The brewing industry in Australia has seen a significant rise in recent years, with both large-scale breweries and microbreweries contributing to its growth. An essential aspect of this industry’s success is the effective use of equipment that ensures precise control over the brewing process. One such piece of equipment is the butterfly valve. Understanding the benefits of butterfly valves within the brewing sector can greatly enhance the efficiency, quality, and safety of the brewing operations. These valves offer numerous advantages including easy maintenance, excellent regulation of flow, and cost-effectiveness, making them an invaluable tool for the Australian brewing industry.

Introduction

The brewing industry in Australia has been experiencing a significant boom in recent years, with a surge in both large-scale breweries and artisanal microbreweries. This growth has been made possible not only by the passion and creativity of Australian brewers, but also by the effective use of innovative technologies and equipment that provide precise control over the brewing process. One such crucial piece of equipment is the wafer butterfly valve. Butterfly valves are flow control devices that can be used to regulate the amount of liquid passing through a system, and they play a vital role in various stages of the brewing process. Understanding the benefits of butterfly valves can greatly enhance the efficiency, quality, and safety of brewing operations.

These valves are known for their easy maintenance, as they can be cleaned and repaired without being fully removed from their system. This feature is highly beneficial in the brewing industry, where maintaining cleanliness is essential to prevent contamination of the brew. Additionally, butterfly valves offer excellent regulation of flow, allowing brewers to accurately control the amount of liquid moving through their systems at any given time. This precise control is critical during various stages of brewing, such as during the transfer of wort from the mash tun to the boil kettle, or when regulating the flow of beer into kegs or bottles for packaging. Furthermore, butterfly valves are cost-effective, providing a high level of functionality and durability at a relatively low cost. This makes them an ideal choice for breweries of all sizes, from small craft operations to large commercial facilities. In conclusion, the use of butterfly valves in the Australian brewing industry offers numerous advantages, contributing to the industry’s ongoing success and growth.

Brief overview of the brewing industry in Australia

The brewing industry in Australia has seen significant growth in recent years, particularly in the craft beer sector. The craft beer industry is currently worth over AUD 800 million and experienced a growth rate of 6.2% from 2015 to 2020. It’s also worth noting that Great Northern Brewing holds the largest market share in the industry at 12%. Despite slight revenue dips in the broader beer manufacturing industry in recent years, the craft beer market continues to expand, projected to reach USD 241.8 million with a CAGR of 5.30% for the period of 2017-2025.

A recent report indicated that the independent craft brewery industry saw a growth of 17.7%, exemplifying the strength of this sector as 92.6% of craft breweries in Australia are independently owned. The beer industry alone contributes to nearly $16.5 billion yearly in economic activity, accounting for around one percent of Australia’s GDP. This growth trend is expected to continue, with the beer and cider market predicted to grow at a CAGR of more than 1% during 2022-2027.

Introduction to butterfly valves and their role in the brewing process

Butterfly valves are a type of flow control device that are widely used in various industries, including the brewing industry. They consist of a disc mounted on a rotating shaft, which when turned, either allows fluid (such as beer wort) to flow through it, or blocks the passage completely. The simplicity and effectiveness of this mechanism make butterfly valves an essential tool in the brewing process. In the brewing industry, they are primarily used to regulate the flow of liquid at various stages of production, from the initial stages of boiling and fermenting the wort, to the final stages of transferring the finished product into kegs or bottles.

The precise control offered by butterfly valves ensures a consistent brewing process, which is crucial for maintaining the quality and flavor of the beer. Furthermore, these valves are easy to clean and maintain, making them ideal for use in breweries where hygiene standards are paramount. By understanding the role and benefits of butterfly valves, breweries can significantly enhance the efficiency and quality of their brewing process.

What are Butterfly Valve?

Butterfly valves are a type of quarter-turn valve used for controlling the flow of a fluid. The ‘butterfly’ in its name is derived from the metal disc, or the butterfly disc, located in the center of the pipe. This disc is mounted on a rod and when the valve is closed, the disc is turned so that it completely blocks off the passageway. When the valve is fully open, the disc is rotated a quarter turn to allow full flow. The position of the disc is often controllable, which allows for moderated flow.

Butterfly valves are known for their simplicity and durability. They are typically low cost and lightweight, making them an economical choice for large-scale applications where a large amount of valves might be necessary. They are versatile and can be used with many different types of fluids and in a variety of different applications, including water supply, wastewater treatment, fire protection, and gas supply. In addition to being durable and cost-effective, butterfly valves also require less space than some other types of valves. Their simple design also allows for quick operation and they are capable of both isolating and regulating flow, making them an incredibly useful tool in many industries.

