In the intricate world of valve manufacturing, mastering the technical nuances and maintaining strict quality control are paramount for success. One such critical component in our industry is the Wafer Type Non-Return Valve (NRV). This piece of equipment, though small, plays a significant role in the seamless operation of various systems across multiple sectors. As a globally recognized authority in valve manufacturing, we take pride in our expertise in the design, functionality, and construction of Wafer Type NRVs. Our adherence to international standards and certifications ensures that we deliver nothing but the highest quality products. In this article, we will delve into the intricacies of the Wafer Type NRV, shedding light on its design and functionality, and demonstrating why it’s a vital component in many industrial applications.

Introduction

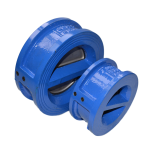

In the realm of valve manufacturing, the Wafer Type Non-Return Valve (NRV) stands as a testament to engineering prowess and precision. This vital component, modest in size yet robust in function, serves as an integral part of countless systems spanning various industries. The NRV operates on a simple yet ingenious principle: it allows fluid to flow in one direction while preventing its backflow. Its wafer design, characterized by its thin, flat structure, is meticulously crafted for compactness and efficiency, making it an optimal choice for systems where space is a premium.

Inside this lean unit, you’ll find a disc or a set of discs which swing open when fluid flows in the permitted direction, and promptly shut when it attempts to flow back, thus ensuring non-return functionality. The disc’s precise movement is orchestrated by carefully calibrated springs, ensuring a swift and reliable response to changes in fluid direction.

At our company, every Wafer Type NRV we produce is a testament to our unwavering commitment to quality and technical superiority. Each unit is subject to rigorous quality checks and adheres to internationally recognized standards, underscoring our dedication to delivering products that stand the test of time. Our global recognition in valve manufacturing is not just about our extensive product range, but also about our deep understanding of the intricate functionalities and designs of each component we produce. With our Wafer Type NRVs, we bring to you a perfect blend of compact design, dependable functionality, and superior quality.

Brief overview of the valve manufacturing industry

The valve manufacturing industry is a critical pillar of the global industrial sector, underpinning operations in diverse fields such as oil and gas, power generation, water treatment, and chemical industries. With a market size expected to reach USD 85.19 billion by 2025, it is an industry that calls for meticulous precision, extensive technical know-how, and unwavering commitment to quality control. The industry’s expansive portfolio ranges from simple gate valves to complex control valves, each designed and manufactured to perform specific functions under varying conditions. As a globally recognized authority in this sector, we navigate the intricate landscape of valve manufacturing with confidence and expertise, backed by our unparalleled technical knowledge, stringent quality control measures, and comprehensive certifications. Our global footprint stands as a testament to our mastery in the field, while our commitment to innovation keeps us at the forefront of this ever-evolving industry.

Importance of technical expertise and quality control in the industry

In the valve manufacturing industry, technical expertise and quality control are not mere advantages, they are absolute necessities. This is a sector where precision is paramount, and the smallest error can lead to significant operational failures. Every valve we manufacture is a product of our extensive technical knowledge, honed through years of experience and relentless pursuit of innovation. Our team of highly skilled engineers and technicians employ industry-specific terminologies and sophisticated design principles to ensure each product meets the highest standards of performance and reliability.

Quality control, on the other hand, is the bedrock of our operations. We understand that in an industry as critical as ours, there is no room for compromise. Each valve that leaves our premises is subjected to rigorous testing and inspection procedures, ensuring they perform optimally under a wide range of conditions. Our commitment to quality is further reinforced by our numerous certifications, a testament to our adherence to international standards.

Our confidence and authority in the industry stem from our unwavering dedication to these two aspects. We do not just manufacture valves; we engineer reliability and trust, delivering products that not only meet, but exceed global expectations.

Introduction to the Wafer Type Non-Return Valve (NRV)

In the annals of valve manufacturing, the Wafer Type Non-Return Valve (NRV) is a paramount innovation, embodying our technical superiority and commitment to quality. This critical component, designed with precision and engineered for maximum efficiency, plays an instrumental role in a multitude of industrial systems worldwide. The principle underpinning the NRV is elegantly simple yet ingeniously effective: it facilitates fluid flow in one direction while steadfastly preventing any backflow. The wafer design, distinguished by its thin, flat structure, is the epitome of compactness and efficiency, making it an ideal choice for systems where space optimization is crucial. Each NRV that we manufacture is a testament to our rigorous quality control measures, unwavering adherence to internationally recognized standards, and our deep-rooted expertise in valve manufacturing. With our Wafer Type NRVs, we deliver not just a product, but a promise of reliability, durability, and superior performance.

