomer seat used in other butterfly valves. This advanced sealing mechanism offers numerous benefits such as bubble-tight shut-off, resistance to high temperatures and pressures, and increased durability.

Furthermore, unlike other butterfly valves that use a circular or conical disc shape to regulate flow, the TOD has an asymmetrically shaped disc with three distinct offsets – shaft offset (the axis of rotation is not aligned with the pipe centerline), cone axis offset (the cone does not exist on the central axis), and sealing surface offset (non-concentric seat). The combination of these offsets enables a “scraping” effect during valve operation that promotes self-cleaning of any debris build-up on the seat.

On the other hand, double eccentric butterfly valves only have two offsets (shaft and cone) while maintaining concentric seating surfaces. These types of valves are commonly used for applications where tight shut-off is not critical but still require excellent control over flow rates.

What medium conditions are triple eccentric used for?

The unique design of triple eccentric valves allows them to handle high pressure and temperature applications efficiently while maintaining tight shut-off capabilities. Unlike traditional gate or globe valves which use a wedge or disk seating mechanism resulting in significant friction during operation, the triple eccentric valve utilizes an off-center shaft with three offsets – the first for sealing against line pressure, the second for reducing operating torque, and the third for eliminating seat wear. This unparalleled feature not only decreases mechanical stress on the valve but also reduces maintenance costs over time.

1) High Pressure Applications: In industries where high-pressure systems are involved such as offshore drilling platforms or natural gas pipelines, using standard gate or butterfly valves can be problematic due to their susceptibility to cavitation (the formation and collapse of vapor bubbles). The triple offset design helps eliminate cavitation by allowing fluid flow directly through its body without any obstructions.

2) High-Temperature Services: Triple offset valves can withstand extreme temperatures up to 1000°C due to their metal-to-metal sealing capability. This makes them ideal for applications involving steam lines in power plants or hot fluids in petrochemical plants.

-150x150.jpg)