As industry leaders in valve manufacturing, we understand the criticality of every component within an HVAC system. One such integral part is the Butterfly Valve, often referred to as the silent workhorse of the UK’s HVAC systems. These compact yet powerful devices play a pivotal role in controlling the flow and isolation within HVAC systems, ensuring optimal performance and energy efficiency. With our stringent quality control, globally recognized certifications, and deep-rooted expertise in this field, we proudly contribute to the UK’s HVAC industry by providing top-tier butterfly valve that underscore our commitment to excellence and reliability.

Introduction

Butterfly valve, often considered the silent workhorse of the UK’s HVAC (Heating, Ventilation, and Air Conditioning) systems, play a pivotal role in regulating the flow of air and other fluids within these systems. They are aptly named for their butterfly-like appearance, consisting of a metal disc positioned in the center of a pipe and a rod passing through the disc to an actuator located on the outside of the valve. This simple yet effective design allows for the swift and efficient control of fluid flow, merely by turning the actuator to rotate the disc either parallel or perpendicular to the flow. The UK’s HVAC systems heavily rely on these valves for their durability, efficiency, and cost-effectiveness. They’re capable of withstanding high pressure and temperature variations, which is crucial in HVAC operations. Moreover, butterfly valve require less material to manufacture than other types of valves, making them a more economical choice. They also take up less space due to their compact design, which is a significant advantage in the often-cramped environments of HVAC installations. Despite their unassuming nature, butterfly valve are integral to the smooth operation of the UK’s HVAC systems, ensuring comfortable and safe indoor environments for homes, offices, and other buildings across the nation.

Brief overview of the role of butterfly valve in HVAC systems.

Butterfly valve play a crucial role in HVAC (Heating, Ventilation, and Air Conditioning) systems, acting as a primary component for controlling the flow of air and other fluids. Their compact and simple design, featuring a disc at the center of a pipe and a rod connected to an external actuator, allows for efficient regulation of fluid flow. By rotating the disc either parallel or perpendicular to the flow, the volume of fluid passing through can be precisely controlled. This ability to withstand high pressure and temperature variations makes butterfly valve particularly valuable in HVAC operations. They ensure the smooth functioning of these systems by maintaining the desired environmental conditions within buildings. Furthermore, their durability, cost-effectiveness, and space-saving design make them a preferred choice in HVAC installations. In essence, butterfly valve are essential for the proper operation of HVAC systems, contributing significantly to indoor comfort and safety.

The importance of butterfly valves in the UK’s HVAC industry.

In the UK’s HVAC industry, butterfly valves are of paramount importance due to their efficiency, reliability, and versatility. Given the UK’s diverse climate conditions, HVAC systems are critical in maintaining comfortable indoor temperatures and air quality. Butterfly valves play a key role in this process by enabling precise control over the flow of air and other fluids within these systems. Their robust design allows them to withstand high pressure and temperature variations, ensuring uninterrupted HVAC operations. Moreover, their cost-effectiveness and compact design make them ideal for the space-constrained settings often found in UK buildings. Additionally, the durability of butterfly valves reduces the need for frequent replacements, contributing to the sustainability of the UK’s HVAC industry. Therefore, butterfly valves are not just a component but a cornerstone of the HVAC industry in the UK, playing a significant role in ensuring indoor comfort and health.

Understanding Butterfly Valve

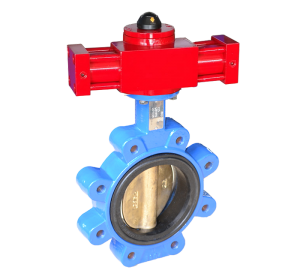

Butterfly valves are a type of flow control device, typically used in large pipe systems for controlling the flow of fluids or air. The name ‘butterfly’ comes from the design of the valve, which consists of a circular disc, or ‘butterfly’, that is mounted on a rotating shaft. When the valve is closed, the disc is turned so that it completely blocks off the pipe. When the valve is fully open, the disc is rotated a quarter turn so that it allows an almost unrestricted passage of the fluid or air. The valve may also be opened incrementally to regulate the flow rate.

These valves are appreciated for their simplicity, reliability, and low cost. They are generally lighter in weight and more compact than other types of valves, making them a practical choice for many applications. The design of the butterfly valve is such that it can withstand high pressure and temperature variations, making them ideal for demanding applications such as those in HVAC systems.

One of the key advantages of butterfly valves is their quick operation – they require only a quarter-turn to open or close fully, allowing for fast isolation. This makes them particularly useful in emergency situations where a rapid shut-off may be necessary.