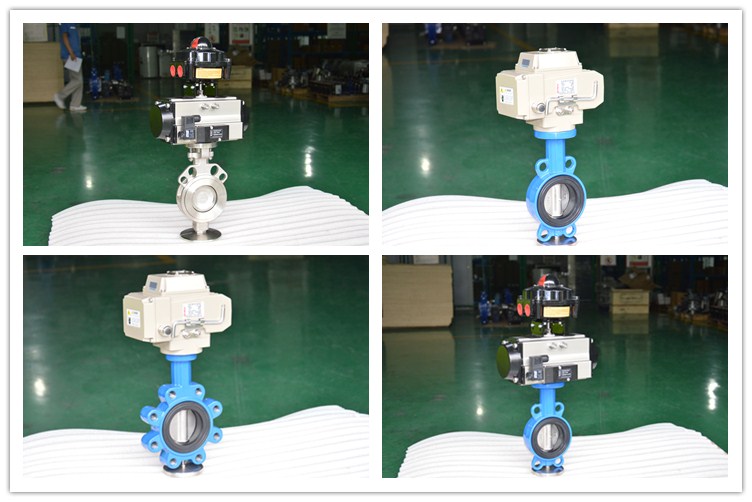

Detailed explanation of butterfly valve, their design, and how they work

Butterfly valves, as their name suggests, operate much like the wings of a butterfly. They are flow control devices that consist of a disc attached to a rotating stem. This disc, also known as the “butterfly,” is the main component that regulates the flow of fluid through the pipe. When the valve is open, the disc is turned parallel to the direction of the flow, allowing fluid to pass freely. When the valve is closed, the disc is rotated by 90 degrees so that it lies perpendicular to the flow, effectively blocking it.

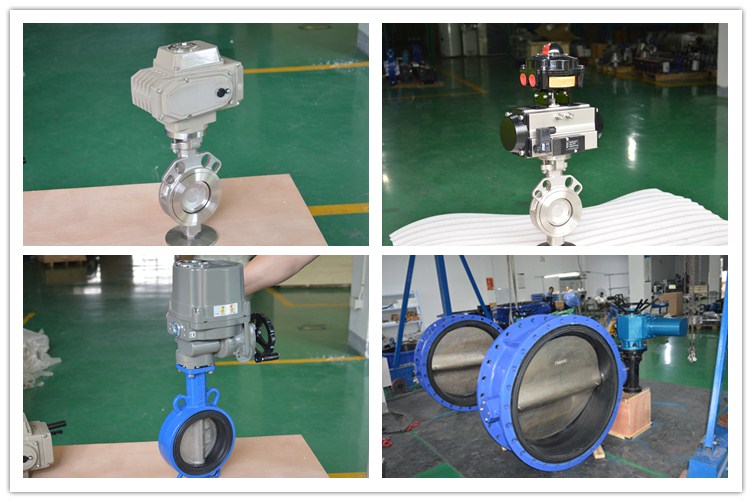

The design of a butterfly valve is relatively simple yet highly effective. The disc is mounted on a rod or “stem” which passes through the center of the pipe. The stem is connected to an actuator located outside the pipe, which can be operated manually or automatically. Manual actuators typically use a handwheel or lever, while automatic actuators can be powered by electricity, air (pneumatic), or other fluids (hydraulic).

One of the key benefits of butterfly valves is their compact and lightweight design. Unlike other types of valves which require multiple components and larger housings, butterfly valves consist of only a few parts and occupy minimal space. This makes them ideal for applications where space constraints are a concern.

In terms of performance, butterfly valves offer excellent flow control capabilities. They can handle large volumes of fluid at high pressures, and their quick operation allows for rapid shut-off in case of emergencies. Furthermore, the streamlined design of the disc creates less resistance to the flow, resulting in lower pressure drop compared to other types of valves.

However, it’s important to note that butterfly valves may not be suitable for all applications. For instance, they may not provide a completely tight seal when closed, especially in high-pressure systems. Also, the disc and stem are always in contact with the flow, which may cause wear and tear over time, particularly with abrasive or corrosive fluids. Therefore, it’s crucial to consider these factors when choosing a butterfly valve for a specific application.

Different types of butterfly valve

Butterfly valves come in several types, each designed to meet specific needs and applications. The most common types include concentric, double-eccentric, and triple-eccentric butterfly valves.