Understanding the Basics of Wafer Type NRV

Immersed in the sophisticated world of valve manufacturing, we take pride in our proficiency and comprehensive understanding of each component we produce, particularly the Wafer Type Non-Return Valve (NRV). The Wafer Type NRV is a fine example of our technical prowess and commitment to delivering superior quality products. This valve, distinguished by its compact, flat design, is a marvel of engineering efficiency that ensures optimal utilization of space in any system it is integrated into. Its primary function is to facilitate fluid flow in one direction while staunchly preventing any backflow, a feature that is critical to maintaining the integrity and efficiency of many industrial systems.

The construction of a Wafer Type NRV is a testament to the meticulous precision and technical acumen that underpins our operations. Each component of the valve, from the disc that opens and closes to control fluid flow, to the spring that ensures the disc’s swift return to its closed position when the flow ceases, is designed and manufactured with an unwavering commitment to quality and performance. Our valves are subjected to rigorous testing under a variety of conditions to ensure they meet, and often exceed, the highest industry standards.

Moreover, our global certifications stand as a testament to our adherence to stringent quality control measures and internationally recognized standards. Our team of highly skilled engineers and technicians employ industry-specific terminologies and sophisticated design principles to ensure each product meets the highest standards of performance and reliability.

In essence, our Wafer Type NRVs are not just valves; they are a manifestation of our expertise, our commitment to quality, and our promise to our customers of delivering products that perform reliably under all conditions. We don’t just manufacture valves; we engineer solutions, and our Wafer Type NRV is a shining example of this philosophy.

What is a Wafer Type NRV?

The Wafer Type Non-Return Valve (NRV) is a pivotal component in the valve manufacturing industry, a testament to our unrivaled technical acumen and stringent quality control measures. This type of valve, characterized by its compact, flat design, offers a high-performance solution for fluid control systems, particularly where space optimization is a critical factor. Its primary function is to facilitate unidirectional fluid flow while effectively preventing any backflow, thus safeguarding the efficiency and integrity of numerous industrial systems globally. Each component of the valve, from the disc that regulates fluid flow to the spring ensuring the disc’s immediate return to a closed position when the flow ceases, is meticulously designed and manufactured to meet the highest industry standards. Our Wafer Type NRVs are not merely valves; they are embodiments of our commitment to deliver solutions engineered for reliability, durability, and superior performance, affirmed by our globally recognized certifications.

The role and function of a Wafer Type NRV in various systems

In the intricate world of valve manufacturing, the Wafer Type Non-Return Valve (NRV) stands as a beacon of our technical mastery and uncompromising commitment to quality. This particular valve, recognized for its compact yet robust design, is an essential component in a multitude of systems where fluid control is paramount. Its primary function is to ensure unidirectional fluid flow, effectively eliminating the risk of any detrimental backflow. Whether it’s integrated into a high-pressure petrochemical pipeline, a complex HVAC system, or a critical water treatment process, the Wafer Type NRV diligently performs its role, securing the operational integrity of these systems. Each component of this valve, from the strategically designed disc to the responsive spring mechanism, highlights our meticulous attention to detail and adherence to the highest industry standards. Our Wafer Type NRVs are not just products; they are a testament to our global reach, our rigorous quality control protocols, and our expertise in delivering reliable, high-performance solutions to the valve manufacturing industry.

