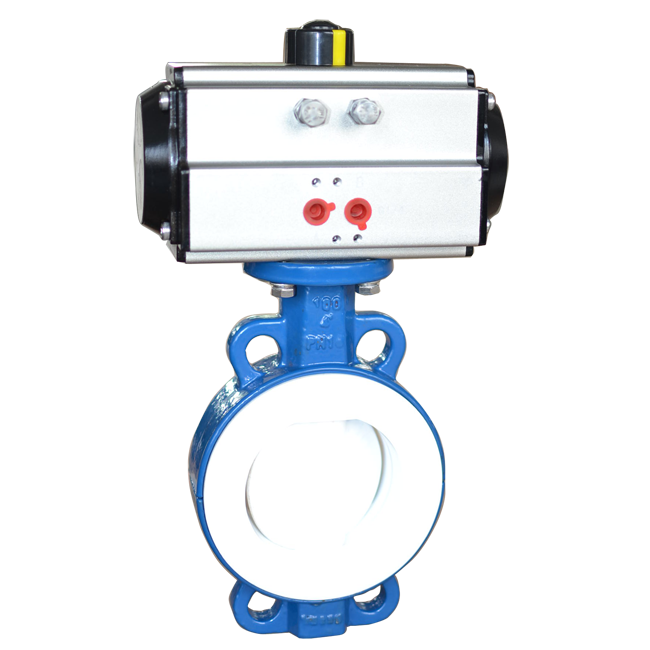

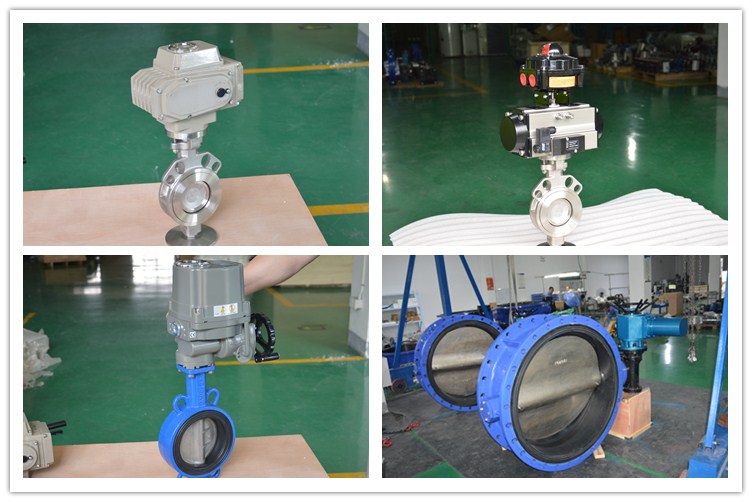

Wafer style butterfly valve

Wafer butterfly valves provide the perfect solution for controlling, throttling or shut off of fluids in any application. This type of wafer type butterfly valve is lightweight, compact and designed to fit between flanges with two-piece body construction, making it easily interchangeable with other types of valves without extensive rework. The unique design features a double-latched seal which allows very high flow rates and minimal pressure loss while also providing excellent sealing performance. The disc is connected to a stem on one side and can rotate around its axis allowing for precise control over the flow rate. Butterfly valve wafer type manufacturers Available in the following sizes: 2inch,3 inch,4 inch,5 inch, 6 inch, 8 inch, wafer valve and 60 inch butterfly valve. Wafer style butterfly valve are also highly reliable and require minimal maintenance, making them an efficient and cost-effective choice when compared to other types of valves available on the market today. Whether you need to regulate pressure or just shut off fluid flow in your system, investing in a quality wafer valves is the best long-term solution you can make.

Application of wafer butterfly valve

The application of our wafer butterfly valves transcends a broad spectrum of industries, each with its unique set of demands and regulatory requirements. These precision-engineered valves serve as critical components in systems where flow control is paramount,

- HVAC Systems: Leveraging advanced sealing technologies and robust construction

- Water Treatment: In the sphere of water treatment and distribution, our butterfly valves play a pivotal role in managing flow rates and pressures

- Marine: The marine industry, with its harsh operating environments and stringent safety norms, relies on our wafer butterfly valves for their corrosion-resistant materials and design versatility, ensuring seamless flow control in ballast water systems, EGCS

- Chemical Processing: Our ptfe butterfly valve address the chemical industry's need for leak-proof, corrosion-resistant flow control solutions, capable of withstanding aggressive substances and varying temperatures

- Petroleum Refining: In the petroleum sector, our wafer butterfly valves are integral to the intricate networks of pipelines and processing units, offering unmatched durability and control in oil and gas transfer, refining processes, and storage operations.

