The industrial sector is a dynamic and complex world, where every component plays a crucial role in the overall performance of a system. One such essential component is the rubber lined butterfly valve. These devices are indispensable in numerous industries, including water treatment, chemical processing, and power generation, due to their efficiency and durability. Europe has long been recognized as a major hub for valve manufacturing, with several leading companies producing high-quality rubber lined butterfly valve. This article aims to explore these prominent European manufacturers, delving into their histories, products, market presence, and reputation. Join us as we navigate the landscape of European valve manufacturing and shed light on the key players in this vital industry.

Introduction

Europe is home to a myriad of leading manufacturers specializing in the production of rubber lined butterfly valves, each contributing significantly to the global industrial sector. With their unique blend of innovation and quality, these manufacturers have carved out a niche for themselves in this competitive market. ABO Valve, Zwick, Hobbs Valve, and Ayvaz are among the top manufacturers in Europe, as per a report on dombor.com. Their products are renowned for their durability, efficiency, and resilience, making them a preferred choice for various industries. Further, companies like TechMatics, VATAC, Glaxochem, Wouter Witzel Euro Valve, ZD Valve, and Armtec are key global manufacturers of rubber lined butterfly valve, contributing to the robust growth of this market. Wouter Witzel, in particular, offers an extensive range of highly durable butterfly valve, known for their superior performance even in the most demanding applications. Another noteworthy company is VALTECCN, which specializes in the production and sales of various valves, including butterfly valve. The market for these valves continues to grow, with sales of rubber lined, plastic lined, and metal lined butterfly valve contributing significantly to the overall market size. These European manufacturers continue to dominate the landscape with their state-of-the-art products, setting high standards for quality, performance, and reliability in the industry.

Brief overview of the blog post

This blog post will provide an in-depth exploration of the leading European manufacturers in the rubber lined butterfly valve industry. We’ll begin with a comprehensive understanding of what rubber lined butterfly valve are and their significance across various industries. Following this, we delve into the European valve manufacturing industry, discussing why Europe holds a prominent position in this field. The main focus of the blog will be profiling the top manufacturers, examining their history, product range, market presence, and reputation. In addition, we’ll provide guidance on factors to consider when choosing a manufacturer and look ahead at future trends in the butterfly valve industry. The aim of this post is to offer valuable insights into the European rubber lined butterfly valve manufacturing landscape and assist readers in making informed decisions when selecting a manufacturer.

Importance and use of rubber lined butterfly valve in various industries

Rubber lined butterfly valves play a crucial role in various industries, thanks to their unique properties and versatile functionality. These valves, characterized by their rubber lining that provides tight sealing, are used for regulating and isolating the flow of liquids, gases, and semi-solids in pipelines. They are widely employed in water treatment plants, where they help control the flow of water and other fluids with precision. In the chemical processing industry, these valves are used for their resistance to corrosion and capacity to handle aggressive chemicals. The power generation sector also relies on rubber lined butterfly valves to manage the flow of steam in power plants. Moreover, in the oil and gas industry, these valves ensure safe and efficient transport of petroleum products through pipelines. Their durability, low maintenance needs, and ability to function under high pressure and temperature conditions make them an essential component in these industries. By providing reliable performance and enhancing operational efficiency, rubber lined butterfly valves have become an integral part of industrial processes.

Mention of Europe’s role as a leading manufacturer

Europe holds a significant position as a leading manufacturer in the global valve industry, particularly in the production of rubber lined butterfly valves. Its advanced and robust manufacturing sector is characterized by technological innovation, stringent quality controls, and a commitment to sustainability, making it a powerhouse in this field. European manufacturers, such as ABO Valve, Zwick, and Wouter Witzel Euro Valve, are renowned for their high-quality, durable, and efficient products that cater to a diverse range of industries worldwide. These companies have earned a reputation for their expertise and craftsmanship, often setting the standards for the industry. Furthermore, Europe’s strategic geographical location facilitates easy export to other continents, enhancing its global market presence. The region’s strong emphasis on research and development also contributes to its leading position, as it continues to pioneer new technologies and solutions in valve manufacturing. In essence, Europe’s role as a leading manufacturer underscores its influence and contribution to the global industrial landscape.