Concentric butterfly valves, also known as resilient-seated butterfly valves, are the simplest and most common type. They feature a disc that is centered within the body of the valve with the stem running through the middle of the disc. This design allows for a 360-degree rotation, but it may not provide a perfect seal, making it suitable for low-pressure applications.

Double-eccentric butterfly valves, also called high-performance butterfly valves, have a stem that is slightly offset from the center of the disc and from the centerline of the bore. This design reduces wear and tear on the valve by allowing the disc to cam out of the seat, resulting in improved sealing capabilities and longer service life than concentric butterfly valves.

Triple-eccentric butterfly valves, or triple-offset butterfly valves, have a metal seat and a seal that is not subjected to friction. The disc is offset from the centerline of the pipe and the centerline of the bore, and the seating surface of the disc is also inclined to the centerline. These offsets allow for an almost frictionless rotation of the disc, which minimizes wear and enables these valves to handle higher pressures and temperatures than the other types.

Each of these types has its own advantages and is suited to different kinds of applications, so it’s important to understand their characteristics when choosing a butterfly valve for a specific purpose.

Importance of Butterfly Valve in the Brewing Process

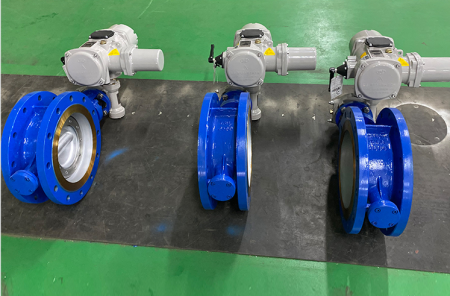

Butterfly valves play a crucial role in the brewing process due to their ability to effectively regulate fluid flow. They are often the valve of choice in many breweries because of their design, functionality, and cost-effectiveness. The brewing process involves multiple stages, such as mashing, boiling, fermenting, and packaging, each requiring precise control over the movement and transfer of liquids. Butterfly valves, with their ability to provide quick and efficient shut-off and modulation of flow, are ideally suited for this purpose.

During mashing, where grains are soaked in hot water to extract sugars, butterfly valves can precisely control the flow rate, ensuring that the correct amount of water is added. In the boiling stage, where the wort is boiled with hops, these valves are used to control the addition of hops and other ingredients. The fermentation process, which transforms the wort into beer, requires strict control over temperature and pressure, and butterfly valves can help maintain these conditions by regulating the flow of cooling agents. Finally, during the packaging stage, these valves can control the flow of beer into bottles or kegs.

Furthermore, the sanitary design of many butterfly valves makes them ideal for use in the food and beverage industry, including breweries. These valves are easy to clean and maintain, reducing the risk of contamination. They are also typically constructed from stainless steel, a material that is resistant to the corrosive effects of the various fluids used in brewing.

In summary, butterfly valves are an integral part of the brewing process. Their ability to provide reliable and efficient flow control, combined with their sanitary design and durability, makes them an essential tool in brewing operations.

Explanation of the brewing process and where butterfly valve fit in

The brewing process consists of several stages, each requiring precise control and regulation of fluid flow, and this is where butterfly valves play a crucial role. The first stage is malting, where malted barley is soaked in hot water through a process called mashing, to convert its starches into fermentable sugars. Butterfly valves are used here to regulate the flow of water and maintain the right temperature.

The next step is lautering, where the liquid part (wort) is separated from the grain husks. The wort then moves into the boiling phase, where it’s boiled and hops are added for bitterness and aroma. Here, butterfly valves control the wort flow and the addition of hops. After boiling, the wort is cooled rapidly, often with the use of a heat exchanger, again using butterfly valves to regulate the flow and temperature of the cooling medium.

Fermentation follows, where the wort is transferred to a fermentation vessel and yeast is added. The yeast ferments the sugars, producing alcohol and carbon dioxide. Butterfly valves are used to control the transfer of the wort and the introduction of the yeast. After fermentation, the beer is conditioned, carbonated, and then transferred to bright beer tanks for final clarification and carbonation adjustment. Butterfly valves assist in these transfers and adjustments.

Finally, the beer is packaged into kegs, cans, or bottles, and butterfly valves are used to control the flow of beer during the filling process. Throughout the entire brewing process, butterfly valves provide critical flow control, allowing brewers to precisely manage their operations, ensuring consistent, high-quality beer.

