In recent years, the demand for motorized butterfly valves has seen a steady increase due to their widespread applications in various industries, such as oil and gas, water treatment, and chemical processing. As a result, understanding the current trends in pricing for these essential components has become increasingly important for both buyers and suppliers. This article aims to provide an overview of the most significant factors influencing the pricing of motorized butterfly valves, including technological advancements, global supply chain disruptions, the growth of e-commerce, customization requirements, and regional market differences. By staying informed about these trends, stakeholders can make more informed decisions when purchasing or selling motorized butterfly valves.

Motorized butterfly valve price Introduction

The pricing of motorized butterfly valves has been subject to several trends in recent years, driven by factors such as technological advancements, global supply chain disruptions, the growth of e-commerce, customization requirements, and regional market differences. With a greater emphasis on energy efficiency and sustainability, manufacturers are investing in research and development to produce more energy-efficient motorized butterfly valves, which can impact their cost. Additionally, the recent disruptions in global supply chains, due to events like the COVID-19 pandemic and trade wars, have led to fluctuations in the availability and pricing of these valves. The rapid expansion of e-commerce platforms has also played a significant role in shaping the valve industry’s pricing landscape, as online retailers often offer competitive prices and discounts to attract customers, thereby influencing traditional B2B sales channels. Furthermore, the increasing demand for customized motorized butterfly valves tailored to specific applications has resulted in manufacturers offering a wider range of options, which can affect pricing depending on the complexity and specialized components involved. Lastly, regional market differences, influenced by factors such as local regulations and market competition, can lead to variations in pricing across different regions. By staying informed about these trends, stakeholders in the motorized butterfly valve industry can make more informed decisions when it comes to purchasing or selling these essential components.