Despite their simplicity, butterfly valves offer a high degree of precision in flow control. By adjusting the angle of the disc, operators can carefully modulate the flow rate of the fluid or air passing through the valve. This level of control makes butterfly valves an essential component in many industrial processes.

In conclusion, understanding butterfly valves involves recognizing their design, function, and benefits. These include their simplicity, cost-effectiveness, compactness, quick operation, and precise flow control capabilities. These characteristics make butterfly valves a vital component in various industries, from HVAC systems to water distribution, chemical processing, and power generation.

Definition and description of butterfly valves.

A butterfly valve is a type of flow control device, used to regulate or isolate the flow of a liquid or gas in a pipe system. It is named for its distinctive design, which includes a disc mounted on a rotating shaft, that resembles a butterfly in flight when in the open position. The disc, which is the closure element, is positioned in the center of the pipe. When the handle or actuator is turned, the disc rotates on the shaft, either parallel or perpendicular to the flow, controlling the passage of fluid. Unlike other types of valves, butterfly valves are known for their simplicity, compactness, and cost-effectiveness. They offer quick operation (requiring only a quarter-turn to open or close), durability, and the ability to withstand high pressure and temperature variations. These characteristics make butterfly valves widely used in various industrial applications, including water distribution, chemical processing, and HVAC systems.

Explanation of how a butterfly valve works.

A butterfly valve operates through a simple yet effective mechanism. At the heart of the valve is a circular disc, also known as the butterfly, which is mounted on a rotating shaft. When the valve is open, the disc rotates to align with the flow direction of the fluid, allowing it to pass through the pipe unhindered. As the valve handle or actuator is turned, the disc rotates around the axis, gradually reducing the path for the fluid to flow through. When the valve is fully closed, the disc is positioned perpendicular to the flow, completely blocking the passage and stopping the fluid flow. This operation requires only a quarter-turn, which makes butterfly valves exceptionally quick to open or close. The ability to regulate the disc’s position also allows for precise control over the flow rate, making butterfly valves an essential tool in many industrial applications where flow control is critical.

Key features of butterfly valve, such as their compact design and cost-effectiveness.

Butterfly valves boast several key features that make them a popular choice in various industrial applications. One of their most notable features is their compact design. Unlike other types of valves that require significant space, butterfly valves are designed to be sleek and space-efficient, making them ideal for systems where space is at a premium. The disc in the butterfly valve, which rotates to control the flow of fluid, is housed within the valve body, keeping the overall size of the valve relatively small. This compactness does not compromise their functionality, as they can effectively control large flow rates. Another major advantage of butterfly valves is their cost-effectiveness. They are typically less expensive than other types of valves due to their simple design and fewer components, which also results in lower maintenance costs. Furthermore, their quick operation, requiring only a quarter-turn to open or close, contributes to operational efficiency, saving time and reducing wear and tear. These features – compactness, cost-effectiveness, and operational efficiency – combine to make butterfly valves an attractive option for effective flow control in a variety of settings.

The Silent Workhorse: Butterfly Valve in HVAC Systems

Butterfly valves, often referred to as the “silent workhorses,” play an indispensable role in HVAC (Heating, Ventilation, and Air Conditioning) systems. Their primary function is to regulate the flow of air, water, or refrigerant throughout the system, ensuring optimal performance and energy efficiency. Given the constant demand for temperature control in various settings – from residential homes to commercial buildings and industrial facilities – butterfly valves are constantly at work, quietly performing their duty.

One of the main reasons butterfly valves are so prevalent in HVAC systems is their compact design. HVAC systems often need to fit into tight spaces, especially in urban environments or crowded mechanical rooms. The sleek, space-efficient design of butterfly valves makes them an optimal choice for such situations. Despite their small size, they can handle large flow rates, making them incredibly efficient for their size.

Another key feature of butterfly valves that makes them ideal for HVAC systems is their cost-effectiveness. Not only are they typically less expensive to install than other types of valves, but their maintenance costs are also relatively low. This is due in part to their simple design, which consists of fewer components that could potentially fail or require replacement.

Additionally, butterfly valves offer quick and precise flow control. With just a quarter-turn, these valves can fully open or close, allowing for rapid adjustments to the system’s flow rate. This quick operation is crucial in HVAC systems, where maintaining a steady temperature often requires frequent adjustments to the flow of air or water.

Lastly, butterfly valves are known for their durability and ability to withstand high pressure and temperature variations, which are common in HVAC systems. This resilience ensures that they can continue to operate effectively over time, despite the demanding conditions.

