When you are looking for a butterfly valve for your system, there are many reasons why selecting a Cast Iron Butterfly Valve is the best choice. These valves offer cost-effectiveness and durability that make them ideal for many different applications. CI butterfly valves are also easy to install and operate with minimal maintenance requirements, making them an efficient solution for a variety of industrial operations. In this blog post, we will look at some of the benefits of choosing a CI butterfly valve as well as some important factors to consider before making a purchase decision.

Introduction

Choosing the right valve for your system is an essential step in ensuring the successful operation of your project. One type of valve that can provide a reliable and cost-effective solution is a cast iron butterfly valve. Offering impressive durability, low maintenance requirements, and easy installation and operation, CI butterfly valves are an excellent choice for many applications. In this blog post, we will discuss the various benefits of CI butterfly valves and factors to consider when selecting them for your particular application.

What is a CI Butterfly Valve?

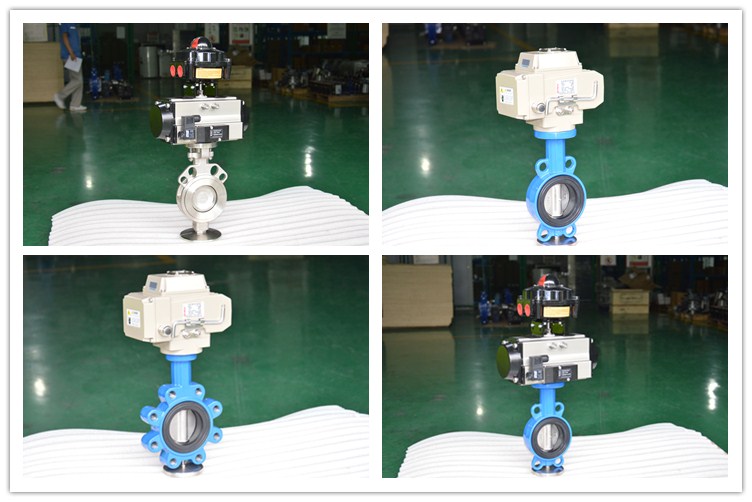

Cast iron butterfly valves are a popular and highly versatile type of valve used in many industrial applications. These valves feature a disc-shaped closure element that rotates within a pipe or duct section to open, close, or regulate the flow of materials. ss butterfly valves are composed of two parts: an inner lid that rotates to control flow and an outer housing which secures the lid in place. The main advantage of choosing CI butterfly valves over other types of valves is their durability and reliable performance.

Made from cast iron, these valves are designed to resist corrosion and wear due to consistent exposure to high pressure, temperature, and material flows. Additionally, wafer butterfly valves require minimal maintenance and can be easily installed or replaced based on the particular application needs. The range of shapes available for these valves also enables flexible installation for limited space constraints.

Moreover, lug butterfly valves provide excellent functionality for various fluid-flow applications as they offer precise control features such as throttling, shuttling, metering, backflow prevention, etc. This makes them ideal for controlling the amount of material that passes through the system while responding quickly to changing system conditions (e.g., emergency situations). In addition, they have a wide range of operating temperatures so they can be effective in both hot and cold water systems. All these factors make CI butterfly valve an attractive choice when it comes to selecting the right valve for your system’s needs. If you’re considering this type of valve for your project, there are several things you should keep in mind – we will discuss those further in our blog post!

Benefits of Choosing a CI Butterfly Valve

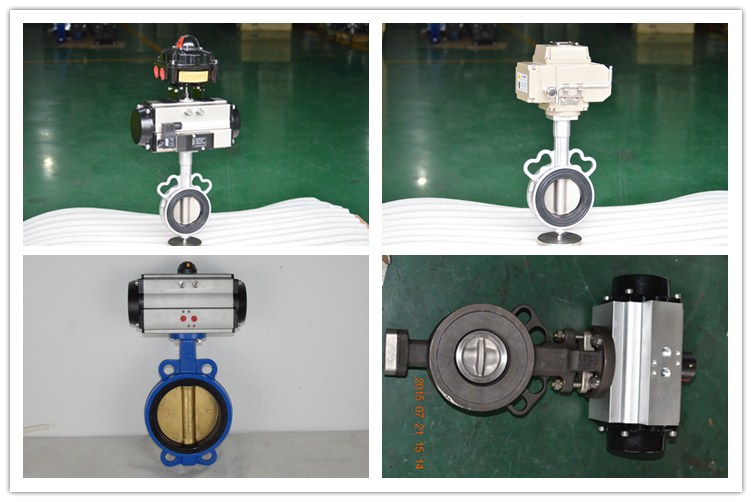

CI butterfly valves offer a range of benefits when compared to other kinds of valves. The primary benefit is their durability and reliable performance, as they are made from cast iron and designed to stand up to harsh environments with high pressures, temperatures, and material flows. This makes them an ideal choice for many industrial applications where performance is key.

Additionally, these valves require minimal maintenance and can be easily installed or replaced based on the particular application needs. In addition to their reliability and durability, cs butterfly valves offer precise control features such as throttling, shuttling, metering, backflow prevention, etc., making them suitable for controlling the amount of material passing through a system while responding quickly to changing system conditions. These valves also come in a wide range of shapes and sizes so installation in tight spaces is possible. Last but not least, the wide range of operating temperatures make them effective for both hot and cold water systems.

