In the world of fluid control systems, the choice of valve type is crucial for ensuring efficient and reliable operations. One such option is the motorized butterfly valve, which offers automation and ease of use in various applications across multiple industries. However, understanding the costs associated with different valve types is essential when making informed decisions about which solution best suits your needs. In this blog post, we will delve into the price comparison between motorized butterfly valves and other conventional methods, examining the factors that influence their costs and discussing when each valve type might be the most cost-effective choice.

Introduction

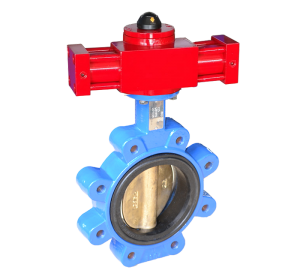

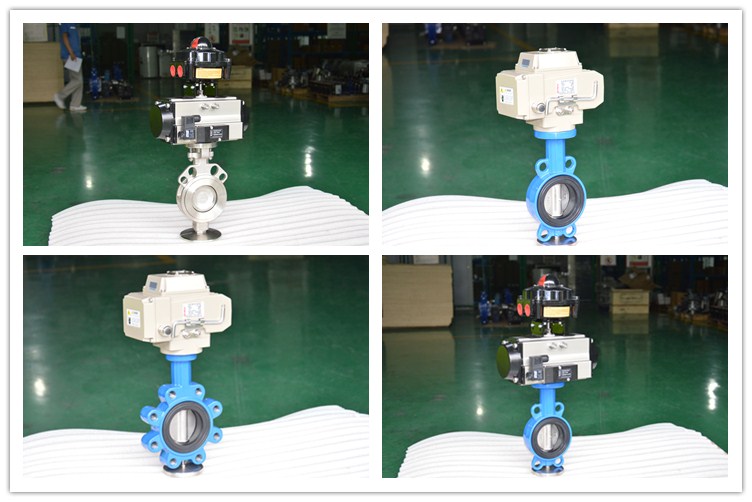

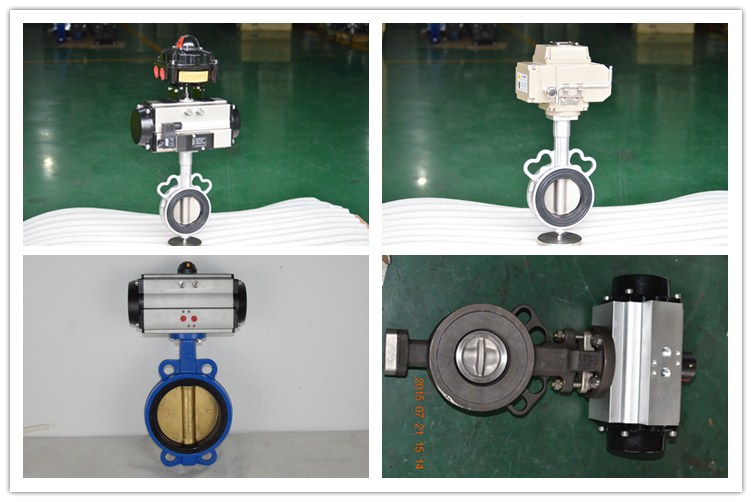

When comparing the price of a electric butterfly valve to other conventional methods, it is essential to consider several factors that contribute to the overall cost of each valve type. Motorized butterfly valves, which consist of a disc mounted on a rotating shaft and an electric motor for automation, are known for their ease of operation, reduced maintenance requirements, and suitability for various industries such as water treatment, oil and gas, and HVAC systems. However, the initial cost of a motorized butterfly valve can be higher than that of other conventional valves like gate, ball, or globe valves due to the added expense of the motor and electronic components. To make a fair comparison, one must also take into account the materials used in constructing the valve, the size, brand, and additional features such as pressure ratings and flow control capabilities. In some cases, the long-term benefits of a motorized butterfly valve, such as reduced labor costs, increased efficiency, and lower maintenance expenses, may outweigh the higher upfront cost compared to other valve types. On the other hand, for applications where automation is not critical or a power source is unavailable, a more traditional valve type might prove to be more cost-effective. Ultimately, the most suitable valve choice depends on the specific needs and requirements of the application, with careful consideration of both the short-term and long-term costs associated with each option.