In conclusion, butterfly valves, with their compactness, cost-effectiveness, quick operation, and durability, are indeed the silent workhorses of HVAC systems. They ensure that these systems can provide consistent, efficient temperature control, contributing significantly to our everyday comfort and productivity.

Detailed discussion on the role of butterfly valves in HVAC systems, emphasizing their efficiency and reliability.

Butterfly valves play a critical role in HVAC systems, significantly contributing to their efficiency and reliability. Their compact design, as stated in an article on Medium, allows them to handle a wide range of flow rates, making them adaptable to varying cooling requirements in HVAC systems. This adaptability is a testament to their efficiency as it allows the HVAC system to properly manage temperature control, regardless of the demand. Butterfly valves are also known for their durability, especially high-temperature butterfly valves that can withstand extreme conditions, further enhancing their reliability in HVAC operations (POV Butterfly Valve). Notably, new advancements in butterfly valve technology have led to more intelligent, energy-efficient, and reliable high-flow solutions in HVAC systems (Belimo). They offer bubble-tight shutoff of liquids, ensuring no leakage and maintaining system efficiency (Xintai Valves). Furthermore, certain butterfly valves can provide real-time data on their performance, allowing for predictive maintenance and improved reliability (IDEX India). Therefore, through their versatility, durability, and advanced features, butterfly valves are vital components that enhance the overall efficiency and reliability of HVAC systems.

How butterfly valve contribute to energy conservation in HVAC systems.

Butterfly valves play a significant role in energy conservation within HVAC (Heating, Ventilation, and Air Conditioning) systems. These valves are central to controlling and regulating the flow of air, water, or refrigerant throughout the system. By precisely managing these flows, butterfly valves ensure that the HVAC system operates at optimal efficiency, thereby minimizing energy wastage. For instance, when less cooling or heating is required, these valves can reduce the flow rate, conserving energy that would otherwise be used unnecessarily. Furthermore, butterfly valves’ quick operation allows for rapid response to changes in demand, preventing overuse of the system’s components and further saving energy. Their durability and ability to withstand high pressure and temperature variations mean they are less likely to fail, avoiding system downtime and unnecessary energy use during repairs or replacements. Some advanced butterfly valves even provide real-time data on their performance, enabling predictive maintenance and ensuring that the system always operates at peak efficiency. Therefore, through their control, efficiency, and reliability, butterfly valves contribute significantly to energy conservation in HVAC systems.

Real-life examples/case studies showing the impact of butterfly valve on HVAC system performance.

There are various real-life examples and case studies that illustrate the profound impact of butterfly valves on HVAC system performance. For instance, a report on Medium highlights how butterfly valves have been effectively utilized in precision cooling systems for chilled water applications. Similarly, research published on MDPI discusses the development of models for butterfly valve installed characteristics, which were then employed for real-time airflow control, showcasing the role of these valves in optimizing HVAC system performance. A success story on Belimo’s website details the positive effects of their award-winning Energy Valve, a type of butterfly valve, in combatting HVAC system issues and promoting long-term sustainability. In another case, an electric car manufacturer has standardized the use of high-performance butterfly valves in water and HVAC utility applications, as stated on Assured Automation’s website. These case studies underline the versatility, reliability, and efficiency of butterfly valves, thereby reinforcing their crucial role in enhancing HVAC system performance.

