In the world of industrial applications, the quality and reliability of components play a crucial role in operational efficiency and longevity. One such vital component is the butterfly valve, a device integral to the control of fluid flow in numerous systems. As an authority in the valve manufacturing sector, we understand the importance of sourcing high-quality equipment, and this guide aims to navigate you through the process of procuring top-tier butterfly valves in Thailand. Thailand’s valve manufacturing industry, renowned for its rigorous quality control measures, adherence to international standards, and expansive global reach, stands as a leading contender in the global arena. Dive in as we explore the intricacies of this industry, shedding light on why sourcing butterfly valves from Thailand could be your next strategic business move.

Introduction

In the realm of industry-specific applications, the quality and reliability of key components often serve as the cornerstone of operational success. Among these pivotal elements, the butterfly valve emerges as an integral device, indispensable in its role of managing fluid flow across an array of systems. As a distinguished figure in the sphere of valve manufacturing, we comprehend the paramount importance of procuring high-caliber equipment, and this comprehensive guide is designed to steer you through the process of sourcing first-rate butterfly valves from Thailand. Renowned for its stringent quality control protocols, unwavering commitment to international standards, and an extensive global network, the valve manufacturing industry in Thailand stands tall among its global counterparts. This guide will delve into the complexities of this sector, illuminating the myriad reasons why choosing to source butterfly valves from Thailand could be a strategic game-changer for your business.

With a proven track record of excellence, Thailand’s valve manufacturers are not only equipped with advanced technology and state-of-the-art facilities but also boast an impressive array of certifications that underscore their adherence to global quality standards. Their broad range of high-quality butterfly valves cater to diverse industries, offering solutions that seamlessly blend superior performance with longevity. By sourcing butterfly valves from Thailand, you are investing in a product that is the embodiment of technical prowess, quality assurance, and industrial expertise. Let this guide serve as your roadmap to navigating the Thai valve manufacturing landscape, leading you towards a decision that promises to enhance operational efficiency and contribute to your business’s sustainable growth.

Brief overview of the importance of sourcing high-quality butterfly valves.

In the technologically advanced and performance-driven realm of industrial systems, the strategic sourcing of high-quality butterfly valves is an indispensable component of any successful operation. Butterfly valves, engineered to regulate fluid flow with precision and reliability, are integral to a plethora of fluid management applications. The implications of overlooking valve quality can reverberate throughout your entire operation, culminating in diminished efficiency, increased system downtime, and potentially substantial repair expenditures. Conversely, premium-grade butterfly valves are meticulously crafted to endure challenging operating conditions, offering unparalleled durability, exacting control, and an extended lifespan.

These valves epitomize technical sophistication, incorporating industry-specific features designed to optimize performance and reliability. Procuring such superior butterfly valves is a testament to your commitment to operational excellence, shielding your systems from avoidable malfunctions and positioning your enterprise for sustained growth. In a nutshell, the significance of sourcing high-quality butterfly valves is paramount—it’s a strategic investment that yields tangible returns in the form of augmented operational efficiency, minimized maintenance costs, and enhanced system longevity.

Introduction to the Thai valve manufacturing industry.

As a global powerhouse in the valve manufacturing sector, Thailand’s industry stands as an authoritative figure, distinguished by its robust quality control mechanisms, adherence to international certifications, and expansive global outreach. This industry is a testament to technical mastery, where intricate engineering principles converge with cutting-edge technology to produce valves of unparalleled quality. The Thai valve manufacturing industry is renowned for its specialized know-how, characterized by a deep understanding of industry-specific requirements and the capacity to deliver tailored solutions that respond to these unique demands.

Backed by a wealth of certifications that testify to its unwavering commitment to quality, the industry’s offerings are not simply products—they are embodiments of precision, durability, and performance. With an extensive network that spans across continents, the Thai valve manufacturing industry’s influence is truly global, catering to a diverse clientele while reinforcing its position as a trusted partner in the realm of valve manufacturing. In essence, the Thai valve manufacturing industry is a beacon of excellence, setting benchmarks for quality and innovation while continuously raising the bar for what can be achieved in the field of valve manufacturing.