Brief explanation of motorized butterfly valves and their applications

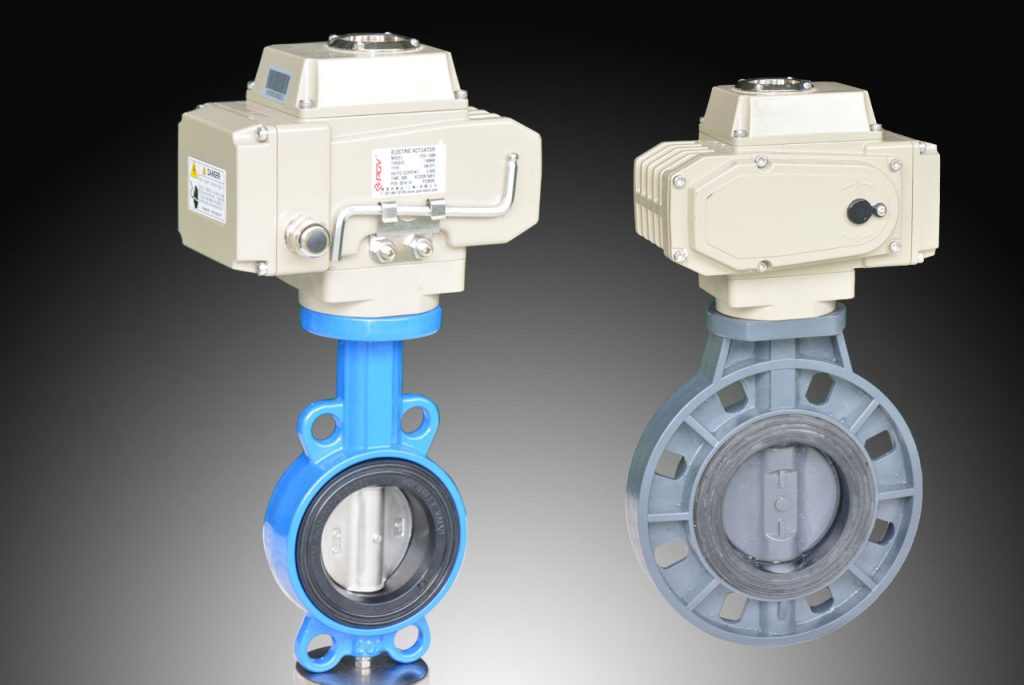

Motorized butterfly valves are flow control devices that consist of a disc mounted on a rotating shaft, which is actuated by an electric motor to regulate the flow of fluids through pipelines. These valves are widely used in various industries such as oil and gas, water treatment, chemical processing, and power generation, due to their ability to handle large volumes of fluid, quick actuation, and low-pressure drop across the valve. The disc’s rotation within the valve body allows for precise control of the flow rate, making motorized butterfly valves suitable for both on/off and throttling applications. Their relatively simple design, ease of maintenance, and cost-effectiveness have made them a popular choice for many industrial processes that require efficient and reliable flow control solutions.

Importance of understanding pricing trends for buyers and suppliers

Understanding pricing trends is crucial for both buyers and suppliers in the motorized butterfly valve industry, as it enables them to make informed decisions that can impact their overall business performance. For buyers, being aware of the market dynamics and factors influencing valve prices allows them to negotiate better deals, optimize their procurement strategies, and ultimately reduce costs. Similarly, suppliers can benefit from understanding pricing trends by identifying opportunities for innovation, improving their competitive positioning, and adjusting their pricing models to enhance profitability. Furthermore, staying updated on industry trends and market fluctuations can help both parties navigate potential challenges, such as supply chain disruptions and regional variations, and capitalize on emerging opportunities. In essence, a comprehensive understanding of pricing trends in the motorized butterfly valve market is essential for fostering successful business relationships and ensuring long-term growth for both buyers and suppliers.

A Shift Towards Energy-Efficient Technology

The growing emphasis on energy efficiency and environmental sustainability has driven a significant shift towards energy-efficient technology in the motorized butterfly valve price industry. This trend is fueled by increasing regulatory requirements, consumer demand for eco-friendly solutions, and the need to reduce operational costs across various sectors. Consequently, manufacturers are investing heavily in research and development to create innovative, energy-efficient motorized butterfly valves that not only meet the stringent performance standards but also help users minimize their energy consumption and carbon footprint. These new valve designs often incorporate advanced materials, improved sealing mechanisms, and state-of-the-art actuator technologies, which can optimize the valve’s overall efficiency and reliability. As a result, the adoption of energy-efficient motorized butterfly valves can lead to substantial cost savings for end-users over the long term, despite their potentially higher initial price compared to traditional models. This shift towards energy-efficient technology is expected to continue shaping the pricing landscape of motorized butterfly valves, as manufacturers strive to balance the need for innovation with cost considerations, while buyers increasingly prioritize sustainable solutions that offer long-term value and performance.

Increasing demand for energy-efficient motorized butterfly valves

The demand for energy-efficient motorized butterfly valve price has been on the rise as industries worldwide recognize the need to reduce energy consumption, minimize environmental impact, and comply with stringent regulations. This increasing demand can be attributed to several factors, including the growing awareness of the benefits of energy-efficient technologies, such as reduced operational costs and enhanced system performance. Additionally, businesses are under increasing pressure to adopt sustainable practices and demonstrate their commitment to environmental stewardship. As a result, manufacturers are focusing on developing innovative, energy-efficient motorized butterfly valves that offer improved performance, reliability, and durability, while also helping end-users achieve their sustainability goals. This trend is expected to continue in the coming years, as the global push for energy efficiency and sustainability gains momentum, further driving the demand for advanced, eco-friendly motorized butterfly valve solutions.

Impact on pricing due to investments in research and development

Investments in research and development (R&D) can have a notable impact on the pricing of motorized butterfly valve price, as manufacturers strive to create innovative products that offer improved performance, efficiency, and sustainability. The process of developing new technologies and materials often involves significant time and financial resources, which can translate into higher production costs for advanced valve designs. As a result, these cutting-edge motorized butterfly valves may initially carry a higher price tag compared to traditional models. However, the long-term benefits of these innovative valves, such as reduced energy consumption, lower maintenance costs, and enhanced system performance, can ultimately offset their initial cost, making them a valuable investment for end-users. Additionally, as R&D efforts continue and economies of scale are achieved, the pricing gap between traditional and advanced motorized butterfly valves may reduce over time, making energy-efficient solutions more accessible to a broader range of customers.

