Description

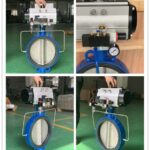

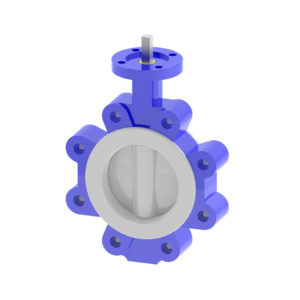

Inflatable Seat Butterfly Valve

The inflatable seat butterfly valve is an innovative and reliable solution for controlling and regulating fluid flow in various industrial applications. Here, we’ll discuss the features, benefits, and specifications of this special valve.

Features and Benefits

- Inflatable Seat Design: The inflatable seat design provides excellent sealing performance and reduces wear and tear on the valve components, ensuring long service life and low maintenance costs.

- Wide Range of Sizes: Available in sizes ranging from DN50 to DN1000, the inflatable seat butterfly valve can accommodate a variety of pipeline diameters and flow rates.

- Various Material Options: The valve is made from a selection of high-quality materials, including ASTM A536 65-45-12, WCB, CF8M for the body, and material options like Nylon-coated ASTM A536 65-45-12, CF8, CF8M, 2507, and 1.4462 for the disc. This ensures compatibility with different media and operating conditions.

- Multiple Seat Materials: The seat materials can be chosen from EPDM, NBR, FRM or PTFE, providing flexibility and compatibility with various fluids and operating temperatures.

- Stainless Steel Components: The valve’s stem, lower stem, retainer, nuts, and screws are made from corrosion-resistant stainless steel for durability and long-lasting performance.

Specifications

- Size: DN50-DN1000

- Body Material: ASTM A536 65-45-12, WCB, CF8M

- Disc Material: ASTM A536 65-45-12 Nylon-coated, CF8, CF8M, 2507, 1.4462

- Seat Material: EPDM, NBR, FRM, PTFE

- Stem Material: SS420, SS431

- Lower Stem Material: SS420, SS431

- Retainer Material: Nylon for DN50-DN300, SS304 for DN350-DN2000

- Bearing Material: RPTFE with Graphite on I.D.

- Weather Seal Material: NBR

- Nuts Material: Stainless steel

- Plug Material: Steel galvanized for DN50-DN300, Cover plate for DN350-DN2000 material same as body with SS304 bolts

- Screw Material: SS304

In conclusion, the inflatable seat pneumatic butterfly valve offers a versatile and reliable solution for fluid flow control in a variety of industrial settings. With its wide range of sizes, material options, and durable construction, these valves provide excellent performance, longevity, and easy maintenance.

| NO. | Part name | Material |

| 1 | Body | ASTM A536 65-45-12, WCB, CF8M |

| 2 | Disc | ASTM A536 65-45-12 Nylon coated, CF8, CF8M, 2507, 1.4462 |

| 3 | Seat | EPDM,NBR,FRM.PTFE |

| 4 | Stem | SS420,SS431 |

| 5 | Lower Stem | SS420,SS431 |

| 6 | Retalner | Nylon for DN50-DN300, SS304 for DN350-DN2000 |

| 7 | Bearing | RPTFE with Graphite on I.D. |

| 8 | Weather seal | NBR |

| 9 | Nuts | Stainless steel |

| 10 | Plug | Steel galvanized for DN50-DN300, Cover plate for DN350-DN2000 material same as body with SS304 bolts |

| 11 | Screw | SS304 |

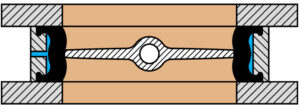

The butterfly valve is closed and the seat is not sealed

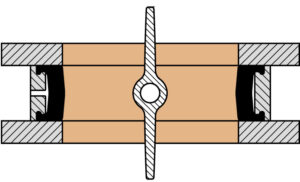

The butterfly valve is closed and the seat is sealed

The butterfly valve is open and the valve seat is not sealed

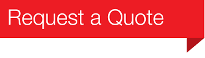

Inflatable seat pneumatic butterfly valve

Discover the power of inflatable butterfly valves for handling powder and powder medium working conditions. Gain a deeper understanding of their fundamental principles by watching the accompanying video. Harness the efficiency and effectiveness of this impressive technology.

FAQs

What is an inflatable butterfly valve?

An Inflatable Butterfly Valve is a specialized type of valve that incorporates a unique inflatable elastomer liner or seat. This liner inflates and deflates to control the flow of material through the pipeline, providing a tight shut-off even when dealing with coarse, abrasive, or granular media.

When the valve is in the open position, the inflatable liner is deflated, allowing for unimpeded flow of material. Upon actuation, the liner inflates, expanding to the interior surface of the valve body and effectively halting the flow. This inflation creates a 100% full bore seal across the valve, reducing friction, preventing leakage and wear, and ensuring optimal flow control.