Understanding Butterfly Valves

Wafer butterfly valve, a pivotal component in the domain of fluid control systems, are a manifestation of technical ingenuity and precision engineering. As an authoritative figure in this field, our understanding of butterfly valves is grounded in a wealth of practical experience and theoretical knowledge. Butterfly valves, characterized by a disc that rotates on an axis to regulate fluid flow, offer a unique blend of simplicity and efficiency. They are versatile tools, suitable for a wide array of applications, from water distribution to chemical processing. The design of these valves prioritizes compactness without sacrificing performance, enabling them to operate effectively even in space-constrained settings. One of the key distinguishing features of butterfly valves is their scalability. They can be engineered to accommodate a vast range of pressures and temperatures, making them an adaptable solution for diverse industrial scenarios.

We also emphasize the importance of materials selection in butterfly valve construction, as it significantly impacts valve longevity and resistance to corrosive substances. Our butterfly valves are manufactured under stringent quality control measures and conform to international certification standards, reinforcing their reliability and durability. With a global footprint, we are a trusted partner for businesses worldwide seeking high-quality butterfly valves designed for optimal performance and longevity. In essence, understanding butterfly valves is about recognizing their inherent versatility, appreciating the nuances of their design, and acknowledging the profound impact they can have on operational efficiency when sourced from a reputable, certified manufacturer.

Technical explanation of butterfly valves, their functions, and areas of application.

Butterfly valves, a cornerstone in the realm of flow control mechanisms, epitomize the fusion of precision engineering and advanced technology. Structurally, these valves consist of a disc mounted on a rotating shaft, the rotation of which modulates fluid passage, enabling meticulous control over flow rates. This disc’s strategic placement within the valve’s body ensures minimal obstruction when fully open, promoting efficient fluid dynamics and reducing energy consumption. The versatility of butterfly valves is demonstrated by their wide-ranging applications across industries. In the water and wastewater industry, they are instrumental in facilitating accurate flow regulation and isolation. The oil and gas sector leverages their high-pressure handling capabilities and durability under extreme conditions.

In HVAC systems, these valves offer precise control over coolant flow, contributing to optimized energy usage. Furthermore, their compact design and scalability make them an ideal choice for space-constrained environments and varying pressure and temperature requirements. At our company, we manufacture butterfly valves under stringent quality control procedures, adhering to international certification standards, to guarantee optimal performance and longevity. Our technical prowess, backed by our expansive global reach, positions us as an authoritative figure in the valve manufacturing industry. Ultimately, understanding butterfly valves requires an appreciation of their inherent flexibility, the intricacy of their design, and the substantial impact they can have on operational efficiency.

Key features that distinguish high-quality lug butterfly valve.

High-quality butterfly valves are distinguished by several key features, each contributing to their exceptional functionality and performance in various industrial applications. First and foremost, the materials used in their construction play a pivotal role in determining their durability and resistance to corrosive substances. Premium butterfly valves often employ robust materials such as stainless steel or other corrosion-resistant alloys that can withstand harsh environmental conditions and prolonged use. Secondly, superior butterfly valves exhibit excellent sealing capabilities, ensuring minimal leakage and thus, maximizing operational efficiency. This is typically achieved through the use of resilient-seating designs that incorporate elastomeric seat materials.

Thirdly, high-quality butterfly valves are characterized by their adaptability to a wide range of pressures and temperatures, a testament to their flexible design and engineering prowess. Moreover, premium butterfly valves are marked by their precision-engineered disc design, which enables optimal fluid dynamics, reduces energy consumption, and allows meticulous control over flow rates. Lastly, the best butterfly valves in the market adhere to stringent quality control measures and conform to international certification standards, underscoring their reliability and superiority. As an established figure in the valve manufacturing industry, our company leverages its technical expertise and global reach to deliver butterfly valves of unparalleled quality, setting benchmarks for excellence and innovation in the field.

