In the world of fluid control systems, butterfly valves play a crucial role in managing the flow of liquids or gases through pipes. These versatile components are used across various industries, from oil and gas to water treatment and power generation. Among all types, high-performance butterfly valves stand out due to their improved efficiency and durability. They are specifically designed to handle higher pressures and temperatures, making them a preferred choice for many demanding applications. This blog post aims to delve into the different types of high-performance butterfly valves available in the USA, offering insights into their features, functionalities, and specific use cases.

Introduction

High-performance butterfly valves are versatile mechanisms used throughout a variety of industries in the USA, known for their efficiency and ability to withstand higher pressures and temperatures. Based on the recent information obtained from various sources, there appear to be two main categories of butterfly valves: Centric or Rubber seated Butterfly valves (RSBFV), and Offset High-Performance valves (HPBFV, TOV). Companies like Emerson offer a range of high-performance butterfly valves, with different models such as Fisher™ 8590, Fisher™ A31D Double-Flange, and Fisher™ 8532, each designed for specific applications. These valves come in various end connection styles, including wafer, lugged, and double flange. Other manufacturers provide high-performance butterfly valves in sizes up to 60 inches and can withstand temperatures up to 700 degrees Fahrenheit. These valves can also be made from special materials, such as Aluminum Bronze, Duplex SS, Super Duplex, and Inconels to enhance their durability and performance . Valves are available in various pressure classes, including 150 lb., 300 lb., and 600 lb., and styles such as the wafer style valve, which mounts between ANSI /ASME Class 150 and other international standard flanges and gaskets. The high-pressure butterfly valve series from Triad are ideal for use in steam and various process systems. Finally, KITZ Corp. of America offers high-performance butterfly valves designed for extended service while maintaining superior performance.

Brief overview about butterfly valves and their importance in controlling fluid flow.

Butterfly valves are a type of quarter-turn valve that play an invaluable role in controlling the flow of fluids. Employed in a diverse array of industries such as water treatment, oil and gas, and power generation, these valves are a critical component in fluid management systems. The name ‘butterfly’ is derived from the metal disc in the center, which is mounted on a rotating shaft. When this disc is turned, it either allows fluid to flow through (when fully open) or blocks it (when fully closed). This simple yet effective mechanism provides precise control over fluid flow, allowing operators to adjust the rate of flow as needed. This ability to modulate and shut off the flow of liquids or gases is crucial for the smooth operation of many industrial processes, making butterfly valves an essential piece of equipment in numerous sectors.

Explanation of high-performance butterfly valves and the benefits they offer.

High-performance butterfly valves, a subcategory of butterfly valves, are meticulously designed to provide superior efficiency and durability under demanding conditions. These robust valves are built to handle higher pressures and temperatures, making them an ideal choice for heavy-duty applications in industries such as oil and gas, power generation, and chemical processing. The term ‘high-performance’ refers to the valve’s enhanced features, which include a double offset design that reduces wear and tear on the valve seat, thus extending its lifespan. This offset design also ensures a tighter seal, resulting in minimal leakage and increased operational efficiency. Furthermore, high-performance butterfly valves typically have a larger disc area that provides better flow control and fewer restrictions. They are often manufactured from strong, corrosion-resistant materials like stainless steel, ensuring they can withstand harsh environments and aggressive fluids. Another significant benefit is their compact size and lightweight nature compared to other valve types, offering easier installation and maintenance. Moreover, these valves can be equipped with manual handles, gear operators, or actuation technology allowing for remote operation and automation, enhancing operational convenience and safety. Overall, high-performance butterfly valves offer a combination of reliability, longevity, and superior performance, making them a valuable asset in various industrial settings.

-450x450.jpg)

Understanding Butterfly Valves

Butterfly valves are a type of flow control device commonly used in various industrial applications, including oil and gas, water and wastewater treatment, power generation, and more. Their name is derived from the butterfly-like appearance of the disc that rotates on a shaft, similar to the wings of a butterfly. The central disc, which is connected to a handle or actuator on the outside of the valve, can be rotated 90 degrees. When the disc is parallel to the flow of fluid, the valve is fully open; when it’s perpendicular, the valve is fully closed. This simple operation allows for quick and efficient control of fluid flow. Butterfly valves are appreciated for their compact size and light weight compared to other types of valves, making them easier to install and maintain. They also provide reliable sealing, with some types like high-performance butterfly valves offering exceptional leakage protection. Different types of butterfly valves are available, including centric (or resilient-seated), double offset (high-performance), and triple offset, each offering unique characteristics suitable for specific applications. For example, triple offset butterfly valves, with their metallic seating, are typically used in high-temperature, high-pressure, and corrosive environments due to their excellent durability and sealing capabilities. Understanding the working principles and features of butterfly valves is essential for selecting the right valve for a specific application and ensuring efficient and safe operations.