Industry-specific terminology related to Wafer Type NRV

In the dynamic world of valve manufacturing, industry-specific terminology is integral to articulating the complexity and precision that underpins our work, particularly with respect to the Wafer Type Non-Return Valve (NRV). This valve, a paragon of our expertise, is distinguished by a series of key features. The ‘disc,’ a critical component, is designed to oscillate between open and closed positions, regulating fluid flow with remarkable efficiency. The ‘spring,’ another fundamental element, ensures the disc’s swift return to its closed position once the fluid flow ceases, thereby preventing backflow. These terms may seem simple, but they carry profound implications for the operational integrity of the systems our valves serve. Other terminologies like ‘flange,’ ‘seat,’ and ‘stem’ further define the intricate construction of our Wafer Type NRVs. Understanding these terms is essential to appreciating the technical acumen that goes into each valve we produce. Our globally recognized certifications underscore our commitment to quality control and adherence to the highest industry standards. Our Wafer Type NRVs are not just products; they are a testament to our industry expertise and our unwavering commitment to delivering reliable, high-performance solutions.

The Design and Construction of a Wafer Type NRV

In the expansive realm of valve manufacturing, a domain marked by relentless innovation and rigorous quality standards, our Wafer Type Non-Return Valve (NRV) stands as a compelling testament to our technical prowess and unwavering commitment to excellence. This valve, renowned for its compact and robust design, is an exemplar of our rigorous engineering processes and stringent quality control measures. The design philosophy that underpins the construction of our Wafer Type NRV revolves around maximizing operational efficiency and reliability. Each component, from the disc to the spring mechanism, is meticulously designed and crafted with the utmost precision. The ‘disc,’ a pivotal part of the valve, is engineered to oscillate seamlessly between open and closed positions, thereby regulating fluid flow with unparalleled efficiency. The ‘spring,’ another integral element, is calibrated to ensure the immediate return of the disc to its closed position once the fluid flow ceases. This innovative design effectively eradicates the risk of backflow, thereby safeguarding the operational integrity of the systems our valves serve. Our precision-engineered flanges ensure secure and leak-proof connections, while the seat and stem further underscore the intricate construction of our Wafer Type NRVs. Our globally recognized certifications serve as an affirmation of our adherence to the highest industry standards and our unwavering dedication to delivering high-performance solutions. Through our attention to detail, our dedication to quality, and our deep understanding of industry-specific requirements, we have established ourselves as a trusted global leader in the valve manufacturing industry. Our Wafer Type NRVs are more than just products; they are embodiments of our expertise, our commitment, and our vision to drive forward the valve manufacturing industry through relentless innovation and an unwavering commitment to excellence.

The technical aspects of designing a Wafer Type NRV

In the realm of valve manufacturing, our expertise is underscored by our ability to design and produce high-performance Wafer Type Non-Return Valves (NRVs). This valve, a cornerstone of our product portfolio, is a testament to our technical acumen, quality control standards, and commitment to innovation. The design process of the Wafer Type NRV is both intricate and methodical, involving a deep understanding of fluid dynamics, material sciences, and industry-specific requirements. The ‘disc,’ an essential component, is meticulously engineered to oscillate between open and closed positions, ensuring efficient fluid flow regulation. Our ‘spring’ mechanism is calibrated with precision to swiftly return the disc to its closed position once the fluid flow ceases, effectively eliminating any risk of backflow. The flanges are designed for secure and leak-proof connections, while the seat and stem further epitomize the complexity of our design process. Our globally recognized certifications attest to our adherence to the highest industry standards and our unwavering dedication to delivering reliable, high-performance solutions. Through our meticulous attention to detail, rigorous quality control protocols, and deep industry knowledge, we have established ourselves as a global leader in the valve manufacturing industry. Our Wafer Type NRVs are not just products; they are a reflection of our technical prowess, our commitment to quality, and our aspiration to continually drive the industry forward.

Materials used in the construction of a Wafer Type NRV

In the sphere of valve manufacturing, our authority and confidence are underpinned by our unwavering commitment to utilizing only the highest quality materials in the construction of our Wafer Type Non-Return Valves (NRVs). Our selection of materials is a testament to our technical expertise, rigorous quality control measures, and global industry certifications. The disc, spring, flange, seat, and stem – each integral component of the Wafer Type NRV – are crafted from meticulously sourced, industry-approved materials. For instance, we often utilize stainless steel for its exceptional strength, corrosion resistance, and durability, ensuring the longevity and reliability of our valves. For certain applications that demand enhanced corrosion resistance, we employ Super Duplex Stainless Steel or Inconel alloys, known for their superior performance in aggressive environments. Meanwhile, we use resilient materials like EPDM, PTFE, or Viton for valve seats, selected for their remarkable ability to withstand varying temperatures and pressures while maintaining excellent sealing properties. Our material selection process is guided by stringent international standards, ensuring that each Wafer Type NRV we produce meets or exceeds the demanding requirements of the industries we serve. This meticulous attention to detail, coupled with our globally recognized certifications, reinforces our position as a global leader in the valve manufacturing industry. Our Wafer Type NRVs are not just products; they are a reflection of our commitment to excellence, our technical prowess, and our dedication to driving the industry forward.