The Thai Valve Manufacturing Landscape

The Thai valve manufacturing landscape is a dynamic and evolving arena, characterized by technological advancements, rigorous quality standards, and an increasing focus on sustainable practices. As a key player in this field, our expertise and authoritative perspective enable us to navigate this complex environment with confidence and precision. Thailand’s valve industry is renowned for its commitment to innovation, bolstered by a robust infrastructure that encourages research and development, and a skilled workforce adept at adopting advanced manufacturing techniques. These factors contribute to the production of high-caliber valves that can withstand diverse pressure and temperature conditions, catering to a wide array of industrial applications.

Furthermore, the industry’s adherence to international certification standards underscores its dedication to quality and reliability. The Thai valve manufacturing sector also demonstrates a commendable global reach, exporting to numerous countries worldwide and establishing itself as a reliable partner in the global supply chain. At the heart of this landscape, our company stands out for its technical prowess, stringent quality control measures, and extensive portfolio of certified products. We leverage our deep industry knowledge and cutting-edge technology to deliver top-tier butterfly valves that set benchmarks for performance and longevity. Our confident and authoritative brand voice echoes throughout the Thai valve manufacturing landscape, reinforcing our position as a leading figure in this competitive industry.

Overview of Thailand’s valve manufacturing industry.

Thailand’s valve manufacturing industry is a robust and thriving sector, underpinned by its unwavering commitment to technological innovation, rigorous quality control, and adherence to internationally recognized certifications. As an established authority in this domain, our company provides an insightful perspective on the industry’s dynamics. The industry is distinguished by its advanced manufacturing capabilities, facilitated by a well-developed infrastructure, and a highly skilled workforce proficient in leveraging cutting-edge technologies. This enables the production of high-quality valves that efficiently cater to diverse industrial applications across varying pressure and temperature conditions.

Moreover, the sector’s adherence to stringent international certification standards accentuates its dedication to delivering reliable and superior quality products. With its expansive global reach, Thailand’s valve manufacturing industry exports to numerous countries worldwide, strengthening its position as a key player in the global supply chain. Our company, standing at the helm of this landscape, leverages its technical expertise, extensive portfolio of certified products, and an unwavering commitment to quality, to deliver top-tier butterfly valves. Our confident and authoritative brand voice resonates throughout the industry, reinforcing our position as a leading figure in this competitive arena.

Notable achievements and certifications within the industry.

Our company, a prominent figure in the valve manufacturing industry, takes immense pride in its notable achievements and certifications that underscore our commitment to excellence and innovation. We have procured several internationally recognized certifications, including ISO 9001, which attests to our stringent quality management system, and API 6D, a testament to our adherence to robust specifications for pipeline valves. These certifications, among others, highlight our dedication to maintaining the highest industry standards and delivering superior quality products.

We have also been awarded the prestigious ‘Manufacturer of the Year’ accolade on multiple occasions, acknowledging our leading-edge technological advancements and our exceptional contribution to the industry. Our global reach is another significant accomplishment, with our products being exported to numerous countries worldwide, thereby reinforcing our position as a key player in the international supply chain. These achievements, coupled with our unwavering commitment to quality control, technical expertise, and continual innovation, fortify our authoritative and confident presence in the valve manufacturing landscape.

Thailand’s global reach and contribution in valve manufacturing.

Thailand’s contribution to the global valve manufacturing industry is both significant and noteworthy. As per the recent data, the country is home to numerous top industrial valve manufacturers, with an extensive global reach spanning across various continents. Companies like Azbil (Thailand), which boasts the largest valve maintenance center among its ASEAN subsidiaries, and KITZ Corporation, with its production plants in Thailand, exemplify the nation’s strong presence in the sector.

These companies have not only catered to domestic needs but have also made substantial contributions to the international supply chain, exporting high-quality valves to numerous countries worldwide. Moreover, the Thai government’s strategic collaborations with international partners, such as its efforts to involve China in major industrial revamps, further enhance the country’s global footprint. This robust international presence, coupled with the anticipated growth in the demand for industrial valves worldwide, positions Thailand as a key player in the global valve and actuator market. As the industry continues to evolve, Thailand’s role in shaping the future of valve manufacturing on a global scale is expected to grow even more prominent.