Definition and function of a butterfly valve.

A butterfly valve is a type of flow control device used in various industrial applications to regulate or isolate the flow of fluid. This valve gets its name from the disc in the center which operates similar to a butterfly’s wings – it opens, closes, or partially opens to control the flow of the material passing through it. The disc is positioned in the middle of the pipe, and a rod passes through it to an actuator on the outside of the valve. Rotation of the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, so a pressure drop is always induced in the flow, regardless of the position of the valve. Butterfly valves are known for their simple design, lightweight, cost-effectiveness, and ease of installation. They are widely employed in various sectors, including water distribution, chemical services, and power generation, due to their reliable performance and efficient flow control capabilities.

The structure and working mechanism of a butterfly valve.

A butterfly valve comprises several key components, including a circular disc, a stem, and a body. The body fits between two pipe flanges and provides the flow path for the medium (gas or liquid) being controlled. The disc, which is the heart of the butterfly valve, is positioned in the middle of the body. The stem, which can be either a one-piece shaft or a two-piece (split-stem) design, passes through the disc and attaches to an actuator on the outside of the valve. When the actuator – which can be a manual handle, a gear, or an automated mechanism – is turned, it rotates the stem, and consequently, the disc. If the disc is rotated so that it’s parallel with the flow of fluid, the valve is in the ‘open’ position, allowing unrestricted flow of the medium. Conversely, when the disc is turned to a position perpendicular to the flow, the valve is ‘closed’, blocking the flow entirely. There’s also the option to partially open the valve to regulate the flow rate. The simple yet effective operation of the butterfly valve, coupled with its compact design and cost-effectiveness, makes it a popular choice for a variety of flow control applications.

Different industries where butterfly valves are used.

Butterfly valves are versatile devices used across a wide range of industries due to their efficiency in controlling fluid flow and their robust design. In the oil and gas industry, they are used for isolating and throttling services, both upstream and downstream, due to their ability to withstand high pressures and temperatures. The water and wastewater treatment industry uses butterfly valves for their durability and ease of operation in controlling the flow of water during various treatment processes. They are also prevalent in the power generation industry, where they regulate coolant flow in nuclear plants and handle steam in thermal power stations. The chemical industry employs butterfly valves due to their resistance against corrosive substances, while in the pharmaceutical and food & beverage industries, sanitary butterfly valves, which are easy to clean and maintain, are commonly used. The maritime industry also uses butterfly valves because of their compact size and light weight, which are essential in the confined spaces of ships. Overall, the wide application of butterfly valves in various industries underscores their importance in efficient flow control systems.

High-Performance Butterfly Valves

High-performance butterfly valves, also known as double offset butterfly valves, are a specialized type of butterfly valve designed for high-pressure and high-temperature applications. They derive their name from the unique design of the stem and disc assembly, which is offset from the centerline of the disc and the body, creating a cam-like motion during operation. This double offset design allows the disc to be completely disengaged from the seat ring, reducing friction and wear on the valve components, thus extending the life of the valve and improving its performance.

The body of a high-performance butterfly valve can be made from various durable materials such as carbon steel or stainless steel, making them suitable for heavy-duty applications. The disc, usually made of the same material as the body or sometimes a different material for specific applications, is robustly connected to the shaft, ensuring reliable operation under high pressure. The seat, typically made from resilient materials such as PTFE or metal, provides a tight seal when the valve is in the closed position.