Our Expertise in Butterfly Valve Manufacturing

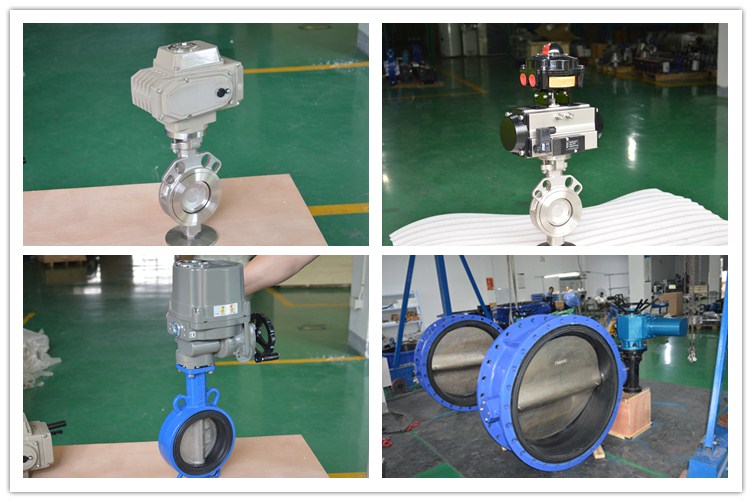

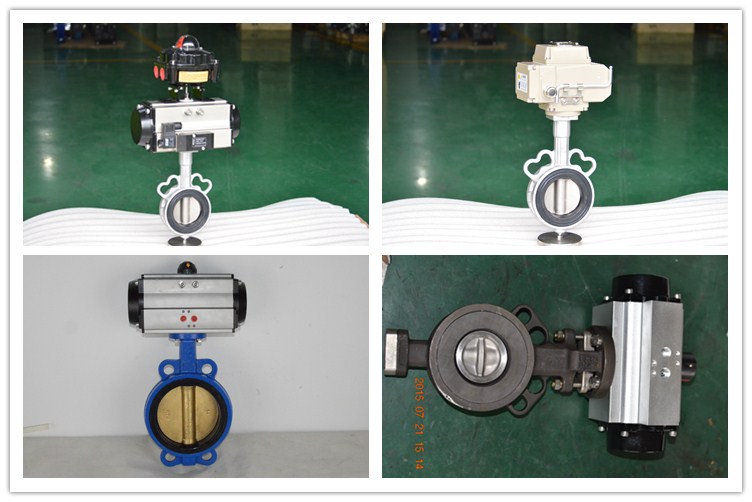

With years of experience in the field, we have honed our expertise in butterfly valve manufacturing, becoming a trusted name in the industry. Our manufacturing process is rooted in precision, quality, and innovation. We utilize state-of-the-art technology and machinery to ensure each butterfly valve we produce meets the highest standards of efficiency, durability, and performance. Our highly skilled engineers meticulously design each valve, taking into account its intended application, whether it’s for HVAC systems, water distribution networks, or industrial processes.

We specialize in producing a wide range of butterfly valves, from resilient-seated to high performance, to cater to diverse needs. Our resilient-seated butterfly valves are known for their excellent sealing capabilities, even in low-pressure environments, making them ideal for HVAC systems and similar applications. On the other hand, our high-performance butterfly valves are designed to withstand extreme conditions, offering superior reliability in high-pressure and high-temperature situations.

In addition, we use only the finest materials in our manufacturing process. Depending on the application, we offer valves made from ductile iron, stainless steel, or even exotic alloys for highly corrosive environments. Each material is carefully selected for its strength, resistance to corrosion, and longevity.

We also prioritize customization, understanding that each client may have specific requirements. Our team works closely with clients to tailor our butterfly valves to their precise specifications, ensuring optimal functionality. Furthermore, our commitment to innovation means we continually strive to improve our products. We invest heavily in research and development, always seeking new ways to enhance the performance and efficiency of our butterfly valves.

Our rigorous testing procedures further set us apart. Every valve we manufacture undergoes comprehensive testing to verify its performance under various conditions. This ensures that our valves not only meet but exceed industry standards and expectations.

In essence, our expertise in butterfly valve manufacturing lies in our unwavering commitment to quality, innovation, and customer satisfaction. We take pride in every valve we produce, knowing that it contributes to the efficient and reliable operation of critical systems worldwide.

Overview of our company’s expertise in manufacturing butterfly valve.

Our company has solidified its reputation as a leader in butterfly valve manufacturing, leveraging years of industry experience and technical expertise. We’re renowned for our meticulous manufacturing process, which combines cutting-edge technology with high-quality materials to create butterfly valves that are both durable and efficient. Our product range is wide and versatile, encompassing resilient-seated butterfly valves known for their excellent sealing capabilities as well as high-performance butterfly valves designed to withstand extreme conditions. Our commitment to customization allows us to tailor these valves to the precise specifications of each client, ensuring optimal functionality across a variety of applications, from HVAC systems to industrial processes. Rigorous testing procedures ensure that our products consistently meet or exceed industry standards. Above all, our dedication to innovation and customer satisfaction sets us apart in the butterfly valve marine manufacturing industry, as we continuously strive to enhance our offerings and deliver solutions that contribute to the efficiency and reliability of critical systems around the world.

Highlighting our adherence to industry standards and certifications.

At our company, we place immense value on our commitment to industry standards and certifications. This dedication underlines our pursuit of excellence and our drive to deliver superior quality in all our offerings. We hold ourselves accountable to rigorous standards and continuously strive to maintain and improve upon them. Our certifications are a testament to our proficiency and expertise, demonstrating our compliance with recognized industry best practices. These achievements not only validate our capabilities but also provide our clients with the assurance that they are partnering with a reliable and competent organization. They serve as a guarantee that we operate with utmost integrity, ensuring the highest levels of service, safety, and efficiency in all our operations.