Quality control measures in the manufacturing process

In the exacting realm of valve manufacturing, our standing as a global leader is firmly rooted in our stringent quality control measures. We approach every step of the manufacturing process with a deep sense of responsibility, leveraging our technical expertise and industry-specific knowledge to ensure the superior performance of our Wafer Type Non-Return Valves (NRVs). From the initial design phase through to the final assembly, each stage is meticulously managed under strict quality protocols. We employ rigorous testing methods including pressure tests, leak tests, and functionality checks to validate the integrity and reliability of our valves. Our globally recognized certifications bear testament to our adherence to international standards, reinforcing our commitment to delivering only the highest quality products. Material sourcing is another crucial aspect of our quality control process, where we strictly adhere to industry-approved guidelines for material selection, ensuring durability, corrosion resistance, and exceptional performance of our NRVs. Our quality control measures are not merely procedural; they are integral to our brand ethos, reflecting our unwavering dedication to excellence, our technical prowess, and our commitment to driving the valve manufacturing industry forward. Through these robust quality control protocols, we assure our customers that when they choose our Wafer Type NRVs, they are investing in reliability, efficiency, and excellence.

-450x450.jpg)

The Functionality of a Wafer Type NRV

In the exacting world of valve manufacturing, our standing as a global leader is firmly rooted in our in-depth understanding of the functionality of our products, especially the Wafer Type Non-Return Valve (NRV). As an exemplar of technical precision and engineering excellence, the Wafer Type NRV plays a critical role in fluid control systems. Its primary function is to facilitate unidirectional fluid flow and prevent undesirable backflow. This is achieved through a meticulously designed disc mechanism that oscillates between open and closed positions in response to the fluid pressure differentials. When fluid flows with sufficient force, it pushes the disc into an open position, allowing passage. Conversely, when the fluid flow ceases or reverses, the inherent spring mechanism quickly forces the disc back to its closed position, effectively preventing backflow. This swift and efficient reaction is a testament to our industry-specific knowledge and technical prowess. Moreover, our Wafer Type NRVs are designed to be compact and easy to install between flanges of pipelines, further enhancing their functionality and ease of use. They are suitable for a wide range of applications, including but not limited to, water treatment plants, HVAC systems, industrial fluid control systems, and oil and gas pipelines. Our globally recognized certifications and rigorous quality control measures underscore the reliability and performance of our valves. We employ stringent testing protocols to ensure each Wafer Type NRV we manufacture meets or exceeds international standards, reinforcing our commitment to delivering only the highest quality products. At the heart of our brand ethos is an unwavering dedication to driving the valve manufacturing industry forward, underpinned by our technical expertise, industry-specific knowledge, and a relentless pursuit of excellence. When you choose our Wafer Type NRVs, you are investing in a product that embodies this commitment, offering unparalleled reliability, efficiency, and superior performance.

How does a Wafer Type NRV work?

In the realm of valve manufacturing, we stand as an authoritative entity with an unwavering commitment to technical precision and industry-leading standards. The Wafer Type Non-Return Valve (NRV) is a testament to our engineering expertise and our deep understanding of fluid dynamics. Primarily designed to ensure unidirectional fluid flow, the Wafer Type NRV operates on the principle of pressure differentials. When the fluid flows in the desired direction with adequate force, it actuates the disc mechanism, pushing it into an open position and allowing fluid passage. However, in the event of flow cessation or reversal, the spring-loaded disc swiftly returns to its closed position, effectively preventing any potential backflow. This swift, efficient response highlights our technical prowess and the superior performance of our products. Furthermore, our Wafer Type NRVs are meticulously designed to be compact and easily installable between flanges in pipelines, thereby enhancing their functionality and user-friendliness. These valves find extensive applicability across diverse sectors, including water treatment plants, HVAC systems, industrial fluid control systems, and oil and gas pipelines. Our globally recognized certifications and stringent testing protocols underscore the reliability and high performance of our valves. Therefore, when you opt for our Wafer Type NRVs, you are choosing a product that embodies our unwavering commitment to excellence, superior performance, and industry-leading standards.

