ANSI butterfly valves are a type of shutoff valve commonly used in industrial and commercial settings. They are widely popular due to their simple design and ease-of-use, making them the ideal choice when it comes to controlling the flow of fluids. In this article, we will discuss the basics of ANSI butterfly valves and provide an overview of their design and construction, how they work, advantages and disadvantages, as well as installation and maintenance considerations.

Introduction to ANSI Butterfly Valves

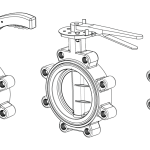

ANSI butterfly valves are a quarter-turn valve designed for shutoff applications. They consist of a disk-shaped closure element mounted in an extended stem, which is connected to an operator such as a handle or gearbox. The disk-shaped closure element has an opening in the middle that allows for the flow of a fluid when the valve is opened, and forms a complete seal when the valve is closed. These valves can be used to regulate and control flows in many different types of systems, including those involved in water distribution, sewage treatment, chemical processing and oil & gas production.

ANSI butterfly valves are available in different materials, such as cast iron, ductile iron and stainless steel, depending on the application they will be used in. They are also manufactured according to various industry standards, such as American National Standards Institute (ANSI). The two most common types of ANSI butterfly valves are resilient seat and double offset. Resilient seat valves use a rubber material as the seating surface which provides good sealing ability, while double offset valves use two sets of hinges for better sealing capability.

What Are the Different Types of ANSI Butterfly Valves?

ANSI butterfly valves come in three main types: resilient seated, double offset, and triple offset. Lug butterfly valves are the most common type and use a rubber or elastomeric seat that provides superior sealing ability. Double offset valves have two hinges on their disk-shaped discs which create some space between the disc and body of the valve, as well as providing additional seating area and increasing resistance against wear & tear.

Triple offset butterfly valve are designed to provide superior sealing capability when compared to other types of butterfly valves. They use three sets of surfaces and contact points between the disk and body of the valve. These types of valves offer high performance with minimal pressure drop across them and can be used in critical applications where reliable shutoff is required. All these different types of ANSI butterfly valves are available in a wide range of materials like cast iron, ductile iron, stainless steel and alloy 20.

Design and Construction of ANSI Butterfly Valves

ANSI butterfly valves are mainly composed of a valve body, stem, disc, and actuator. The valve body is usually made out of cast iron, ductile iron or stainless steel, depending on the application it will be used in. The stem connects the disc with the operator, and can be made from metals such as stainless steel or brass. The disc is typically a disk-shaped piece that has an opening in the middle which allows for the flow of fluid when opened. This opening can be round or rectangular depending on its intended purpose. Lastly, an actuator is used to open and close the valve either manually with a handle or automatically using an electric motor or pneumatic actuator.

All these components work together to form a complete butterfly valve that provides reliable shutoff and excellent performance in many different types of applications.

How Do ANSI Butterfly Valves Work?

ANSI butterfly valves are designed to regulate and control the flow of liquids or gases in a system. They accomplish this by using a disk-shaped closure element that is connected to a stem which in turn is operated by an actuator.

When the actuator is activated, it lifts the disk off its seat allowing for fluid flow through the valve. When the actuator is deactivated, the disk returns to its seat, sealing off the valve and preventing any further flow. The advantage of this type of valve lies in its ability to open quickly and allow flow with minimal pressure drop, making them ideal for applications where fast response times are required. Additionally, they are also capable of providing tight shutoff when completely closed due to their sealing capabilities.

Advantages and Disadvantages of ANSI Butterfly Valves

ANSI butterfly valves are a popular option for many applications due to their relatively low cost, simple design and high performance characteristics. One of the main advantages of this type of valve is its ability to open and close quickly with minimal pressure drop, making them ideal for applications that require fast response times or have large variations in flow rates. Additionally, these valves are able to provide tight shutoff when completely closed due to their sealing capabilities.

However, there are some drawbacks to this type of valve including its susceptibility to corrosion due to its exposed moving parts as well as being vulnerable to cavitation damage caused by rapid changes in fluid velocity. Consequently, it is important for engineers to make sure the design parameters of an application match the working conditions before specifying ANSI butterfly valves.

Choosing the Right ANSI Valve for Your Application

Selecting the right ANSI valve for your application requires careful consideration of the operating conditions, application requirements and design parameters. Factors such as pressure, temperature and flow rate need to be taken into account before selecting the appropriate valve type. Additionally, some valves are better suited to certain types of media than others and it is important to make sure the chosen valve is compatible with the particular material or liquids being handled. It is also important to consider other factors such as leakage rates, seat materials and actuation options in order to ensure a successful installation. Finally, it is important to make sure that any safety regulations or codes relating to your application are met before specifying an ANSI valve.

Installation and Maintenance Guidelines for ANSI Butterfly Valves

Installing and maintaining ANSI butterfly valves is relatively straightforward, however, following best practices is essential for reliability and performance .Before installation, it is important to inspect the valve for any signs of damage and make sure that all gaskets are in good condition. To ensure a successful installation, it is advisable to use an appropriate data plate containing the complete assembly details such as size and material designation. Furthermore, adhering to the recommended torque values during assembly into the pipeline ensures proper sealability. After installation, regular inspections should be carried out at least once every six months in order to check for any signs of wear or corrosion. Additionally, making sure that the valve stem assembly is lubricated regularly can help prevent seizing due to changes in temperature or humidity.

Conclusion

We have established the fundamentals of an ANSI butterfly valve, from its design and construction to its installation and maintenance. Working with the right valve for your particular application is essential for achieving durable and reliable performance. Understanding these key points can help you make a more informed decision when it comes to selecting and installing an ANSI butterfly valve. Finally, working with experienced professionals throughout the whole process can help ensure that all safety regulations are followed and that the resulting system performs efficiently and effectively over time.