When sourcing quality parts for a 2 inch butterfly valve, there are a variety of factors to consider. From the type of material used to the design requirements and vendor reputation, these factors can all have an influence on the performance and reliability of an industrial system. It’s important to equip machinery with quality components that will last, so understanding what these considerations are is vital for success.

Overview of 2 Inch Butterfly Valves

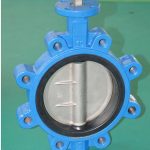

2 inch butterfly valves are a type of industrial pipe fitting commonly used to control the flow of fluids, gases and other substances in an efficient manner. These valve actuators sit between two lengths of pipe and open or close with the turning of a handle or wheel. They feature an inner disc that can be positioned at different points along the circumference of the valve opening, allowing for precise adjustments in the volume or direction of flow.

Butterfly valves are popular because they offer low pressure drop, require less space than other alternatives and come in a range of materials suitable for almost any application. Additionally, they’re easy to install and maintain, making them ideal for industrial settings where maintenance costs must be kept low.

Benefits of Quality Parts

Quality parts for a wafer butterfly valve are essential in order to ensure optimal performance and longevity of the equipment. High-grade materials can make all the difference when it comes to safety, durability and leak prevention. Additionally, the parts must be designed to match the conditions of each application as well as any other components with which they will interact. Quality parts also require less maintenance and repair work over time, allowing for cost savings throughout the life of the system. This is why it’s so important to take time to research different suppliers and thoroughly evaluate factors such as manufacture quality, product features, warranty coverage, turnaround times and more before making a purchasing decision.

Wafer type butterfly valve

Discover the dimensions of wafer butterfly valves! Sizes range from 2″ -40″. Watch our informative video to gain insights into this essential butterfly valve technology.

Factors to Consider When Sourcing Quality Parts

When sourcing quality parts for a lug butterfly valve, there are several important factors to consider. First and foremost is the grade or type of material being used in the part. Lower-grade materials may be cheaper but they can wear out quickly and won’t stand up under extreme conditions. Additionally, it’s important to look at how long the supplier has been in business, since this will give insight into their production capabilities and experience. Other considerations include service capabilities such as turnaround times, pricing structure, and whether or not custom parts can be provided on demand. Last but not least, product warranties should also be taken into account as these offer extra insurance against defects or poor performance in an applied setting.

Material Type

The material type of a part is an important factor to consider when selecting quality parts for a 2-inch butterfly valve. Different grades of materials have different characteristics and performance levels, so knowing which one is best suited to the specific application is essential. In some cases, metals such as stainless steel or carbon steel may be ideal and in other applications, plastics or composite materials may be preferable. It’s also important to understand the effects of corrosion and temperature extremes on the materials being considered. Taking the time to research the different grades and types of materials will ensure that the right part is selected for optimal performance and long-term use.

Design Requirements

Design requirements are another key factor to consider when sourcing quality parts for a 2 inch butterfly valve. It’s important to think through the exact specifications and size requirements of the part, as well as how it will interact with other components in an overall system. In many cases, specific materials and configurations may be necessary to ensure safety and precise operation, so understanding the exact design needs ahead of time is critical. Customized or off-the-shelf parts can be obtained for most applications, but knowing what works best for a particular use case is essential when looking for optimal performance. china ball valve

Vendor Reputation and Experience

When sourcing parts for a flanged butterfly valve, it is important to consider the reputation and experience of the vendor. A good supplier should have a track record of providing reliable, high-quality parts with timely delivery and excellent support services.

It’s also beneficial to find out how long they have been in business, which can give an indication of their commitment levels, as well as the types of products they supply and how flexible they are when it comes to customization. Knowing that you can trust the vendor to provide what is required is essential for any successful project or installation.

Certification and Testing Standards

Certification and testing standards are also important to consider when sourcing parts for a 2-inch butterfly valve. Checking out whether the vendor has ISO 9001 certification or equivalent is a good indication that they are committed to quality assurance and traceability, while looking up what safety tests may be required by law can help ensure that the part is suitable for its intended purpose. Understanding any relevant laboratory testing protocols can provide more confidence in the part’s performance, as well as peace of mind that it has been assessed for potential risks.

Conclusion

When sourcing quality parts for your 2 inch butterfly valve, there are several factors to consider from the vendor’s reputation and experience to certification and testing standards. Doing your research can ensure that you get parts that meet your needs and are compliant with relevant regulations. It is also important to factor in cost as well as any potential delivery delays or customization options needed. Investing time into selecting the right vendor and part can make all the difference to the success of a project, so be sure to keep these key considerations in mind.