Understanding Rubber Lined Butterfly Valve

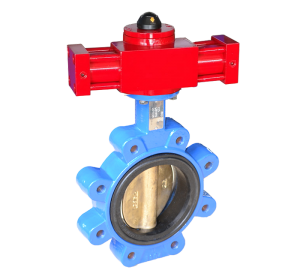

Rubber lined butterfly valves are a specific type of industrial valve that plays a crucial role in many sectors, from water treatment to chemical processing. At its core, a butterfly valve is a quarter-turn valve used to regulate or isolate the flow of a fluid. The valve gets its name from the disc in the center – the ‘butterfly’ – which pivots to open or close the valve. The ‘rubber lined’ part of the name refers to the lining of rubber on the valve’s body and disc. This rubber lining provides a tight seal, even at low differential pressures, ensuring that there are no leaks when the valve is closed.

These valves are characterized by their durability, low maintenance needs, and ability to function under a wide range of temperature and pressure conditions. They also offer high resistance to corrosion, making them suitable for handling aggressive chemicals in industries such as chemical processing. The rubber lining can be made from various materials, including natural rubber, EPDM, or Nitrile, each offering different levels of resistance to heat, abrasion, and chemicals.

One of the main advantages of rubber lined butterfly valves is their compact and lightweight design compared to other types of valves, such as ball or gate valves. This makes them easier to install, especially in tight spaces or where weight is a concern. Their simple design also means they have fewer parts that can wear out or need maintenance, reducing their overall operating costs. In addition, they provide a fast and efficient method of starting, stopping, and regulating flow, making them ideal for applications where quick control of the flow is required.

Despite their simplicity, rubber lined butterfly valves are versatile and widely used in various industries. For example, in water treatment plants, they help control the flow of water and other fluids with precision. In the power generation sector, they manage the flow of steam in power plants. And in the oil and gas industry, they ensure the safe and efficient transport of petroleum products through pipelines.

Understanding the properties and uses of rubber lined butterfly valves is essential for anyone involved in industries where flow control is critical. As technology advances, we can expect to see even more applications for these versatile, reliable, and cost-effective valves.

Explanation of what rubber lined butterfly valve are

Rubber lined butterfly valves are a specific type of control valve used in various industries to regulate or isolate the flow of different substances, such as liquids, gases, and semi-solids. The term ‘butterfly’ in the name refers to the disc located in the center of the valve, which rotates like a butterfly’s wings to open or close the valve. The ‘rubber lined’ aspect signifies the rubber coating on the body and the disc of the valve. This lining ensures a tight seal, preventing leaks even at low differential pressures. These valves are known for their durability, compact design, and ability to operate under a wide range of temperature and pressure conditions. The rubber lining, which can be made from various materials, offers excellent resistance to corrosion, making these valves suitable for handling aggressive chemicals or other harsh substances.

Detailed information on their functionality and benefits

Rubber lined butterfly valves function by using a disc, which is centrally positioned and attached to an actuator. The actuator, when turned, rotates the disc either parallel or perpendicular to the flow of fluid. When the disc is turned so that it’s parallel, the fluid can pass through freely, indicating the valve is in the ‘open’ position. When it’s turned perpendicular, it blocks the passage of fluid, meaning the valve is ‘closed’. The rubber lining on these valves ensures a tight seal when the valve is in the closed position, preventing any leakage.