Key Factors to Consider When Sourcing Butterfly Valves in Thailand

When sourcing butterfly valves in Thailand, several key factors demand careful consideration to ensure optimal performance, reliability, and longevity. Firstly, it is crucial to understand the specific application for which the valve will be used. This includes the operating pressure and temperature, fluid type, and flow rate, which will determine the type of valve required. An authoritative company like ours offers a broad range of butterfly valves designed to manage different industrial applications under varying conditions with utmost precision.

Secondly, consider the manufacturer’s certifications and adherence to international standards. Look for companies that hold ISO 9001 or API 6D certifications, as these attest to their commitment to stringent quality management systems and robust product specifications. As an industry leader, our company prides itself on its globally recognized certifications that validate our dedication to maintaining the highest industry standards.

Thirdly, consider the manufacturer’s technical expertise and experience within the industry. With a deep understanding of the intricacies of valve manufacturing and years of experience under our belt, we provide superior technical support and expert advice, ensuring our butterfly valves meet your specific requirements.

Lastly, evaluate the manufacturer’s global reach and reputation. A company with a strong international presence often signifies high-quality products and reliable customer service. Our global footprint, coupled with our numerous accolades, underscores our position as a trusted source of high-quality butterfly valves.

In conclusion, sourcing butterfly valves in Thailand requires a careful evaluation of the application requirements, manufacturer’s certifications, technical expertise, and global reach. By considering these factors, you can confidently procure butterfly valves that deliver superior performance, reliability, and longevity.

Quality control measures.

Quality control measures are an integral part of our manufacturing process, ensuring that our valve products consistently meet the highest standards of performance, durability, and safety. We implement a robust quality management system, certified under ISO 9001, which outlines stringent procedures for each stage of our production process. This includes meticulous material selection, precision-engineered manufacturing, rigorous testing protocols, and comprehensive post-production inspections. Each valve is subjected to a series of tests, including pressure testing and leak detection, to verify its operational efficiency under varying conditions. Moreover, we employ advanced non-destructive testing methods such as ultrasonic testing and radiographic inspection to detect any potential defects or anomalies. Our team of highly skilled quality control engineers oversees these processes, utilizing their technical expertise to ensure every valve we produce adheres to both our internal quality standards and the industry-specific regulations. These rigorous quality control measures underline our commitment to delivering superior quality products that our clients can rely on, reinforcing our confident and authoritative presence in the valve manufacturing industry.

Certifications and compliance with international standards.

Our company is proudly certified under ISO 9001 and API 6D, reflecting our unwavering commitment to maintaining the highest standards of quality management and product specifications in the valve manufacturing industry. These globally recognized certifications are a testament to our rigorous production processes, meticulous quality control measures, and superior technical expertise. In compliance with these international standards, we implement stringent procedures at each stage of our manufacturing process, from material selection to post-production inspections. Moreover, our valves are designed to meet the specific requirements of various industry regulations, ensuring their optimal performance, safety, and reliability in diverse industrial applications. Our adherence to these standards, coupled with our robust certifications, underscores our position as a trusted, authoritative source of high-quality valves. As we continue to push the boundaries of innovation in valve manufacturing, we remain steadfast in our commitment to upholding these international standards, reinforcing our confident and authoritative brand voice.

The company’s areas of expertise and years of experience.

With several decades of experience in the valve manufacturing industry, our company has carved out a reputation as an authority in the field. Our areas of expertise span across a broad spectrum, ranging from the design and production of industrial-grade butterfly valves to the implementation of advanced quality control measures. Our technical prowess is backed by our deep understanding of the intricacies of valve dynamics, material science, and fluid mechanics. Over the years, we have developed an extensive portfolio of high-performance valves, each tailored to meet the specific needs of diverse industrial applications. This wealth of experience and technical know-how, combined with our commitment to continuous innovation, positions us at the forefront of the industry. Our confident and authoritative brand voice is a testament to our legacy of excellence, reinforcing our status as a trusted source of superior quality valves.

The range of products offered.