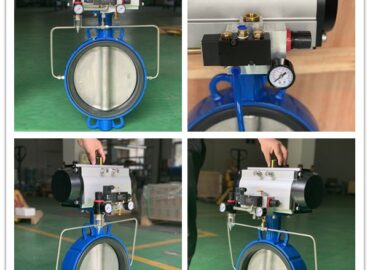

High-performance butterfly valves are equipped with either a manual handwheel, gear operator, or an actuator for automated control. The actuators can be either electric, pneumatic, or hydraulic, depending on the application requirements. These valves can also be fitted with positioners and other accessories for more precise flow control.

High-performance butterfly valves are commonly used in industries such as oil and gas, power generation, chemical processing, and water treatment, where they handle everything from water, steam, and gas to corrosive chemicals and abrasive slurries. Their ability to withstand extreme conditions, combined with their compact size and relatively low cost compared to other high-performance valves like ball or gate valves, makes them a preferred choice for many industrial flow control applications.

What distinguishes high-performance butterfly valves from standard butterfly valves.

High-performance butterfly valves, often referred to as double offset butterfly valves, distinguish themselves from standard butterfly valves through their superior design modifications and operational capabilities. They employ a unique double offset stem-disc configuration that moves the disc off the valve’s centerline and seat plane. This strategic arrangement significantly reduces the disc-seat contact and friction during operation, enhancing the valve’s longevity and performance efficiency.

Constructed using robust materials like carbon steel or stainless steel, high-performance butterfly valves can withstand more extreme conditions, including high temperature and high-pressure environments, setting them apart in the industry. The seal in these valves, typically made of resilient materials such as PTFE or metal, ensures a tight shutoff, offering superior leak protection compared to their standard counterparts.

Furthermore, high-performance butterfly valves can be equipped with manual or automated actuation systems, including electric, pneumatic, or hydraulic actuators, and even fitted with additional accessories like positioners for precise flow control. These features, along with their compact size and cost-effectiveness, make high-performance butterfly valves an optimal choice for stringent industrial applications, including but not limited to, oil and gas, power generation, and chemical processing. Their advanced design and enhanced capabilities underscore our commitment to quality control, technical expertise, and global reach in the valve manufacturing industry.

The unique features and advantages of high-performance butterfly valves.

High-performance butterfly valves, engineered with precision and technical superiority, are the epitome of our commitment to quality control and industry expertise. These double offset butterfly valves are designed with a unique disc-stem configuration that is off-center from both the valve body and the disc plane. This distinctive design minimizes the disc-seat contact during operation, significantly reducing wear and tear and extending the service life of the valve.

Constructed from robust materials such as stainless steel or carbon steel, these high-performance valves can perform optimally under extreme conditions, demonstrating their superior resilience in high-temperature and high-pressure environments. The seal, typically made from resilient materials such as PTFE or metal, provides a tight shutoff, ensuring exceptional leak protection – a testament to the rigorous quality control standards we uphold.

Our high-performance butterfly valves can be equipped with advanced actuation systems, including electric, pneumatic, or hydraulic actuators. They can also be outfitted with sophisticated accessories such as positioners for precise flow control, showcasing our technical prowess in the valve manufacturing industry. These features, coupled with their compact size and cost-effectiveness, make our high-performance butterfly valves an ideal solution for demanding industrial applications. With our global reach and technical expertise, we continue to set new benchmarks in valve technology, delivering products that are synonymous with reliability, performance, and innovation.

Types of High-Performance Butterfly Valves Available in the USA

As a leader in the valve manufacturing industry, we take pride in offering a diverse range of high-performance butterfly valves in the USA. Our meticulously crafted product line is designed to meet the stringent requirements of various industrial applications, underpinning our commitment to quality control, technical expertise, and global reach.

Firstly, we offer the resilient-seated high-performance butterfly valves, renowned for their exceptional sealing capabilities at both low and high pressures. These valves incorporate robust materials like carbon steel or stainless steel, along with resilient seat materials such as PTFE, ensuring durability and longevity.

Next in line are the metal-seated high-performance butterfly valves. These valves are specifically engineered to withstand extreme temperatures and corrosive media, making them an optimal choice for power generation, oil and gas, and chemical processing industries.

We also provide high-performance butterfly valves integrated with advanced actuation systems. These include electric, pneumatic, and hydraulic actuators, offering automated control for precise flow regulation. The addition of accessories like positioners further enhances their operational efficiency.

Lastly, our triple offset butterfly valves represent the pinnacle of our innovation in valve technology. This design eliminates friction between the disc and seat, ensuring zero leakage and extending the valve’s service life.