Briefly introduce motorized butterfly valve ราคา and their applications

motorized butterfly valve price are an innovative solution for controlling the flow of fluids in various systems, offering automated operation and precise flow regulation. These valves consist of a disc mounted on a rotating shaft, which is actuated by an electric motor to open or close the valve as needed. Motorized butterfly valves have become increasingly popular in a wide range of industries due to their efficiency, reliability, and ease of use. Some common applications include water treatment plants, oil and gas pipelines, HVAC systems, and chemical processing facilities. By automating the flow control process, motorized butterfly valves not only reduce labor costs but also enhance system performance, making them a valuable addition to many fluid control systems.

Explain the importance of understanding the costs associated with different valve types

Understanding the costs associated with different valve types is crucial for making informed decisions when designing and implementing fluid control systems. The choice of a valve impacts not only the initial investment but also the long-term operational expenses, such as maintenance, replacement, and energy consumption. By evaluating the costs associated with various valve types, businesses can optimize their systems for maximum efficiency and cost-effectiveness, ultimately contributing to their bottom line. Moreover, a comprehensive understanding of the costs involved allows for better budgeting, planning, and resource allocation, ensuring that projects stay on track and deliver the desired results. In addition, comparing the costs of different valve types helps identify the most suitable solution for specific applications, taking into account factors such as flow control requirements, pressure ratings, and environmental conditions. This enables businesses to strike the perfect balance between performance, reliability, and cost, ultimately leading to more sustainable and efficient fluid control systems.

State the goal of the blog post: to compare the price of motorized butterfly valve ราคา with other conventional methods

The primary objective of this blog post is to provide a comprehensive comparison of the costs associated with motorized butterfly valves and other conventional valve types. By examining various factors influencing the price, such as materials, size, brand, and additional features, we aim to offer valuable insights that will help readers make informed decisions when selecting the most appropriate valve solution for their specific applications. Through a detailed analysis of the advantages and disadvantages of motorized butterfly valves, as well as a thorough examination of their price in relation to other conventional methods, we hope to equip our readers with the knowledge necessary to optimize their fluid control systems for maximum efficiency and cost-effectiveness. Ultimately, our goal is to empower businesses to make well-informed choices that best align with their unique requirements and budgetary constraints, ensuring the successful implementation of reliable and efficient fluid control solutions.

What is a motorized butterfly valve ราคา?

A motorized butterfly valve price list is a type of flow control device that integrates an electric motor to automate the operation of the valve, allowing for precise and efficient regulation of fluid flow in various systems. The primary components of a motorized butterfly valve include a disc mounted on a rotating shaft and an actuator, which houses the electric motor responsible for turning the shaft. As the motor rotates the shaft, the disc inside the valve either opens or closes, controlling the flow of fluid through the pipeline. This automated operation enables accurate flow regulation with minimal manual intervention, resulting in reduced labor costs and increased system efficiency. Motorized butterfly valves are widely used across numerous industries, such as water treatment plants, oil and gas pipelines, HVAC systems, and chemical processing facilities, where they provide reliable and consistent flow control for a diverse range of fluids. Their compact design, ease of installation, and low maintenance requirements make motorized butterfly valves an attractive option for many applications, particularly those that demand automation and precise flow management. In summary, motorized butterfly valves are advanced flow control devices that offer enhanced efficiency, reliability, and versatility, making them a popular choice for a wide variety of industries and applications.

Describe the basic structure and function of a butterfly valve

A butterfly valve is a flow control device that features a simple yet effective design, consisting primarily of a circular disc mounted on a rotating shaft within a pipe or duct. The basic function of a butterfly valve is to regulate the flow of fluids, such as liquids, gases, or semi-solids, by adjusting the position of the disc. When the disc is aligned parallel to the direction of fluid flow, the valve is fully open, allowing maximum flow through the pipeline. Conversely, when the disc is rotated perpendicular to the flow, the valve is closed, effectively blocking the passage of fluid. The shaft can also be positioned at various angles between the open and closed positions to achieve precise control over the flow rate. Butterfly valves are known for their compact design, ease of operation, and relatively low cost, making them a popular choice for a wide range of applications across multiple industries, including water treatment, oil and gas, power generation, and chemical processing.