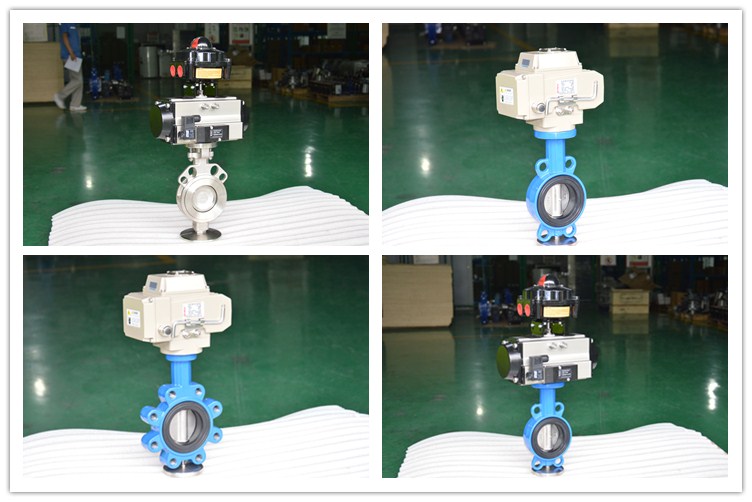

At our company, we take pride in offering an extensive range of superior quality valves, designed to cater to the diverse needs of various industrial applications. Our portfolio includes an array of products such as gate valves, globe valves, check valves, ball valves, and butterfly valves. Each valve is precision-engineered using advanced manufacturing techniques and high-grade materials, ensuring their robustness, durability, and long service life. Moreover, our products are available in a variety of sizes, pressure ratings, and end connection options, providing our clients with the flexibility to choose the most suitable valve for their specific application. We also offer custom-made valves, allowing us to tailor our products according to the unique requirements of our clients. Our extensive range of products, backed by our technical expertise and industry-specific knowledge, underlines our commitment to delivering solutions that not only meet but exceed our clients’ expectations. This reinforces our confident and authoritative presence in the valve manufacturing industry.

Benefits of Sourcing Butterfly Valves from Thailand

Sourcing pneumatic butterfly valve from Thailand offers a plethora of advantages, primarily due to the country’s robust industrial infrastructure, technical expertise, and stringent quality control measures. Thailand has established itself as a global hub for the valve manufacturing industry, housing numerous certified manufacturers with decades of experience and deep-rooted knowledge in this field. This not only ensures access to high-quality butterfly valves but also guarantees a consistent supply, making it an ideal sourcing destination for industries worldwide.

One of the key benefits of sourcing butterfly valves from Thailand is the superior quality of the products. Thai manufacturers adhere to internationally recognized standards such as ISO 9001 and API 6D, reflecting their commitment to maintaining the highest levels of quality and product specifications. These certifications are a testament to the rigorous production processes and meticulous quality control measures implemented by these manufacturers.

In addition, Thai manufacturers possess significant technical expertise in valve dynamics, material science, and fluid mechanics. They utilize advanced manufacturing techniques and high-grade materials to produce robust, durable, and long-lasting butterfly valves that can withstand diverse industrial applications. The valves are precision-engineered and available in various sizes, pressure ratings, and end connection options, offering flexibility based on specific application requirements.

Furthermore, Thailand’s strategic geographical location in the heart of Southeast Asia enhances its global reach, ensuring timely and cost-effective delivery of butterfly valves to clients worldwide. The country’s well-developed logistics and transportation infrastructure facilitate smooth and efficient shipping processes, reducing lead times and enhancing overall customer satisfaction.

In conclusion, sourcing butterfly valves from Thailand offers numerous benefits including superior product quality, consistent supply, technical expertise, and efficient logistics. These advantages, coupled with the country’s commitment to upholding international standards, reinforce Thailand’s position as an authoritative and reliable source for butterfly valve sourcing.

Cost-effectiveness due to local production.