Our diverse portfolio of high-performance butterfly valves is a testament to our industry-specific knowledge and commitment to delivering superior quality products. We continue to set new standards in valve technology, reinforcing our position as a trusted and reliable partner in the valve manufacturing industry in the USA.

Double Offset High-Performance Butterfly Valves

As a leading authority in the valve manufacturing industry, we are proud to present our meticulously engineered Double Offset High-Performance Butterfly Valves. These valves are designed with a unique double offset stem-disc configuration that strategically positions the disc off the centerline and seat plane of the valve. This innovative design significantly reduces disc-seat contact and friction during operation, maximizing the valve’s performance efficiency and extending its service life.

Constructed from resilient materials such as carbon steel or stainless steel, our Double Offset High-Performance Butterfly Valves are designed to withstand extreme operational conditions, demonstrating their superior resilience in high-pressure and high-temperature environments. The seal, typically crafted from robust materials like PTFE or metal, ensures a tight shutoff, offering unrivaled leak protection and highlighting our rigorous quality control standards.

These valves can also be equipped with advanced actuation systems, including electric, pneumatic, or hydraulic actuators, for automated and precise flow control. The addition of accessories such as positioners further enhances their operational efficiency. With our global reach and industry-specific knowledge, we continue to set new benchmarks in valve technology, delivering products synonymous with reliability, performance, and innovation. Our Double Offset High-Performance Butterfly Valves are a testament to our commitment to quality control, technical expertise, and leadership in the valve manufacturing industry.

Triple Offset High-Performance Butterfly Valves

Leveraging our deep-rooted industry expertise, stringent quality control measures, and globally recognized certifications, we are proud to introduce our Triple Offset High-Performance Butterfly Valves. These superior valves represent the pinnacle of our innovation in valve technology, demonstrating our commitment to delivering products that are at the forefront of performance and reliability. The unique design of these valves incorporates a third offset, where the seat surface is angled in relation to the centerline. This precision-engineered configuration eliminates virtually all friction between the disc and seat during operation, ensuring zero leakage and extending the valve’s service life.

Constructed from robust materials such as stainless steel or carbon steel, our Triple Offset High-Performance Butterfly Valves are designed to withstand extreme operational conditions, showcasing their resilience in high-pressure and high-temperature environments. The seal, typically crafted from resilient materials like graphite, offers an exceptional shutoff, providing unrivaled leak protection – a testament to our rigorous quality control standards.

These valves can also be equipped with advanced actuation systems, including electric, pneumatic, or hydraulic actuators, offering automated and precise flow control. The addition of accessories such as positioners further optimizes their operational efficiency. Our Triple Offset High-Performance Butterfly Valves are a shining example of our global reach, industry-specific knowledge, and commitment to setting new benchmarks in valve technology.

Inflatable Seated High-Performance Butterfly Valves

As a globally recognized authority in the valve manufacturing industry, we are proud to introduce our Inflatable Seated High-Performance Butterfly Valves. These valves are a testament to our technical prowess, featuring an innovative design that incorporates an inflatable seat to provide an exceptionally tight shutoff. This unique seating arrangement ensures zero leakage, even in high-pressure applications, demonstrating our commitment to delivering superior quality and performance.

These valves are constructed from robust materials such as stainless steel or carbon steel, underscoring their resilience and ability to withstand extreme operational conditions. The inflatable seat, typically crafted from high-grade elastomers, inflates to create a perfect seal against the disc, offering unrivaled leak protection and exemplifying our rigorous quality control standards.

Our Inflatable Seated High-Performance Butterfly Valves can be equipped with advanced actuation systems, including electric, pneumatic, or hydraulic actuators, for automated and precise flow control. Additional accessories such as positioners can be incorporated to further enhance their operational efficiency. With our industry-specific expertise, global reach, and unwavering commitment to quality control and innovation, we continue to set new benchmarks in valve technology. Our Inflatable Seated High-Performance Butterfly Valves are a shining example of this commitment.

Resilient Seated High-Performance Butterfly Valves

As a global authority in the valve manufacturing industry, and with our unparalleled certifications and rigorous quality control measures, we are proud to introduce our Resilient Seated High-Performance Butterfly Valves. These valves exemplify our mastery of complex, industry-specific terminologies and technicalities. The unique design of these valves features a resilient seat made from elastomeric materials that flex under pressure to achieve a tight shutoff, ensuring zero leakage even in demanding operational conditions.