Discussion on our rigorous quality control process.

Our rigorous quality control process is a cornerstone of our commitment to excellence. We believe that exceptional quality doesn’t happen by chance, but rather, it’s the result of meticulous planning and execution. Our process begins with sourcing the highest quality raw materials, followed by stringent monitoring during the production phase. Each product undergoes multiple stages of inspections to detect and rectify any deviations from our set standards. Our quality control team, equipped with advanced testing tools, ensures that every product meets our exacting specifications before it leaves our facilities. This rigorous approach helps us maintain consistency in our offerings, reduce errors, and uphold our reputation for delivering products and services of the highest calibre.

Global Reach and Local Impact

Global Reach and Local Impact is a concept that encapsulates the ability of businesses, organizations, or initiatives to influence and make a significant difference not only at a local level but also on an international scale. It’s about harnessing the power of a global network to effect change and bring about progress in local communities. With the advent of technology and digital platforms, the world has become more interconnected than ever before, providing an unprecedented opportunity for entities to extend their reach beyond geographical boundaries. This global reach allows organizations to tap into diverse markets, acquire a varied customer base, gain access to international resources, and learn from global best practices. However, while global reach is important, maintaining local impact is equally vital. Local impact refers to the tangible and positive changes an organization can bring about in its immediate community. It’s about understanding local culture, needs, and challenges, and tailoring strategies to address these. Whether it’s by creating employment opportunities, contributing to the local economy, or implementing sustainable practices, organizations with a strong local impact are those that respect and enrich the communities they operate in. Therefore, the essence of Global Reach and Local Impact lies in striking a balance between expanding horizons and maintaining a strong local presence. It’s about leveraging global opportunities to create sustainable, meaningful change at a local level.

Explanation of our global reach and how we cater to the UK’s HVAC industry.

Our company’s global reach is a testament to our commitment to delivering world-class HVAC solutions across the globe. We have established a strong presence in several international markets, thanks to our advanced technology, superior quality of products, and exceptional customer service. Despite our global footprint, we maintain a keen focus on local industries, including the UK’s HVAC sector. We understand that each market has its unique challenges and requirements, and the UK is no exception. With its diverse climate conditions and stringent energy efficiency regulations, the UK HVAC industry demands highly reliable and eco-friendly solutions. To cater to these needs, we leverage our global expertise and local understanding to provide customized HVAC systems that meet the UK standards for energy efficiency, performance, and sustainability. Our dedicated UK team works closely with clients to understand their specific requirements, offering tailored solutions that not only ensure optimal indoor climate control but also contribute to lower energy costs and reduced environmental impact. Through this blend of global reach and local focus, we are able to deliver on our promise of superior HVAC solutions, wherever our customers are.

Conclusion

In conclusion, butterfly valves have indeed proven to be the silent workhorse of the UK’s HVAC systems. Their simplicity in design, ease of use, and unparalleled efficiency have made them an integral component in ensuring the smooth operation of HVAC systems across the country. With their ability to control the flow of air, water, or other fluids with precision, they play a crucial role in maintaining optimal indoor climate conditions, thereby contributing significantly to the comfort and well-being of individuals in residential, commercial, and industrial settings.

Moreover, their robustness and durability make them a cost-effective solution for HVAC systems. They require minimal maintenance, can withstand harsh conditions, and have a long lifespan, providing great value for money. The versatility of pneumatic butterfly valve also cannot be overlooked. Available in various sizes and materials, they can be tailored to meet the specific requirements of different HVAC applications, making them a highly adaptable solution for a range of scenarios.

Furthermore, as the UK continues to advance its sustainability goals, the role of butterfly valves in promoting energy efficiency is more relevant than ever. By aiding in the regulation of HVAC systems, these valves help reduce unnecessary energy consumption, supporting the UK’s commitment to reducing its carbon footprint.

However, as we move forward, it is essential that we continue to innovate and improve upon these foundational components. The future of the UK’s HVAC industry relies on our ability to adapt to changing needs and technological advancements. And in this evolving landscape, butterfly valves, the silent workhorse, will undoubtedly continue to play a pivotal role.

So, whether you’re a homeowner seeking to maintain a comfortable living environment, a business owner looking to create a productive workspace, or an industry professional striving to optimize system performance, remember the significant contribution of butterfly valves. They may be silent and unassuming, but their impact on the UK’s HVAC systems is loud and clear.