Description

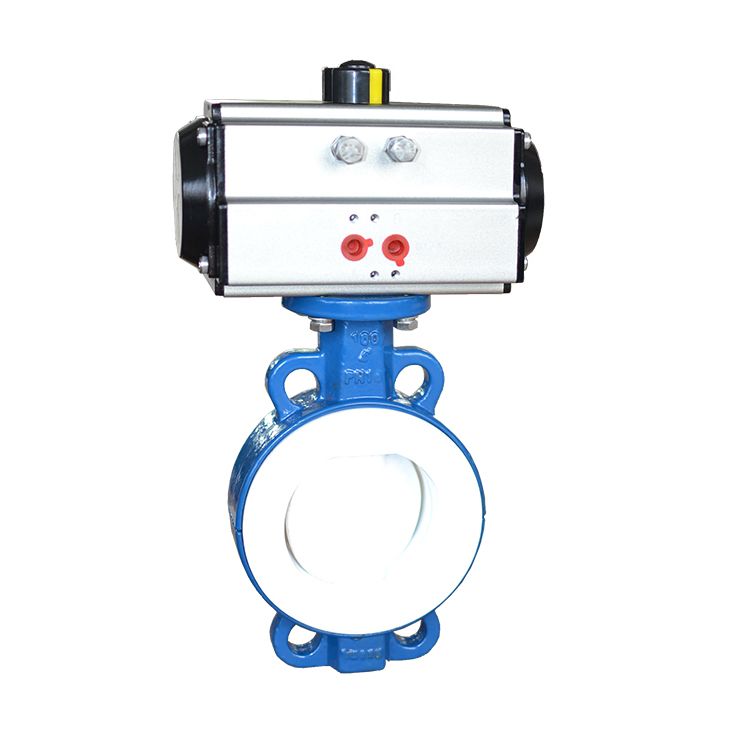

Electric pfa lined butterfly valve

Electric PFA lined butterfly valves are ideal for applications involving chemical, biological and pharmaceutical processes. The high-temperature PFA lining offers superior chemical resistance and corrosion protection over standard metal valves. Additionally, electric PFA lined butterfly valves are self-lubricating, providing a smoother operation than manual operated valves and reducing the need for regular maintenance. These electric butterfly valve can be used in a wide range of industrial process control applications such as shutoff, throttling or regulating service in chemical plants, oil refineries, water treatment units and food processing facilities. Furthermore, they require less energy consumption while offering efficient control over flow rate and pressure. Invest in an electric Teflon lined butterfly valve today for superior results!

FEATURES

- Easily automate with the ISO5211 direct mounting pad, designed for convenient integration.

- Three PTFE impregnated SS316L bearings to ensure precise alignment of the disc-shaft, guaranteeing optimal performance.

- PTFE-liner that protects against chemically toxic and highly corrosive media. Additionally, our rubber liner is versatile and suitable for a wide range of industrial applications.

- The stable sealing between the liner and disc is achieved through the use of a silicon rubber energized back behind the PTFE seat. This innovative design offers a wide range of temperature capabilities, ensuring optimal performance.

- By utilizing a one-piece disc-shaft design, valve torque is minimized and Kv is enhanced, resulting in improved performance.

- Achieve a bubble-tight seal even at full pressure rating.

- This item can be easily disassembled, allowing for material-specific recycling possibilities.