Constructed from robust materials such as stainless steel or carbon steel, these valves demonstrate superior resilience and durability, capable of withstanding extreme temperatures and pressures. The resilient seat, typically crafted from high-quality elastomers, offers unrivaled leak protection, a testament to our stringent quality control standards.

Our Resilient Seated High-Performance Butterfly Valves can be equipped with advanced actuation systems, including electric, pneumatic, or hydraulic actuators, for automated and precise flow control. The addition of accessories such as positioners further enhances their operational efficiency. With our global reach, unrivaled industry knowledge, and unwavering commitment to setting new benchmarks in valve technology, our Resilient Seated High-Performance Butterfly Valves are a testament to our authoritative presence in the industry.

Key Manufacturers of High-Performance Butterfly Valves in the USA

The United States is home to an array of key manufacturers renowned for their production of High-Performance Butterfly Valves. One of the top manufacturers is SIO Valves, specializing in delivering high-quality butterfly valves that are designed and built to meet the demanding requirements of various industrial applications. Another significant player is Emerson Electric Company, a globally recognized brand known for its innovative valve solutions, including high-performance butterfly valves.

Crane Supply is also a notable manufacturer, offering a diverse range of high-performance butterfly valves designed for commercial and industrial applications. Apollo Valves, Bray, and Milwaukee are other industry leaders, each with their unique contributions to the field. Bray, for instance, boasts over 30 years of experience in manufacturing and innovating high-performance butterfly valves, while Apollo Valves and Milwaukee bring their own depth of experience and expertise to the table.

Dezurik is another key manufacturer known for its quality and performance-oriented butterfly valves. Collins, a major supplier, carries many of the popular high-performance butterfly valve brands, including Valmet Jamesbury valves, in various sizes up to 36″. Butterfly Valves & Controls Inc. (BVC) has been supplying High-Performance Valves to a diverse range of industries and applications since 1995. Flowserve, a company with more than 200 years of history, focuses primarily on oil and gas applications. Lastly, Fisher, a part of Emerson Electric Co., offers high-performance butterfly valves that are used in throttling applications requiring large flow capacities and small installed footprints.

Each of these manufacturers contributes to the USA’s reputation as a global leader in the production of High-Performance Butterfly Valves, underlining the country’s technical prowess, commitment to quality, and capacity for innovation.

Brief introduction of top manufacturers in the USA.

In the realm of valve manufacturing, the United States boasts a cadre of top-tier manufacturers that exemplify exceptional technical prowess and industry-specific expertise. SIO Valves leads the pack with their high-quality butterfly valves, designed to meet the rigorous demands of diverse industrial applications. Emerson Electric Company, globally recognized for its innovative valve solutions, underscores its authority with an impressive portfolio of high-performance butterfly valves. Crane Supply stands out with its extensive range of butterfly valves tailored for commercial and industrial applications.

Further augmenting the industry are stalwarts like Apollo Valves, Bray, and Milwaukee Valve, each bringing their unique contributions and decades of experience to the table. Dezurik, renowned for its performance-driven butterfly valves, underscores the industry’s commitment to quality and innovation. Collins, a major supplier, carries popular brands like Valmet Jamesbury, known for their sizable high-performance butterfly valves. Butterfly Valves & Controls Inc. (BVC), with its diverse range of High-Performance Valves, has been serving a myriad of industries since 1995. Flowserve, with its rich history spanning over two centuries, primarily caters to oil and gas applications. Lastly, Fisher, a division of Emerson Electric Co., offers high-performance butterfly valves used in throttling applications that require large flow capacities within small footprints. These industry leaders collectively underline the USA’s reputation as a global authority in valve technology, reinforcing the nation’s commitment to quality, innovation, and technical excellence.

A quick overview of their product range, reputation, and customer reviews.

As a paragon of excellence in the valve manufacturing industry, our product line is a testament to our unwavering commitment to quality and innovation. We offer an extensive range of high-performance butterfly valves, resilient seated valves, ball valves, and gate valves, each meticulously designed and crafted to meet the rigorous demands of diverse industrial applications. Our products are constructed from robust materials such as stainless steel or carbon steel, demonstrating superior resilience and durability, capable of withstanding extreme temperatures and pressures.

