A butterfly valve is a type of flow control device that utilizes a disc-shaped element and pivoting motion to regulate the flow of liquids or gases. This type of valve is commonly used in various applications, such as industrial piping systems, residential water lines and even automotive areas where accurate regulation and control of fluid pressure is required. It can be used to start, stop or adjust the flow rate within these systems. Butterfly valves are known for their simplicity, durability and cost-effective nature compared to other options available on the market.

Introduction

A butterfly valve is a form of quarter-turn valve with a disc shaped closure element. The valve is used to regulate flow in pipelines and its operation is relatively simple: when the disc is parallel to the flow, it allows unrestricted movement of fluid; when it is perpendicular, flow is blocked. Butterfly valves are used in various industries such as energy production, oil and gas, water supply and more due to their ability to maintain flow control with minimal pressure loss.

Definition of butterfly valve

A butterfly valve is a form of quarter-turn valve that is used to regulate the flow of fluid in pipelines. It consists of a circular disc-shaped closure element, which is mounted on a rod and passes through the body of the valve. The closure element rotates at 90 degrees to either open or close off the flow in the pipeline. When the disc is parallel to the flow, it allows unrestricted movement; when it is perpendicular, flow is blocked. Butterfly valves are durable and can provide maximum control with minimal pressure loss, making them ideal for various industries such as energy production, oil and gas, water supply and more.

Overview of common applications for butterfly valves

Butterfly valves are popular in a variety of applications, including oil and gas pipelines, energy production plants, water supply lines and more. They are often used in these applications because they offer an easy solution for controlling the flow of liquids with minimal pressure loss. Additionally, their robust design ensures longevity and makes them suitable for applications under various temperature, pressure, and chemical conditions. Furthermore, their ability to provide precise control over flow direction also makes them suited for use in systems where precision is a must.

Types of Butterfly Valves

Butterfly valves come in a variety of types, including concentric, double offset, and triple offset butterfly valves. Concentric butterfly valves feature a circular closure element that is mounted onto the valve body by a single stem. This configuration allows for quick and easy operation with minimal pressure loss, making it ideal for flow regulation in industrial applications. Double-offset valves are composed of two discs which are connected by two stems and rotate independently of each other at 90 degrees when opened or closed.

This type of valve is especially useful when accurate flow control is needed to avoid turbulence and cavitation. Triple-offset valves have three discs that are connected with three separate stems, allowing for greater precision when controlling flow in high-pressure systems. They are also effective at preventing wear due to the softer seating surfaces on their discs than those found on concentric or double-offset models. Each type of butterfly valve offers its own distinct advantages, making them suitable for various industries depending on the specific requirements.

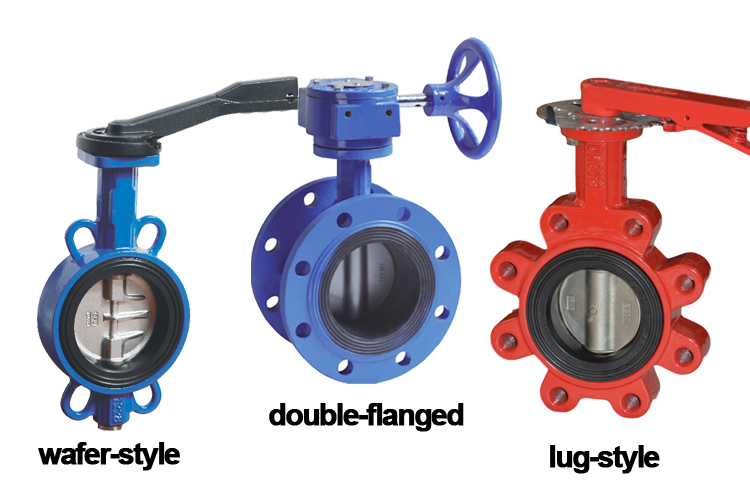

Wafer-style butterfly valves

Wafer style butterfly valve are widely used in many industrial applications due to their ease of installation, low cost, and excellent performance. They offer a reliable seal and minimal leakage using two metal discs connected with a stem. This type of valve is often found in wastewater applications, as it offers excellent sealing ability even when the system pressure is low. Additionally, wafer-style butterfly valves are lightweight and require little maintenance, making them ideal for use in tight spaces or difficult locations. These versatile valves offer efficient control for systems that may be subject to fluctuating temperatures or pressures and can be easily modified to suit specific requirements.

Lug-style butterfly valves

Lug style butterfly valve are a popular choice for industrial applications where tight shutoff and low pressure drops are required. They offer reliable sealing using two metal discs connected by a single spindle that can be opened or closed in either direction. The lug type of valve provides a higher seating pressure than other models, making it suitable for water systems with high-pressure requirements. A significant advantage of the lug style is its ability to hold up with very little maintenance and provide a secure connection between its body and pipe flange. Additionally, lug-style butterfly valves are cost effective and easy to install, making them an ideal solution for many industries.