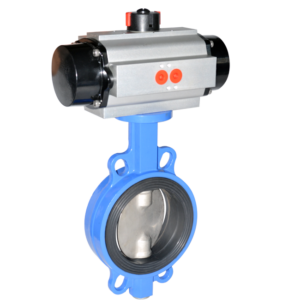

PARTS LIST AND MATERIAL SPECIFICATION

| No. | Part name | Material | |||

| 1 | Body | GGG40 | |||

| 2 | Disc/shaft one piece | CF8M | 1.4462 | CF8M FEP lined | CF8 EPDM lined |

| 3 | Seat | PTFE,FPM,EPDM,PU,NBR | PTFE | EPDM | |

| 4 | Seat Energizer | SR | |||

| 5 | Weather seal | NBR | |||

| 6 | Bearing | PTFE impregnated SS316L | |||

| 7 | Gland | PTFE | |||

| 8 | Screw | SS304 | |||

| 9 | Belleville washer | SS304 | |||

| 10 | Stuffing collar | SS316 | |||

| 11 | O ring | FPM | |||

| 12 | V ring | PTFE | |||

TECHNICAL DATA

| Body style | wafer |

| Nominal diameter | 2″ – 24″ (DN50mm – DN600mm) |

| Top flange | ISO5211 |

| Operating pressure | 16bar for DN50-DN200, 10bar for DN250-DN600 |

| Temperature range | -20 °C to + 180 °C (depending on pressure, medium and material) |

| Flange accommodation | EN 1092 PN 6/PN10/PN16 ASME Class 150 AS 4087 PN10/ PN16 JIS 5K/10K |

| Operation | Hand lever, gear box, pneumatic actuator, electric actuator |

Electric actuator

On-off type: feedback signal: Passive contact signal/4-20mA/ resistance signals.

Regulation type: Input signal 4-20mA/0-10V/1-5V;

Feedback signal: 4-20mA/0-10V/1-5V

Voltage: AC220V\380V\110V\24V、DC12V\24V etc; Special voltage can be customized.

Explosion-proof class: Can be choose explosion-proof type EX d IIBT4

| Type | Control type | Function |

| Electric actuator | ON-OFF type | Feedback: the active signal, passive contact signal, resistance, 4-20mA |

| Regulation type | Input and output signal: 4-20mA, 0-10v, 1-5v, switch, MODBUS, PROFIBUS field bus | |

| Filed operation | The field, remote control switch regulation and MODBUS, PROFIBUS field bus |

| SIZE | A | B | C | D | E | F | d | G | H | L | WT(kg) | |

| DN | INCH | |||||||||||

| 50 | 2″ | 126 | 65 | 13.5 | 116 | 11 | 50 | 8 | 65 | 25 | 43 | 2 |

| 65 | 2 1/2″ | 138 | 79 | 13.5 | 136 | 11 | 50 | 8 | 65 | 59 | 46 | 3 |

| 80 | 3″ | 138 | 79 | 13.5 | 136 | 11 | 50 | 8 | 65 | 59 | 46 | 3 |

| 100 | 4″ | 167 | 97 | 17.5 | 170 | 14 | 70 | 10 | 90 | 86 | 52 | 5 |

| 125 | 5″ | 180 | 129 | 17.5 | 196 | 14 | 70 | 10 | 90 | 112 | 56 | 7 |

| 150 | 6″ | 203 | 142 | 18.5 | 227 | 17 | 70 | 10 | 90 | 140 | 56 | 8 |

| 200 | 8″ | 228 | 172 | 18.5 | 279 | 17 | 102 | 12 | 125 | 191 | 60 | 13 |

| 250 | 10″ | 266 | 213 | 24.5 | 336 | 22 | 102 | 12 | 125 | 241 | 58 | 22 |

| 300 | 12″ | 291 | 242 | 24.5 | 392 | 22 | 102 | 12 | 125 | 290 | 78 | 31 |

| 350 | 14″ | 332 | 262 | 30 | 445 | 27 | 125 | 14 | 150 | 331 | 78 | 44 |

| 400 | 16″ | 363 | 303.5 | 30 | 503 | 27 | 125 | 14 | 150 | 377 | 102 | 64 |

| 450 | 18″ | 397 | 324.5 | 39 | 553 | 36 | 140 | 18 | 175 | 425 | 114 | 86 |

| 500 | 20″ | 425 | 357 | 39 | 608 | 36 | 140 | 18 | 175 | 474 | 127 | 116 |

| 600 | 24″ | 498 | 419 | 49 | 717 | 46 | 165 | 22 | 210 | 570 | 154 | 179 |

FAQs

What is a Lined ptfe pfa butterfly valve?