Examples of new energy-efficient models and their Motorized butterfly valve price

The emergence of new energy-efficient models of motorized butterfly valve price has brought about innovative designs and features, which can have an impact on their pricing. These advanced valves often incorporate cutting-edge materials, such as high-performance elastomers and lightweight alloys, which can improve sealing capabilities and reduce wear and tear. Additionally, they may employ state-of-the-art actuator technologies that optimize energy consumption while maintaining precise flow control. Some examples of energy-efficient motorized butterfly valves include those with brushless DC motors, which offer higher efficiency, lower noise, and longer service life compared to traditional motors, or those with smart control systems that enable real-time monitoring and adjustments for optimal energy usage. While these advanced valve models may come with a higher initial price due to the costs associated with R&D and the use of premium materials, their long-term benefits in terms of energy savings, reduced maintenance, and enhanced performance justify the investment. As demand for energy-efficient solutions continues to grow and manufacturing processes become more streamlined, it is expected that the pricing of these innovative motorized butterfly valves will become increasingly competitive, making them more accessible to a wider range of customers.

Impact of Global Supply Chain Disruptions

The global supply chain disruptions, caused by factors such as the COVID-19 pandemic, trade tensions, and natural disasters, have had a significant impact on industries worldwide, including the motorized butterfly valve market. These disruptions have led to increased lead times, fluctuating raw material prices, and challenges in sourcing components, all of which can affect the pricing and availability of motorized butterfly valves. As manufacturers struggle to maintain production levels and meet the growing demand for their products, they may be forced to pass on the increased costs to their customers, leading to higher prices for motorized butterfly valves. Additionally, the uncertainty and volatility in the global supply chain can make it difficult for buyers and suppliers to accurately predict and plan for future pricing trends, potentially impacting their procurement strategies and overall business performance.

In response to these challenges, companies are increasingly focusing on enhancing their supply chain resilience by diversifying their sourcing strategies, investing in local suppliers, and adopting digital technologies to improve visibility and collaboration across the supply chain. Furthermore, some manufacturers are exploring nearshoring or reshoring production facilities to reduce their reliance on overseas suppliers and mitigate the risks associated with global supply chain disruptions. In the long term, these efforts to build more robust and agile supply chains may help stabilize the pricing landscape for motorized butterfly valves and ensure a more reliable supply of these essential flow control devices to various industries.

Explanation of recent supply chain disruptions (COVID-19, trade wars)

Recent supply chain disruptions, such as the COVID-19 pandemic and trade wars, have significantly impacted industries across the globe, including the motorized butterfly valve market. The COVID-19 pandemic, in particular, has led to factory shutdowns, labor shortages, and transportation bottlenecks, causing delays in production and delivery of essential components and finished products. Similarly, trade wars and tariffs have created uncertainties in the global trade environment, affecting the availability and cost of raw materials and components, which in turn, influence the pricing of motorized butterfly valves. These disruptions have highlighted the vulnerabilities in the global supply chain and emphasized the need for businesses to implement more resilient and agile strategies to mitigate risks and maintain operational efficiency. As a result, companies are increasingly focusing on diversifying their supplier base, exploring local sourcing options, and leveraging digital technologies to enhance supply chain visibility and collaboration, ultimately aiming to minimize the impact of future disruptions on their operations and customers.