Discussion on why they are crucial for successful brewing

Butterfly valves are crucial for successful brewing due to their efficiency in controlling and regulating the flow of liquids at various stages of the brewing process. The precision offered by these valves allows brewers to maintain consistency in their operations, which is key to producing high-quality beer. From the initial mashing stage, where precise amounts of water need to be mixed with malted barley, to the boiling phase, where hops are added, butterfly valves enable accurate control over the flow of ingredients. In the fermentation stage, these valves help maintain optimal conditions by controlling the flow of cooling agents, ensuring that the yeast ferments the sugars effectively. Furthermore, butterfly valves’ ability to provide a tight shut-off prevents leakage and wastage, contributing to the overall efficiency and cost-effectiveness of the brewing process. Their easy-to-clean design also helps maintain hygiene standards, reducing the risk of contamination, which is critical in brewing. Therefore, butterfly valves play an indispensable role in ensuring the success of brewing operations.

Benefits of Butterfly Valve in Brewing

The use of butterfly valves in brewing offers a multitude of benefits, contributing significantly to the efficiency and quality of the brewing process. One of the primary advantages is their ability to provide precise control over the flow of liquids, which is critical at every stage of brewing, from mashing and boiling to fermentation and packaging. This precision ensures consistency in the brewing process, which is vital for maintaining the quality and taste of the beer.

Butterfly valves are also valued for their quick actuation and ability to provide a tight shut-off, preventing leakage and wastage of valuable ingredients. Their compact design saves space, which is often a premium in brewing facilities. The ease of operation and maintenance is another significant benefit. Butterfly valves can be quickly and easily opened and closed, and if maintenance is required, many designs allow the internal components to be accessed without removing the entire valve from the pipeline.

Moreover, butterfly valves used in brewing are typically made of stainless steel, making them highly resistant to the corrosive effects of the different fluids involved in brewing. This extends their lifespan and reduces the need for frequent replacements. The sanitary design of these valves, which are easy to clean and disinfect, is another crucial advantage, helping to prevent contamination and ensuring that high hygiene standards are maintained throughout the brewing process.

Lastly, butterfly valves are cost-effective compared to other types of valves. They are generally cheaper to purchase, install, and maintain, yet they offer the same, if not better, performance in controlling and regulating flow. This makes them an economical choice for breweries, especially those operating on a tight budget. In conclusion, the benefits of butterfly valves make them an indispensable component in brewing, contributing to the production of high-quality beer while ensuring efficiency and cost-effectiveness.

Discussion on how butterfly valve improve efficiency in the brewing process

Butterfly valves play an essential role in enhancing efficiency in the brewing process due to their design and functionality. These valves are known for their sealing efficiency, providing leak-tight seals that prevent wastage of valuable resources and maintain the integrity of the brewing process. They can be quickly opened and closed, facilitating fast and efficient flow control, ideal for various applications in brewing. This rapid actuation allows for precise regulation of fluid flow at different brewing stages, from mashing to boiling to fermentation, improving overall operational efficiency.

In addition, butterfly valves, such as the double-acting butterfly valve, allow for precise flow control, which is critical in industrial operations like brewing. The valve’s design, with a metal disc mounted on a rod, ensures it can completely block off the passageway when closed, offering effective control over the fluid flow.

Furthermore, tri-clamp butterfly valves offer added benefits by enabling flow control through locking, contributing to improved efficiency in the brewing system. Properly selected and maintained control valves, including butterfly valves, can significantly increase efficiency, safety, and profitability in the brewing industry.

Explanation of how butterfly valve can save money in the long run

Butterfly valves can save money in the long run in several ways. First, they are generally more affordable to purchase and install than other types of valves, offering initial cost savings. Their compact design requires less material to manufacture, contributing to their lower cost. Additionally, their simple structure means that they require less maintenance, which reduces ongoing operational costs. When maintenance is required, many butterfly valve designs allow for the internal components to be accessed without removing the entire valve from the pipeline, saving time and labor costs.

Furthermore, the efficiency of butterfly valves in controlling and regulating flow can lead to significant cost savings over time. Their ability to provide a tight shut-off prevents leakage, reducing wastage of valuable resources. This precise control over fluid flow also improves the efficiency of the brewing process, potentially leading to higher yields and better quality beer, which can increase profitability.

Finally, the durability and longevity of butterfly valves, particularly those made of corrosion-resistant materials like stainless steel, mean that they do not need to be replaced as frequently as other types of valves. This further reduces long-term costs. Therefore, while the upfront cost of butterfly valves may be relatively low, the real value lies in their potential for long-term cost savings.