One of the significant benefits of these valves is their versatility. They can handle a wide range of temperatures and pressures, and can be used with many different types of fluids, including those that are corrosive or abrasive. Additionally, the rubber lining provides excellent resistance against wear and tear, extending the valve’s lifespan and reducing maintenance needs. These valves are also known for their compact and lightweight design, making them easy to install and ideal for systems where space or weight is a concern. Furthermore, they offer efficient control over fluid flow, making them invaluable in industries where precise flow regulation is required, such as in water treatment plants or chemical processing facilities. In essence, the functionality and benefits of rubber lined butterfly valves make them an essential component in a variety of industrial applications.

Key industries where these valves are used

Rubber lined butterfly valves are used in a plethora of industries due to their versatility, durability, and ability to regulate fluid flow effectively. In the water treatment industry, these valves play a pivotal role in controlling the flow of water during various stages of treatment. The chemical processing industry also relies heavily on these valves, as they can handle corrosive substances without getting damaged, thanks to the protective rubber lining. Similarly, in the oil and gas industry, they are used to manage the flow and transport of petroleum products through pipelines safely and efficiently. Power generation plants utilize these valves to regulate the flow of steam, providing precise control over power production processes. Furthermore, in the food and beverage industry, these valves are used owing to their ability to maintain high levels of hygiene while controlling the flow of various liquids during production. Thus, rubber lined butterfly valves have established themselves as a key component in numerous industries around the globe.

Top European Manufacturers of Rubber Lined Butterfly Valve

Several top European manufacturers specialize in the production of rubber lined butterfly valves, contributing significantly to various industries worldwide. A notable manufacturer is VAG, known for its focus on water valves, including reliable and professional control valves, butterfly valves, and gate valves. Another leading manufacturer is Wouter Witzel Euro valve, which has carved a niche for itself by delivering unique rubber lined butterfly valves globally. In the chemical, oil and gas, power, and shipbuilding markets, ABO stands out with its expertise in resilient seated butterfly valves and PTFE lined butterfly valves. Alfa Europe also deserves mention for its bonded liner butterfly valves produced using the latest design technology, including vulcanized rubber liner by injection molding. Lastly, Victaulic, although not solely based in Europe, produces various types of butterfly valves, including rubber-lined butterfly valves, stainless steel butterfly valves, and carbon steel marine butterfly valves, serving diverse industry needs. These manufacturers exemplify the best in European valve manufacturing, combining innovation, quality, and reliability in their products.

Factors to Consider When Selecting a Manufacturer

When selecting a manufacturer, especially for critical components like rubber lined butterfly valves, several factors need to be taken into consideration. Firstly, the manufacturer’s reputation and track record in the industry are crucial. This can be evaluated by looking at their past projects, client testimonials, awards, and recognitions. Secondly, the quality of their products is paramount. The manufacturer should have strict quality control procedures and use high-grade materials to ensure the durability and longevity of their valves. It would be beneficial if they hold relevant certifications like ISO standards that vouch for their quality management systems.

Thirdly, consider their technical expertise and innovation capabilities. A good manufacturer stays abreast with the latest technologies and trends in the industry and incorporates them into their product designs for better performance and efficiency. They should also have the ability to customize their products according to your specific requirements. Fourthly, customer service is another important factor. The manufacturer should provide excellent pre- and post-sale support, including consultation, installation guidance, maintenance, and troubleshooting services.

Furthermore, the manufacturer’s delivery capabilities are vital. They should have reliable supply chains and logistics to ensure timely delivery of products. In addition, consider their environmental and sustainability practices. A responsible manufacturer will have measures in place to minimize their environmental impact and promote sustainable practices. Lastly, while cost is an important factor, it should not compromise the quality of the product. Therefore, choose a manufacturer who offers competitive prices without compromising on quality, service, and reliability.