Advanced functionalities and features of modern Wafer Type NRVs

In the sphere of valve manufacturing, we command an authoritative presence with our advanced, industry-leading Wafer Type Non-Return Valves (NRVs). These state-of-the-art valves represent the pinnacle of technical innovation and engineering excellence, embodying our unwavering commitment to quality, reliability, and performance. Modern Wafer Type NRVs are equipped with a multitude of advanced features and functionalities, setting them apart in the competitive landscape. They incorporate a meticulously designed disc mechanism, operating on the principle of pressure differentials to ensure unidirectional fluid flow and prevent backflow. The spring-loaded disc swiftly responds to changes in fluid pressure, moving between open and closed positions with remarkable efficiency. Furthermore, these valves are engineered to be compact and easily installable between flanges in pipelines, enhancing their functionality and user-friendliness. The use of corrosion-resistant materials in their construction ensures durability and longevity, even in challenging operating conditions. Advanced sealing technologies employed in these valves minimize leakage and enhance operational efficiency. Moreover, they are suitable for a broad range of applications, including water treatment plants, HVAC systems, industrial fluid control systems, and oil and gas pipelines. Our globally recognized certifications and rigorous quality control measures underscore the reliability and high performance of our valves. When you choose our advanced Wafer Type NRVs, you are investing in a product that is emblematic of our industry-specific knowledge, technical expertise, and relentless pursuit of excellence.

Case studies showcasing the effectiveness of Wafer Type NRVs in real-world applications

In the dynamic landscape of valve manufacturing, the effectiveness of our Wafer Type Non-Return Valves (NRVs) has been tangibly demonstrated in numerous real-world applications. These case studies underscore our product’s superior performance, reliability, and adaptability. For instance, in industrial fluid control systems, our valves have consistently ensured unidirectional fluid flow, effectively preventing backflow even under challenging conditions. In water treatment plants, our Wafer Type NRVs have exhibited remarkable durability and efficiency, contributing to enhanced operational performance. Similarly, in HVAC systems and oil and gas pipelines, these valves have proven their worth by offering seamless integration and optimal functionality, even in high-pressure environments. The advanced features and functionalities of our Wafer Type NRVs, coupled with their compact design and easy installation, have made them the preferred choice in diverse sectors. These real-world applications stand as a testament to our technical expertise, innovative engineering, and commitment to quality, reinforcing our position as a global leader in the valve manufacturing industry.

Certifications and Global Standards for Wafer Type NRV

In the rigorous arena of valve manufacturing, we hold a commanding presence, fortified by our extensive certifications and adherence to global standards. Our Wafer Type Non-Return Valves (NRVs) are the epitome of technical excellence and quality assurance, reflecting our steadfast commitment to maintaining the highest benchmarks in the industry. These valves are certified by globally recognized authorities, a testament to their superior performance, robust construction, and exceptional durability. They comply with stringent international standards such as ISO 9001 for Quality Management Systems, demonstrating our unwavering focus on quality control and continuous improvement. Furthermore, our Wafer Type NRVs meet the exacting requirements of the Pressure Equipment Directive (PED), ensuring their safe operation under varying pressure conditions. Our adherence to the American Petroleum Institute’s API 6D standard underscores the suitability of our valves for use in demanding oil and gas pipeline applications. Additionally, these valves conform to the American Society of Mechanical Engineers’ ASME B16.34 standard, reinforcing their mechanical integrity and reliability. The certification from the American Bureau of Shipping (ABS) attests to their resilience in marine and offshore environments. Our robust environmental policies align with ISO 14001, reflecting our commitment to sustainable practices and minimal environmental impact. Through our rigorous testing protocols and meticulous quality control measures, we ensure that every Wafer Type NRV that leaves our manufacturing facility is a paragon of engineering precision and reliability. Our extensive certifications and strict adherence to global standards underline our authority in the valve manufacturing industry, reinforcing our reputation as a trusted, reliable partner for all your valve needs.