The inflatable butterfly valve’s design offers significant advantages over traditional valves, particularly in industries dealing with bulk materials. Its ability to provide a tight shut-off even in the presence of coarse or abrasive media makes it ideal for applications in sectors such as mining, food processing, pharmaceuticals, and chemical industries.

What are the advantages of using inflatable seat butterfly valves over traditional valves?

Embodying our legacy of innovation and technical excellence in the valve manufacturing industry, Inflatable Butterfly Valves are a game-changer, offering distinct advantages over traditional valves.

- Superior Sealing: Traditional butterfly valves often struggle to achieve a perfect seal, especially when dealing with coarse or granular media. Inflatable Butterfly Valves, with their unique inflatable liner, create a 100% full bore seal across the valve when inflated, ensuring a tight shut-off and preventing leakage.

- Reduced Wear and Tear: The inflation and deflation mechanism of the liner minimizes friction between the valve components, significantly reducing wear and tear. This contributes to a longer service life, enhancing operational efficiency and cost-effectiveness.

- Versatility: Inflatable Butterfly Valves are designed to handle a wide range of materials, including those that are abrasive, corrosive or granular in nature. This versatility makes them suitable for diverse industries, from mining and food processing to pharmaceuticals and chemical industries.

- Optimal Flow Control: The inflatable liner provides an unimpeded flow path when deflated, ensuring optimal flow control. This is particularly beneficial in applications where precise control of material flow is crucial.

- Enhanced Safety: The fail-safe design of our Inflatable Butterfly Valves enhances operational safety. In the event of air supply failure, the liner deflates, allowing the valve to return to its default position.

What do you think is the biggest advantage of using inflatable butterfly valves in powder processing?

As a global authority in the valve manufacturing industry, we can confidently assert that the use of Inflatable Butterfly Valves presents a significant advantage in powder processing operations.

The most notable advantage lies in their superior sealing capability. Traditional valves often struggle to achieve an effective seal with fine, powdered materials due to the particles’ propensity to lodge in small spaces, leading to leaks and inefficiencies. However, Inflatable Butterfly Valves utilize an inflatable elastomer liner that expands to create a 100% full bore seal across the valve when inflated. This tight shut-off prevents any powder from escaping, ensuring optimal containment and efficiency in the handling of powdered materials.

Furthermore, the liner deflates when the valve is in the open position, providing an unobstructed flow path for the powder. This feature allows for precise control over the flow of powdered materials, which is crucial in powder processing operations where maintaining product consistency and quality is paramount.

In addition, the inflation and deflation mechanism of the liner minimizes friction between the valve components, significantly reducing wear and tear. This results in enhanced durability and longevity, even when dealing with abrasive powdered materials – a common challenge in the powder processing industry.

Therefore, in powder processing applications, the use of Inflatable Butterfly Valves translates into increased operational efficiency, product quality, and cost-effectiveness, affirming our commitment to delivering industry-leading fluid control solutions.