Effects on the availability and pricing of motorized butterfly valves

The availability and pricing of motorized butterfly valve price have been significantly affected by recent supply chain disruptions, such as the COVID-19 pandemic and trade wars. These disruptions have led to production delays, shortages of raw materials and components, and increased transportation costs, which in turn, impact the overall availability of motorized butterfly valve price in the market. As manufacturers struggle to cope with the challenges posed by these disruptions, they may be forced to adjust their production schedules or even halt production temporarily, resulting in reduced supply and longer lead times for customers. Additionally, the increased costs associated with sourcing raw materials and components, as well as surging freight charges, may prompt manufacturers to pass on these cost increases to their customers, leading to higher prices for motorized butterfly valve price. In response to these challenges, companies are focusing on enhancing their supply chain resilience by adopting diversified sourcing strategies, investing in local suppliers, and leveraging digital technologies to improve visibility and collaboration across the supply chain, ultimately aiming to stabilize the availability and pricing of motorized butterfly valves in the long run.

Strategies adopted by manufacturers to cope with supply chain challenges

In the face of supply chain challenges posed by disruptions such as the COVID-19 pandemic and trade wars, manufacturers have been adopting various strategies to maintain operational efficiency and ensure product availability. One key strategy involves diversifying their supplier base, which reduces dependency on a single source and mitigates risks associated with potential disruptions. By engaging multiple suppliers across different geographical locations, manufacturers can better navigate uncertainties and maintain a steady flow of raw materials and components. Another approach is to invest in local suppliers and nearshoring or reshoring production facilities, which can minimize transportation costs and lead times, while also reducing exposure to global trade tensions and tariffs.

Additionally, manufacturers are increasingly leveraging digital technologies to enhance supply chain visibility and collaboration. By adopting solutions such as supply chain management software, IoT devices, and data analytics tools, companies can gain real-time insights into their supply chain operations, enabling them to make informed decisions and respond more effectively to disruptions. Furthermore, some manufacturers are focusing on building strategic partnerships and alliances within their industry, allowing them to pool resources, share information, and collaborate on solutions to overcome supply chain challenges.

These strategies, when combined, can help manufacturers build more resilient and agile supply chains, ultimately minimizing the impact of disruptions on their operations and ensuring continued availability and competitive pricing of motorized butterfly valves for their customers.

Growth of E-commerce in Valve Industry

The growth of e-commerce has significantly impacted the valve industry, offering new opportunities and challenges for both manufacturers and customers. The shift towards online sales platforms has expanded the reach of valve manufacturers, enabling them to tap into new markets and customer segments without the need for a physical presence. This increased accessibility has made it easier for customers to source motorized butterfly valves and other flow control devices, as they can now easily compare products, pricing, and specifications from multiple suppliers with just a few clicks.

In addition to providing greater convenience, e-commerce platforms have also introduced new sales and marketing strategies for valve manufacturers. By leveraging digital marketing techniques, such as search engine optimization, social media advertising, and email campaigns, manufacturers can better target their intended audience and generate leads more effectively. Furthermore, online platforms enable manufacturers to offer personalized customer experiences through chatbots, virtual assistants, and tailored product recommendations, enhancing customer satisfaction and fostering brand loyalty.

However, the growth of e-commerce in the valve industry also presents challenges, particularly in terms of product quality assurance, counterfeit products, and cybersecurity risks. To address these concerns, manufacturers must invest in robust quality control measures and collaborate with reputable online platforms that prioritize customer safety and data protection. Additionally, manufacturers need to adopt agile supply chain strategies to meet the demands of the fast-paced e-commerce environment, ensuring timely delivery of products and maintaining competitive pricing.

Overall, the growth of e-commerce in the valve industry has transformed the way manufacturers and customers interact, offering new avenues for market expansion and customer engagement. By embracing digital technologies and adapting their business models to the evolving landscape, valve manufacturers can capitalize on the opportunities presented by e-commerce and ensure their continued success in the market.