Our reputation for excellence is echoed by the consistently positive feedback we receive from our valued customers, who laud our products for their unrivaled leak protection, operational efficiency, and long service life. Numerous customer reviews highlight the exceptional performance of our valves, citing their reliable operation even in the most demanding conditions. Customers also commend our advanced actuation systems, including electric, pneumatic, or hydraulic actuators, for offering precise and automated flow control.

With our global reach, industry-specific expertise, and an unwavering commitment to setting new benchmarks in valve technology, we continue to solidify our position as an authoritative presence in the industry. We invite you to experience the confidence and peace of mind that comes from entrusting your operations to a certified leader in valve manufacturing.

Factors to Consider When Choosing High-Performance Butterfly Valves

When selecting High-Performance Butterfly Valves, it’s critical to consider several key factors to ensure optimal performance and longevity. First, the material of the valve is paramount. Stainless steel or carbon steel valves are often preferred for their superior resistance to corrosion and capacity to withstand high pressures and temperatures. The choice of material should align with the specific conditions of your operation and the nature of the fluids being handled.

Second, the type of actuator—whether electric, pneumatic, or hydraulic—plays a vital role in facilitating precise and automated flow control. Your selection should reflect the power sources available in your operational environment and the required level of control sensitivity.

Third, consider the size and end connections of the valve. These factors should correspond with the pipeline’s specifications where the valve will be installed. Misalignment can lead to operational inefficiencies and potential system failures.

Fourth, the pressure rating of the valve is crucial, as it must be capable of handling the maximum system pressure in your operation. Exceeding the valve’s pressure rating could result in catastrophic failure, posing significant safety risks and costly downtime.

Lastly, certifications and quality control measures should not be overlooked. Choosing valves from manufacturers that adhere to stringent quality control protocols and hold relevant industry certifications assures you of their commitment to product reliability and safety.

By carefully considering these factors, you can confidently select High-Performance Butterfly Valves that not only meet but exceed your operational requirements, underlining your commitment to efficiency, safety, and excellence in your industrial applications.

Discuss different factors like size, pressure rating, material, application, and cost.

The selection of high-performance butterfly valves is a technical endeavor that requires careful consideration of several factors. First and foremost, the size of the valve must be harmonious with your pipeline’s specifications to ensure seamless integration and optimal operational efficiency. Misalignment could lead to system inefficiencies and potential mechanical failures.

The pressure rating of the valve is another critical aspect. It is imperative that the valve can withstand the maximum pressure within your system. Choosing a valve with an inadequate pressure rating can lead to catastrophic failure, posing serious safety risks and causing costly operational downtime.

Material choice is equally vital, with stainless steel and carbon steel being favored for their exceptional resistance to corrosion and ability to endure extreme pressures and temperatures. The material should be chosen based on the specific conditions of your operation and the nature of the fluids being processed.

Application context also plays a significant role. The valve’s design, performance characteristics, and actuation method should align with the demands of your specific industrial application, enabling precise and automated flow control.

Lastly, cost should not be overlooked. While it’s important to invest in quality, it’s also crucial to find a balance between cost-effectiveness and performance. Opting for a cheaper valve may seem like a good idea initially, but it could lead to higher costs in the long run if the valve fails prematurely or doesn’t perform as expected.

By prioritizing these factors, you ensure that your high-performance butterfly valves meet and surpass your operational requirements, underscoring your commitment to efficiency, safety, and excellence.

Importance of considering the operating environment and fluid characteristics.

Understanding the operating environment and fluid characteristics is paramount when selecting high-performance butterfly valves. The operating environment, including factors such as temperature, pressure, and the presence of corrosive elements, directly influences the material choice and design of the valve. Stainless steel or carbon steel valves, for instance, are known for their exceptional resistance to corrosion and ability to withstand extreme pressures and temperatures.

Fluid characteristics, on the other hand, dictate the specific type of valve required. For example, abrasive fluids may necessitate valves with reinforced seats and discs to mitigate wear and tear. Similarly, certain corrosive fluids may require valves made from specialty alloys to prevent degradation and maintain valve integrity.