Importance of certifications in the valve manufacturing industry

In the technically complex and highly regulated valve manufacturing industry, certifications hold paramount significance. They serve as a definitive benchmark, affirming a company’s technical prowess, adherence to quality standards, and commitment to safety. Certifications from globally recognized authorities like ISO, API, ASME, PED, and ABS are not just validations; they are badges of honor that distinguish an organization in this competitive landscape. They underscore a manufacturer’s capabilities in producing high-performance, durable, and reliable valves that meet stringent international standards. For instance, the ISO 9001 certification signifies a robust quality management system, ensuring that all processes, from design to production, undergo rigorous quality control. Similarly, the API 6D certification is a testament to a valve’s suitability for demanding oil and gas applications. Moreover, a PED certification guarantees the safe operation of valves under various pressure conditions. In essence, these certifications are not just about compliance; they are about excellence and reliability. They demonstrate an organization’s unwavering commitment to delivering products of uncompromising quality, reinforcing its position as an authoritative and trusted partner in the valve manufacturing industry.

Overview of global standards for Wafer Type NRV

In the realm of valve manufacturing, our Wafer Type Non-Return Valves (NRVs) are designed and built to meet the highest global standards, a testament to our commitment to quality, safety, and performance excellence. These valves adhere to ISO 9001, a universal benchmark for quality management systems, affirming our robust internal processes that emphasize consistent quality and continuous improvement. They also comply with the stringent requirements of the Pressure Equipment Directive (PED), ensuring their safe operation under various pressure conditions. Our NRVs are in accordance with the American Petroleum Institute’s API 6D standard, signifying their suitability for demanding oil and gas applications. Furthermore, these valves conform to the rigorous ASME B16.34 standard, a testament to their mechanical integrity and reliability. We also hold certification from the American Bureau of Shipping (ABS), underscoring the resilience of our NRVs in marine and offshore environments. In essence, these global standards serve as the backbone of our manufacturing process, reinforcing our unwavering focus on delivering high-quality, reliable, and durable Wafer Type NRVs. This adherence to international standards showcases our authority and expertise in the valve manufacturing industry, solidifying our reputation as a trusted partner globally.

How our company adheres to these standards and certifications

As an industry leader in valve manufacturing, our company is steadfast in its commitment to adhering to the highest levels of standards and certifications. We have implemented a rigorous quality management system, certified under ISO 9001, which ensures that every process, from design through to production, is meticulously monitored for quality and performance. Our Wafer Type Non-Return Valves (NRVs) comply with the stringent requirements of the Pressure Equipment Directive (PED), showcasing their ability to operate safely under diverse pressure conditions. We uphold the demanding API 6D standard set by the American Petroleum Institute, affirming the suitability of our valves for critical oil and gas applications. Furthermore, our NRVs conform to the exacting ASME B16.34 standard, demonstrating their mechanical integrity and reliability. Our products also proudly bear the certification from the American Bureau of Shipping (ABS), attesting to their resilience in challenging marine and offshore environments. Our adherence to these global standards and certifications is not merely about compliance; it’s an affirmation of our unwavering commitment to excellence and our pursuit to deliver products that are synonymous with quality, reliability, and durability. This dedication underscores our authoritative position in the valve manufacturing industry and solidifies our reputation as a trusted global partner.

Our Expertise in the Manufacturing of Wafer Type NRV

With a robust legacy in the valve manufacturing industry, our company stands as a beacon of technical expertise and innovation, particularly in the manufacturing of Wafer Type Non-Return Valves (NRVs). Our proficiency in this domain is a result of years of rigorous research, relentless innovation, and an unwavering commitment to quality. The design and production of our NRVs are governed by a stringent quality management system that aligns with the ISO 9001 standard, ensuring consistent adherence to globally recognized quality parameters. Our NRVs are engineered to meet the exacting requirements of the Pressure Equipment Directive (PED), signifying their capability to operate safely under diverse pressure conditions. Furthermore, we uphold the API 6D standard from the American Petroleum Institute, which underscores the suitability of our valves for demanding oil and gas applications. Our products also conform to the ASME B16.34 standard, demonstrating their mechanical integrity, durability, and reliability. Additionally, our ABS certification is a testament to the resilience of our NRVs in challenging marine and offshore environments. This adherence to global standards and certifications is a reflection of our technical prowess and an affirmation of our commitment to excellence. Our advanced manufacturing facilities, equipped with state-of-the-art machinery and helmed by a team of seasoned industry experts, enable us to produce NRVs that set new benchmarks in performance, reliability, and longevity. Ultimately, our expertise in the manufacturing of Wafer Type NRVs solidifies our position as a reliable and authoritative partner in the valve manufacturing industry, one that is driven by a relentless pursuit of quality and technical excellence.