Explain the role of the motor in automating the valve’s operation

The motor plays a pivotal role in automating the operation of a butterfly valve by providing the necessary torque to rotate the shaft and control the position of the disc within the valve. The electric motor, housed within the actuator, receives signals from a control system or a remote operator, which dictates the desired degree of valve opening or closing. Upon receiving these commands, the motor rotates the shaft, causing the disc to either open or close, thereby regulating the flow of fluid through the pipeline. This automated operation allows for precise and efficient flow control without the need for manual intervention. Additionally, it enables real-time adjustments and fine-tuning of fluid flow rates in response to changing system conditions or requirements. By automating the valve’s operation, the motor not only enhances system efficiency and performance but also reduces labor costs and the potential for human error, making motorized butterfly valves a valuable addition to various fluid control applications across numerous industries.

List some common industries and applications that use motorized butterfly valve ราคา

motor operated butterfly valve have found widespread use across a diverse range of industries and applications, thanks to their efficiency, reliability, and ease of automation. One common industry where these valves are utilized is water treatment, where they help regulate the flow of water in processes such as filtration, distribution, and wastewater management. In the oil and gas sector, motorized butterfly valves are employed to control the flow of crude oil, natural gas, and various petrochemical products through pipelines and processing facilities. HVAC systems often rely on these valves to manage the circulation of air, heating, and cooling fluids, ensuring optimal indoor climate control in residential, commercial, and industrial settings. Chemical processing plants use motorized butterfly valves to handle the flow of corrosive and hazardous chemicals with precision and safety. Additionally, power generation facilities, including nuclear, hydroelectric, and thermal power plants, incorporate motorized butterfly valves to manage fluid flow in critical processes, such as steam generation and cooling systems. In summary, the versatility and performance of motorized butterfly valves make them a preferred choice for numerous applications across a wide array of industries.

Comparison of motorized butterfly valve ราคา and Other Conventional Valves

Motorized butterfly valves offer several advantages over other conventional valve types, making them an attractive choice for a wide range of applications. One key benefit is the automation provided by the integrated electric motor, which enables precise and efficient flow control without the need for manual intervention. This automation not only reduces labor costs but also increases system reliability and responsiveness, allowing for real-time adjustments to fluid flow based on changing conditions or requirements. In contrast, conventional valves such as gate or globe valves often require manual operation or additional components for automation, potentially increasing complexity and maintenance needs.

Another advantage of motorized butterfly valves is their compact design, which makes them ideal for installations with limited space. Their streamlined structure allows for easy installation and reduced weight compared to other valve types, such as ball or diaphragm valves, which may have more complex designs and larger footprints. Furthermore, butterfly valves typically exhibit lower pressure drops and higher flow capacities than many conventional valves, ensuring optimal system performance and efficiency.

Motorized butterfly valves are also known for their versatility, as they can handle a wide variety of fluids, including liquids, gases, and semi-solids, across a broad range of temperatures and pressures. This adaptability makes them suitable for numerous industries and applications, as mentioned earlier. On the other hand, some conventional valves may have limitations in terms of the types of fluids they can effectively manage or the operating conditions they can withstand.

However, it is essential to note that motorized butterfly valves may not be the ideal solution for every application. For instance, they may not provide the same level of tight sealing as some other valve types, which could be crucial in specific high-pressure or hazardous fluid applications. Additionally, the initial cost of motorized butterfly valves may be higher than that of traditional manual valves due to the inclusion of the electric motor and actuator. Nonetheless, the long-term benefits of automation, reduced maintenance, and improved efficiency often outweigh the initial investment, making motorized butterfly valves a cost-effective option in many cases.

In conclusion, when comparing motorized butterfly valves to other conventional valve types, it is essential to consider factors such as automation, space constraints, fluid compatibility, and overall system performance. While motorized butterfly valves offer numerous advantages, it is crucial to carefully evaluate the specific requirements of each application to determine the most suitable valve solution.

Introduce the most common types of conventional valves (e.g., gate valves, ball valves, globe valves, etc.)

Conventional valves come in various types, each serving a specific purpose and offering unique advantages depending on the application. Some of the most common types include gate valves, ball valves, globe valves, and diaphragm valves. Gate valves are widely used in systems requiring an on-off control mechanism, with their primary function being to either fully open or close the fluid flow path. Ball valves, known for their quick operation and tight sealing, use a rotating ball with a bore to regulate fluid flow and are commonly employed in high-pressure applications. Globe valves, characterized by their spherical body and linear motion, excel at throttling and flow regulation, making them ideal for situations that demand precise control over fluid flow rates. Diaphragm valves, which utilize a flexible diaphragm to control flow, are particularly suitable for handling corrosive, abrasive, or viscous fluids, as well as those containing suspended solids. Each of these conventional valve types offers distinct benefits and limitations, and selecting the most appropriate valve depends on factors such as the nature of the fluid, operating conditions, and specific system requirements.