PN10 Flange size

| NPS | DN | OD | PCB | Bolt | n-bolt |

| 3/8 | DN10 | 90 | 60 | 14 | 4 |

| 1/2 | DN15 | 95 | 65 | 14 | 4 |

| 3/4 | DN20 | 105 | 75 | 14 | 4 |

| 1 | DN25 | 115 | 85 | 14 | 4 |

| 11/4 | DN32 | 140 | 100 | 18 | 4 |

| 11/2 | DN40 | 150 | 110 | 18 | 4 |

| 2 | DN50 | 165 | 125 | 18 | 4 |

| 21/2 | DN65 | 185 | 145 | 18 | 8 |

| 3 | DN80 | 200 | 160 | 18 | 8 |

| 4 | DN100 | 220 | 180 | 18 | 8 |

| 5 | DN125 | 250 | 210 | 18 | 8 |

| 6 | DN150 | 285 | 240 | 22 | 8 |

| 8 | DN200 | 340 | 295 | 22 | 8 |

| 10 | DN250 | 395 | 350 | 22 | 12 |

| 12 | DN300 | 445 | 400 | 22 | 12 |

| 14 | DN350 | 505 | 460 | 22 | 16 |

| 16 | DN400 | 565 | 515 | 26 | 16 |

| 18 | DN450 | 615 | 565 | 26 | 20 |

| 20 | DN500 | 670 | 620 | 26 | 20 |

| 24 | DN600 | 780 | 725 | 30 | 20 |

| 28 | DN700 | 895 | 840 | 30 | 24 |

| 32 | DN800 | 1015 | 950 | 33 | 24 |

| 36 | DN900 | 1115 | 1050 | 33 | 28 |

| 40 | DN1000 | 1230 | 1160 | 36 | 28 |

| 48 | DN1200 | 1455 | 1380 | 39 | 32 |

| 56 | DN1400 | 1675 | 1590 | 42 | 36 |

| 64 | DN1600 | 1915 | 1820 | 48 | 40 |

| 72 | DN1800 | 2115 | 2020 | 48 | 44 |

| 80 | DN2000 | 2325 | 2230 | 48 | 48 |

PN16 Flange size

| NPS | DN | OD | PCB | Bolt | n-bolt |

| 3/8 | DN10 | 90 | 60 | 14 | 4 |

| 1/2 | DN15 | 95 | 65 | 14 | 4 |

| 3/4 | DN20 | 105 | 75 | 14 | 4 |

| 1 | DN25 | 115 | 85 | 14 | 4 |

| 11/4 | DN32 | 140 | 100 | 18 | 4 |

| 11/2 | DN40 | 150 | 110 | 18 | 4 |

| 2 | DN50 | 165 | 125 | 18 | 4 |

| 21/2 | DN65 | 185 | 145 | 18 | 8 |

| 3 | DN80 | 200 | 160 | 18 | 8 |

| 4 | DN100 | 220 | 180 | 18 | 8 |

| 5 | DN125 | 250 | 210 | 18 | 8 |

| 6 | DN150 | 285 | 240 | 22 | 8 |

| 8 | DN200 | 340 | 295 | 22 | 12 |

| 10 | DN250 | 405 | 355 | 26 | 12 |

| 12 | DN300 | 460 | 410 | 26 | 12 |

| 14 | DN350 | 520 | 470 | 26 | 16 |

| 16 | DN400 | 580 | 525 | 30 | 16 |

| 18 | DN450 | 640 | 585 | 30 | 20 |

| 20 | DN500 | 715 | 650 | 33 | 20 |

| 24 | DN600 | 840 | 770 | 36 | 20 |

| 28 | DN700 | 910 | 840 | 36 | 24 |

| 32 | DN800 | 1025 | 950 | 39 | 24 |

| 36 | DN900 | 1125 | 1050 | 39 | 28 |

| 40 | DN1000 | 1255 | 1170 | 42 | 28 |

| 48 | DN1200 | 1485 | 1390 | 48 | 32 |

| 56 | DN1400 | 1685 | 1590 | 48 | 36 |

| 64 | DN1600 | 1930 | 1820 | 56 | 40 |

| 72 | DN1800 | 2130 | 2020 | 56 | 44 |

| 80 | DN2000 | 2345 | 2230 | 62 | 48 |

JIS 10k flange size

| NPS | DN | OD | PCB | Bolt | n-bolt |

| 3/8 | DN10 | 90 | 65 | 15 | 4 |

| 1/2 | DN15 | 95 | 70 | 15 | 4 |

| 3/4 | DN20 | 100 | 75 | 15 | 4 |

| 1 | DN25 | 125 | 90 | 19 | 4 |

| 11/4 | DN32 | 135 | 100 | 19 | 4 |

| 11/2 | DN40 | 140 | 105 | 19 | 4 |

| 2 | DN50 | 155 | 120 | 19 | 4 |

| 21/2 | DN65 | 175 | 140 | 19 | 4 |

| 3 | DN80 | 185 | 150 | 19 | 8 |

| 31/2 | (DN90) | 195 | 160 | 19 | 8 |

| 4 | DN100 | 210 | 175 | 19 | 8 |

| 5 | DN125 | 250 | 210 | 23 | 8 |

| 6 | DN150 | 280 | 240 | 23 | 8 |

| 7 | (DN175) | 305 | 265 | 23 | 12 |

| 8 | DN200 | 330 | 290 | 23 | 12 |

| 9 | (DN225) | 350 | 310 | 23 | 12 |

| 10 | DN250 | 400 | 355 | 25 | 12 |

| 12 | DN300 | 445 | 400 | 25 | 16 |

| 14 | DN350 | 490 | 445 | 25 | 16 |

| 16 | DN400 | 560 | 510 | 27 | 16 |

| 18 | DN450 | 620 | 565 | 27 | 20 |

| 20 | DN500 | 675 | 620 | 27 | 20 |

| 22 | (DN550) | 745 | 680 | 33 | 20 |

| 24 | DN600 | 795 | 730 | 33 | 24 |

| 26 | (DN650) | 845 | 780 | 33 | 24 |

| 28 | DN700 | 905 | 840 | 33 | 24 |

| 30 | (DN750) | 970 | 900 | 33 | 24 |

| 32 | DN800 | 1020 | 950 | 33 | 28 |

| 34 | (DN850) | 1070 | 1000 | 33 | 28 |

| 36 | DN900 | 1120 | 1050 | 33 | 28 |

| 40 | DN1000 | 1235 | 1160 | 39 | 28 |

| 44 | DN1100 | 1345 | 1270 | 39 | 28 |

| 48 | DN1200 | 1465 | 1380 | 39 | 32 |