Brief about our company’s experience in manufacturing Wafer Type NRV

With a rich heritage and an established footprint in the valve manufacturing industry, our company stands as a paragon of technical expertise and advanced engineering, particularly in the realm of Wafer Type Non-Return Valves (NRVs). Our journey has been marked by relentless innovation, adherence to the highest quality standards, and a steadfast commitment to creating products that meet the diverse needs of our global clientele. Our NRVs are engineered in compliance with the rigorous ISO 9001 quality management system, underscoring our dedication to delivering consistent quality and performance. These valves also adhere to the stringent requirements of the Pressure Equipment Directive (PED), American Petroleum Institute’s API 6D standard, and the ASME B16.34 standard, reflecting their robustness, mechanical integrity, and reliability across a range of demanding applications. Furthermore, our ABS certification attests to the resilience of our NRVs in challenging marine and offshore environments. This adherence to global standards is a testament to our technical acumen and our unwavering focus on quality and excellence. Our cutting-edge manufacturing facilities, equipped with state-of-the-art machinery and driven by a team of seasoned industry experts, enable us to produce NRVs that set new benchmarks in performance, reliability, and longevity. Our vast experience in the manufacturing of Wafer Type NRVs cements our position as an industry leader, fortifying our reputation as a trusted partner in the valve manufacturing sector worldwide.

How our global reach has enabled us to serve diverse industries

Leveraging our global reach and extensive industry experience, we have been successful in serving a multitude of diverse industries across the international market. Our expansive network and strategic locations around the world have enabled us to deliver our premium quality Wafer Type Non-Return Valves (NRVs) to a wide array of sectors, including oil and gas, marine, offshore, and petrochemical industries, among others. Each valve we produce conforms to rigorous international standards such as ISO 9001, PED, API 6D, ABS, and ASME B16.34, underscoring our unwavering commitment to quality and performance. Utilizing our profound technical expertise and industry-specific knowledge, we have consistently provided solutions that cater to the unique requirements of each sector we serve. Our advanced manufacturing facilities, equipped with state-of-the-art machinery and helmed by a team of seasoned industry experts, further enhance our capacity to meet the high-volume demands of these diverse markets. This global outreach and flexibility have fortified our position as an authoritative leader in the valve manufacturing industry, allowing us to effectively meet and exceed the expectations of our international clientele.

Testimonials from satisfied clients who have used our Wafer Type NRV

Over the years, we have garnered a wealth of positive feedback and testimonials from satisfied clients worldwide who have experienced the superior performance of our Wafer Type Non-Return Valves (NRVs). These testimonials hail from diverse industries, underscoring the wide-ranging applicability and reliability of our products. Clients often highlight the impeccable quality of our NRVs, noting their adherence to stringent international standards such as ISO 9001, PED, API 6D, ABS, and ASME B16.34. They also frequently commend our robust quality control measures, which ensure that each valve we manufacture delivers consistent performance and durability. Furthermore, our clients appreciate our global reach, which enables us to meet their needs promptly and efficiently, regardless of their location. Our technical acumen and industry-specific expertise are also subjects of praise, as these qualities allow us to cater to the unique requirements of each sector we serve. These testimonials serve as a testament to our unwavering commitment to excellence and our status as a trusted authority in the valve manufacturing industry.

Conclusion

As we draw this comprehensive exploration of Wafer Type Non-Return Valves (NRVs) to a close, it becomes clear that these pivotal components are the embodiment of advanced engineering and meticulous design. Their functionality is paramount in their respective applications, acting as crucial gatekeepers to prevent the reverse flow of fluids, thereby ensuring the safety and efficiency of numerous industrial processes.