Provide a brief description of each valve type

Gate valves are characterized by their simple design, consisting of a sliding gate that moves perpendicular to the flow direction to either open or close the valve. They are primarily used for on-off control in systems where minimal flow resistance is desired, and are not well-suited for throttling purposes due to potential erosion and vibration issues.

Ball valves feature a spherical ball with a bore through its center, which rotates 90 degrees to align or block the fluid flow path. Known for their quick operation, tight sealing, and durability, ball valves are commonly employed in high-pressure applications and can handle a wide range of fluids, including gases, liquids, and slurries.

Globe valves consist of a movable disc or plug that regulates fluid flow by moving linearly towards or away from a stationary seat, altering the flow area. With their excellent throttling capabilities and precise flow control, globe valves are widely used in applications that require accurate regulation of flow rates, such as steam systems and chemical processing plants.

Diaphragm valves use a flexible diaphragm, typically made of elastomeric materials, to modulate fluid flow by deforming in response to an external force. The diaphragm’s flexibility and its ability to isolate the fluid from the valve’s other components make it particularly suitable for handling corrosive, abrasive, or viscous fluids, as well as those containing suspended solids.

Each valve type serves specific purposes and offers unique advantages depending on the application, with factors such as fluid characteristics, operating conditions, and system requirements playing a crucial role in determining the most suitable valve choice.

Discuss the key differences and similarities between motorized butterfly valve ราคา and other conventional valves

Motorized butterfly valves and other conventional valves, such as gate, ball, globe, and diaphragm valves, share the fundamental purpose of controlling fluid flow within a system. However, they exhibit key differences in design, operation, and suitability for various applications. One significant distinction is the level of automation; motorized butterfly valves incorporate an electric motor to automate valve operation, enabling precise and efficient flow control without manual intervention. In contrast, conventional valves often require manual operation or additional actuator components for automation.

Design-wise, motorized butterfly valves are known for their compact and streamlined structure, which allows for easy installation and reduced weight. This feature contrasts with some conventional valves, such as ball or globe valves, that may have more complex designs and larger footprints. Butterfly valves typically offer lower pressure drops and higher flow capacities than many conventional valves, ensuring optimal system performance and efficiency.

In terms of similarities, both motorized butterfly valves and other conventional valves are designed to handle a wide variety of fluids, including liquids, gases, and semi-solids, across a broad range of temperatures and pressures. However, the specific fluid compatibility and operating conditions may vary depending on the valve type and materials used, making it essential to carefully assess each application’s requirements.

A notable difference lies in the sealing capabilities of these valves. While motorized butterfly valves offer reliable sealing in most applications, they may not provide the same level of tight sealing as some other valve types, such as ball valves, in high-pressure or hazardous fluid applications.

Overall, the key differences and similarities between motorized butterfly valves and other conventional valves lie in their design, automation, fluid handling capabilities, and sealing properties. Selecting the most appropriate valve solution depends on factors such as the nature of the fluid, operating conditions, and specific system requirements.

Factors Influencing the Price of Valves

Several factors influence the price of valves, including the materials used, valve type, size, design complexity, and additional features or customization. Material selection plays a significant role in determining the cost, as different materials offer varying levels of durability, corrosion resistance, and compatibility with specific fluids. Commonly used materials for valve construction include brass, bronze, stainless steel, and various plastic polymers, each with different price points and performance characteristics. For instance, stainless steel valves may come at a higher price due to their enhanced corrosion resistance and strength but can be more cost-effective in the long run for aggressive or corrosive fluid applications.

The type and design complexity of the valve also impact the price, with some valve types, such as ball or globe valves, generally being more expensive than others due to their intricate internal mechanisms and higher sealing capabilities. Larger valves typically cost more than smaller ones due to the increased material and manufacturing requirements. Additionally, specialized designs or features, such as high-pressure ratings, cryogenic capabilities, or custom sizing, can contribute to increased costs.