Rapid expansion of e-commerce platforms for valve sales

The rapid expansion of e-commerce platforms for valve sales has revolutionized the way manufacturers and customers interact in the valve industry. This growth has provided manufacturers with new opportunities to reach a wider audience and enter new markets without the constraints of a physical presence. Customers, on the other hand, benefit from the convenience and ease of comparing products, prices, and specifications from multiple suppliers at their fingertips. The rise of e-commerce platforms has also led to the adoption of innovative sales and marketing strategies, such as digital marketing techniques, personalized customer experiences, and virtual assistants that cater to customer needs more effectively. However, it is crucial for manufacturers to address challenges related to product quality assurance, counterfeit products, and cybersecurity risks in the e-commerce environment. By investing in quality control measures and partnering with trusted online platforms, manufacturers can ensure customer safety and satisfaction while capitalizing on the immense potential offered by the rapidly expanding e-commerce landscape in the valve industry.

Competitive pricing and discounts offered by online retailers

The competitive pricing and discounts offered by online retailers have significantly impacted the valve industry, particularly with the growth of e-commerce platforms. Online retailers often offer lower prices for motorized butterfly valves due to reduced overheads, such as rent, labor costs, and utility bills, compared to traditional brick-and-mortar stores. Additionally, online retailers can leverage economies of scale to negotiate better pricing from manufacturers and pass on the savings to customers. Furthermore, online retailers frequently offer promotional discounts, bundle deals, and loyalty programs to incentivize repeat purchases and attract new customers.

However, it is important to note that competitive pricing and discounts can sometimes lead to price wars and erode profit margins for manufacturers and suppliers. To remain competitive, manufacturers must focus on enhancing their product differentiation, quality, and customer service, rather than solely relying on pricing strategies. Additionally, they need to adopt agile supply chain strategies to ensure fast and reliable delivery of products, as timely delivery is often a key factor in customers’ purchasing decisions.

Overall, the competitive pricing and discounts offered by online retailers have transformed the valve industry, offering customers more choices and affordability while challenging manufacturers to innovate and differentiate their products and services to remain competitive in the online marketplace.

How this trend is affecting traditional B2B sales channels and pricing

The rise of e-commerce and online retailers in the valve industry has disrupted traditional B2B sales channels and pricing strategies. With the increased availability of motorized butterfly valves through online platforms, traditional B2B sales channels, such as distributors and wholesalers, are facing new competition from manufacturers selling directly to customers. This shift has prompted traditional channels to expand their value proposition beyond just product sales, such as offering technical support, custom solutions, and other value-added services.

Moreover, the pressure on pricing exerted by online retailers has led to a general downward trend in prices in the industry, forcing traditional B2B sales channels to adapt their pricing strategies to remain competitive. To maintain profitability, they may focus on offering more specialized products or services that cater to specific customer needs, rather than competing solely on price.

Overall, the trend towards e-commerce and online retailing is challenging traditional B2B sales channels and pricing strategies in the valve industry. As the industry continues to evolve, it will be critical for businesses to remain agile and innovative in adapting to new market dynamics while continuing to provide value to their customers.

Motorized butterfly valve price Customization and Specialized Applications

Customization and specialized applications have become increasingly important in the valve industry as customers demand more tailored solutions to meet their specific needs. Customization allows manufacturers to offer unique and differentiated products that cater to specific customer requirements, which can enhance customer satisfaction and loyalty. Specialized applications, such as valves designed for extreme temperatures or corrosive environments, require specialized expertise and engineering capabilities, which can provide a competitive advantage for manufacturers that possess these skills. Offering customization and specialized applications also requires strong collaboration between manufacturers and customers, enabling the development of solutions that are tailored to specific end-users’ needs. However, customization and specialized applications can increase the complexity of the manufacturing process, requiring additional resources and expertise. Manufacturers must ensure that they have the necessary capacity and capabilities to deliver these solutions while maintaining quality control and meeting customer deadlines. Overall, customization and specialized applications are vital components of the valve industry, enabling manufacturers to differentiate themselves and offer unique solutions that address specific customer requirements.