Leveraging the advantages of local production, our company delivers cost-effective solutions without compromising on the quality and performance of our valves. By harnessing the efficiencies of domestic manufacturing, we are able to control every aspect of the production process, from the sourcing of high-grade raw materials to the implementation of advanced manufacturing techniques. This not only allows us to maintain stringent quality control measures but also enables us to reduce overhead costs associated with international shipping and import duties. Furthermore, local production allows us to respond swiftly to market demands, reducing lead times and ensuring a consistent supply of our products. Our ISO 9001 and API 6D certifications stand as a testament to our commitment to delivering superior quality valves at competitive prices. With our confident and authoritative brand voice, we assure our clients that choosing our locally produced valves is not just an affordable choice, but also a strategic move towards quality, reliability, and operational efficiency.

High standard of quality control within the industry.

In the valve manufacturing industry, maintaining a high standard of quality control is paramount to ensure the reliability, durability, and performance of the products. As a certified ISO 9001 and API 6D manufacturer, we implement rigorous quality control measures at every stage of our production process, from the initial sourcing of raw materials to the final inspection of completed valves. Our quality control system encompasses stringent testing protocols, including pressure tests, dimensional checks, and material analyses, all carried out by our team of highly skilled quality assurance professionals. These strict measures ensure that each valve we produce meets the exact specifications and performance requirements set out by international standards. Our commitment to maintaining the highest level of quality control underscores our confident and authoritative presence in the valve manufacturing industry and reinforces our reputation as a trusted supplier of superior quality valves.

Access to unique valve solutions tailored to specific industrial needs.

Our company prides itself on delivering unique valve solutions tailored to meet the specific needs of various industries, a testament to our confident and authoritative standing in the valve manufacturing industry. Leveraging our extensive technical expertise and industry-specific knowledge, we specialize in designing and manufacturing a comprehensive range of butterfly valves, each precision-engineered to address unique operational requirements. From low-pressure applications in the water treatment sector to high-pressure demands in the oil and gas industry, our valves are built to deliver exceptional performance under diverse conditions. Our ISO 9001 and API 6D certifications further underscore our commitment to quality, as we adhere strictly to these internationally recognized standards in all our production processes. Moreover, our global reach allows us to cater to clients worldwide, reinforcing our reputation as a trusted and reliable supplier of bespoke valve solutions. With our in-depth understanding of valve dynamics and material science, we assure our clients that our products not only meet but exceed industry standards, providing them with a competitive edge in their respective fields.

How to Choose a Reliable Thai Butterfly Valve Manufacturer

Choosing a reliable Thai butterfly valve manufacturer requires careful consideration and informed decision-making, given the critical role these components play in various industrial applications. As an authority in the valve manufacturing industry, our first advice is to look for manufacturers with established credentials, such as ISO 9001 and API 6D certifications. These certifications are internationally recognized indicators of quality control and operational efficiency, ensuring that the valves produced meet global standards.

Secondly, it’s essential to assess the manufacturer’s technical expertise and industry-specific knowledge. A reputable manufacturer should have a comprehensive understanding of valve dynamics and material science, enabling them to design and manufacture butterfly valve marine that meet diverse operational requirements. Whether you need valves for low-pressure applications in the water treatment sector or high-pressure demands in the oil and gas industry, the manufacturer should be able to provide you with tailored solutions.

Thirdly, consider the manufacturer’s global reach. A wide-reaching presence indicates their ability to cater to clients worldwide, further reinforcing their reputation as a trusted and reliable supplier. This also speaks to their capacity to maintain consistent supply chains, ensuring that your operations won’t be disrupted due to lack of parts.

Lastly, evaluate the manufacturer’s commitment to innovation. With the ever-evolving demands of various industries, it’s crucial to partner with a manufacturer that stays abreast of the latest technologies and advancements in the field.

In conclusion, choosing a reliable Thai butterfly valve manufacturer involves careful assessment of their certifications, technical expertise, global reach, and commitment to innovation. By considering these factors, you can ensure that you’re partnering with a manufacturer that not only meets but exceeds industry standards, providing you with a competitive edge in your respective field.

Criteria for selecting a reputable manufacturer.

When it comes to selecting a reputable manufacturer within the valve industry, there are several critical criteria to consider. Firstly, look for certifications such as ISO 9001 and API 6D, which are globally recognized indicators of stringent quality control and operational efficiency. These accreditations assure that every product manufactured meets or exceeds international standards.