Automation is another factor that can influence valve pricing, as motorized or actuated valves often come at a higher initial cost compared to manual valves. However, the long-term benefits of automation, such as reduced labor costs, improved efficiency, and better system control, can offset the higher upfront investment, making automated valves a cost-effective choice in many cases.

Quality and certification standards also play a role in determining valve prices. Valves that meet industry-specific certifications or undergo rigorous testing and quality control processes may command higher prices, but they usually offer better performance, reliability, and safety, reducing the likelihood of failure and associated maintenance costs.

Lastly, the manufacturer’s reputation and after-sales support can influence valve pricing, as well-established brands with strong customer support networks may charge a premium for their products. While it may be tempting to opt for lower-priced valves, it is crucial to consider factors such as performance, reliability, compatibility, and long-term costs to ensure the most cost-effective and suitable valve choice for a given application.

List the main factors that affect the price of valves, such as materials, size, brand, and additional features

The price of valves is influenced by several key factors, including materials, size, brand reputation, and additional features or customization. Material selection plays a crucial role in determining cost, as different materials like brass, bronze, stainless steel, and plastic polymers offer varying levels of durability, corrosion resistance, and compatibility with specific fluids, each at different price points. The size of the valve also affects the price, with larger valves generally costing more due to increased material and manufacturing requirements. Brand reputation can impact pricing, as well-established manufacturers with strong customer support networks may charge a premium for their products. Lastly, additional features or customization, such as automation, specialized designs, high-pressure ratings, or industry-specific certifications, can contribute to increased costs. When selecting a valve, it is essential to consider these factors along with performance, reliability, and long-term costs to ensure the most suitable and cost-effective choice for a given application.

Explain how these factors can influence the overall cost of a motorized butterfly valve ราคา compared to other conventional valve types

The overall cost of a electric actuator butterfly valve compared to other conventional valve types can be influenced by factors such as materials, size, brand reputation, and additional features or customization. Motorized butterfly valves inherently come at a higher initial cost due to the integration of an electric motor for automation. However, their compact design and streamlined structure can offset this cost by reducing material and manufacturing requirements compared to more complex valve types like ball or globe valves. Material selection also plays a role in cost differences, as motorized butterfly valves may use different materials for the valve body and disc, affecting durability, corrosion resistance, and fluid compatibility. Brand reputation can impact the price comparison, as well-known manufacturers with strong customer support networks may charge a premium for their motorized butterfly valves, ensuring better performance, reliability, and after-sales service. Additional features or customization, such as high-pressure ratings or industry-specific certifications, can increase the cost of both motorized butterfly valves and other conventional valve types. While the upfront cost of motorized butterfly valves may be higher, the long-term benefits of automation, reduced maintenance, and improved efficiency often outweigh the initial investment, making them a cost-effective choice in many cases when compared to other conventional valve types.

Price Comparison: motorized butterfly valve ราคา vs. Other Conventional Valves

When comparing the prices of motorized butterfly valves to other conventional valves, such as gate, ball, globe, and diaphragm valves, it is essential to consider factors like materials, size, automation, brand reputation, and additional features or customization. Motorized butterfly valves inherently come at a higher initial cost due to the integration of an electric motor for automation, which offers precise control and efficiency without manual intervention. However, their compact design and streamlined structure can offset this cost by reducing material and manufacturing requirements compared to more complex valve types like ball or globe valves.

Material selection also plays a role in price differences, as various materials like brass, bronze, stainless steel, and plastic polymers offer varying levels of durability, corrosion resistance, and compatibility with specific fluids, each at different price points. The size of the valve impacts the price, with larger valves generally costing more due to increased material and manufacturing requirements.

Brand reputation can impact the price comparison, as well-known manufacturers with strong customer support networks may charge a premium for their motorized butterfly valves, ensuring better performance, reliability, and after-sales service. Additional features or customization, such as high-pressure ratings, cryogenic capabilities, or industry-specific certifications, can increase the cost of both motorized butterfly valves and other conventional valve types.

While the upfront cost of motorized butterfly valves may be higher than some conventional valve types, the long-term benefits of automation, reduced maintenance, and improved efficiency often outweigh the initial investment, making them a cost-effective choice in many cases. It is crucial to consider the overall value provided by the valve, including its suitability for the specific application, performance, reliability, and long-term costs, rather than focusing solely on the initial price when comparing motorized butterfly valves to other conventional valve types.