Increasing demand for customized motorized butterfly valve price

The demand for customized motorized valve price has been increasing in the valve industry due to the unique requirements of end-users. Customers are seeking solutions that are tailored to their specific needs, such as size, material, actuation type, and compatibility with existing systems. Customization enables manufacturers to provide solutions that meet these specific requirements, providing greater functionality, reliability, and efficiency for customers. Additionally, the trend towards Industry 4.0 and automation has increased the demand for motorized butterfly valves that can be integrated into complex control systems. Customization also allows for easier integration into existing systems, reducing installation time and costs. However, offering customized solutions can require additional resources and expertise, which may increase costs and lead times. Manufacturers must balance the benefits of customization with the challenges of meeting customer demands while maintaining cost-effectiveness and production efficiency. Overall, the increasing demand for customized motorized butterfly valves reflects the growing need for tailored solutions in the valve industry to meet the unique requirements of end-users in various applications.

Specialized applications driving the need for tailored solutions

Special applications in the valve industry are driving the need for tailored solutions that meet specific customer requirements. Specialized applications, such as those in the oil and gas, chemical, and water treatment industries, require unique valve solutions that can withstand extreme temperatures, pressures, and corrosive environments. These specialized applications demand highly engineered solutions that are customized to meet specific performance requirements, safety standards, and regulatory compliance. Customized solutions for specialized applications can provide customers with greater productivity, reliability, and efficiency, leading to lower costs, increased uptime, and improved safety. However, manufacturing customized solutions for specialized applications requires extensive expertise and resources, with a focus on quality control and meeting customer deadlines. Manufacturers must be capable of delivering high-quality, customized solutions that meet the rigorous demands of specialized applications, while maintaining cost-effectiveness and production efficiency. In conclusion, specialized applications are driving the need for tailored solutions in the valve industry, highlighting the critical importance of customization and engineering capabilities for manufacturers who wish to remain competitive in this market segment.

Effects on pricing due to customization options and specialized components

Customization options and specialized components can have a significant impact on pricing in the valve industry. Offering customization options can increase costs due to the additional engineering, design, and manufacturing efforts required to develop tailored solutions that meet specific customer requirements. Additionally, specialized components such as high-temperature alloys or corrosion-resistant materials can also increase costs due to their relatively high prices compared to standard materials. However, offering customized solutions and specialized components can also provide an opportunity for manufacturers to differentiate themselves in the market and command a higher price premium for their products. The price premium may be justified by the enhanced functionality, reliability, and efficiency provided by customized solutions and specialized components. Ultimately, the pricing strategy of manufacturers will depend on their capabilities to deliver quality customized solutions and specialized components while maintaining cost-effectiveness and competitiveness. Therefore, customization options and specialized components can significantly impact pricing in the valve industry, highlighting the importance of balancing customer demand and market competition with production efficiency and profitability.

Motorized butterfly valve price Regional Market Differences

Regional market differences exist in the valve industry due to varying factors such as economic conditions, regulations, cultural practices, and technological advancements. For instance, in developed economies, such as North America, Europe, and Japan, the valve industry has matured, and demand is relatively stable. These regions have stringent regulatory requirements that drive the adoption of high-quality valves that comply with safety standards. Additionally, there is a focus on efficiency, energy conservation, and sustainability, leading to an increase in demand for smart and energy-efficient valves.

In emerging economies, such as China, India, and Brazil, the valve industry is still developing, with rising demand driven by population growth, rapid industrialization, and urbanization. These regions have lower labor costs, which can lead to price competition, driving down prices. Furthermore, these countries have different regulatory requirements, and compliance with international safety standards may not be mandatory. The focus is on cost-effective solutions that meet basic requirements, leading to a preference for simpler valve solutions.

In the Middle East, the valve industry is heavily influenced by the oil and gas sector, which drives demand for specialized valves that can withstand extreme temperatures and pressures. Additionally, this region faces water scarcity challenges, leading to an increasing demand for valves used in water treatment and desalination plants.