Quality of the valves

When selecting a manufacturer for valves, the quality of the valves is a paramount factor to consider. Firstly, the materials used in the manufacturing process should be high-grade and suitable for the intended application. For instance, if the valves are to be used in corrosive environments, they must be made of materials that can withstand such conditions. Secondly, the manufacturer should adhere to stringent quality control procedures to ensure every valve produced meets the required standards. This includes various tests such as pressure tests, leakage tests, and functionality tests. Thirdly, the design of the valves should be innovative and efficient to ensure optimal performance. Fourthly, certifications like ISO standards can provide assurance about the manufacturer’s commitment to quality. Also, consider whether the manufacturer offers warranties or guarantees on their products, which can serve as an indication of their confidence in the quality of their valves. Lastly, check customer reviews and testimonials to get insights into the experiences of previous customers regarding the quality of the valves.

Pricing

When selecting a manufacturer, pricing is a crucial factor that directly impacts your project’s budget and ROI. However, it’s important not to make decisions based solely on the price tag. While finding a manufacturer with competitive pricing is essential, it’s equally important to ensure that the cost isn’t compromising the quality of the product. The cheapest option might end up costing more in the long run due to maintenance, repairs, or replacements. Therefore, consider the value for money rather than just the initial cost. Analyze the total cost of ownership, which includes not only the purchase price but also factors like installation costs, maintenance expenses, and potential downtime costs due to malfunctions. Additionally, transparency in pricing is paramount. Ensure the manufacturer provides a comprehensive quote detailing all costs, including any additional charges for shipping, handling, or customizations. This will help avoid any unexpected costs down the line. Ultimately, the goal is to find a manufacturer that offers high-quality products at a fair and competitive price.

After-sales service

After-sales service is a significant factor to consider when choosing a manufacturer. This service often distinguishes great manufacturers from average ones, as it reflects the company’s commitment to customer satisfaction beyond the point of sale. After-sales service can include various aspects such as warranty support, maintenance and repair services, provision of spare parts, technical support, and troubleshooting guidance. A manufacturer with excellent after-sales service will be able to promptly and effectively address any issues or concerns that arise after you’ve started using their product. This not only ensures the longevity and optimal performance of the product but also saves you potential time and costs associated with product malfunction or failure. Therefore, when selecting a manufacturer, look into their after-sales policies and track record. Check customer reviews and testimonials to glean insights into other customers’ experiences with the manufacturer’s after-sales service. Remember, a company that stands by its products after the purchase will likely be a reliable partner in your business operations.

Reputation and reviews

Reputation and reviews are vital aspects to consider when choosing a manufacturer. They provide insights into the manufacturer’s reliability, quality of products, and customer service. A manufacturer with a solid reputation in the industry is likely to deliver high-quality products and services consistently. Online reviews from previous customers can offer valuable first-hand information about their experiences with the manufacturer. These reviews can highlight the strengths and weaknesses of the manufacturer, including product quality, customer service, after-sales support, and overall customer satisfaction. However, while positive reviews are a good sign, it’s also important to pay attention to how the manufacturer responds to negative feedback. Their response can give you an idea of their commitment to customer satisfaction and their ability to handle problems effectively. It’s crucial to do thorough research and consider multiple sources of information to get a comprehensive understanding of the manufacturer’s reputation.

Certifications and compliance with standards

Certifications and compliance with standards are critical indicators of a manufacturer’s commitment to quality, safety, and ethical business practices. These certifications can assure you that the manufacturer’s processes and products have been rigorously tested and meet recognized industry standards. For instance, an ISO (International Organization for Standardization) certification validates that the manufacturer adheres to international standards of quality management and continuous improvement. Similarly, compliance with environmental standards like the ISO 14001 signifies the manufacturer’s dedication to sustainable practices. If you’re in a specialized field, ensure the manufacturer complies with industry-specific standards, such as the FDA regulations for food and drug manufacturers or CE marking for products sold within the European Economic Area. Compliance with these standards guarantees that the products are safe for use and meet the required performance specifications. Therefore, always verify the manufacturer’s certifications and compliance with relevant standards to ensure you’re partnering with a credible and reliable entity.