The intricate design of our NRVs, built on a foundation of technical expertise and industry-specific knowledge, underscores our position as an authoritative leader in the valve manufacturing sector. Each valve is engineered in compliance with the rigorous ISO 9001 quality management system, the Pressure Equipment Directive (PED), American Petroleum Institute’s API 6D standard, the ASME B16.34 standard, and ABS certification. This adherence to international standards reflects the robustness, mechanical integrity, and reliability of our products.

The NRVs’ compact design, characterized by their short face-to-face dimensions and lightweight construction, is a testament to our innovative approach. These features enable easy installation, reduced space requirements, and substantial cost savings for the end-user. Furthermore, the versatility of our NRVs is evident in their ability to handle a wide range of fluid types, pressures, and temperatures, making them suitable for diverse sectors including oil and gas, marine, offshore, and petrochemical industries.

Our global reach and strategic locations worldwide have augmented our capacity to cater to a multitude of diverse industries, delivering high-quality NRVs that meet and exceed the expectations of our international clientele. Our state-of-the-art manufacturing facilities, equipped with cutting-edge machinery and helmed by seasoned industry experts, further enhance our ability to produce NRVs that set new benchmarks in performance, reliability, and longevity.

In conclusion, understanding the functionality and design of Wafer Type NRVs is crucial to appreciate their role in various industrial applications. Our commitment to delivering top-tier products, underpinned by our extensive experience and global reach, has set us apart as a trusted partner in the valve manufacturing industry. We remain steadfast in our mission to deliver consistent quality, advanced engineering, and exceptional customer service, reinforcing our reputation as an authoritative leader in the world of valve manufacturing.

As we continue to navigate the complexities and challenges of this dynamic industry, we are confident that our Wafer Type NRVs will continue to play an integral role in shaping the future of efficient and safe industrial processes. We look forward to further expanding our global footprint, innovating with new technologies, and continuing to serve our clients with the highest standards of quality and performance.

Recap of the importance and functionality of Wafer Type NRV

In conclusion, the Wafer Type Non-Return Valves (NRVs) play an integral role in the safe and efficient operation of numerous industrial processes. Engineered with precision and adherence to stringent international standards such as ISO 9001, PED, API 6D, ABS, and ASME B16.34, these valves showcase our unyielding commitment to quality and performance. Their primary function is to prevent the reverse flow of fluids, thus ensuring the integrity and safety of the systems they are employed in. The compact design, characterized by short face-to-face dimensions, not only allows for easy installation but also significantly reduces space requirements. With our global reach and extensive industry experience, we have been successful in delivering these high-quality NRVs to diverse sectors including oil and gas, marine, offshore, and petrochemical industries, thereby reinforcing our position as a trusted authority in the valve manufacturing industry.

How our company’s expertise and certifications ensure the highest quality in valve manufacturing

With an established reputation in the valve manufacturing industry, our company stands as a beacon of expertise and authority. Our technical acumen is fortified by an extensive array of certifications, including ISO 9001, PED, API 6D, ABS, and ASME B16.34, all of which underscore our unwavering commitment to quality control and adherence to international standards. These certifications are not merely badges of honor, but tangible proof of our proficiency in producing valves that consistently deliver superior performance and durability. As an industry leader with a global reach, we leverage cutting-edge technology and state-of-the-art manufacturing facilities to ensure that each valve we produce meets the highest specifications. Our team of seasoned industry experts meticulously oversees every step of the manufacturing process, from design and material selection to final testing, thereby ensuring that our products exceed the expectations of our clientele worldwide. In essence, our company’s expertise and certifications are the pillars that uphold our promise of delivering the highest quality in valve manufacturing.

Call to action for further consultation or inquiry about our Wafer Type NRV

Leveraging our unparalleled expertise in the valve manufacturing industry, we invite you to explore the superior performance and quality of our Wafer Type Non-Return Valves (NRVs). Equipped with a wealth of industry-specific knowledge and backed by an array of prestigious certifications, our team stands ready to assist you in identifying the optimal valve solution tailored to your specific requirements. We encourage you to reach out for a consultation or further inquiry, where our expert team can provide detailed insights into the design, functionality, and application of our top-tier NRVs. Let us guide you towards achieving enhanced operational efficiency and safety in your industrial processes. It’s time to experience the excellence that comes with our global authority in valve manufacturing. Connect with us today.