- Power Plants: Power generation facilities depend on our High performance butterfly valve for controlling the flow of steam, water, and other fluids, ensuring uninterrupted power supply and operational safety in cooling systems

- Food & Beverage Industry: Our Sanitary butterfly valve are designed to comply with the highest standards of hygiene and safety, essential for the food and beverage sector, ensuring precise control and contamination-free handling of liquids and semi-solids.

- Paper Manufacturing: In the paper production industry, our valves contribute to efficient water, pulp, and chemical management, supporting the complex processes involved in paper manufacturing with solutions that emphasize durability and precision.

- Our wafer butterfly valves stand as a testament to our global reach and areas of expertise in the valve manufacturing industry. Our relentless pursuit of excellence

What are the flange standards for butterfly valves?

-

- ANSI Class 125 B16.1

- ANSI Class 150 B16.5,B16.47

- EN PN6 1092-1.1092-2

- EN PN10 1092-1,1092-2

- EN PN16 1092-1,1092-2

- JIS 5K B2211

- JIS 10K B2212

- JIS 16K B2213

PN10 PN16 valve flange size

| NPS | DN | OD | PCB | Bolt | n-bolt |

| 3/8 | DN10 | 90 | 60 | 14 | 4 |

| 1/2 | DN15 | 95 | 65 | 14 | 4 |

| 3/4 | DN20 | 105 | 75 | 14 | 4 |

| 1 | DN25 | 115 | 85 | 14 | 4 |

| 11/4 | DN32 | 140 | 100 | 18 | 4 |

| 11/2 | DN40 | 150 | 110 | 18 | 4 |

| 2 | DN50 | 165 | 125 | 18 | 4 |

| 21/2 | DN65 | 185 | 145 | 18 | 8 |

| 3 | DN80 | 200 | 160 | 18 | 8 |

| 4 | DN100 | 220 | 180 | 18 | 8 |

| 5 | DN125 | 250 | 210 | 18 | 8 |

| 6 | DN150 | 285 | 240 | 22 | 8 |

| 8 | DN200 | 340 | 295 | 22 | 8 |

| 10 | DN250 | 395 | 350 | 22 | 12 |

| 12 | DN300 | 445 | 400 | 22 | 12 |

| 14 | DN350 | 505 | 460 | 22 | 16 |

| 16 | DN400 | 565 | 515 | 26 | 16 |

| 18 | DN450 | 615 | 565 | 26 | 20 |

| 20 | DN500 | 670 | 620 | 26 | 20 |

| 24 | DN600 | 780 | 725 | 30 | 20 |

| 28 | DN700 | 895 | 840 | 30 | 24 |

| 32 | DN800 | 1015 | 950 | 33 | 24 |

| 36 | DN900 | 1115 | 1050 | 33 | 28 |

| 40 | DN1000 | 1230 | 1160 | 36 | 28 |

| 48 | DN1200 | 1455 | 1380 | 39 | 32 |

| 56 | DN1400 | 1675 | 1590 | 42 | 36 |

| 64 | DN1600 | 1915 | 1820 | 48 | 40 |

| 72 | DN1800 | 2115 | 2020 | 48 | 44 |

| 80 | DN2000 | 2325 | 2230 | 48 | 48 |

| NPS | DN | OD | PCB | Bolt | n-bolt |

| 3/8 | DN10 | 90 | 60 | 14 | 4 |

| 1/2 | DN15 | 95 | 65 | 14 | 4 |

| 3/4 | DN20 | 105 | 75 | 14 | 4 |

| 1 | DN25 | 115 | 85 | 14 | 4 |

| 11/4 | DN32 | 140 | 100 | 18 | 4 |

| 11/2 | DN40 | 150 | 110 | 18 | 4 |

| 2 | DN50 | 165 | 125 | 18 | 4 |

| 21/2 | DN65 | 185 | 145 | 18 | 8 |

| 3 | DN80 | 200 | 160 | 18 | 8 |

| 4 | DN100 | 220 | 180 | 18 | 8 |

| 5 | DN125 | 250 | 210 | 18 | 8 |

| 6 | DN150 | 285 | 240 | 22 | 8 |

| 8 | DN200 | 340 | 295 | 22 | 12 |

| 10 | DN250 | 405 | 355 | 26 | 12 |

| 12 | DN300 | 460 | 410 | 26 | 12 |

| 14 | DN350 | 520 | 470 | 26 | 16 |

| 16 | DN400 | 580 | 525 | 30 | 16 |

| 18 | DN450 | 640 | 585 | 30 | 20 |

| 20 | DN500 | 715 | 650 | 33 | 20 |

| 24 | DN600 | 840 | 770 | 36 | 20 |

| 28 | DN700 | 910 | 840 | 36 | 24 |