Discussion on the robustness and longevity of butterfly valve

Butterfly valves are known for their robustness and longevity, which are critical factors in their widespread use across various industries. These valves, particularly those made from durable materials like stainless steel or cast iron, are recognized for their strength and durability. They offer excellent resistance to wear and tear from abrasive media, contributing to their durability.

Furthermore, certain types of butterfly valves, such as the triple offset butterfly valve marine, are designed to eliminate deformation and friction, resulting in a higher life expectancy. Butterfly valves also tend to be less prone to corrosion and ferritic buildup compared to other types of valves due to their body design.

However, the lifespan of a butterfly valve can depend on several factors, including the application it’s used in, the materials used in its construction, and the frequency of maintenance. Despite these factors, with proper maintenance, butterfly valves are highly durable and can withstand extensive use over time.

Explanation of how simple it is to use and maintain these valves

Butterfly valves are renowned for their simplicity in both usage and maintenance. Their operation is straightforward: a quarter-turn of the handle or actuator either opens or closes the valve, allowing for quick and easy control of fluid flow. This simple mechanism reduces the time taken to operate the valves, making them efficient choices in applications requiring frequent operation.

Maintenance of butterfly valves is also relatively hassle-free. Their compact design means fewer parts to manage or replace, reducing the complexity of upkeep. In many designs, internal components can be accessed and serviced without removing the entire valve from its installation, saving on labor costs and downtime.

Furthermore, the robust construction of butterfly valves contributes to their low maintenance needs. They are less prone to wear and tear, and corrosion-resistant materials used in their construction, like stainless steel, further diminish the need for frequent maintenance. Overall, the simplicity of use and ease of maintenance make butterfly valves a cost-effective choice for many fluid control applications.

Discussion on the flexibility and adaptability of butterfly valve in different brewing conditions

Butterfly valves are appreciated for their flexibility and adaptability in different brewing conditions, making them a popular choice in the brewery industry. Their design allows them to handle a wide range of temperatures and pressures, which is crucial in various stages of brewing. For instance, they can withstand the high temperatures during boiling and sterilization processes, as well as the low temperatures during fermentation and storage.

Moreover, butterfly valves offer precise flow control, which is essential for maintaining the consistency and quality of the brew. With just a quarter-turn, they can be fully opened, fully closed, or partially opened to regulate the flow rate.

Their compact design also makes them suitable for breweries with space constraints, as they require less space compared to other types of valves. Additionally, their ease of maintenance reduces downtime, which is critical in a brewing process where timing is key.

Furthermore, they are compatible with various types of media, including water, wort, and beer, making them versatile for different stages of brewing. The corrosion-resistant materials used in their construction, like stainless steel, ensure they can handle the acidic environment in brewing without degrading over time. This flexibility and adaptability make butterfly valves an efficient and reliable choice in various brewing conditions.

Choosing the Right Butterfly Valve for Your Brewery

Choosing the right butterfly valve for your brewery is a critical decision, as the efficiency and quality of your brewing process heavily rely on it. The first consideration should be the type of media the valve will handle. Butterfly valves are versatile and can manage various types of media, including water, wort, and beer. Therefore, understanding the characteristics of these media, such as their viscosity and corrosiveness, is crucial to choose a valve that can handle them efficiently.

Another key factor is the operating conditions, such as temperature and pressure. Butterfly valves can handle a wide range of temperatures and pressures, but it’s essential to choose a valve designed to withstand the specific conditions in your brewery. For instance, if your brewing process involves high temperatures during boiling or sterilization or low temperatures during fermentation or storage, the chosen valve should be able to operate efficiently under these conditions.

The valve’s size is also important. The valve should fit perfectly in your pipeline system to ensure optimal flow control. A valve that is too large or too small can lead to inefficiencies and potential damage to the system. Additionally, consider the space constraints in your brewery. Butterfly valves are known for their compact design, making them ideal for installations where space is limited.

Lastly, consider the ease of maintenance. Butterfly valves are generally easy to maintain due to their simple design and fewer parts. However, some designs allow for easier access to internal components and can be serviced without removing the entire valve from its installation. This feature can save valuable time and labor costs in a brewing process where timing is key. By carefully considering these factors, you can choose the right butterfly valve that meets your brewery’s specific needs and enhances your brewing process.

Factors to consider when selecting a lug butterfly valve (size, material, type, etc.)