Present a detailed price comparison of motorized butterfly valve ราคา and other conventional valves based on different factors (e.g., size, materials, etc.)

A detailed price comparison of motorized butterfly valves and other conventional valves based on different factors, such as size and materials, reveals that each valve type offers a unique cost structure depending on the specific requirements of an application. Motorized butterfly valves typically have a higher initial cost due to the integration of an electric motor for automation. However, their compact and streamlined design can offset this cost by reducing material and manufacturing requirements compared to more complex valve types like ball or globe valves.

Size is another critical factor affecting the price of both motorized butterfly valves and conventional valves. Generally, larger valves require more material and manufacturing resources, leading to higher costs. For example, a 4-inch motorized butterfly valve may be more expensive than a 2-inch valve made from the same materials, as it requires more material for the valve body and disc, as well as a more powerful motor for operation.

Material selection plays a significant role in price differences between motorized butterfly valves and conventional valves. Common materials used in valve construction include brass, bronze, stainless steel, and various plastic polymers, each with different price points and performance characteristics. For instance, a stainless steel motorized butterfly valve may come at a higher price due to its enhanced corrosion resistance and strength but can be more cost-effective in the long run, especially for aggressive or corrosive fluid applications.

In summary, the price comparison of motorized butterfly valves and other conventional valves depends on several factors, including size, materials, and automation features. It is crucial to consider the overall value provided by the valve, including its suitability for the specific application, performance, reliability, and long-term costs, rather than focusing solely on the initial price when comparing motorized butterfly valves to other conventional valve types.

Highlight any specific scenarios where the cost of a motorized butterfly valve ราคา may be more or less expensive than other valve types

There are specific scenarios where the cost of a motorized butterfly valve may be more or less expensive than other valve types. In situations requiring precise flow control and automation, motorized butterfly valves can be more cost-effective than manual valve types, despite their higher initial cost. The automated operation reduces labor costs, improves efficiency, and offers better system control than manual valves. On the other hand, for applications involving high-pressure or hazardous fluids where tight sealing is crucial, other valve types such as ball valves may be more expensive but necessary due to their superior sealing capabilities.

In terms of size, motorized butterfly valves can be more cost-effective for larger pipe systems, as their compact and streamlined design results in lower material and manufacturing costs compared to more complex valve types like globe valves. Additionally, for applications that require frequent valve cycling or need to handle abrasive or corrosive fluids, motorized butterfly valves made from corrosion-resistant materials like stainless steel may be more expensive upfront but offer long-term savings due to reduced maintenance and replacement costs.

In summary, the cost of a motorized butterfly valve may be more or less expensive than other valve types depending on factors such as automation requirements, fluid compatibility, sealing capabilities, and size. Careful consideration of these factors and the specific needs of the application will help determine the most suitable and cost-effective valve solution.

Advantages and Disadvantages of motorized butterfly valve ราคา

Motorized butterfly valves offer several advantages and disadvantages when compared to other valve types, making them suitable for specific applications while posing challenges in others. One of the primary advantages of motorized butterfly valves is their automation capabilities, which provide precise flow control, reduced labor costs, improved efficiency, and better system control without manual intervention. The integration of an electric motor allows for remote operation and real-time monitoring of the valve’s position, streamlining the management of fluid handling systems.

Another advantage of motorized butterfly valves is their compact and streamlined design, which requires less material and manufacturing resources compared to more complex valve types like ball or globe valves. This design results in a smaller footprint and lighter weight, making them ideal for space-constrained installations and reducing the load on supporting structures.

Motorized butterfly valves also offer relatively low operating torque requirements, which can lead to energy savings due to the smaller motors needed for actuation. Additionally, their quick opening and closing capabilities minimize the time required for valve cycling, reducing wear and tear on the valve components and extending the service life.

However, motorized butterfly valves also have some disadvantages. One notable drawback is their limited sealing capabilities compared to other valve types like ball or gate valves. The disc in a butterfly valve does not provide a tight seal when closed, making them unsuitable for high-pressure or hazardous fluid applications where leak prevention is crucial.

Another disadvantage of motorized butterfly valves is the potential for cavitation or turbulence in the fluid flow, particularly when the valve is partially open. This can cause increased noise, vibration, and erosion of the valve components, leading to reduced performance and a shorter service life.