Cultural practices also impact the valve industry, with regions such as Europe placing a higher emphasis on environmental conservation and sustainability, leading to increased demand for eco-friendly valves. In contrast, regions such as Asia prioritize cost-effectiveness, reliability, and durability.

Technological advancements also play a significant role in regional market differences, with developed economies adopting more advanced technologies such as smart valves and Industry 4.0 solutions. Emerging economies are still catching up with technology adoption but are poised for growth as the adoption of digital technologies accelerates.

Overall, regional market differences in the valve industry reflect the diverse needs and priorities of different regions, highlighting the importance of understanding local markets’ nuances to remain competitive and meet customer demands.

Comparison of pricing trends in different regions (North America, Europe, Asia-Pacific)

Pricing trends in the valve industry vary across different regions, with North America, Europe, and Asia-Pacific having distinct pricing dynamics. In North America and Europe, the valve industry is mature and highly competitive, leading to relatively stable prices. However, in recent years, there has been some price pressure due to increased competition from low-cost manufacturers in Asia-Pacific. The focus in these regions is on technological advancements, energy efficiency, and sustainability, leading to the adoption of advanced valve solutions that command a premium price.

In contrast, in Asia-Pacific, the valve industry is still developing, with lower labor costs leading to price competition. The market is highly fragmented, with many small- to medium-sized manufacturers offering low-cost valve solutions. The focus is on cost-effectiveness, reliability, and durability, with price being a significant factor driving purchasing decisions.

Overall, while pricing trends differ across regions, there is a growing trend towards value-added solutions, such as smart valves and Industry 4.0 solutions, that command a premium price. Manufacturers that can deliver customized solutions that meet specific customer requirements will be well-positioned to compete in the market, regardless of pricing dynamics in their region. Furthermore, regional market differences highlight the importance of understanding local markets’ nuances to develop effective pricing strategies that balance customer demand and market competition with production efficiency and profitability.

Factors influencing regional price differences (local regulations, market competition)

Regional price differences in the valve industry are influenced by various factors, including local regulations and market competition. Local regulations such as safety standards, environmental regulations, and import/export tariffs can impact pricing dynamics. For instance, in regions with stringent safety and environmental regulations, manufacturers may need to invest more in research and development to comply, leading to higher prices. Similarly, import/export tariffs can increase the cost of materials, components, or finished products, leading to higher prices for customers.

Market competition is also a significant factor influencing regional price differences. In regions with high competition, such as Asia-Pacific, manufacturers may offer lower prices to remain competitive, resulting in a price-sensitive market. In contrast, regions with lower competition, such as the Middle East, may command a premium price due to limited options, specialized applications, or unique customer requirements.

Cultural practices and economic conditions can also influence regional price differences. For instance, in regions where cost-effectiveness is a high priority, such as Southeast Asia, manufacturers may offer simpler and more affordable valve solutions that meet basic requirements. In comparison, regions with a focus on sustainability and energy efficiency, such as Europe, may prefer advanced valve solutions that command a premium price.

Overall, regional price differences in the valve industry are driven by various factors, highlighting the importance of understanding local markets’ nuances to develop effective pricing strategies that balance market competition, regulatory compliance, and customer demand with production efficiency and profitability.

Opportunities for buyers to leverage regional price variations

Regional price variations in the valve industry can present opportunities for buyers to leverage cost savings. Buyers can take advantage of price differences by sourcing valves from regions with lower prices or negotiating better deals with suppliers. However, buyers must also consider other factors besides price, such as regulatory compliance, quality, and delivery times, when making purchasing decisions. For instance, sourcing valves from regions with lower labor costs may lead to significant cost savings, but buyers must also ensure that the supplier meets safety standards and can deliver high-quality products reliably. Additionally, buyers must factor in the cost of transportation, import/export tariffs, and exchange rates, which can impact the final price. Overall, leveraging regional price variations requires careful consideration of multiple factors beyond price, highlighting the importance of conducting thorough research and due diligence before making purchasing decisions.