| 32 | DN800 | 1025 | 950 | 39 | 24 |

| 36 | DN900 | 1125 | 1050 | 39 | 28 |

| 40 | DN1000 | 1255 | 1170 | 42 | 28 |

| 48 | DN1200 | 1485 | 1390 | 48 | 32 |

| 56 | DN1400 | 1685 | 1590 | 48 | 36 |

| 64 | DN1600 | 1930 | 1820 | 56 | 40 |

| 72 | DN1800 | 2130 | 2020 | 56 | 44 |

| 80 | DN2000 | 2345 | 2230 | 62 | 48 |

ASME ANSI CLASS 150LB flange size

| NPS | DN | OD | PCB | Bolt | n-bolt |

| 1/2 | DN15 | 89 | 60.5 | 16 | 4 |

| 3/4 | DN20 | 99 | 69.8 | 16 | 4 |

| 1 | DN25 | 108 | 79.2 | 16 | 4 |

| 11/4 | DN32 | 117 | 88.9 | 16 | 4 |

| 11/2 | DN40 | 127 | 98.6 | 16 | 4 |

| 2 | DN50 | 152 | 120.6 | 19 | 4 |

| 21/2 | DN65 | 178 | 139.7 | 19 | 4 |

| 3 | DN80 | 190 | 152.4 | 19 | 4 |

| 31/2 | (DN90) | 216 | 177.8 | 19 | 8 |

| 4 | DN100 | 229 | 190.5 | 19 | 8 |

| 5 | DN125 | 254 | 215.9 | 22.5 | 8 |

| 6 | DN150 | 279 | 241.3 | 22.5 | 8 |

| 8 | DN200 | 343 | 298.4 | 22.5 | 8 |

| 10 | DN250 | 406 | 362 | 25.5 | 12 |

| 12 | DN300 | 483 | 431.8 | 25.5 | 12 |

| 14 | DN350 | 533 | 476.2 | 28.5 | 12 |

| 16 | DN400 | 597 | 539.8 | 28.5 | 16 |

| 18 | DN450 | 635 | 577.8 | 32 | 16 |

| 20 | DN500 | 693 | 635 | 32 | 20 |

| 22 | (DN550) | 749 | 692.2 | 35 | 20 |

| 24 | DN600 | 813 | 749.3 | 35 | 20 |

JIS 10k butterfly valve flange size

| NPS | DN | OD | PCB | Bolt | n-bolt |

| 3/8 | DN10 | 90 | 65 | 15 | 4 |

| 1/2 | DN15 | 95 | 70 | 15 | 4 |

| 3/4 | DN20 | 100 | 75 | 15 | 4 |

| 1 | DN25 | 125 | 90 | 19 | 4 |

| 11/4 | DN32 | 135 | 100 | 19 | 4 |

| 11/2 | DN40 | 140 | 105 | 19 | 4 |

| 2 | DN50 | 155 | 120 | 19 | 4 |

| 21/2 | DN65 | 175 | 140 | 19 | 4 |

| 3 | DN80 | 185 | 150 | 19 | 8 |

| 31/2 | (DN90) | 195 | 160 | 19 | 8 |

| 4 | DN100 | 210 | 175 | 19 | 8 |

| 5 | DN125 | 250 | 210 | 23 | 8 |

| 6 | DN150 | 280 | 240 | 23 | 8 |

| 7 | (DN175) | 305 | 265 | 23 | 12 |

| 8 | DN200 | 330 | 290 | 23 | 12 |

| 9 | (DN225) | 350 | 310 | 23 | 12 |

| 10 | DN250 | 400 | 355 | 25 | 12 |

| 12 | DN300 | 445 | 400 | 25 | 16 |

| 14 | DN350 | 490 | 445 | 25 | 16 |

| 16 | DN400 | 560 | 510 | 27 | 16 |

| 18 | DN450 | 620 | 565 | 27 | 20 |

| 20 | DN500 | 675 | 620 | 27 | 20 |

| 22 | (DN550) | 745 | 680 | 33 | 20 |

| 24 | DN600 | 795 | 730 | 33 | 24 |

| 26 | (DN650) | 845 | 780 | 33 | 24 |

| 28 | DN700 | 905 | 840 | 33 | 24 |

| 30 | (DN750) | 970 | 900 | 33 | 24 |

| 32 | DN800 | 1020 | 950 | 33 | 28 |

| 34 | (DN850) | 1070 | 1000 | 33 | 28 |

| 36 | DN900 | 1120 | 1050 | 33 | 28 |

| 40 | DN1000 | 1235 | 1160 | 39 | 28 |

| 44 | DN1100 | 1345 | 1270 | 39 | 28 |

| 48 | DN1200 | 1465 | 1380 | 39 | 32 |

What parameters need to be provided to buy a butterfly valve?

When looking to buy a wafer butterfly valves, there are a few important parameters that you should keep in mind. The first parameter is the size of the valve. Depending on the application, you'll need to specify how big or small it needs to be. This will determine how much flow can pass through it and also affect its weight and ease of installation.