Flanged butterfly valves

Flanged butterfly valve are one of the most popular types of valve used in industrial settings. They are lightweight, easy to install and provide reliable seal performance. The flanged design allows for secure connection between the valve and the pipeline and provides higher pressure sealing than other types of valves. The flange offers additional support and stability to the assembly, making them suitable for high-pressure and high-temperature applications. Additionally, many flanged butterfly valves come with a manual override function in case of emergency shutoff or when automated control is not available. Flanged valves are also highly resistant to corrosion, making them an ideal choice for harsh environments.

The Benefits of Butterfly Valves

Butterfly valves provide efficient and reliable flow control solutions for a variety of applications in many industries. One of their principal advantages is that they are lightweight and easy to install, making them ideal for tight spaces or low-clearance installations. This type of valve provides both tight shutoff and decreased pressure drops, resulting in smoother operation and reduced energy consumption.

Moreover, lug butterfly valves offer superior seal performance due to their two metal discs connected by a single spindle that can be opened or closed with either direction. They also provide better seating pressure than other valves due to their lug style design, making them an excellent choice for water systems with high pressure requirements.

Additionally, there is very little maintenance required with wafer butterfly valves due to the wear resistant materials they are typically manufactured from. Furthermore, butterfly valves are cost effective solutions that offer flexibility during installation and can be used in a wide range of temperatures and pressures as well as corrosive environments.

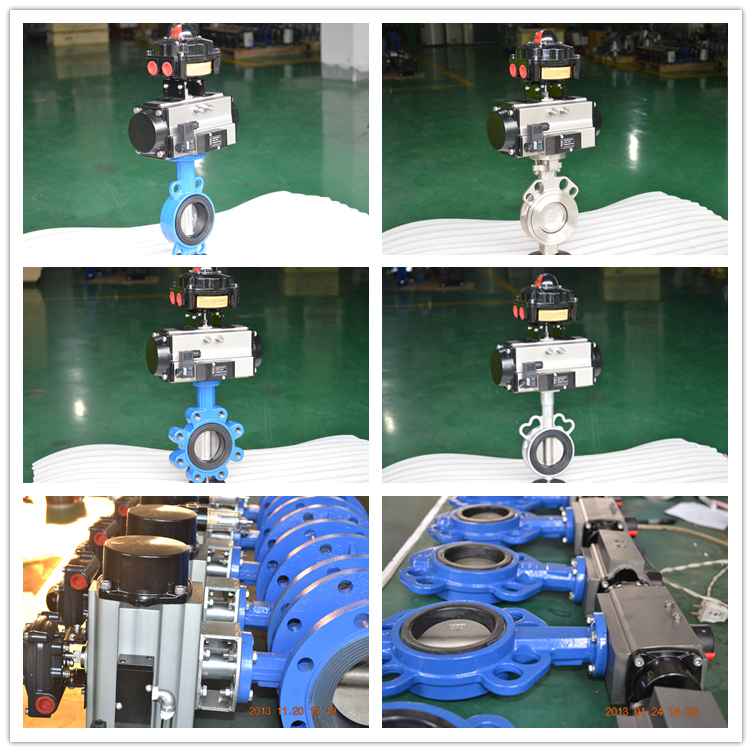

Durability and longevity

Pneumatic Butterfly valves are known for their durability, thanks to the wear-resistant materials they are usually made from. This makes them an ideal choice for applications where there is a risk of abrasion, such as pipelines carrying abrasive materials. Additionally, some manufacturers build butterfly valves using special alloys that offer better resistance to extreme temperatures and pressures than conventional plastics or metals. Furthermore, the self-contained design of most butterfly valves limits the possibility of mechanical failure due to its low number of moving parts, making them reliable and safe for long-term use.

Maximum flow control with minimal pressure drop

Butterfly valves provide maximum flow control with minimal pressure drop due to the two metal discs connected by a single spindle. This allows them to be opened and closed with either direction, ensuring precise and consistent control over the flow of liquid or gas. In addition, their lug style design helps to reduce leakage, providing better sealing than traditional valves. Finally, thanks to their lightweight construction and internal components, butterfly valves also provide improved pressure drops compared to other available options; giving you more control without sacrificing efficiency.

Common Issues With Butterfly Valves and How To Avoid Them

Common issues with butterfly valves can include leaks, seizing, stiction and abrasion. These problems can arise from improper installation or a lack of maintenance, so it’s important to make sure all components are properly installed and regularly inspected. Leaks can be avoided by making sure the valve is adequately sealed when first installed, and regular inspections will help identify any developing problems before they worsen. Seizing can be prevented by avoiding contamination of the valve seat and ensuring correct lubrication between moving parts. To avoid stiction (sticking), internal components should be kept clean and free of debris for consistent performance. Finally, abrasion can be reduced by using wear-resistant materials in areas that may experience friction due to fluid flow. By taking these steps, butterfly valves can remain reliable and efficient for long-term use