Motorized butterfly valve price Conclusion

In conclusion, there are several current trends in the pricing of electric butterfly valve. One trend is the adoption of digital technologies that enable remote monitoring and control of valve performance, leading to higher prices for smart valves. Another trend is the increasing demand for eco-friendly valves that reduce energy consumption and carbon emissions, leading to a premium price for sustainable solutions. Furthermore, the use of specialized materials such as high-temperature alloys and corrosion-resistant coatings can increase prices due to their relatively high costs compared to standard materials.

Regional market differences also impact the pricing of motorized butterfly valves, with varying economic conditions, regulations, and cultural practices influencing pricing dynamics. Developed regions such as North America and Europe have mature markets with stable pricing, while emerging regions such as Asia-Pacific have lower labor costs and competing manufacturers, leading to price pressure. Additionally, local regulations such as safety standards and import/export tariffs can impact prices, highlighting the importance of understanding local markets’ nuances when developing pricing strategies.

Overall, the pricing of motorized butterfly valves price is influenced by several factors, including technological advancements, sustainability initiatives, specialized materials, and regional market differences. Manufacturers must balance customer demand, regulatory compliance, and production efficiency to remain competitive and profitable in the market. Similarly, buyers must consider multiple factors beyond price when making purchasing decisions, such as quality, delivery times, and transportation costs. By understanding current pricing trends and market dynamics, manufacturers and buyers can make informed decisions to achieve their goals and stay ahead of the competition.

Recap of the main points discussed in the article

In this article, we discussed the current trends in the pricing of electric actuated butterfly valves. We first identified the adoption of digital technologies, such as smart valves, as a trend that can increase prices due to the added functionality and convenience they provide. We also highlighted the growing demand for eco-friendly solutions that reduce energy consumption and carbon emissions, leading to a premium price for sustainable valves. Furthermore, we noted that specialized materials such as high-temperature alloys and corrosion-resistant coatings can increase prices due to their high costs compared to standard materials. We then examined how regional market differences impact pricing dynamics, with developed regions having stable prices and emerging regions experiencing price pressure due to lower labor costs and competition. Finally, we concluded that understanding current pricing trends and market dynamics is crucial for manufacturers and buyers to make informed decisions about pricing strategies and purchasing decisions.

Importance of staying informed about pricing trends to make better purchasing decisions

Staying informed about pricing trends is essential for making better purchasing decisions in the valve industry. By tracking current pricing dynamics, buyers can identify opportunities to leverage cost savings by sourcing valves from regions with lower prices or negotiating better deals with suppliers. Additionally, understanding pricing trends can help buyers anticipate future price fluctuations and plan their procurement strategies accordingly. For instance, if prices for a particular valve type are expected to increase due to rising material costs, buyers can procure the valves earlier or negotiate longer-term contracts to lock in favorable rates. Overall, staying informed about pricing trends enables buyers to make better-informed purchasing decisions that balance cost-effectiveness, quality, and delivery times to meet the needs of their organization.

Future outlook for the motorized butterfly valve industry and its impact on pricing

The future outlook for the motorized butterfly valve price industry is positive, with increasing demand for automation, remote monitoring, and energy efficiency driving growth. As industries across the globe continue to automate their processes, motorized butterfly valves are becoming increasingly popular due to their ability to operate on a wide range of applications and provide accurate control. Additionally, the growing focus on sustainability and eco-friendliness is expected to drive up demand for energy-efficient and high-performance valves, ultimately leading to higher prices. The use of advanced materials, such as nanomaterials and composites, may also become more prevalent in valve manufacturing, leading to higher prices due to the relatively high cost of these materials. However, the impact of pricing trends will vary by region, with differing economic conditions, regulations, and cultural practices influencing pricing dynamics. Overall, the future outlook for the motorized butterfly valve industry is promising, and staying informed about the latest trends and technologies will be essential for manufacturers and buyers looking to remain competitive and profitable in the market.