Finally, the higher initial cost of motorized butterfly valves due to the integration of an electric motor can be a deterrent for some users. However, the long-term benefits of automation, such as reduced labor costs and improved efficiency, can offset the higher upfront investment in many cases.

In summary, motorized butterfly valves offer several advantages, such as automation capabilities, compact design, and energy savings, making them suitable for various applications. However, their disadvantages, including limited sealing capabilities and the potential for cavitation, must be considered when selecting the most appropriate valve type for a specific application.

Discuss the main advantages of using motorized butterfly valve ราคา, such as automation, ease of operation, and reduced maintenance requirements

Motorized butterfly valves offer several key advantages that make them an attractive choice for many fluid handling applications. One of the main benefits is automation, which allows for precise flow control and remote operation without manual intervention. This not only reduces labor costs but also improves efficiency and system control, enabling operators to monitor and adjust valve positions in real-time. Another advantage of motorized butterfly valves is their ease of operation, stemming from their compact and streamlined design. The lightweight construction and low torque requirements make it easier to install and operate these valves, resulting in reduced energy consumption and smaller motors needed for actuation. Furthermore, motorized butterfly valves often have lower maintenance requirements compared to other valve types due to their simple design and quick opening and closing capabilities. The reduced wear and tear on valve components extend the service life and minimize the need for frequent maintenance or replacements, leading to long-term cost savings. Overall, the main advantages of using motorized butterfly valves, such as automation, ease of operation, and reduced maintenance requirements, make them a valuable addition to various fluid handling systems.

Address the potential disadvantages, including higher initial costs and the need for a power source

Despite the numerous advantages of motorized butterfly valves, there are certain potential disadvantages that need to be considered. One notable drawback is the higher initial cost associated with these valves due to the integration of an electric motor for automation. This upfront investment might be a deterrent for some users, but it’s essential to weigh the long-term benefits, such as reduced labor costs, improved efficiency, and lower maintenance requirements, against the initial expense. Another potential disadvantage is the need for a reliable power source to operate the electric motor. In environments where power supply may be inconsistent or unavailable, this requirement can pose challenges and may necessitate the use of backup power systems or alternative actuation methods, such as pneumatic or hydraulic actuators. However, advancements in power management technologies and the availability of energy-efficient motors can help mitigate these concerns. In summary, while there are potential disadvantages to using motorized butterfly valves, including higher initial costs and the need for a power source, the overall benefits often outweigh these drawbacks, making them a worthwhile investment for many fluid handling applications.

Compare these pros and cons with those of other conventional valve types

When comparing the pros and cons of motorized butterfly valves with those of other conventional valve types, it is essential to consider factors such as automation, sealing capabilities, cost, and maintenance requirements. Motorized butterfly valves offer significant advantages in terms of automation, ease of operation, and reduced maintenance due to their compact design and quick opening and closing capabilities. However, they may come with a higher initial cost and the need for a reliable power source.

In contrast, other conventional valve types, such as ball, gate, or globe valves, may provide superior sealing capabilities, making them more suitable for high-pressure or hazardous fluid applications where leak prevention is crucial. These valves can also be operated manually, pneumatically, or hydraulically, offering versatility in terms of actuation methods. However, their more complex designs can lead to increased material and manufacturing costs, heavier weight, and higher maintenance requirements.

Another example is diaphragm valves, which are well-suited for handling corrosive or abrasive fluids due to their minimal contact between the valve body and the process fluid. While they offer excellent sealing capabilities and lower maintenance requirements, their flow control capabilities may be limited compared to motorized butterfly valves.

In summary, each valve type presents a unique set of pros and cons that must be carefully considered based on the specific requirements of an application. While motorized butterfly valves excel in automation, ease of operation, and reduced maintenance, other conventional valve types may offer better sealing capabilities or versatility in actuation methods. Ultimately, the most suitable valve type will depend on factors such as fluid type, pressure, temperature, and desired flow control characteristics.

motorized butterfly valve ราคา Conclusion

In the world of fluid handling systems, selecting the most suitable valve type for a specific application can be a complex task. Not only do engineers need to consider factors such as fluid type, pressure, temperature, and flow control, but they must also weigh the costs and benefits of each valve type. One popular option is the motorized butterfly valve, which offers several advantages, such as automation capabilities, ease of operation, and reduced maintenance requirements. But how does the price of a motorized butterfly valve compare to other conventional valve types? In this blog post conclusion, we will explore this topic in detail.