At our company, we leverage our industry-specific expertise and globally recognized certifications to deliver valves that not only meet but exceed these operational considerations. Our rigorous quality control measures ensure that each valve we manufacture is capable of withstanding the unique demands of its intended application, delivering reliable performance and longevity. By prioritizing the operating environment and fluid characteristics, we help our clients optimize their industrial operations, promoting efficiency, safety, and operational excellence.

Conclusion

In conclusion, the realm of high-performance butterfly valves is both vast and nuanced, offering a diverse range of options designed to meet the unique demands of various industrial applications. From carbon steel to stainless steel variants, from wafer to lug style designs, and from manual to automated actuation methods, the choices are plentiful and purpose-built for specific operational needs.

As we’ve explored in this blog post, choosing the right marine butterfly valve requires a deep understanding of the operating environment, fluid characteristics, pressure requirements, and pipeline specifications. It’s not a one-size-fits-all proposition, but rather a careful selection process that aligns with your system’s specific demands.

Moreover, it’s crucial to consider the valve’s material, size, pressure rating, and cost to ensure optimal performance and longevity. A well-chosen valve not only enhances operational efficiency but also contributes to safety and overall system reliability.

In the USA, our company stands at the forefront of high-performance butterfly valve manufacturing, leveraging industry-specific expertise and globally recognized certifications to deliver products that exceed standard expectations. Our commitment to stringent quality control measures ensures each valve we manufacture is capable of withstanding the unique demands of its intended application.

Whether you’re dealing with corrosive fluids, high-pressure environments, or abrasive materials, we have a valve solution for you. Our technical consultants are always ready to guide you through the selection process, ensuring you choose a valve that best meets your operational requirements.

Remember, in the world of industrial operations, every component counts, and every detail matters. The choice of your butterfly valves can make a significant difference in your system’s performance. Choose wisely, choose quality, choose us for your high-performance butterfly valve needs. With our extensive experience, technical expertise, and unwavering commitment to quality, we’re here to help you optimize your industrial processes and achieve operational excellence.

Recap of the importance and benefits of high-performance butterfly valves.

To recap, high-performance butterfly valves are an integral component in a variety of industrial applications, playing a pivotal role in controlling the flow of fluids through pipelines. Their robust design, coupled with their ability to withstand extreme pressures and temperatures, makes them a reliable choice for even the most demanding operational environments.

Our high-performance butterfly valves are distinguished by their precision-engineered construction, crafted from materials such as stainless steel or carbon steel that offer exceptional resistance to corrosion. These valves are designed to deliver optimal performance, longevity, and reliability, ensuring seamless flow control and minimal maintenance needs.

The benefits of choosing our high-performance butterfly valves extend beyond their operational efficiency. They support safety protocols, reduce system downtime, and contribute to overall cost-effectiveness by minimizing the need for frequent replacements or repairs. With our globally recognized certifications and stringent quality control measures, we guarantee that every valve we manufacture meets and exceeds industry standards.

In essence, our high-performance butterfly valves represent our commitment to technical excellence, global reach, and unwavering quality. They embody our brand’s authority and confidence in the valve manufacturing industry, providing our clients with solutions that are not just effective, but also technologically advanced and compliant with global quality benchmarks.

Final thoughts on selecting the right type for specific applications.

In final thoughts, selecting the right high-performance butterfly valve for your specific application is a critical decision that requires a thorough understanding of your operational environment and fluid characteristics. Our company, backed by globally recognized certifications and extensive industry expertise, stands ready to guide you through this complex selection process.

Whether you need a carbon steel valve capable of withstanding high pressures, or a stainless steel variant designed for corrosive environments, we have the technical knowledge and manufacturing capabilities to meet your needs. Our range of valves, from wafer to lug style designs, manual to automated actuation methods, are all meticulously crafted to ensure optimal performance and longevity.

At our company, we believe in delivering more than just a product; we offer solutions that enhance operational efficiency, promote safety, and contribute to the overall reliability of your system. Our stringent quality control measures ensure that every valve we manufacture not only meets but also exceeds industry standards.

So, when it comes to choosing a high-performance butterfly valve, trust us to provide you with a solution that is not only tailored to your specific needs but also backed by our unwavering commitment to quality, global reach, and technical excellence.