When selecting a butterfly valve, several key factors should be considered to ensure optimal performance and longevity. First, size is crucial – the valve should be appropriately sized for your pipeline system to ensure efficient flow control. A valve that’s too large or small could lead to inefficiencies and potential damage. Next, the material of the valve plays a significant role in its durability and suitability for certain applications. For instance, stainless steel butterfly valves are often chosen for their corrosion resistance and strength, making them suitable for handling various types of media, including corrosive substances.

The type of butterfly valve is also an important consideration. There are different types, including concentric, double-eccentric, and triple-eccentric butterfly valves, each with their unique features and benefits. Your choice would depend on your specific application requirements. For instance, a triple-eccentric butterfly valve might be ideal for high-pressure and temperature applications due to its tight sealing mechanism.

Lastly, consider the operational conditions such as pressure and temperature ranges. The chosen valve should be able to withstand the specific conditions in your application. For instance, if your process involves high temperatures or pressures, the valve should be designed to operate efficiently under these conditions. Other considerations might include ease of maintenance, cost, and the valve’s compatibility with the existing system. By considering all these factors, you can select a butterfly valve that best fits your specific needs and enhances your system’s overall efficiency.

Tips on how to choose a reliable supplier

Choosing a reliable supplier is a critical part of ensuring the smooth operation and success of your business. Several factors should be considered when making this decision. First, assess the supplier’s reputation in the market. You can do this by checking online reviews, asking for references, and seeking recommendations from other businesses in your industry. This will give you insights into the supplier’s reliability, quality of products or services, and their customer service.

Secondly, consider their expertise and experience in your specific industry. A supplier with extensive knowledge about your industry’s needs and challenges will be more equipped to provide tailored solutions that meet your specific requirements. Moreover, an experienced supplier is likely to be more stable and dependable.

Thirdly, evaluate the supplier’s financial stability. A supplier in good financial health is less likely to run into problems that could affect their ability to deliver. You can check their financial status through various online resources or ask them directly for financial references.

Lastly, consider their communication and customer service. A good supplier should be easy to communicate with, responsive to inquiries, and proactive in addressing any issues that arise. They should also offer strong after-sales support. By considering these factors, you can choose a supplier that not only meets your business’s current needs but also is capable of supporting your growth in the long term.

Conclusion

In conclusion, the role of butterfly valves in Australia’s brewing industry cannot be overstated. These compact and versatile valves have proven to be a game-changer, offering a range of benefits that enhance efficiency, improve product quality, and lower production costs.

Firstly, their ability to handle different types of media, from water to wort and beer, with varying viscosity and corrosiveness, makes them an invaluable asset in any brewery’s pipeline system. Secondly, their robust design enables them to withstand a wide range of operating conditions, including high and low temperatures and pressures common in brewing processes. This durability translates into longer service life, reducing the need for frequent replacements and thereby lowering maintenance costs.

Moreover, the compact design of butterfly valves makes them ideal for installations where space is at a premium, a common scenario in many breweries. Their size also allows for more efficient flow control, contributing to improved operational efficiency. Furthermore, their ease of maintenance, due in part to their simple construction and fewer parts, saves valuable time and labor costs, further enhancing their cost-effectiveness.

However, achieving these benefits hinges on choosing the right butterfly valve for your specific needs. This decision should be based on several key factors such as the type of media the valve will handle, the operating conditions it will be subjected to, the size of the valve relative to your pipeline system, and the ease of maintenance.

By carefully considering these factors and partnering with a reliable supplier, Australian breweries can harness the full potential of butterfly valves, further boosting their competitiveness in this vibrant industry. As we continue to see advances in valve technology, it’s clear that butterfly valves will remain a critical component in the brewing process, underpinning the industry’s pursuit of excellence in beer production.

Recap of the main points discussed in the article

In the article, we delved into the significant role pneumatic butterfly valve play in Australia’s brewing industry. We discussed their versatility in handling different types of media, including water, wort, and beer, and their ability to withstand various operating conditions. Their compact design, which makes them ideal for space-constrained installations, was also highlighted. Furthermore, we noted the cost-effectiveness of these valves, attributed to their durability and ease of maintenance. Lastly, we emphasized the importance of selecting the right butterfly valve based on several factors such as the type of media, operating conditions, valve size, and ease of maintenance. The article concluded by underscoring the need to partner with a reliable supplier to fully harness the benefits of butterfly valves in the brewing process.

-150x150.jpg)