The second important parameter is butterfly valve torque rating, which determines how much pressure it can handle without malfunctioning or becoming damaged. It's typically measured in Newton-metres (Nm) so make sure you know exactly what level of torque your specific application requires before buying.

Thirdly, consider materials used for construction as they determine strength, durability and corrosion resistance of the butterfly valve this makes stainless steel butterfly valve a popular choice since it will last longer under harsher conditions than plastic butterfly valve would endure. Lastly, think about operational temperature ranges when selecting a butterfly valve since extreme temperatures may require specialised materials for maximum performance and longevity.

Which is better wafer or lugged butterfly valve?

When selecting any type of valve for a specific application, it is important to consider the size and pressure rating requirements of the system. In general, wafer butterfly valves are used when reduced weight and cost are desired while lugged butterfly valves provide enhanced structural integrity. The primary difference between wafer and lugged butterfly valves is that the lugged design has two sets of bolts attaching each side of the valve body to its companion flanges, whereas a wafer design typically utilizes only one set of bolts affixed on either side.

Wafer butterfly valves are lighter, lower in cost and easier to install than their lugged counterpart due to their simpler design which requires fewer components (just halves). This makes them ideal when quick installation or replacement times need to be met or if space availability is limited as they can be installed into very tight spaces without having to install additional gaskets/seals. Wafers have been known to cause higher levels of vibration due mainly to their weaker housing compared with lugs which often require extra supports or braces against high pressures.. Additionally, because a wafer relies on just one set of bolts rather than two like an ISO / Lug Butterfly style does there’s an increased risk for leakage at pipe connections if not fastened properly or using suitable grades/types of mounting nuts & washers etc..

What is a wafer type butterfly valve installed?

A wafer type butterfly valve is a quarter turn rotary valve that is typically used to control and isolate mediums such as air, gas, steam, water, oil and other liquids. It consists of a circular disc mounted onto a shaft which is in the centre of the body. The disc can rotate 90 degrees from open to closed positions depending on the direction of flow. The wafer style butterfly valve not only acts as an isolation device but also provides some throttling action due to its semi-lunar shape design.

Wafer type butterfly valves are installed between two flanged pipe fittings by bolting it directly into them using four stud bolts or lag screws in accordance with ANSI/ASME B16.5 standards for pipe flanges and standard pressure ratinigs (ANSI Class 150/300). In order to achieve a leak-proof seal between the mating flanges, two flat gaskets are inserted between them which must be rated for pressures above those expected in operation.