A Lined PTFE (Polytetrafluoroethylene) PFA (Perfluoroalkoxy) butterfly valve is a high-performance control device engineered to provide superior resistance against corrosive media and extreme temperatures. Tailored for demanding applications, this type of valve is characterized by its robust construction where the internal components, particularly the disc and the body, are lined with PTFE or PFA. These fluoropolymers are praised for their excellent chemical stability and low friction properties, which result in minimal wear and longevity of service life under harsh operating conditions.

In the architecture of a Lined PTFE PFA butterfly valve, the disc is designed to rotate within the lined valve body to regulate or halt fluid flow. The use of PTFE and PFA linings ensures a near-universal chemical compatibility, making these valves ideal for handling aggressive chemicals, solvents, and other substances that could degrade standard materials. Furthermore, the linings contribute to a tight seal, reducing the risk of leaks—a critical consideration in stringent process environments.

What is a Lined ptfe pfa f46 butterfly valve used for?

A Lined PTFE PFA F46 Butterfly Valve is a highly specialized industrial component, integral to the management of process flows within intricate piping systems. Primarily, this kind of butterfly valve is utilized in applications involving aggressive and corrosive fluids where superior resistance to chemical degradation is paramount.

The integration of PTFE (Polytetrafluoroethylene) or PFA (Perfluoroalkoxy alkanes) lining, combined with the robust F46 (perfluorinated resin) backing, ensures an exceptional seal against harsh substances, thereby maintaining the integrity and performance of the system. These linings are characterized by outstanding thermal stability, chemical inertness, and low friction properties, which contribute to the valve’s longevity and reliability.

In terms of operational environments, Lined PTFE PFA F46 Butterfly Valves are adept at handling a wide spectrum of temperatures and pressures, making them suitable for deployment across various sectors. These industries include chemical processing, petrochemical refineries, pharmaceutical manufacturing, food and beverage production, water treatment facilities, and semiconductors, to name a few.

How do I choose a Lined ptfe pfa f46 valve?

Selecting a Lined PTFE PFA F46 Butterfly Valve necessitates a meticulous assessment of numerous critical factors to ensure optimal compatibility and performance within your specific application. As a vanguard in the valve manufacturing industry, we recommend considering the following criteria with precision:

- Chemical Compatibility: Ascertain that the materials used for the valve lining, such as PTFE or PFA, are fully resistant to the chemical properties of the process media. Our valves are designed to withstand a broad range of corrosive substances, ensuring longevity and reliability.

- Operating Conditions: Evaluate the pressure and temperature profile of your application. Our valves are engineered to perform flawlessly within a specified range; ensuring the valve’s specifications align with your system’s requirements is paramount.

- Flow Requirements: Understand the flow characteristics needed for your process. The valve’s design should enable precise throttling, offering seamless flow control. Our expertise ensures that each valve provides superior flow modulation tailored to our clients’ exacting needs.

- Size and Fit: Select a valve size and end connection type that accurately conforms to your existing piping system. Our valves come in various sizes and connective options, guaranteeing a perfect integration with industry-standard pipelines.

- Certification and Standards Compliance: Verify that the valve adheres to relevant industry standards and certifications, which attest to its quality and safety. Our products are manufactured under stringent quality control protocols, backed by certifications that exemplify our commitment to excellence.

- Maintenance and Durability: Factor in the ease of maintenance and the expected service life of the valve. Our Lined PTFE PFA F46 Butterfly Valves are crafted to provide superior durability with minimal maintenance demands, ensuring uninterrupted operation and reduced life-cycle costs.

- Support and Service: Consider the level of support and service available. With our global presence and unwavering dedication to customer service, we stand behind every valve with comprehensive support, from selection to post-installation services.