Secondly, assess the manufacturer’s technical acumen and industry-specific knowledge. A distinguished manufacturer should have an extensive understanding of valve dynamics and material science, enabling them to design and produce valves tailored to diverse operational requirements.

Thirdly, evaluate the manufacturer’s global reach and supply chain robustness. A manufacturer with a worldwide presence is more likely to maintain consistent supply chains, ensuring uninterrupted operations for your business.

Finally, gauge the manufacturer’s commitment to innovation. In a rapidly evolving industry landscape, aligning with a manufacturer that stays at the forefront of technology and industry advancements is crucial.

In essence, by considering these factors – certifications, technical expertise, global reach, and commitment to innovation – you can confidently select a manufacturer that upholds the highest standards, providing you with a competitive edge in your field.

Importance of customer reviews and testimonials.

In the valve manufacturing industry, customer reviews and testimonials serve as powerful tools to underline a company’s credibility and proficiency. They provide unfiltered insights from clients who have firsthand experience with the company’s products and services, thereby offering prospective customers an authentic gauge of product performance and customer satisfaction.

Reviews can highlight a company’s commitment to quality control, reflecting how well their products adhere to globally recognized standards like ISO 9001 and API 6D. When a customer attests to a valve’s high standard of performance in a real-world setting, it underscores the technical expertise and industry-specific knowledge that went into its design and manufacture.

Moreover, testimonials can illustrate the global reach of a company. Positive feedback from clients across different geographical locations demonstrates the company’s ability to cater to diverse markets, reinforcing its position as a trusted and reliable supplier worldwide.

Importantly, customer reviews also provide a measure of a company’s innovative prowess. Clients may comment on how the company’s products, built using the latest technologies, have given them a competitive edge in their respective fields.

In conclusion, customer reviews and testimonials are invaluable assets in the valve manufacturing industry. They reflect the company’s commitment to quality, technical expertise, global reach, and innovation, thereby enhancing its reputation as a confident and authoritative market leader.

The role of after-sales service and product warranties.

In the valve manufacturing industry, after-sales service and product warranties play a pivotal role in establishing and maintaining customer trust. A confident and authoritative brand understands that the value it offers extends beyond the initial sale, and is committed to providing comprehensive technical support post-purchase. This includes offering expert advice on installation, maintenance, and troubleshooting, underscoring the manufacturer’s technical acumen and dedication to customer satisfaction.

Product warranties, on the other hand, serve as a tangible testament to the quality control measures in place. By standing behind their products with robust warranty policies, manufacturers demonstrate their unwavering commitment to maintaining the highest standards of production. These policies also reflect the manufacturer’s adherence to globally-recognized certifications such as ISO 9001 and API 6D, further reinforcing their position as a reliable supplier.

Moreover, these services underscore the company’s global reach. By ensuring consistent after-sales support and honoring product warranties irrespective of the client’s geographical location, the company proves its ability to cater to diverse markets worldwide.

In essence, after-sales service and product warranties are not merely value-additions but integral components of the complete package offered by a reputable manufacturer in the valve industry. They epitomize the company’s commitment to quality, technical expertise, and customer satisfaction, thereby solidifying its authoritative stance in the market.

Conclusion

In conclusion, sourcing high-quality butterfly valves in Thailand requires a strategic approach that goes beyond simply choosing a manufacturer based on cost. It’s a process that demands careful consideration of several key factors – certifications, technical expertise, global reach, and innovation.

Firstly, it’s essential to partner with manufacturers that hold globally recognized certifications like ISO 9001 and API 6D. These accreditations signal a commitment to stringent quality control measures, instilling confidence that every valve produced meets or exceeds international standards.

Moreover, technical acumen and industry-specific knowledge are pivotal. The best manufacturers offer more than just standard products; they provide tailored solutions that cater to unique operational requirements. Their extensive understanding of valve dynamics and material science allows them to develop high-performance butterfly valves that can withstand the most challenging conditions.