The Future of Rubber Lined Butterfly Valve

The future of rubber lined butterfly valves seems to be promising given their vast range of applications in various industries such as water treatment, oil and gas, power generation, and more. With advancements in technology, these valves are expected to become more efficient, durable, and versatile. The advent of smart technology and automation is set to revolutionize the way these valves function. For instance, the integration of Internet of Things (IoT) devices with these valves could allow for real-time monitoring and predictive maintenance, reducing the risk of sudden failures and improving operational efficiency.

Furthermore, the push towards sustainability is likely to drive the development of eco-friendly materials for rubber lining. These materials would not only be resilient and long-lasting but also have a minimal environmental impact at the end of their lifecycle. In terms of design, we can expect to see innovations aimed at improving performance, such as optimized disk shapes for better flow control and reduced energy consumption.

On the market side, the demand for rubber lined butterfly valves is projected to grow steadily due to increasing infrastructural development, especially in emerging economies. The need for reliable and efficient fluid control systems in these rapidly urbanizing regions provides ample opportunities for expansion.

However, manufacturers will need to navigate challenges such as fluctuating raw material prices and stringent regulatory standards. They must also stay abreast of technological trends and customer needs to maintain a competitive edge. By focusing on innovation, sustainability, and quality, manufacturers can position themselves to capitalize on the bright future of rubber lined butterfly valves. This is a forecast based on current trends and could change with shifts in technology, regulation, and market dynamics.

Current trends in the industry

The current trends in the industry are being shaped by technological advancements and changes in consumer behaviors. Key trends include the rise of AI, Augmented and Virtual Reality, Biotechnology, and Fintech platforms that are transforming the way businesses operate and interact with their customers. The Industry 4.0 revolution, led by Internet of Things (IoT), is dominating the industrial sector, enhancing efficiency and productivity.

3D printing is another significant trend, especially impactful in prototyping and manufacturing. Generative AI is boosting business productivity, while the growth of e-commerce continues to persist post-pandemic. 5G technology is also vastly improving communication speed and reliability.

Additionally, environmentalism has emerged as a key trend, with more businesses adopting sustainable practices and consumers favoring environmentally friendly products. Lastly, the Metaverse, Digital Twins, and Industrial Cloud are gaining momentum, indicating a shift towards a more digitized and interconnected world. These trends indicate a future where technology and sustainability are likely to drive industry growth and innovation.

Technological advancements and their impact

Technological advancements have had a profound impact on virtually every aspect of our lives, reshaping the way we work, communicate, and interact with the world around us. In the business sector, innovations such as artificial intelligence, machine learning, blockchain technology, and data analytics have revolutionized operations, enabling automation, enhancing efficiency, and providing valuable insights for decision-making. Communication has been transformed by social media and digital platforms, making it easier than ever to connect with people across the globe. In healthcare, advancements in biotechnology, telemedicine, and electronic health records have improved patient care and outcomes.

On a societal level, technology has also played a vital role in addressing global challenges, such as climate change and the COVID-19 pandemic. For instance, renewable energy technologies are facilitating the transition towards a more sustainable future, while digital tools and platforms have enabled remote work and learning, helping societies adapt to the new normal during the pandemic. However, these advancements also come with challenges, including data privacy concerns, digital divide, and job displacement due to automation. It is crucial that as we continue to innovate, we also address these issues to ensure that the benefits of technology are accessible and inclusive.

Future predictions for the market

The future of the market is likely to be shaped by several key trends and factors. One of the most significant is the continued digital transformation across sectors, driven by advancements in technologies like artificial intelligence, blockchain, Internet of Things, and 5G. These technologies are expected to drive growth in various industries, including fintech, healthcare, retail, and manufacturing, among others. Another trend that’s expected to influence the market is the growing emphasis on sustainability. Companies that prioritize environmentally friendly practices and offer sustainable products or services are likely to attract more consumers, given the increasing awareness about climate change and environmental issues.