First, it is essential to note that the initial cost of a motorized butterfly valve can be higher than some other conventional valve types due to the integration of an electric motor for automation. However, this upfront investment should not be viewed in isolation. Instead, it’s crucial to consider the long-term benefits and overall value provided by the valve, including its suitability for the specific application, performance, reliability, and maintenance costs.

When comparing motorized butterfly valves with other conventional valve types, such as ball, gate, or globe valves, it’s important to recognize that each valve type offers a unique cost structure depending on factors such as size, materials, and automation features. For instance, larger valves generally require more material and manufacturing resources, leading to higher costs. Similarly, the selection of materials used in valve construction, such as brass, bronze, stainless steel, or various plastic polymers, will impact the price of the valve based on their different price points and performance characteristics.

From a maintenance perspective, motorized butterfly valves often have lower maintenance requirements compared to other valve types due to their simple design and quick opening and closing capabilities. This can translate to long-term cost savings, as reduced wear and tear on valve components extend the service life and minimize the need for frequent maintenance or replacements.

In terms of automation, motorized butterfly valves provide a clear advantage over manual valve types. The automated operation reduces labor costs, improves efficiency, and offers better system control than manual valves. In scenarios where precise flow control and automation are critical, motorized butterfly valves can be more cost-effective than manual valve types, despite their higher initial cost.

Ultimately, the price comparison of motorized butterfly valves and other conventional valve types depends on several factors, including size, materials, automation features, and the specific requirements of an application. To make the most informed decision, engineers and plant operators must carefully consider the overall value provided by the valve, rather than focusing solely on the initial price. By doing so, they can select the most suitable and cost-effective valve solution that meets their unique fluid handling needs.

Summarize the key points discussed in the blog post

In conclusion, the blog post highlights the importance of considering various factors when comparing the price of motorized butterfly valves with other conventional valve types. While motorized butterfly valves offer several advantages such as automation capabilities, ease of operation, and reduced maintenance requirements, they may have a higher initial cost due to the electric motor integration. However, it’s essential to weigh the long-term benefits and overall value provided by the valve for the specific application. Factors such as size, materials, and automation features play a crucial role in determining the cost-effectiveness of motorized butterfly valves compared to other valve types like ball, gate, or globe valves. By carefully evaluating these factors and the unique fluid handling needs, engineers and plant operators can make informed decisions and select the most suitable and cost-effective valve solution for their applications.

Offer recommendations for when a motorized butterfly valve may be the most cost-effective choice, and when other conventional methods might be more suitable

When selecting the most cost-effective valve solution, it is crucial to consider the unique requirements of each fluid handling application. A motorized butterfly valve may be the most cost-effective choice in scenarios where automation, ease of operation, and reduced maintenance are of high importance. These valves are particularly suitable for applications involving moderate pressure and temperature, and non-hazardous fluids, where their quick opening and closing capabilities and compact design offer significant advantages. However, other conventional valve types, such as ball or gate valves, might be more suitable for high-pressure applications or situations where tight sealing capabilities are critical, due to their superior sealing performance. Similarly, diaphragm valves can be a better choice for handling corrosive or abrasive fluids, as they minimize contact between the valve body and the process fluid. Ultimately, the most cost-effective valve solution will depend on factors such as fluid type, pressure, temperature, and desired flow control characteristics, with engineers and plant operators needing to carefully evaluate these aspects to make the best decision for their specific application.

Encourage readers to carefully consider their specific needs and requirements when selecting a valve type

In the complex world of fluid handling systems, it is vital for engineers and plant operators to carefully consider their specific needs and requirements when selecting a valve type. As every application has unique characteristics, such as fluid type, pressure, temperature, and flow control requirements, a one-size-fits-all approach is not suitable. By thoroughly analyzing these factors and understanding the advantages and disadvantages of each valve type, decision-makers can make informed choices that best align with their application’s demands. This careful evaluation not only ensures optimal performance and efficiency but also contributes to long-term cost savings and system reliability. Remember, the most suitable valve choice is not solely determined by initial costs, but rather by a combination of factors that ultimately contribute to the overall value and effectiveness of the fluid handling system.