Overall, selecting a CI butterfly valve for your application can provide you with tremendous benefits that you can count on for long-term performance. With careful consideration regarding shape, size and design factors coupled with its strong resilience characteristics, this valve type provides both quality outputs with low costs over the life cycle of use.

Cost-Effective

Cost-effectiveness is a key factor for companies and individuals when considering any type of investment. It’s important to keep in mind that the initial purchase price should not be the only factor considered when deciding which product or service to choose. For that reason, cost-effectiveness must also be measured over the life cycle of use.

Some products may have a high initial butterfly valve price but require minimal maintenance or replacement costs over time, while others may have a lower initial price but require frequent maintenance or repairs. By carefully considering both short-term and long-term costs associated with a product, it is possible to determine which option will bring the most savings in the long run.

This is especially important when evaluating options that are purchased infrequently so as not to miss out on cost savings down the road. Furthermore, choosing cost-effective alternatives can help reduce environmental impact due to fewer resources being used and less waste generated. At the end of the day, cost-effectiveness goes beyond immediate financial implications and can make a difference for people and businesses in many ways.

Durable and Low Maintenance

Durability and low maintenance are key features to consider when selecting a product or service. Durable items can last longer and require fewer repairs, while low maintenance options don’t require frequent attention in order to function properly.

For example, when choosing between two similar products, one of them may be more durable and require less maintenance over its life cycle than the other. In this case, the more cost-effective option would be the more durable and low maintenance item even if it is initially more expensive. Overall, selecting products that balance both cost-effectiveness with durability and low maintenance is key for optimizing long-term savings, performance and sustainability. Doing so helps ensure that you get the most out of your investment without having to go through frequent repairs to keep things running smoothly.

Easy Installation and Operation

Easy installation and operation are crucial for delivering a seamless user experience. People don’t want to spend hours on setting up or learning how to use a product, so the less complicated the process, the better. For this reason, products that have simple instructions for setup and require minimal effort to operate are preferable over those that take more time and effort to install or understand. This is especially true for items that need frequent access, such as software subscriptions and home appliances like air conditioners and TVs. Easy installation and operation come with another benefit too: they are often less expensive than comparable items which require more complex setup and configuration processes. For businesses, this can mean significant cost savings due to reduced labor costs associated with lengthy setup times and customer service inquiries.

Factors to Consider When Selecting a CI Butterfly Valve

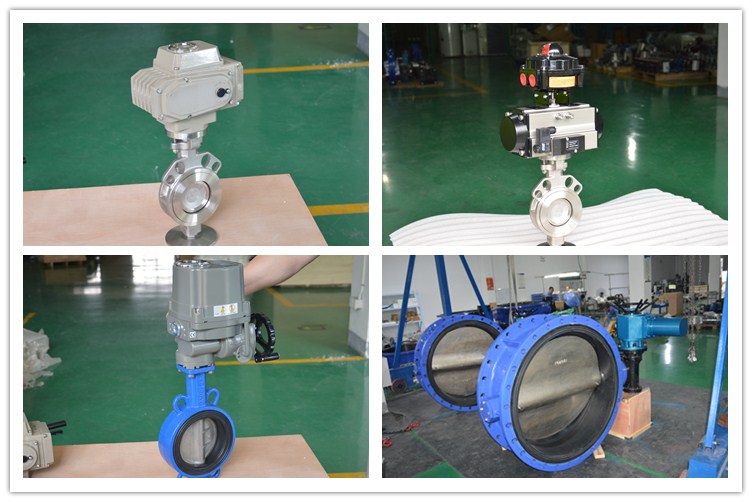

When selecting a control valve butterfly, there are many factors to consider. Firstly, the valve should have sufficient flow capacity for the intended application; this will affect the size and design of the valve. Secondly, you should ensure that the material and construction of the valve is compatible with its intended environment; for example, a corrosive process stream may require stainless steel or other specialty materials. Additionally, different types of valves offer varying levels of adjustment accuracy and flow characteristics – these include linear (or rotary) flow control valves, globe valves and ball valves.

You should also pay attention to how easily the valve can be accessed and maintained. For instance, some butterfly valves can be opened or closed manually while others can only be operated by an automated system such as a PLC. Lastly, it is important to check whether an actuator is available as an optional component; this will provide additional control and flexibility over the valve operation. Overall, when selecting a CI Butterfly Valve, you should consider all these points in order to make sure that you are getting a quality product that meets your specific needs.

Conclusion

In conclusion, there are a number of reasons to choose a wafer Butterfly Valve for your system. These valves offer a range of advantages, including superior flow characteristics, ease of maintenance and installation, and accuracy in control. Additionally, butterfly valves are available in different materials and designs, allowing you to select the right one for your specific application needs. Finally, by investing in an automated valve system rather than a manual one, you can save time and money while realizing greater accuracy and reliability. All these factors make the CI Butterfly Valve the ultimate choice when selecting a control-valve solution for your system.

-370x270.jpg)