Moreover, the post-pandemic recovery will also play a crucial role in shaping the market. As economies rebound from the effects of COVID-19, sectors like travel and hospitality that were hit hard by the pandemic are anticipated to see significant growth. On the other hand, sectors that thrived during the pandemic, such as e-commerce and remote work solutions, may have to adapt to changing consumer behaviors as more people return to in-person activities. It’s also worth noting that geopolitical tensions, policy changes, and economic uncertainties can impact the market unpredictably. Therefore, while these predictions provide a general direction, it’s important for businesses and investors to stay informed and adaptable.

Conclusion

In conclusion, the European market for rubber lined butterfly valves is a dynamic and competitive field, with several leading manufacturers setting new standards in quality, innovation, and customer service. From the precision engineering of German manufacturers to the bespoke designs of Italian valve makers, these companies are at the forefront of this industry, providing solutions that meet the diverse needs of customers across various sectors.

Manufacturers like KSB, Emerson Electric, and Hobbs Valve have distinguished themselves through their commitment to quality and their ability to produce valves that can withstand harsh conditions and rigorous use. They are not just manufacturing products; they are creating solutions tailored to the specific requirements of each client and project. Their success lies in their relentless pursuit of excellence, their investment in research and development, and their understanding of the evolving demands of the market.

Moreover, these manufacturers are also cognizant of the environmental impact of their operations. They are taking significant steps to reduce their carbon footprint, improve energy efficiency, and promote sustainability. It is encouraging to see these industry leaders taking responsibility for their environmental impact and paving the way for more sustainable manufacturing practices.

The rubber lined butterfly valves produced by these manufacturers play a crucial role in a wide range of industries, including water treatment, oil and gas, and chemical processing. Their products ensure the safe and efficient operation of piping systems, contributing to the productivity and profitability of their clients’ businesses.

Looking ahead, the future of the rubber lined butterfly valve industry in Europe appears promising. As technology continues to advance, we can expect to see further innovations in valve design and manufacturing processes. The increasing emphasis on sustainability will likely drive the development of more environmentally friendly products and practices. The continued growth of industries that rely on these valves suggests that demand will remain strong.

In the end, the success of these leading European manufacturers of rubber lined butterfly valves is a testament to their expertise, their dedication to quality, and their ability to adapt to changing market conditions. They set the bar high for other players in the industry and provide valuable lessons for companies aspiring to achieve similar levels of success. They are not just manufacturers; they are pioneers, innovators, and leaders in their field.

Recap of the key points discussed

In this discussion, we delved into the world of rubber lined butterfly valves, focusing particularly on leading European manufacturers such as KSB, Emerson Electric, and Hobbs Valve. We highlighted their commitment to quality, innovation, and customer service, as well as their ability to tailor solutions to specific client needs. The role that these products play in diverse industries, including water treatment, oil and gas, and chemical processing was also emphasized. Additionally, we noted the significant steps these manufacturers are taking toward sustainability and reducing environmental impact. Looking forward, we explored the promising future of the industry, with technological advancements likely driving further innovation and an increasing emphasis on sustainability shaping the development of environmentally friendly products and practices.

Final thoughts on the importance of choosing the right manufacturer

In conclusion, the importance of choosing the right manufacturer for rubber lined butterfly valves cannot be understated. The right manufacturer does not only provide a high-quality, durable product but also offers exceptional customer service, innovative solutions, and a commitment to sustainability. With the right manufacturer, you can ensure the optimal performance of your piping systems, contributing to the overall efficiency and productivity of your operations. Furthermore, by choosing a manufacturer that prioritizes sustainability, you can align your business with environmentally responsible practices, which is becoming increasingly important in today’s business landscape. Therefore, investing time and effort in selecting the right manufacturer is not just about securing a reliable product; it’s about forging a partnership that can drive your business forward while also making a positive impact on the environment.